Clamping base for automatically turning over workpiece during milling

A technology for automatic turning of workpieces, applied in metal processing mechanical parts, clamping, manufacturing tools, etc., can solve the problems of reducing processing efficiency, increasing processing time, and unable to automatically complete the turning of workpieces, so as to shorten processing time and increase processing. Quantity and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

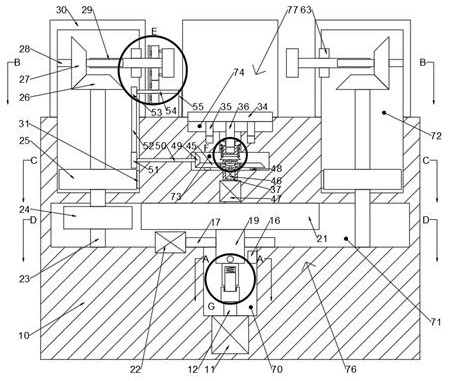

[0021] Combine below Figure 1-8 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

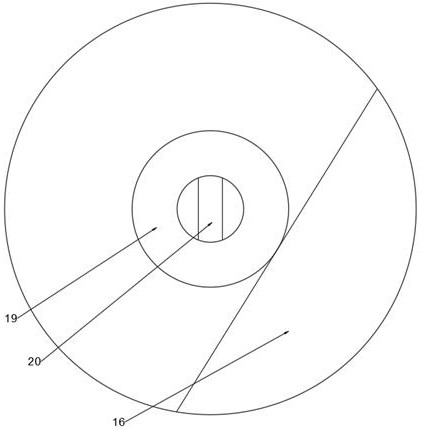

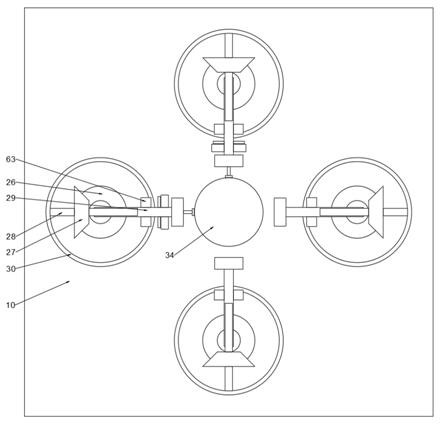

[0022] A clamping base for automatically turning workpieces during milling of the device of the present invention includes a body 10, a power chamber 70 is provided on the lower side of the body 10, and a moving chamber 71 is provided on the upper side of the power chamber 70. The upper side of the chamber 71 is provided with a rotating chamber 73, the upper side of the rotating chamber 73 is provided with a supporting chamber 74, and the upper side of the body 10 is fixed with four circumferentially di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com