Full-automatic soil sample preparation system

A soil sample and preparation system technology, applied in the field of soil sample preparation, can solve problems such as affecting efficiency, increasing costs, and occupying space on a laboratory bench.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

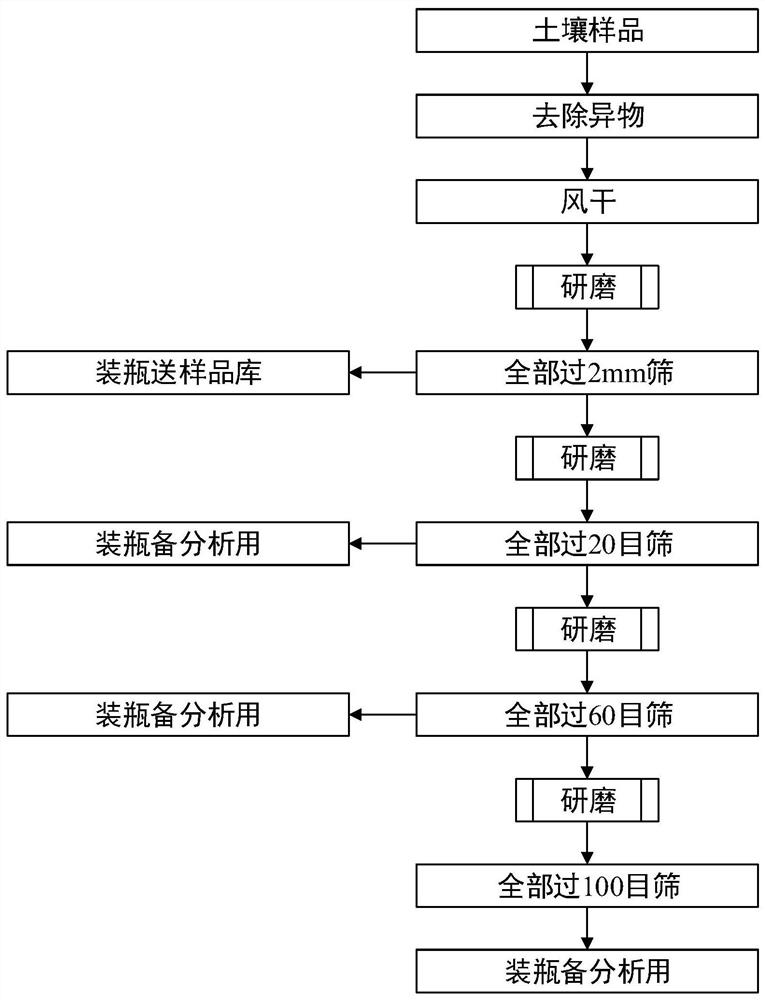

Method used

Image

Examples

Embodiment 1

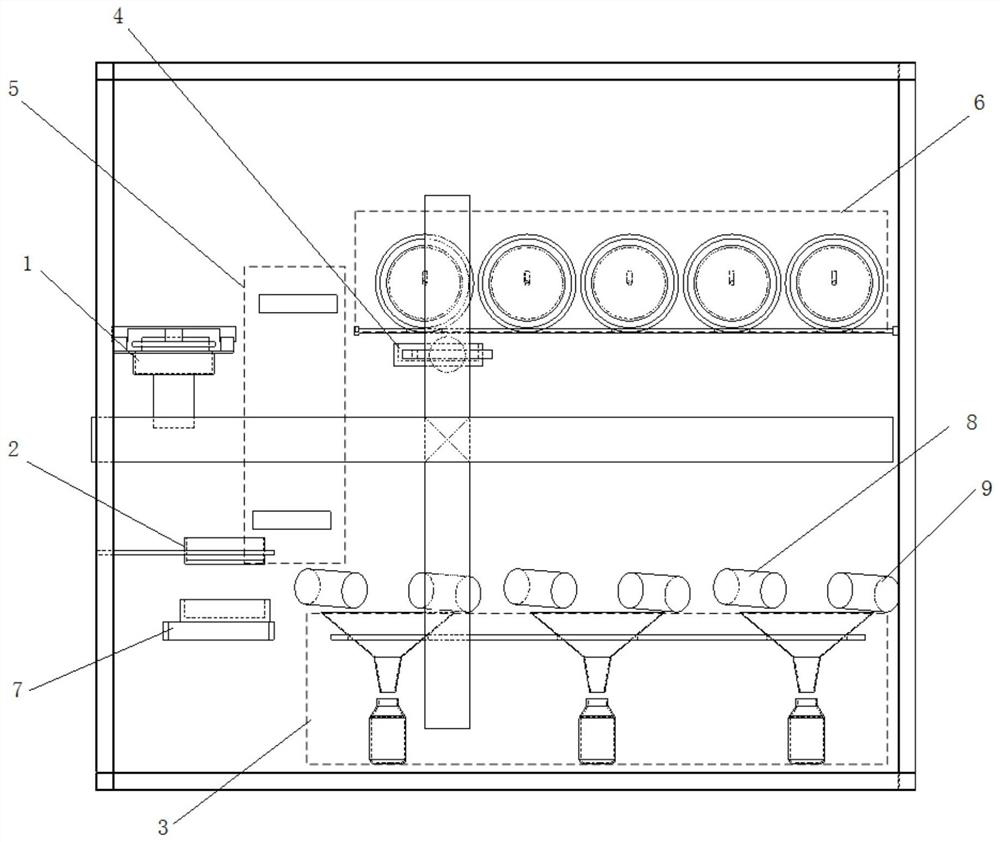

[0033] Example 1: See attached figure 2 , A fully automatic soil sample preparation system, which includes: grinding and grinding mechanism 1, screening mechanism 2, sample loading mechanism 3, manipulator 4, cleaning assembly 5. In addition, the system can be optionally expanded with a drying and heating mechanism 6, weighing Heavy mechanism 7, laser particle size analysis mechanism 8 and X-ray fluorescence spectrometer 9;

[0034] The drying and heating mechanism 6 is used for drying the soil sample;

[0035] The grinding and grinding mechanism 1 is used to grind the dried soil sample;

[0036] The screening mechanism 2 is used to screen the ground soil sample;

[0037] The weighing mechanism 7 is used to weigh the sieved soil sample;

[0038] The sample loading mechanism 3 is used to sample the soil samples after being sieved in quarter method;

[0039] Manipulator 4 is used to transfer soil samples;

[0040] The cleaning component 5 is used to clean the container containing the soil...

Embodiment 2

[0043] In Example 2, on the basis of Example 1, the specific structures of the grinding and grinding mechanism 1, the screening mechanism 2, the sample loading mechanism 3, the manipulator 4, the cleaning assembly 5, the drying and heating mechanism 6, and the weighing mechanism 7 are defined :

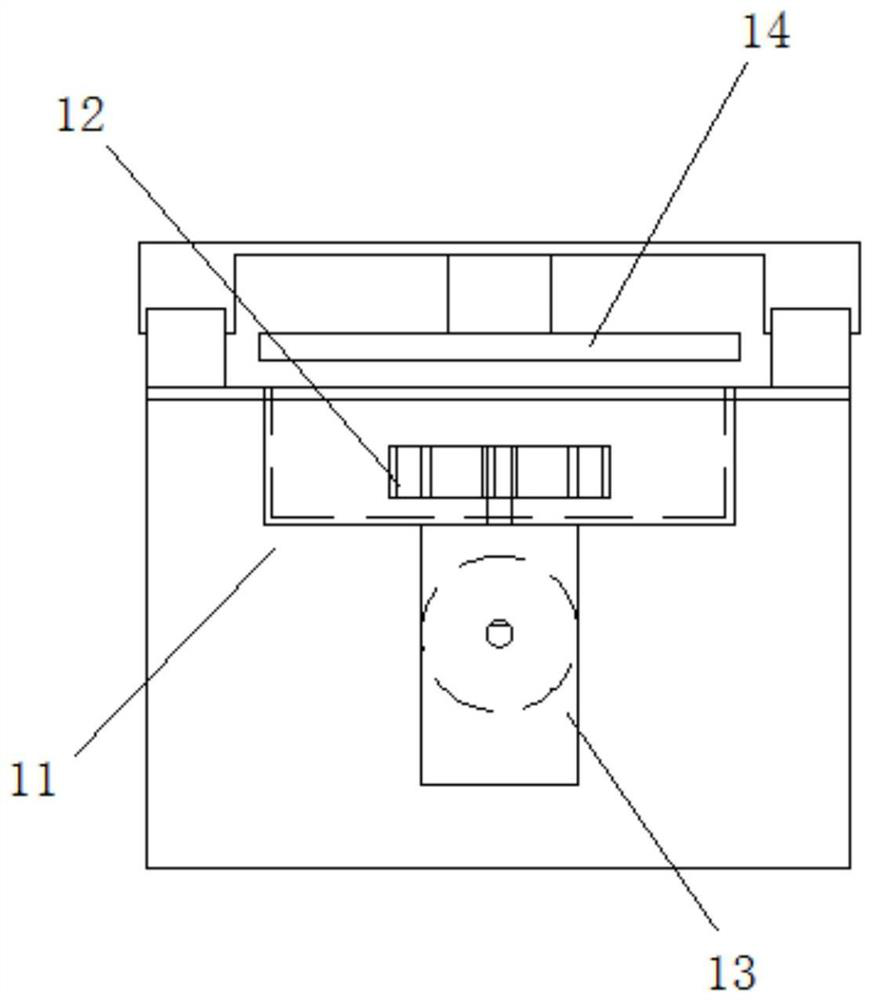

[0044] See attached Picture 8 , The drying and heating mechanism 6 includes: a drying cylinder 61 and a radiant heating device 62; during drying, the drying cylinder 61 itself rotates and the inside is in a negative pressure state, which can accelerate the evaporation of moisture and increase the drying speed; at the same time, the radiant heating device 62 can eliminate the negative pressure As a result, the gas in the cylinder absorbs heat when the gas volume expands, resulting in a rapid decrease in sample temperature. Maintain the sample in the drying cylinder 61 within a reasonable range between the normal room temperature and the upper limit of the soil sample preparation temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com