Technique for treating high-ammonia-nitrogen wastewater by recycling ammonium sulfate through MVR (Mechanical Vapor Recompression) ammonia distillation

A high ammonia nitrogen and ammonium sulfate technology, which is applied in special treatment targets, water/sewage treatment, water treatment parameter control, etc. The effect of reducing resistance drop and ensuring heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

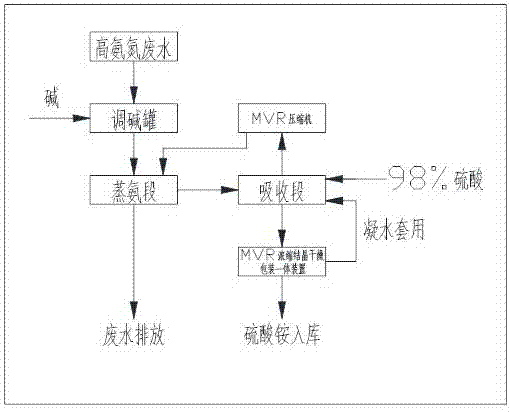

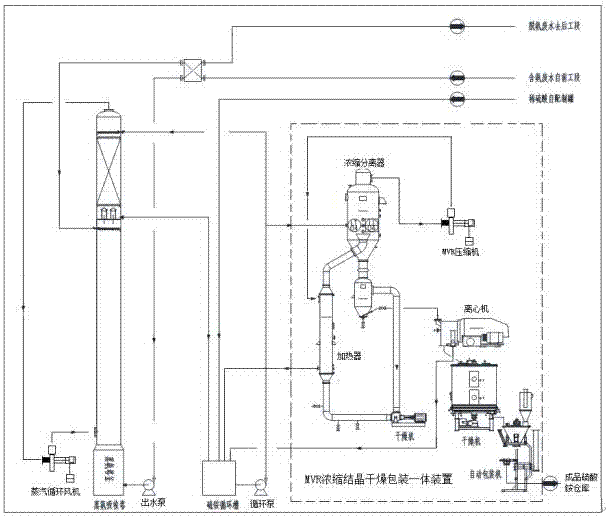

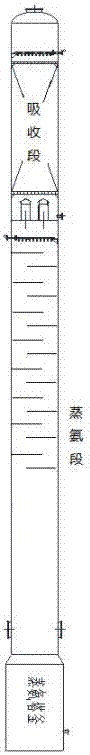

[0025] see Figure 1-Figure 3 , in the embodiment of the present invention, a kind of technology of MVR distilling ammonia and recovering ammonium sulfate to treat high-ammonia-nitrogen wastewater, including alkali adjustment of high-ammonia-nitrogen wastewater, MVR distilling ammonia and recovering ammonium sulfate process, realizes steam closed-circuit circulation distilling ammonia to treat high-ammonia-nitrogen wastewater, and the treated The ammonia nitrogen in the wastewater is less than 10mg / L, and a 25% ammonium sulfate solution is produced, which is concentrated and crystallized by MVR to recover industrial ammonium sulfate.

[0026] Among them, the high ammonia nitrogen wastewater alkali adjustment process is: the high ammonia nitrogen wastewater enters the alkali adjustment tank and uses lime or sodium hydroxide and other alkaline substances to adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com