Patents

Literature

123results about How to "Guaranteed heat transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

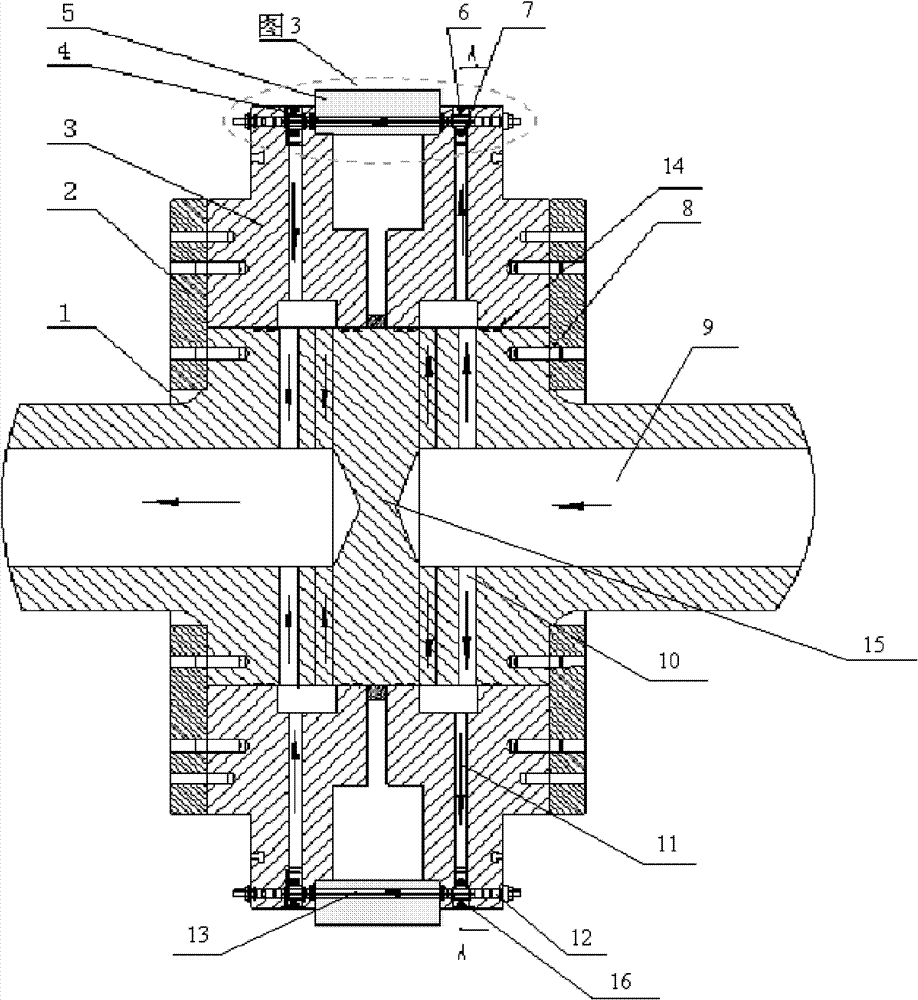

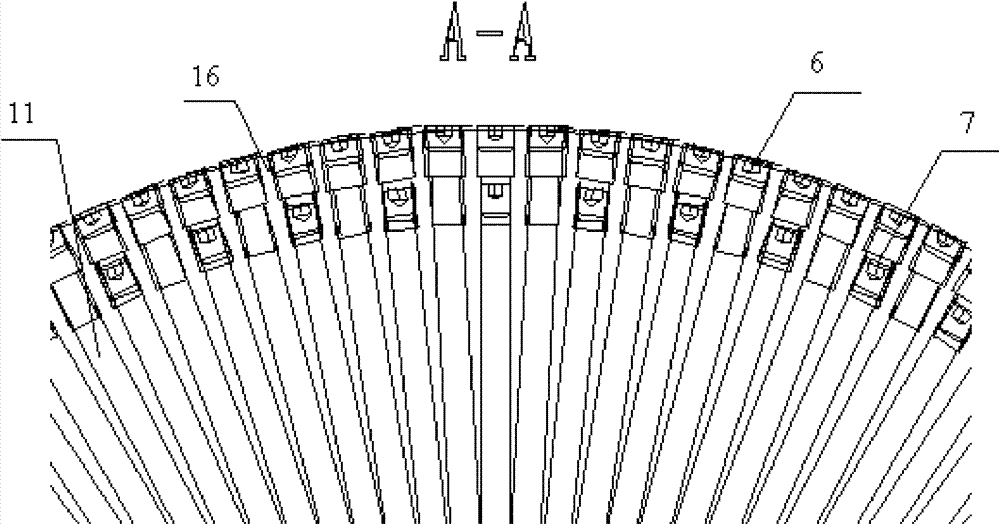

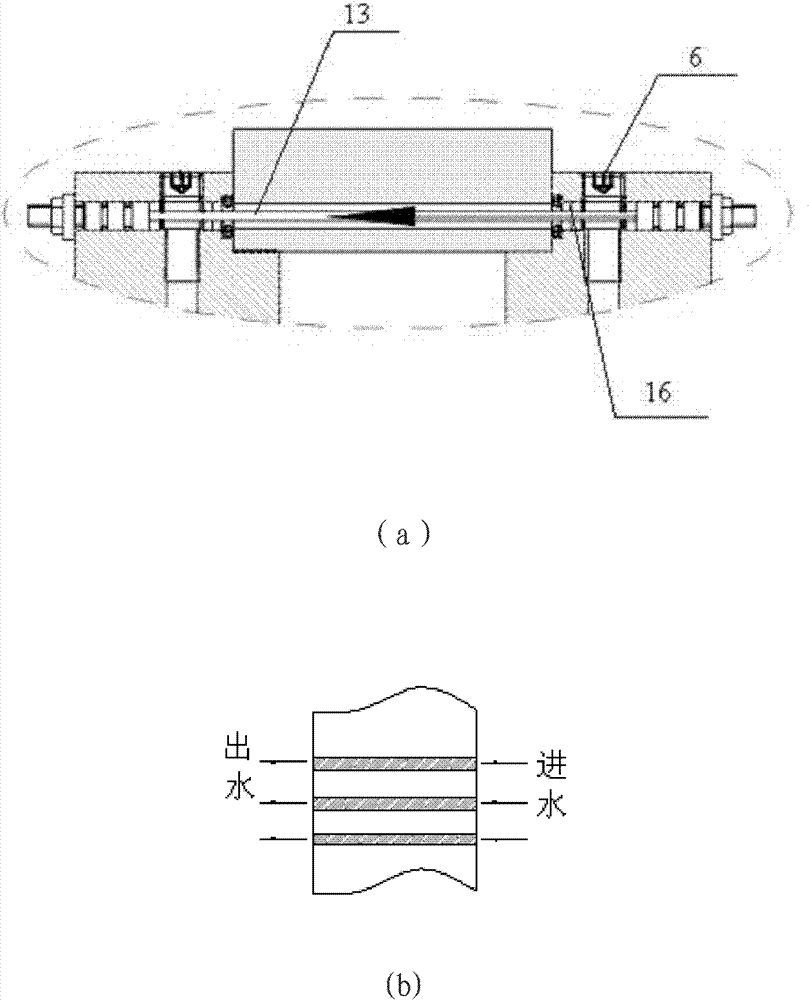

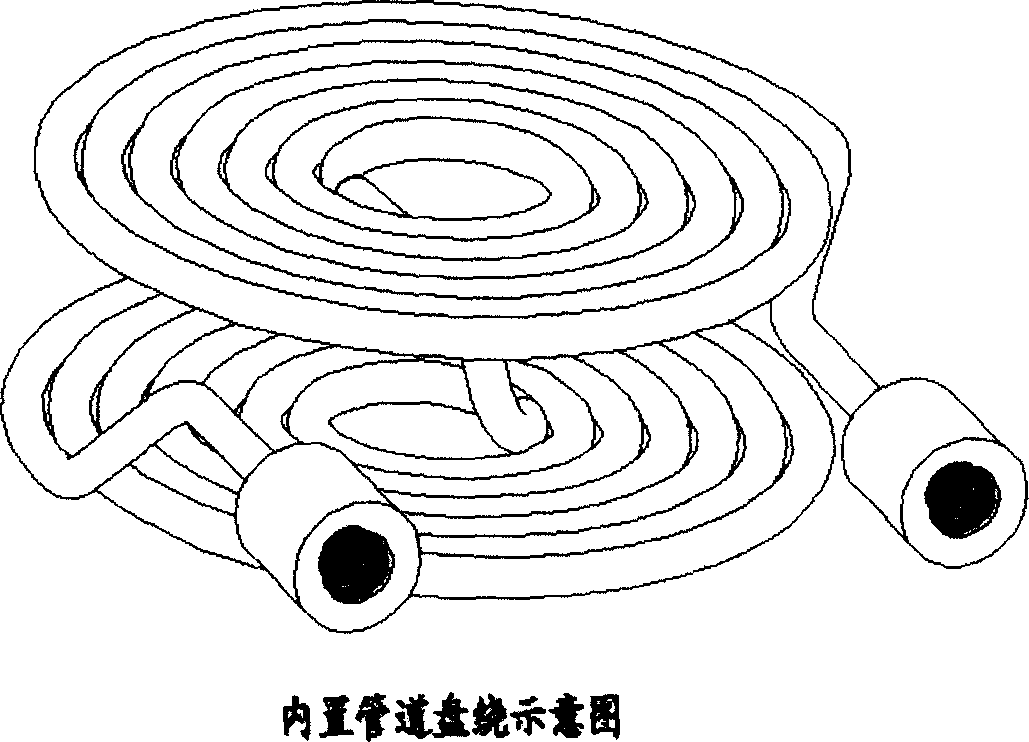

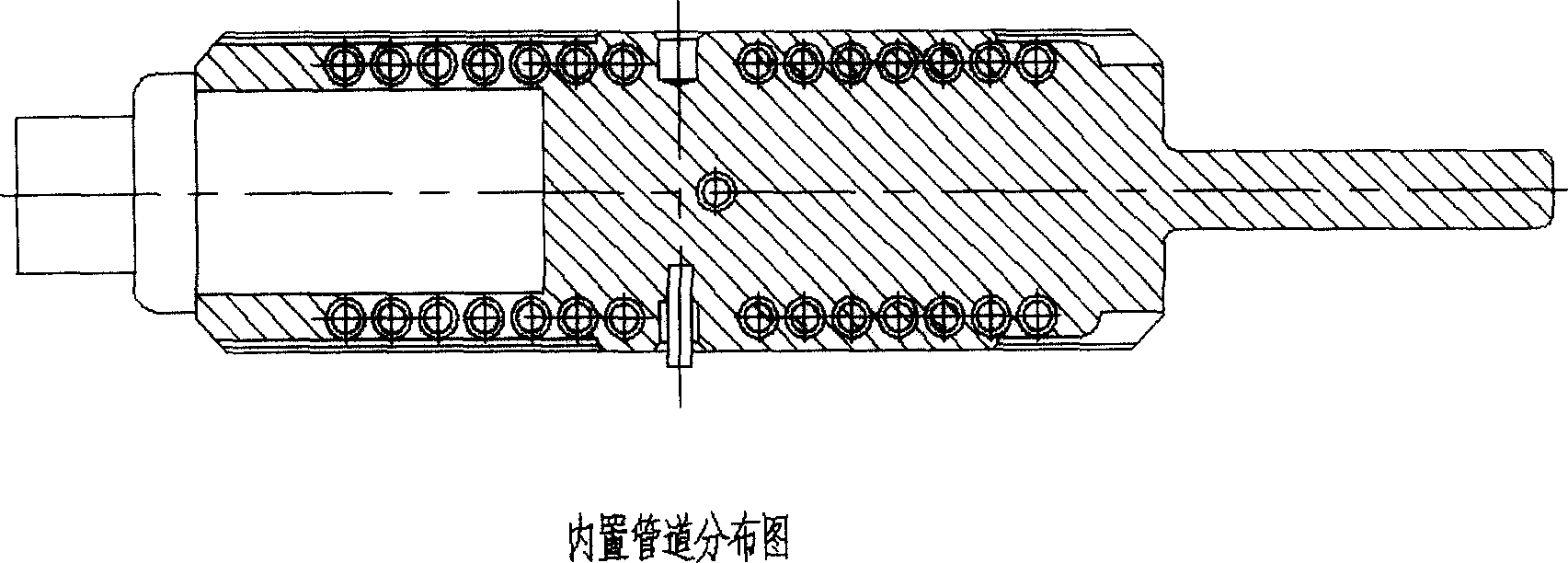

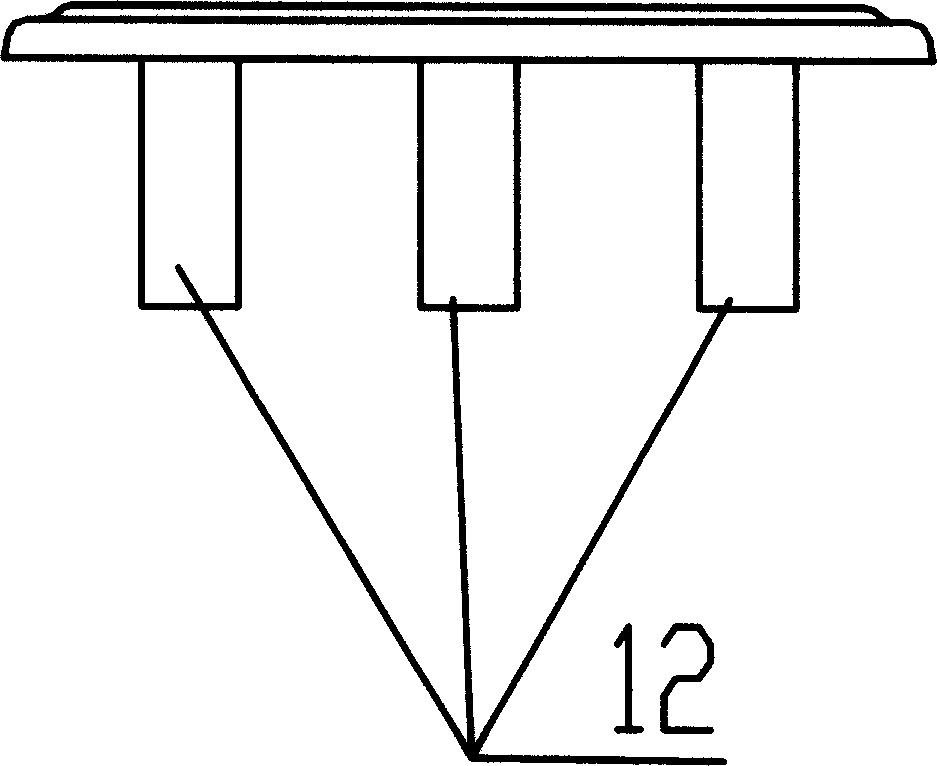

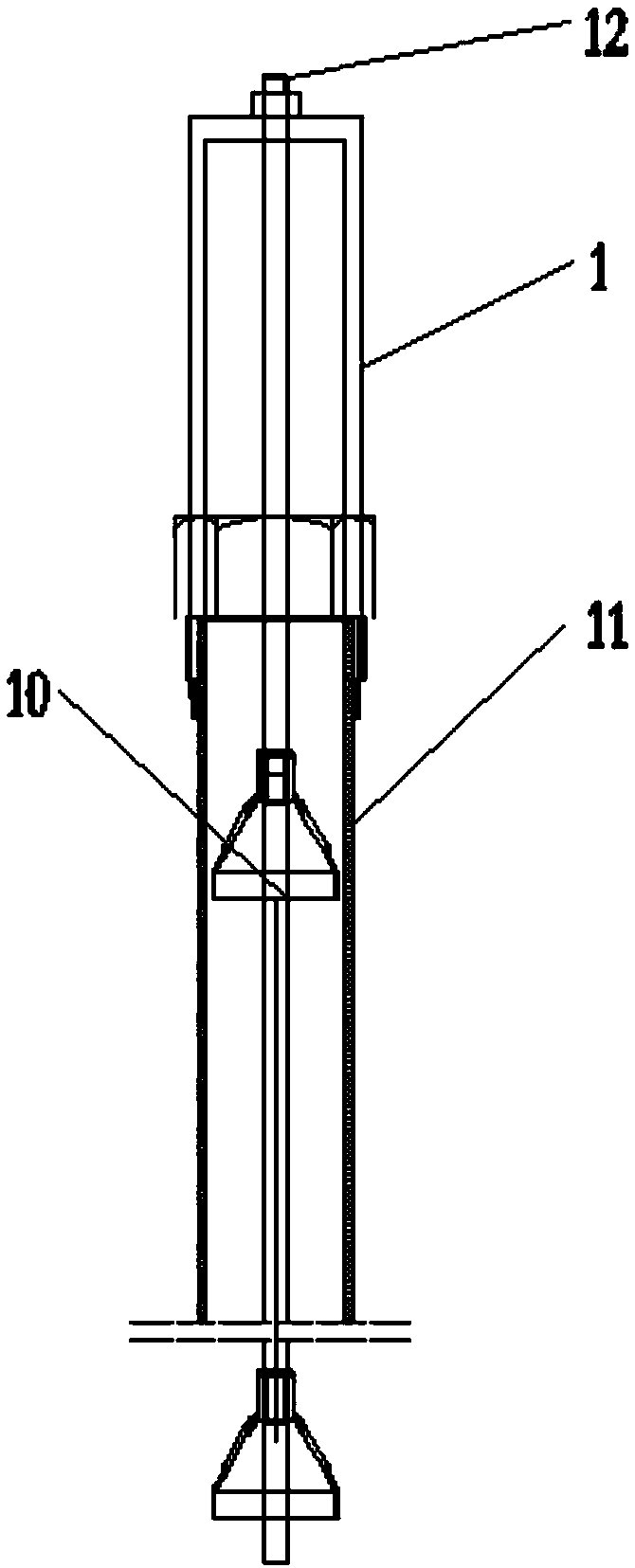

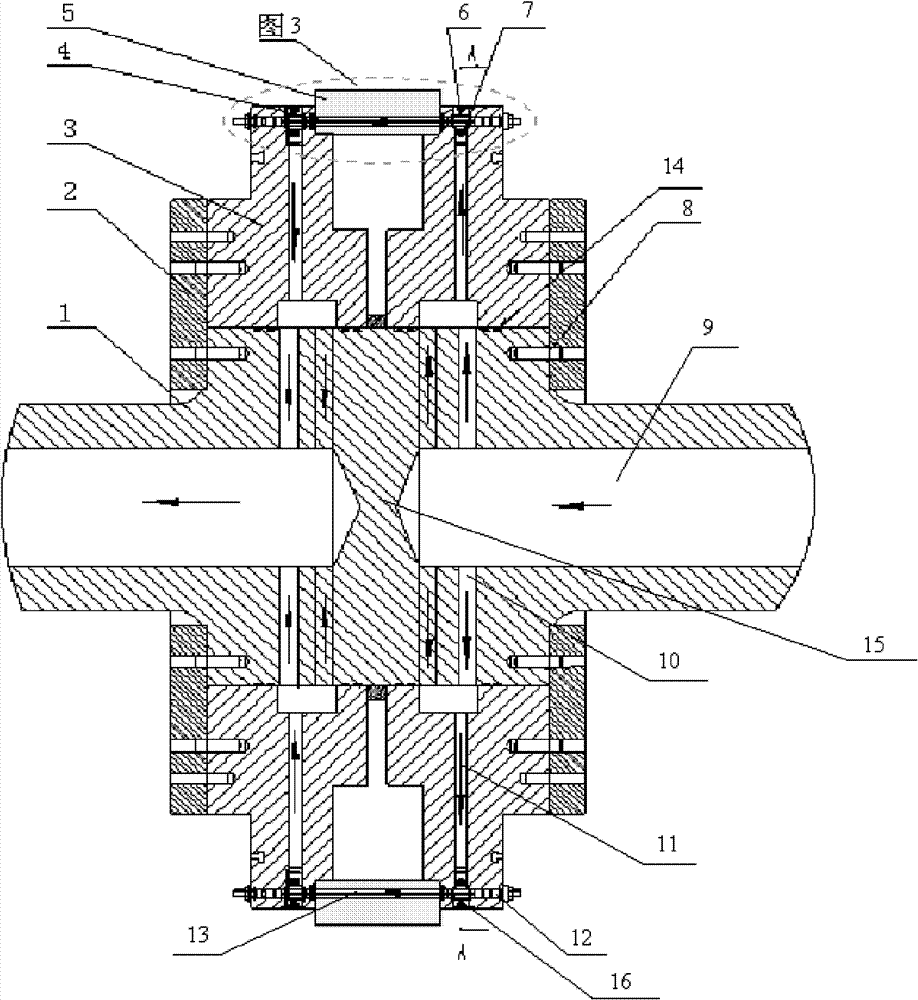

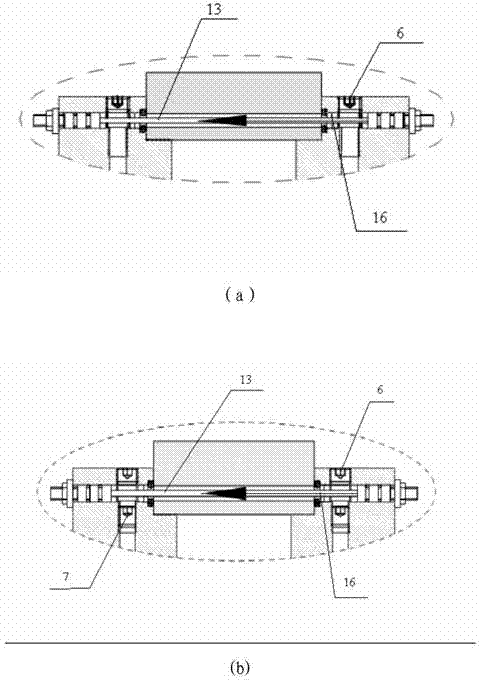

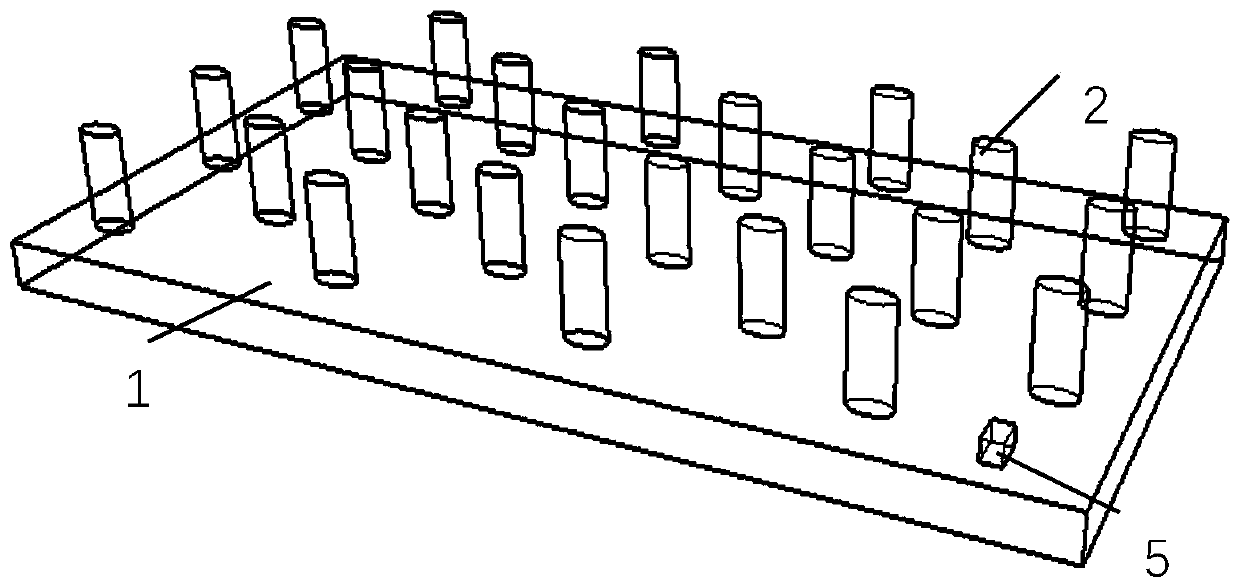

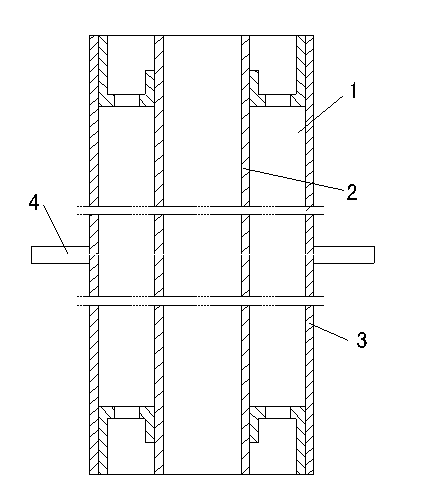

Amorphous crystallizer

The invention provides a crystallizer which is mainly used for preparing amorphous alloy. The amorphous crystallizer is composed of a copper sleeve 5, a copper sleeve support 3 and a rotary spindle 1; when the crystallizer works, cold water flows in from a water inlet end of the rotary spindle and flows into the copper sleeve 5 along the pore channels in the rotary spindle 1 and the copper sleeve support 3; the cold water absorbs the heat of molten steel transferred from the outer surface of the copper sleeve; and then the hot water returns to a water outlet end in the rotary spindle from the copper sleeve support 3 at the other end of the copper sleeve 5 along the path opposite to the cold water and flows out so as to circularly cool the molten steel. The crystallizer provided by the invention has the advantages that: the cooling efficiency is high, the surface temperature of the copper sleeve is uniform, a water flow dead angle does not exist in the copper sleeve, the axial cooling of the copper sleeve is uniform, the mechanical performance is good, and the working precision is high; and the heat transfer effect of applying the amorphous crystallizer to cool the molten steel is guaranteed.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

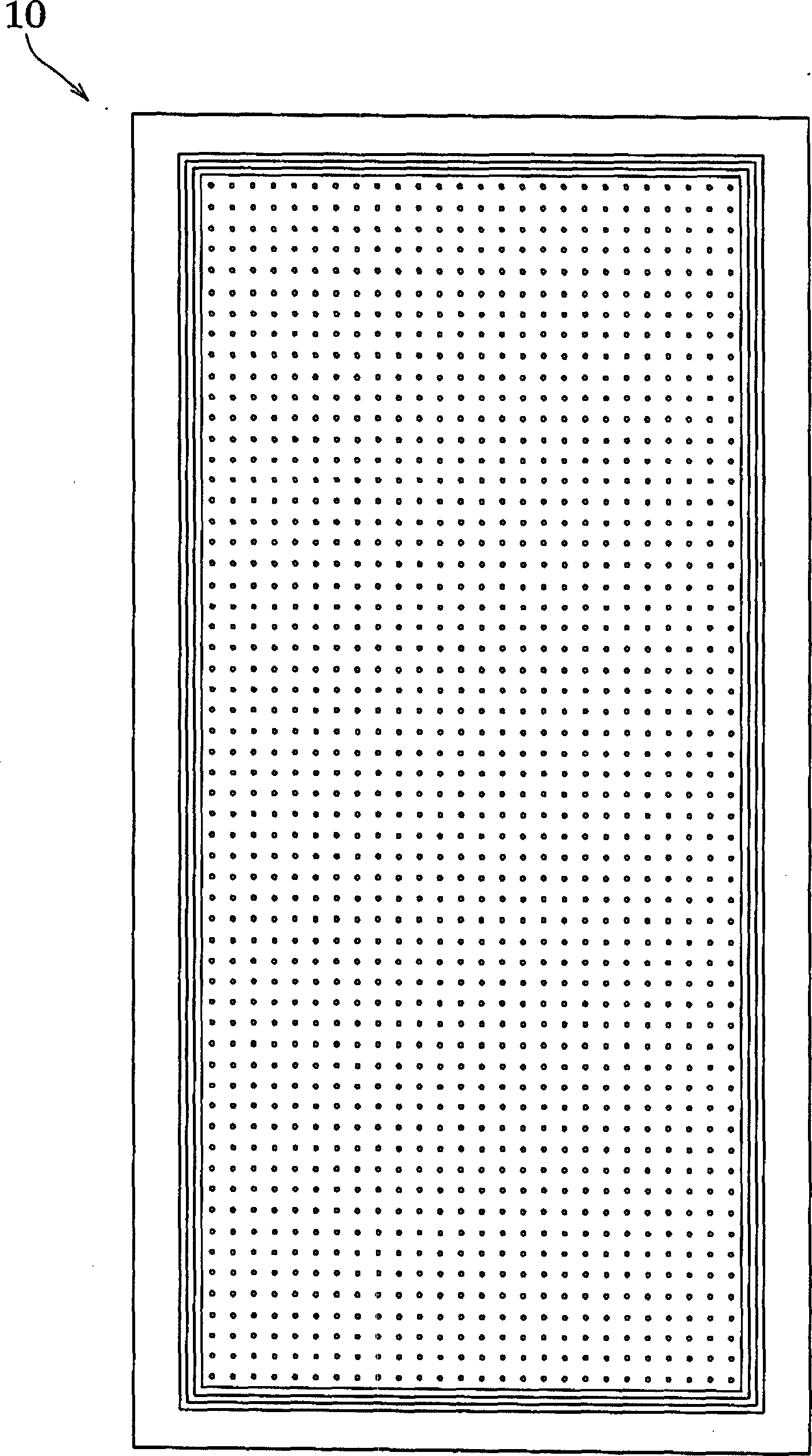

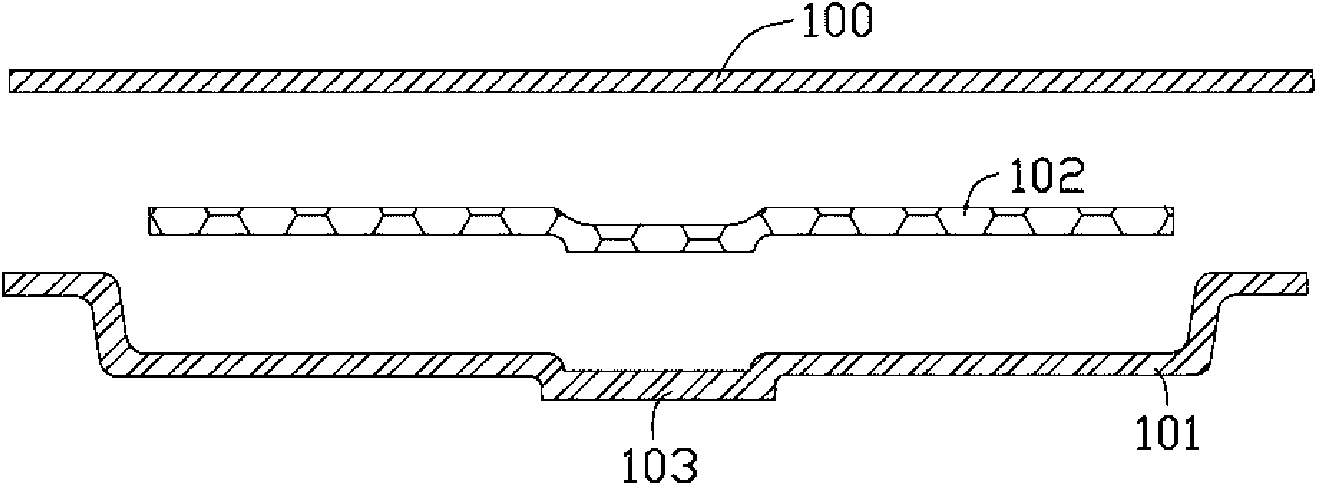

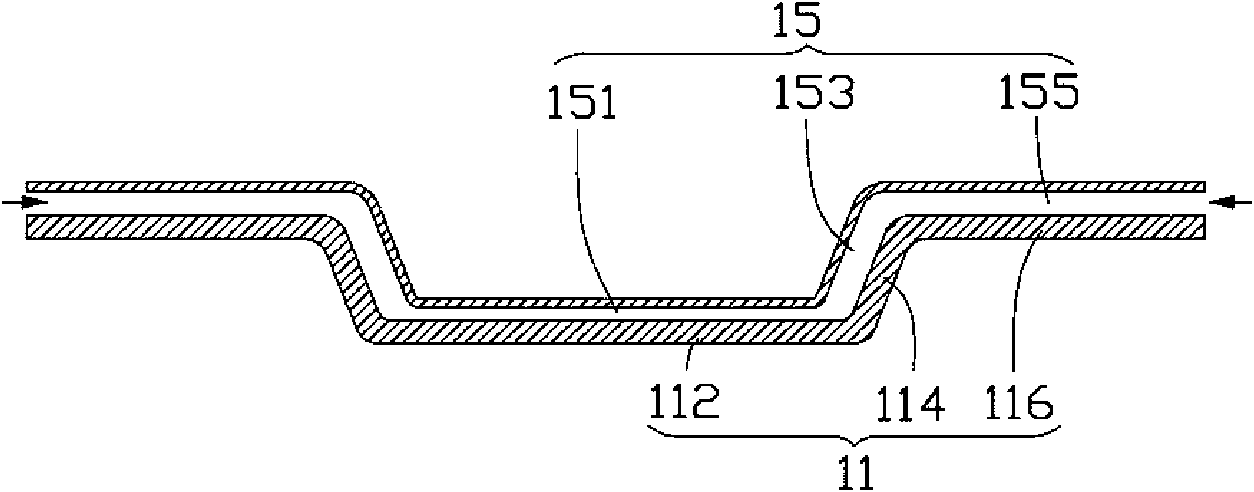

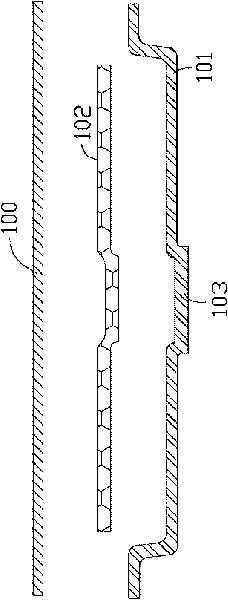

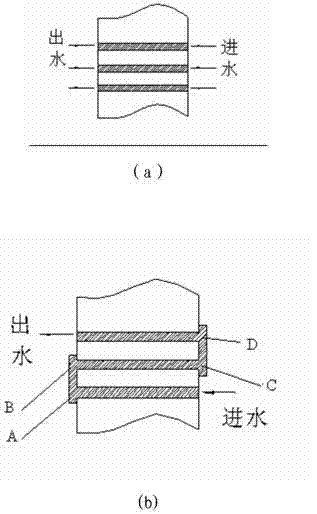

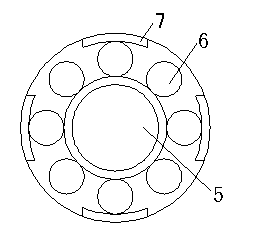

Heat exchange plate

InactiveCN1815123AGuaranteed heat transfer effectImprove heat exchange efficiencyHeat transfer modificationLaminated elementsEngineering

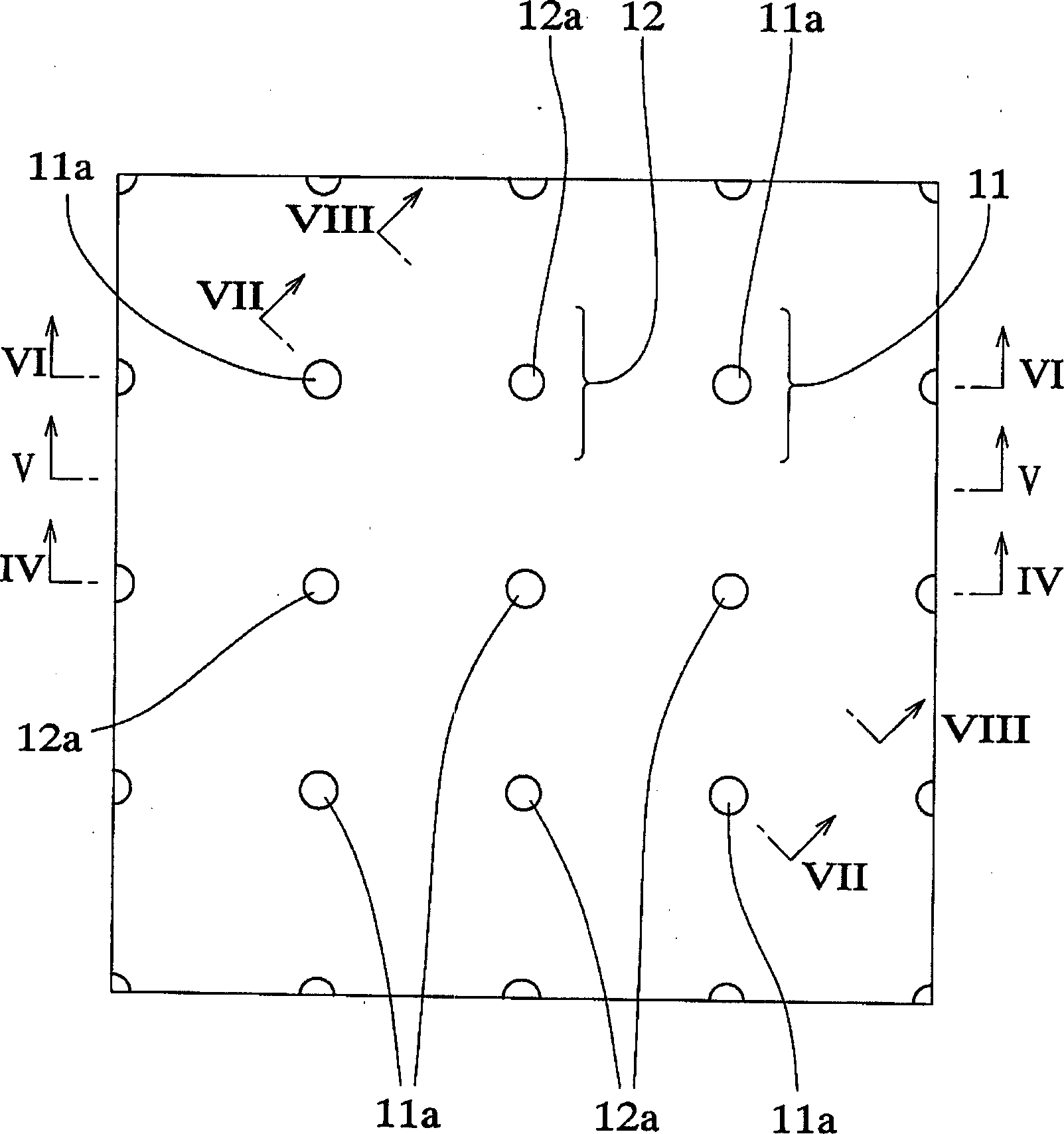

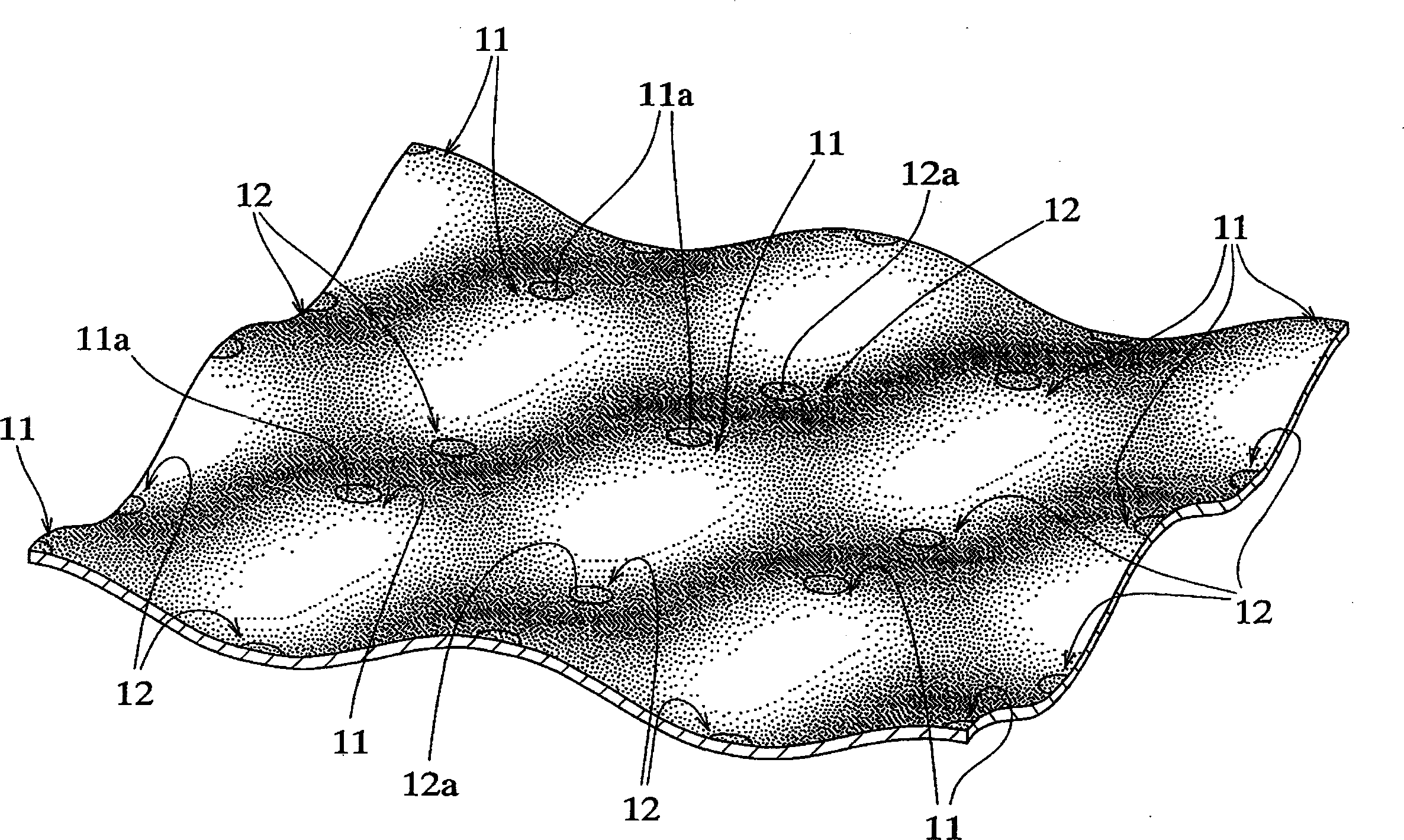

A heat exchange plate has protrusions and recesses. The protrusion having a curved outer peripheral surface is surrounded by adjacent protrusions placed at regular intervals on a circle around the protrusion with the same central angle relative to the center of the protrusion. The recess having a curved inner peripheral surface that partially extends to the curved outer peripheral surface of the protrusion is placed in a predetermined arrangement that is deviated by the same pitch from the predetermined arrangement of the protrusions. The recesses provide on the other surface of the plate with the same configuration as the protrusions. The protrusions provide on the surface of the plate with the same configuration as the recesses, so as to provide on the opposite surfaces of the metallic plate with the same pattern of irregularity.

Owner:XENESYS

Irregularly-shaped rotary heat pipe applicable to various rotation speeds

InactiveCN104266516AGuaranteed reflowGuaranteed stirringIndirect heat exchangersEngineeringHeat pipe

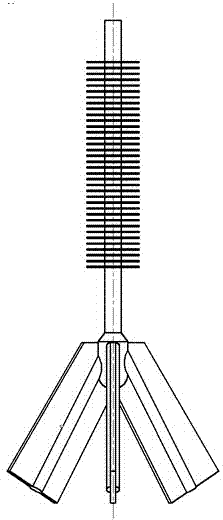

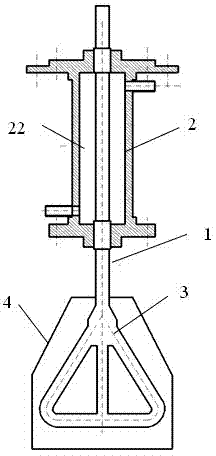

The invention discloses an irregularly-shaped rotary heat pipe applicable to various rotation speeds. The heat pipe comprises a heat pipe main body, wherein the lower section of the heat pipe main body is a heat pipe evaporation section; the upper section of the heat pipe main body is a heat pipe cooling section; a condensate reflow structure is machined on the inner wall of the heat pipe; the lower end of the heat pipe evaporation section is provided with at least one branch layer; each branch layer is provided with at least two dendritic heat absorbing pipes; the heat absorbing pipes are uniformly distributed by taking the heat pipe main body as the center and extend towards the side lower part; the outer surfaces of the heat absorbing pipes are provided with ribs to form blades. Under the condition that the evaporation section of the heat pipe type stirring paddle is at a lower rotation speed, the gravity is used as main power for reflow of a working medium. Under the condition of higher rotation speed, centrifugal force produced by rotation is used as main power for reflow, so that the heat pipe type stirring paddle has excellent adaptability at various rotation speeds.

Owner:NANJING UNIV OF TECH

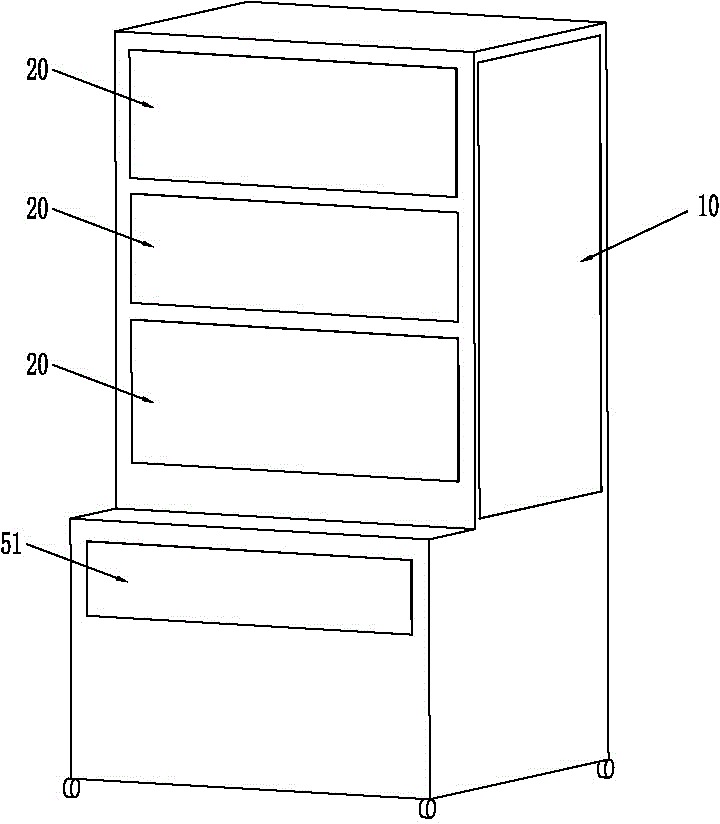

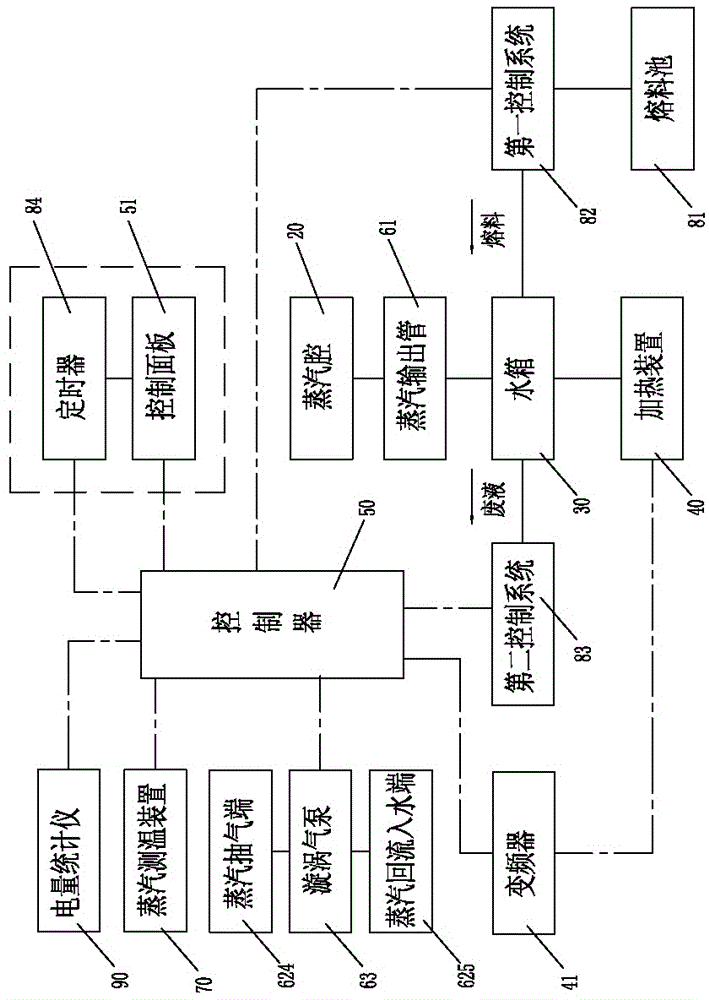

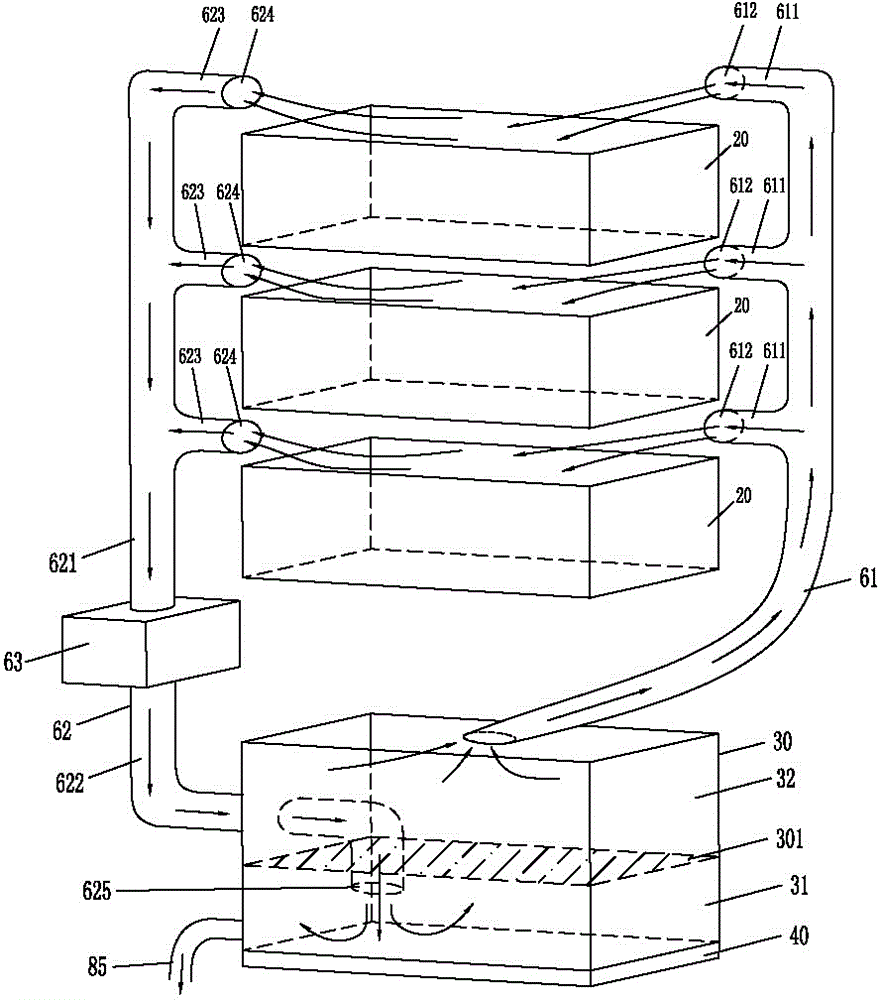

High-precision temperature controlling and energy saving stewing cabinet intelligently and automatically removing scale

ActiveCN104939669AEvenly distributedStable temperatureMultiple-unit cooking vesselsFood preparationTemperature controlControl system

The invention discloses a high-precision temperature controlling and energy saving stewing cabinet intelligently and automatically removing scale. The high-precision temperature controlling and energy saving stewing cabinet intelligently and automatically removing the scale comprises a stewing cabinet body. The stewing cabinet body is provided with a steam cavity, a water tank, a heating device, a steam circulating conveying system, a segment temperature controlling and energy saving control system, an automatic scale removing system, a controller and a control panel, wherein the steam circulating conveying system is used for ensuring that the steam is even and the temperature is stable; the segment temperature controlling and energy saving controlling system is used for improving the food stewing effect; the automatic scale removing system is used for cleaning the water tank, and the controller and the control panel are used for intelligently controlling stewing operation. A vortex air pump is used for pumping steam in the steam cavity into the water tank for cyclic heating, the steam is distributed evenly, the temperature is stable, food is heated evenly, leaked steam is reduced, the energy utilization rate is increased, the stewing time is short, energy and water are saved, efficiency is high, segment temperature controlling stewing is conducted on the food, and the taste of the food is better. The automatic scale removing system cleans scale in the water tank regularly, cleanliness and the efficient heat transferring effect of the water tank are kept, and the purposes of reducing energy consumption and improving the performance of the stewing cabinet are ensured.

Owner:DONGGUAN KEYUE ELECTRONICS TECH

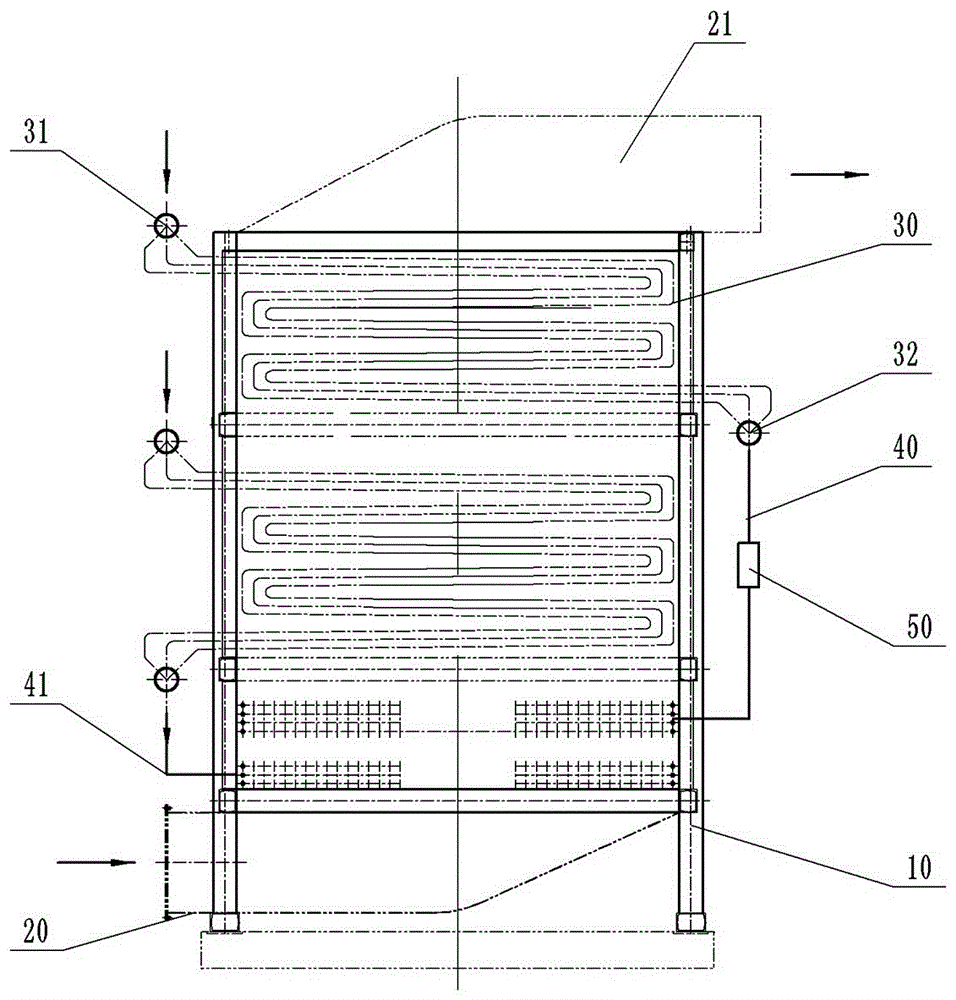

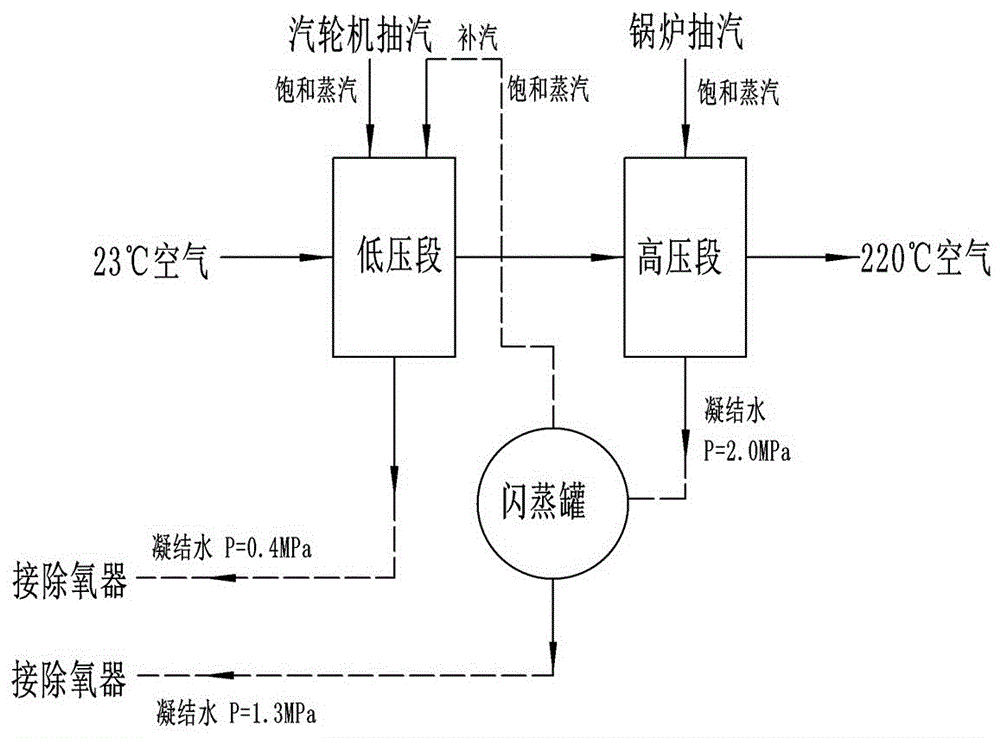

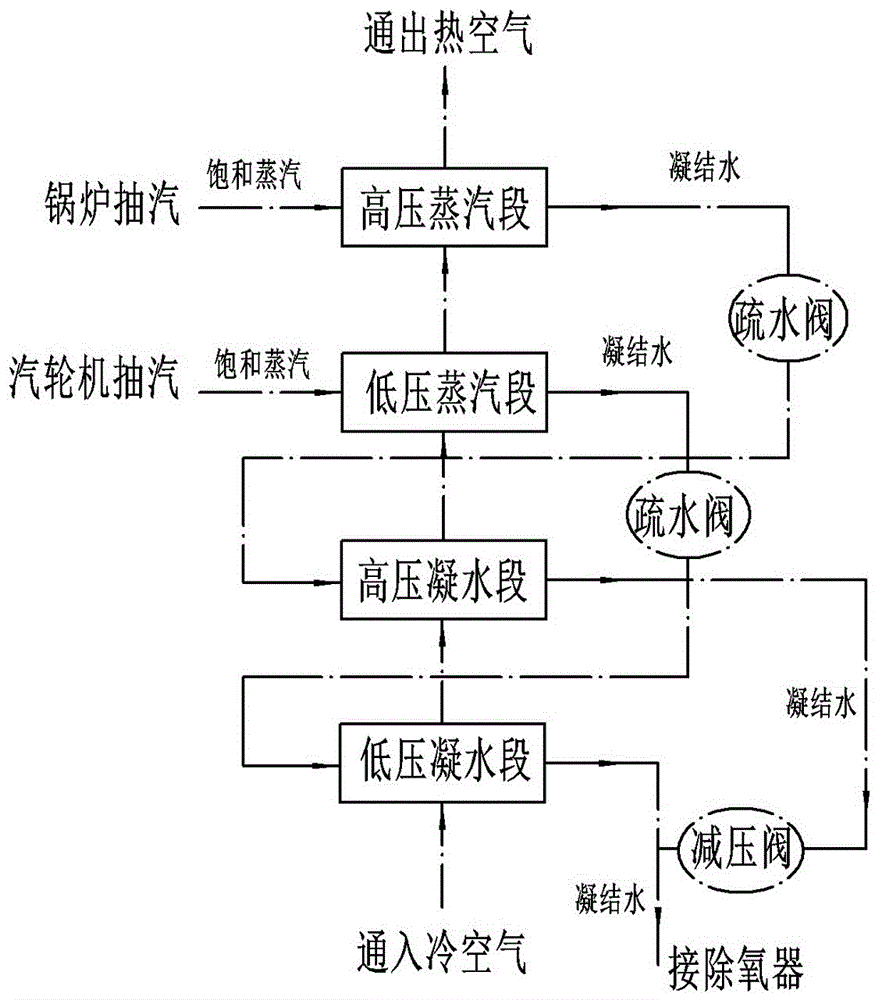

Steam air preheating system of waste incineration boiler

ActiveCN106439855AImprove heating efficiencyImprove the heating effectLiquid degasificationFeed water supplyAir preheaterDeaerator

The application of the invention discloses a steam air preheating system of a waste incineration boiler. The steam air preheating system comprises a deaerator, an air duct box and a four-section type steam air preheater, wherein the four-section type steam air preheater sequentially comprises a high-pressure steam section, a low-pressure steam section, a high-pressure condensed water section and a low-pressure condensed water section from the top to the bottom, an outlet header of the high-pressure steam section communicates with an inlet header of the high-pressure condensed water section through a first pipeline, an outlet header of the low-pressure steam section communicates with an inlet header of the low-pressure condensed water section through a second pipeline, and draining valves are arranged on both the first pipeline and the second pipeline; and an outlet header of the high-pressure condensed water section communicates with an outlet header of the low-pressure condensed water section through a third pipeline, a pressure reducing valve is arranged on the third pipeline, and the outlet header of the low-pressure condensed water section communicates with the deaerator. Compared with the prior art, the system is high in energy utilizing rate and high in air heating efficiency. The system adopting vertical arrangement saves land occupying space and is favorable to the overall arrangement of the boiler.

Owner:广州广重企业集团有限公司

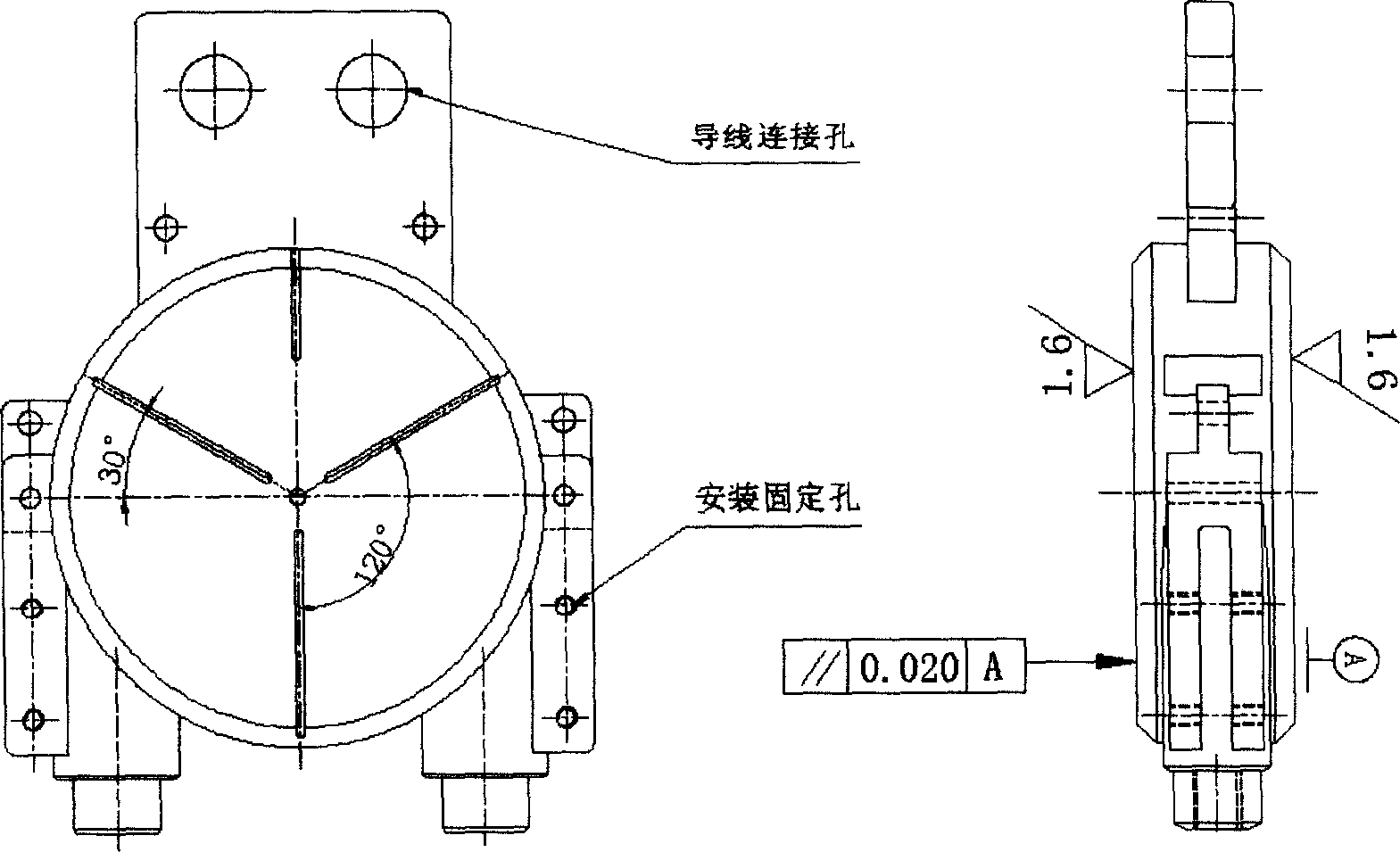

Thyratron transistor valve water-cooling radiator

ActiveCN1767183ASmall water resistance and thermal resistanceReduce maintenanceSemiconductor/solid-state device detailsSolid-state devicesWater pipeHardness

The invention relates to a thyristor valve group water cooling radiator in the field of electronic technology. It adopts plate touching conduction structure with the parallel degree of the two plates below 0.02 mm and the surface crudity degree below 1.6ª–m; The interface of the cooing water pipe is an entrance and a exit; the embed canal apprises the plate; it arranges the special wire connecting hole and fixed hole. The embed canal material uses low carbon stainless steel pipe and adds the element which can elevate the compression strength in the aluminum alloy of the plate. It adopts special embed canal surface processing craft and casing surface aluminum alloy electroplating craft.

Owner:CHINA ELECTRIC POWER RES INST

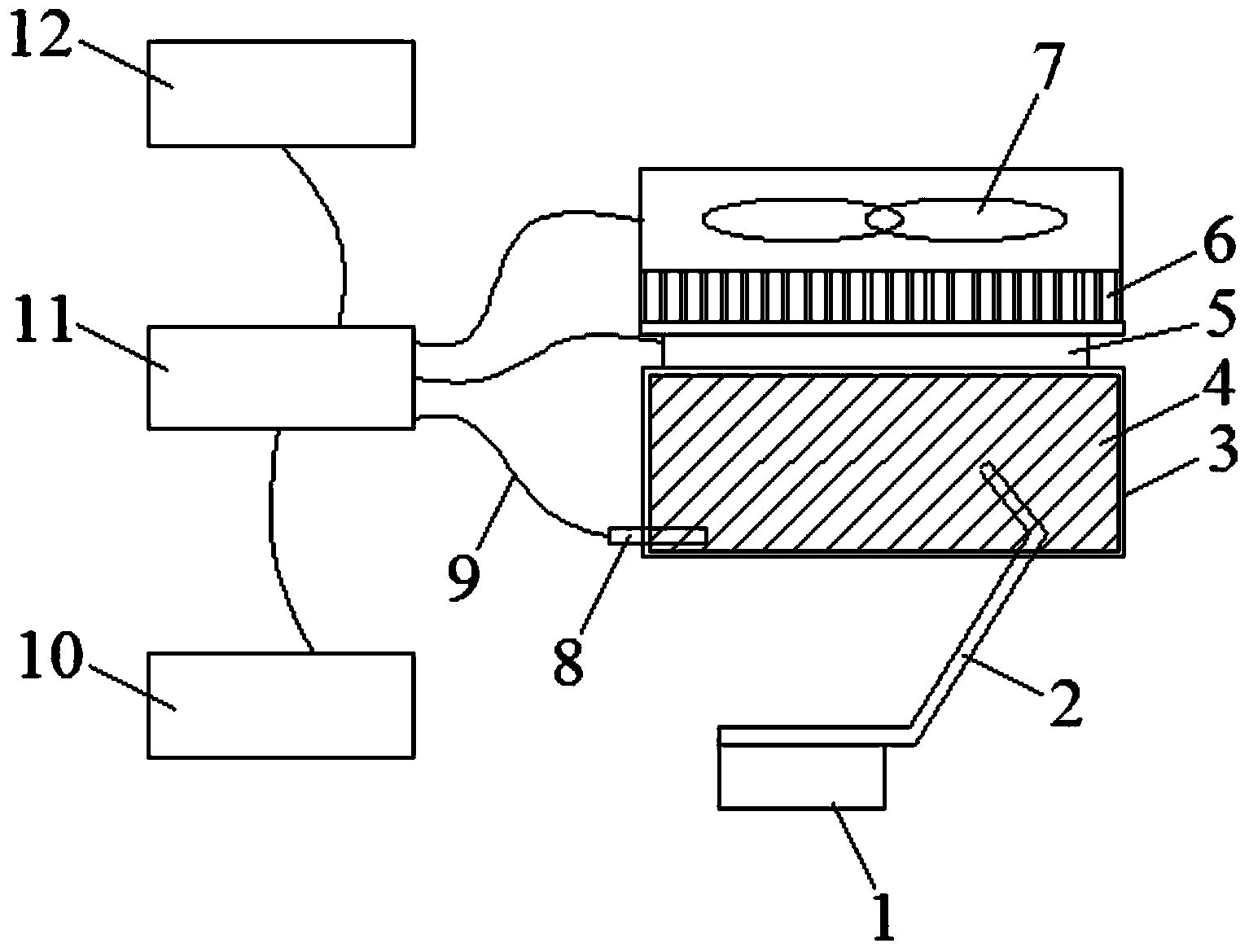

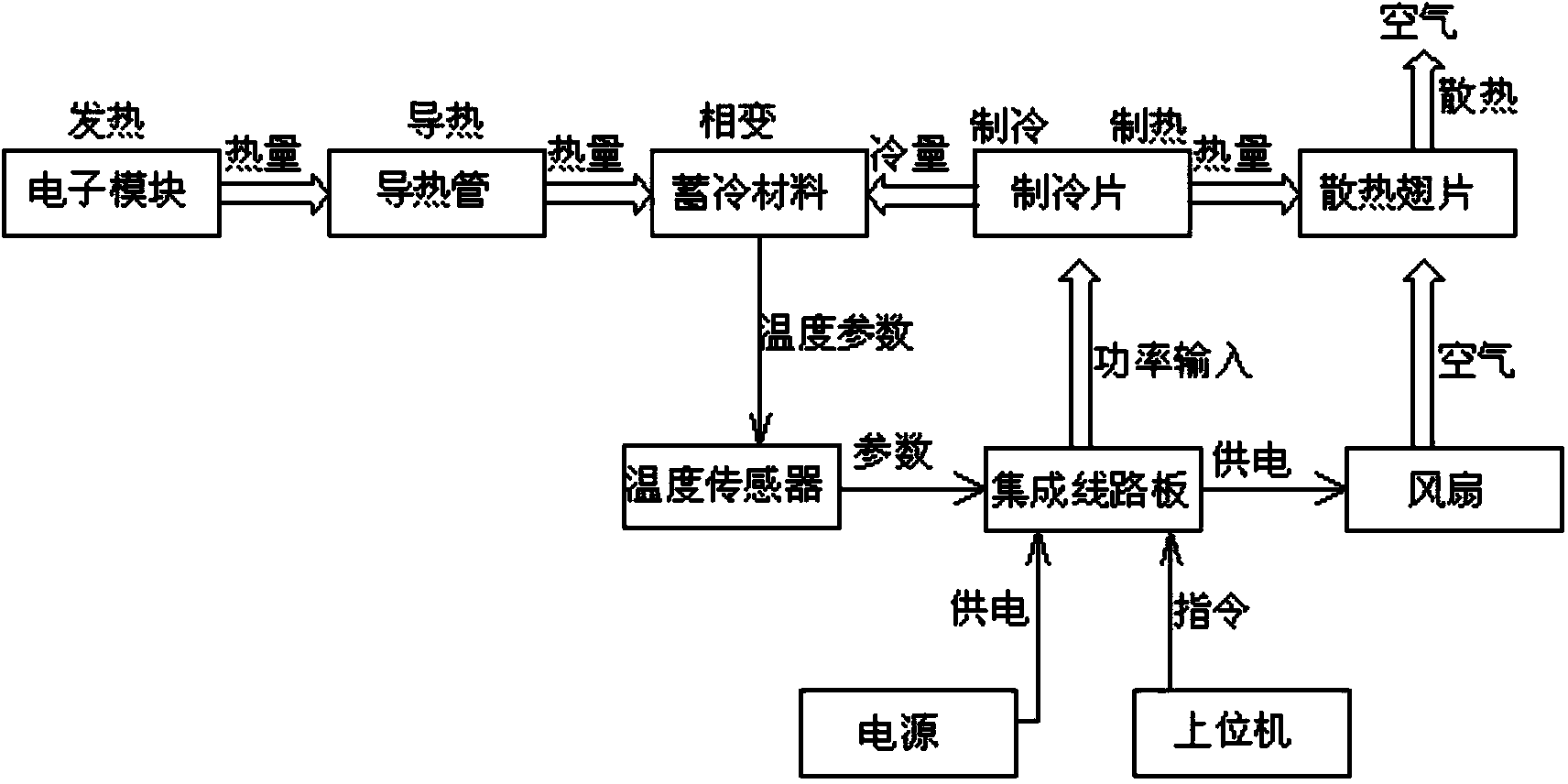

Airborne electronic module cooling device with cold accumulation function and operating method

InactiveCN104302157AGuaranteed working temperatureReduce volumeCooling/ventilation/heating modificationsMicrocomputerMicrocontroller

The invention discloses an airborne electronic module cooling device with the cold accumulation function and an operating method. The airborne electronic module cooling device comprises an electronic module, a cold accumulation part, a refrigeration part, a cooling part and a control part. The cold accumulation part comprises a heat conduction tube, a heat insulation container and a cold accumulation material. The refrigeration part comprises a semiconductor chilling plate. The cooling part comprises cooling fins and a fan. The control part comprises a temperature sensor, an integrated circuit board and an upper computer. The airborne electronic module cooling device is uniformly controlled by a single-chip microcomputer on the integrated circuit board, and control can be automatically carried out on operation of the device according to the preset temperature and input power. The device is small in size, low in power consumption, light in mass, high in integration level, flexible to arrange, high in expansibility, especially suitable for cooling electronic modules with small cooling surfaces and capable of keeping the working temperature of the electronic modules under the condition of power supply insufficiency.

Owner:合肥天鹅制冷科技有限公司

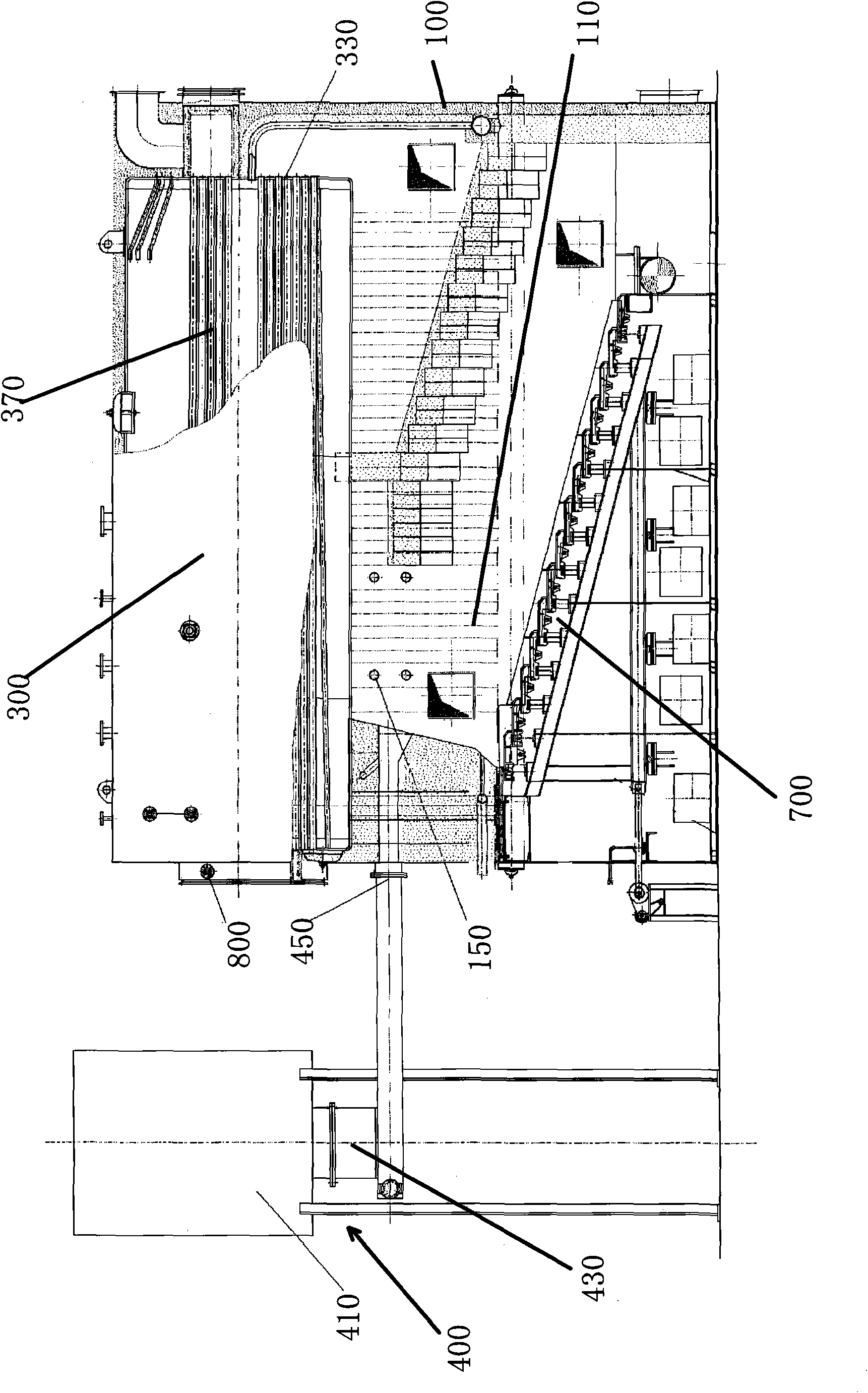

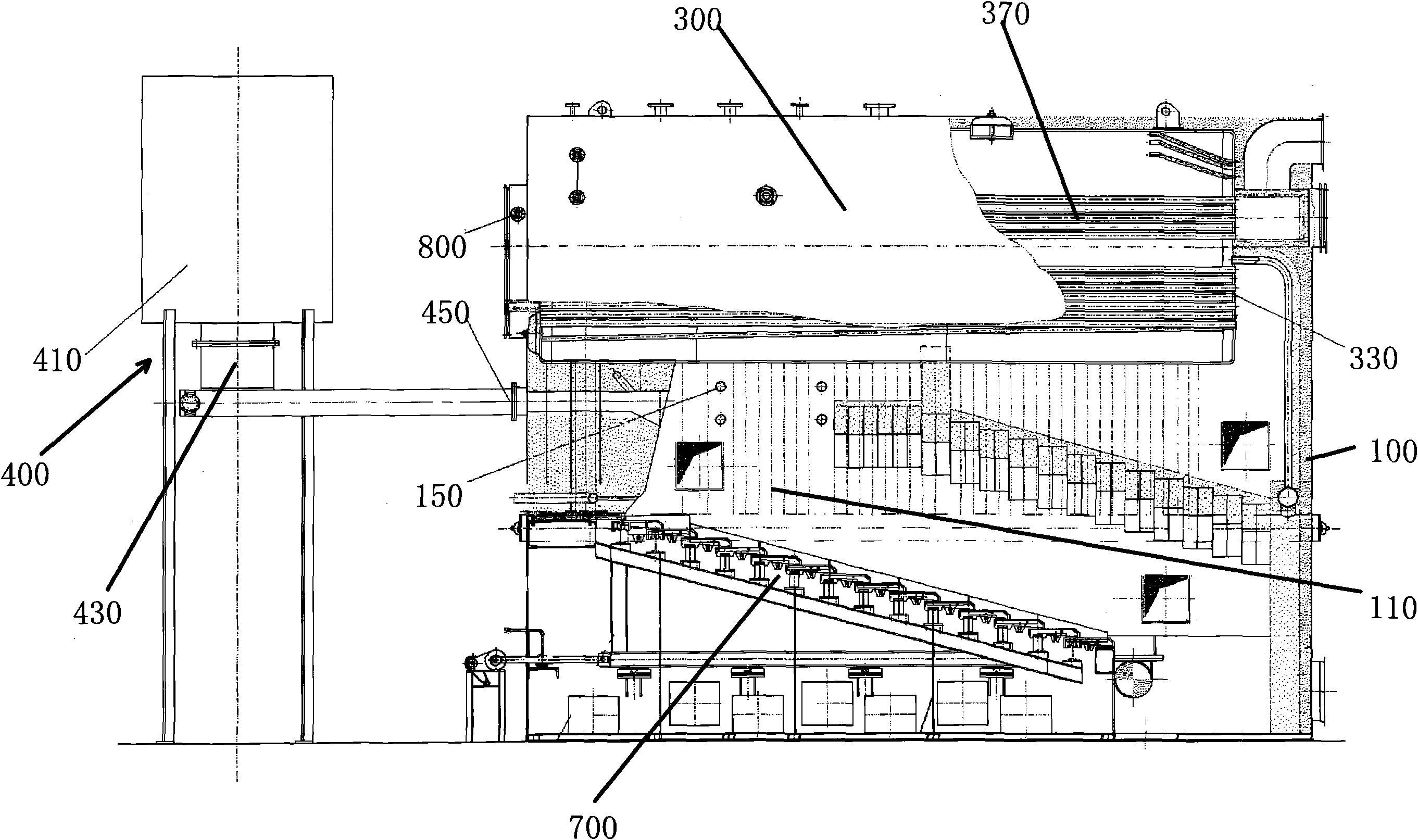

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

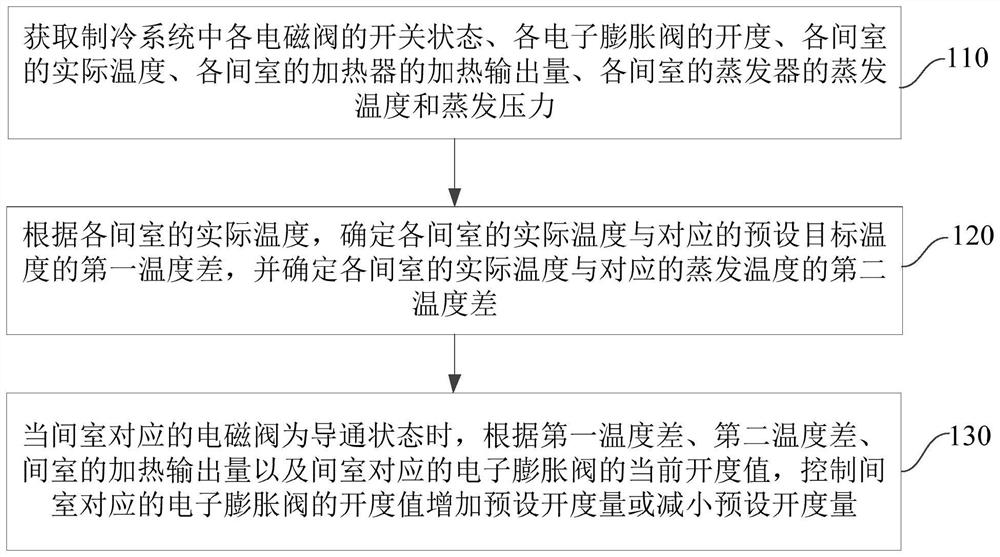

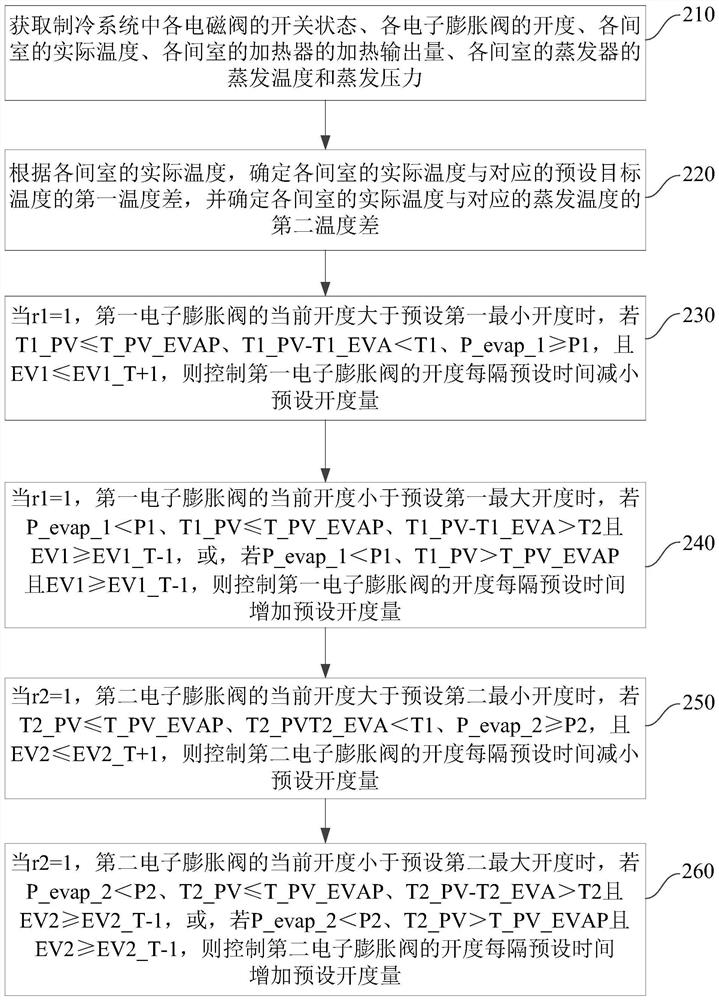

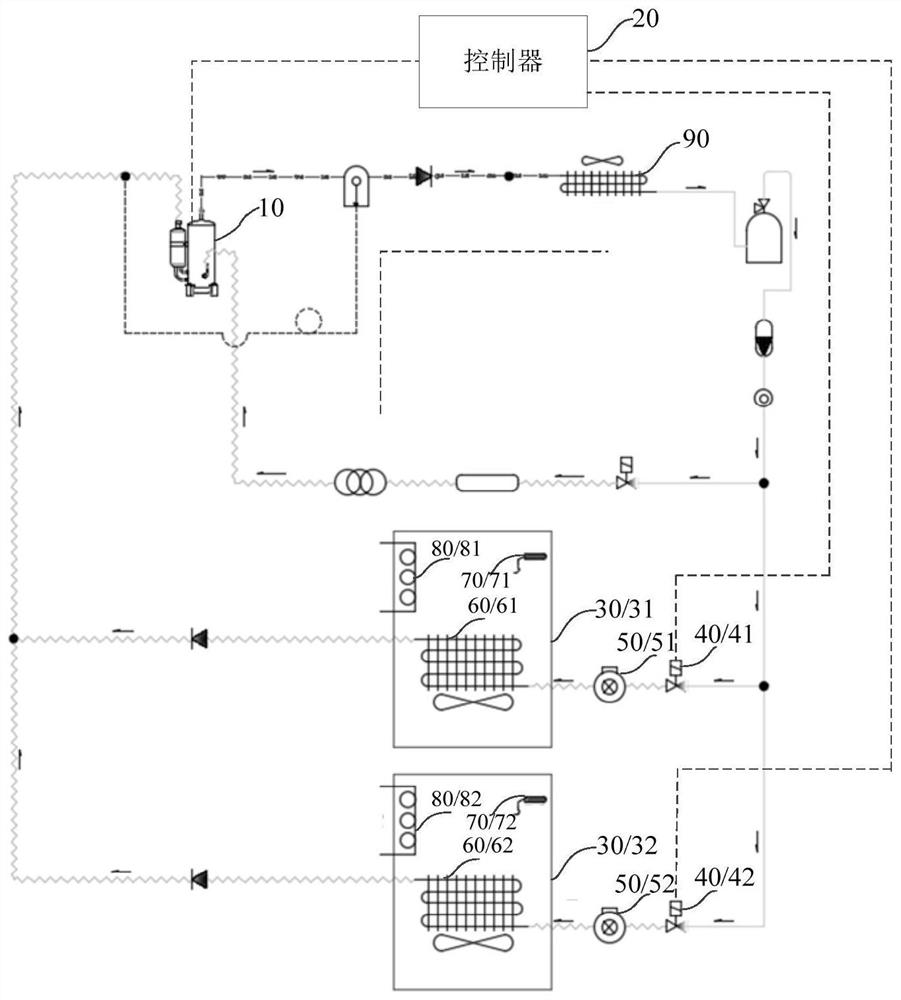

Control method and device for multi-chamber electronic expansion valve of refrigerating system and refrigerating system

ActiveCN112665254AAvoid temperature fluctuationsIncrease the preset opening amountMechanical apparatusCompression machines with non-reversible cycleMechanical engineeringElectronic expansion valve

An embodiment of the invention discloses a control method and device for a multi-chamber electronic expansion valve of a refrigerating system and the refrigerating system. The method comprises the steps that the on-off state of each electromagnetic valve in the refrigerating system, the opening degree of each electronic expansion valve, the actual temperature of each chamber, the heating output quantity of a heater of each chamber and the evaporation temperature and the evaporation pressure of an evaporator of each chamber are obtained; a first temperature difference between the actual temperature of each chamber and a preset target temperature is determined, and a second temperature difference between the actual temperature of each chamber and the evaporation temperature is determined; and when the electromagnetic valves corresponding to the chambers are in the conducting states, according to the first temperature differences, the second temperature differences, the heating output quantities of the chambers and the current opening degree values of the electronic expansion valves corresponding to the chambers, the opening degree values of the electronic expansion valves corresponding to the chambers are controlled to be increased or decreased by the preset opening degree value. According to the technical scheme, temperature fluctuations of the chambers can be avoided, the heat transfer temperature difference and the system flow can be guaranteed, and the pressure of the low-pressure end of the system is prevented from being changed into negative pressure.

Owner:JIANGSU TUOMILUO ENVIRONMENTAL TEST EQUIP CO LTD

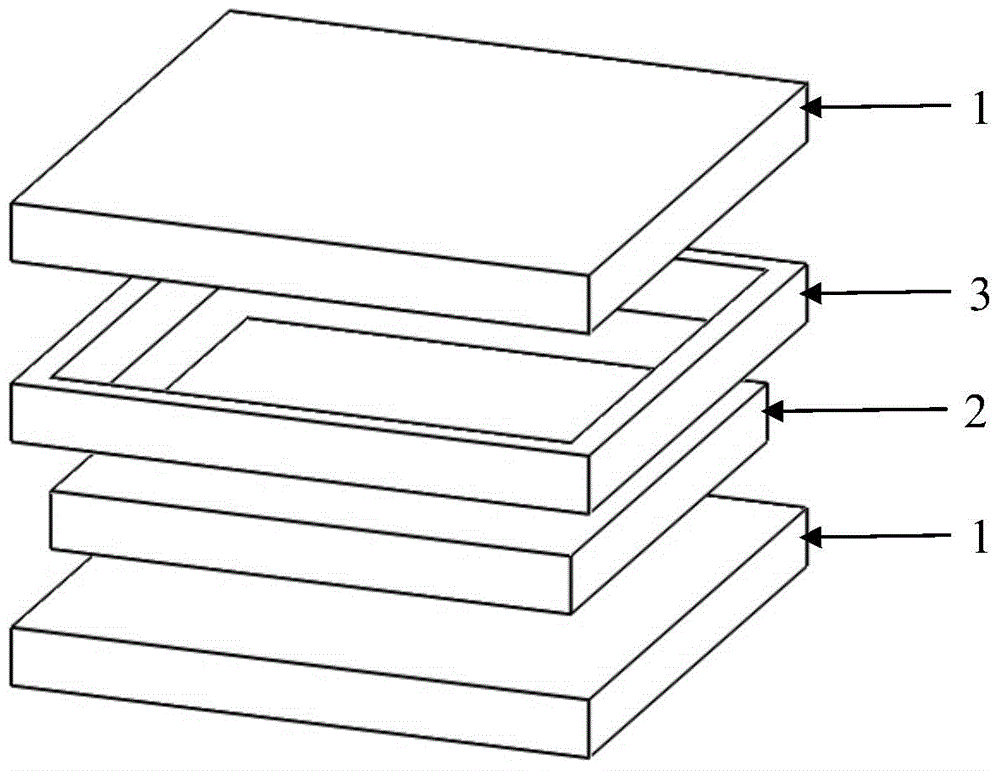

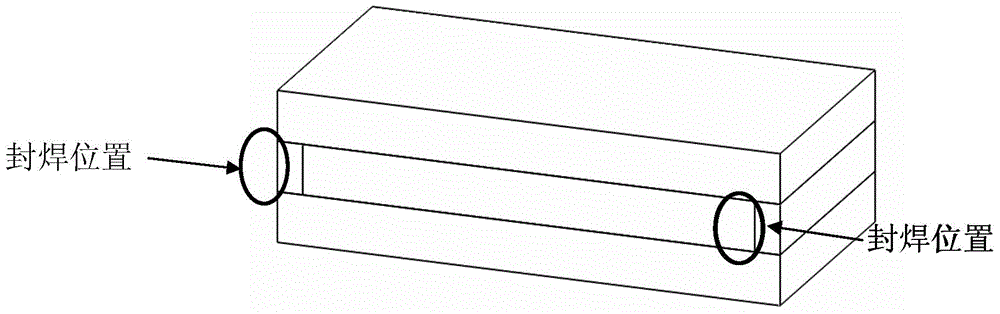

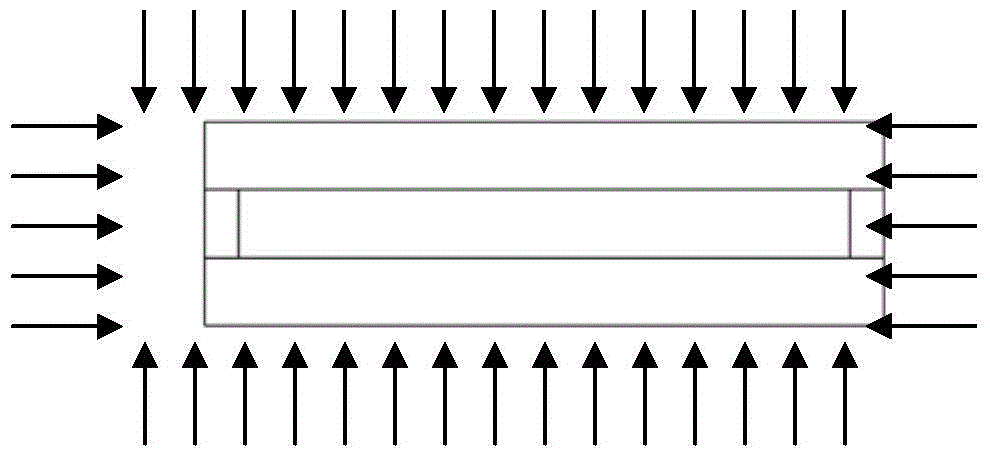

Cu-W/Cu-Cu composite board preparation method

InactiveCN104625623AHigh thermal conductivityImproved coefficient of thermal expansionBinding forceNanotechnology

The invention provides a Cu-W / Cu-Cu composite board preparation method. According to the method, based on sealing weld and hot isostatic pressure technologies, structure optimization is conducted on sandwich composite materials, and finally near-net formed products are prepared. The Cu-W / Cu-Cu composite board preparation method is short in technological process, near-net in forming, especially suitable for large-scale industrial production and high in composite interlamination binding force, the strength and thermal property of the composite materials are guaranteed effectively, and the heat dissipation problem of high-dissipation-power electronic devices can be solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

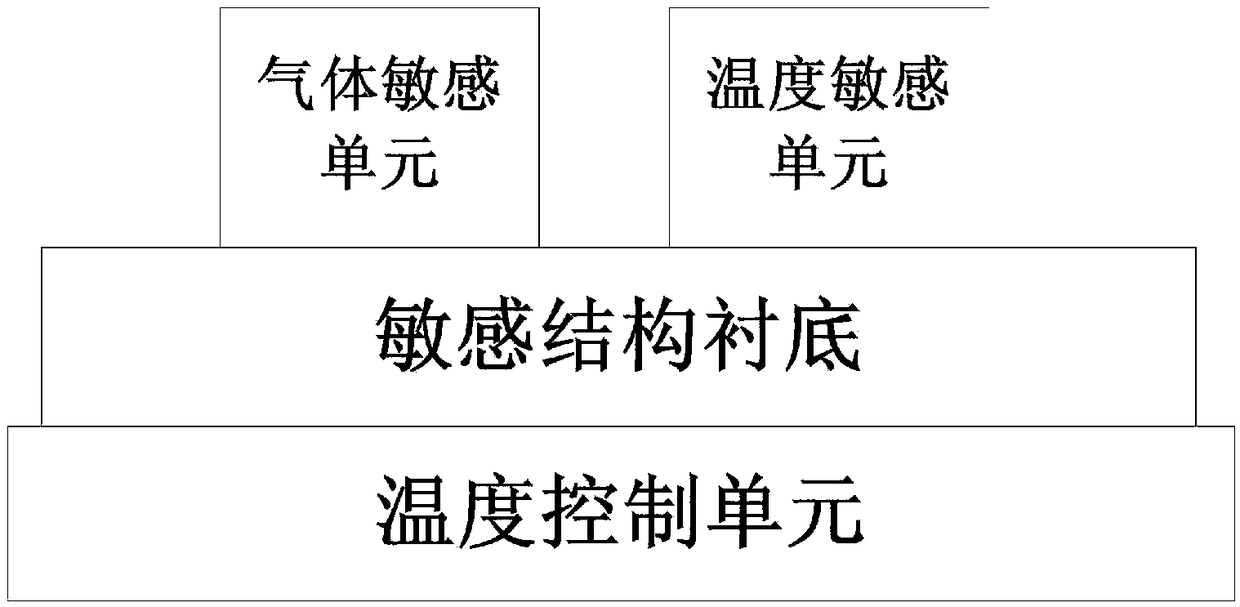

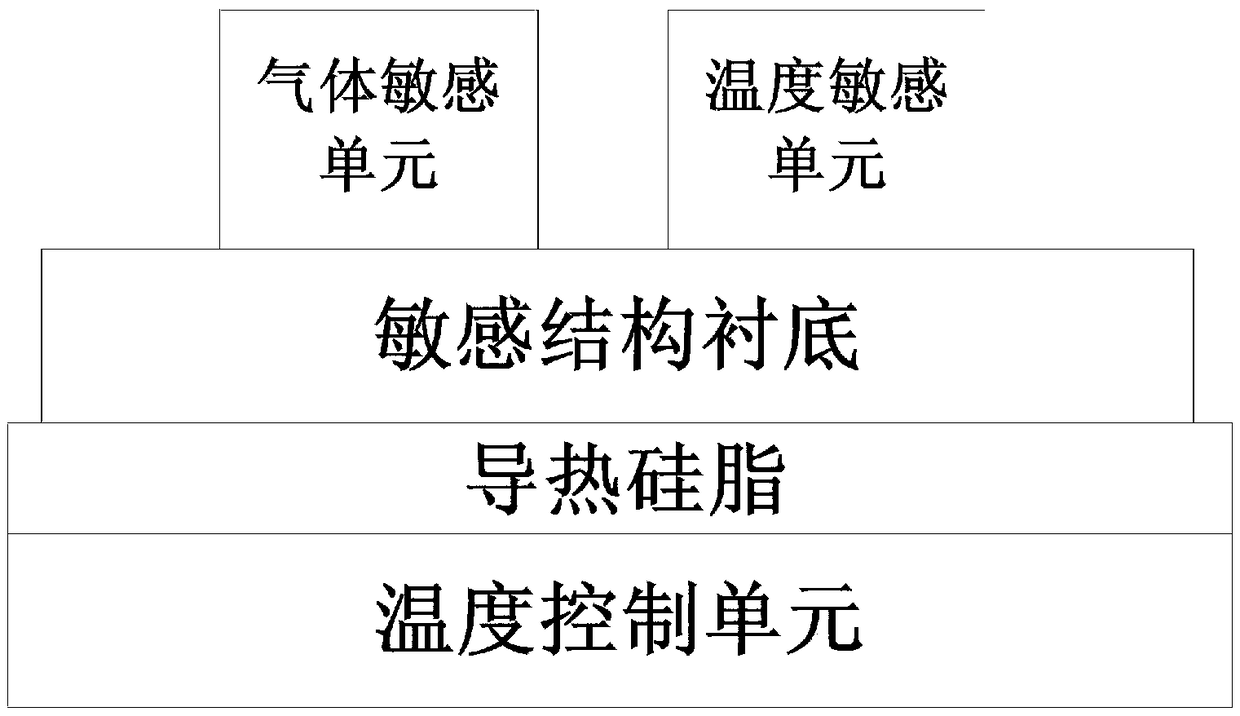

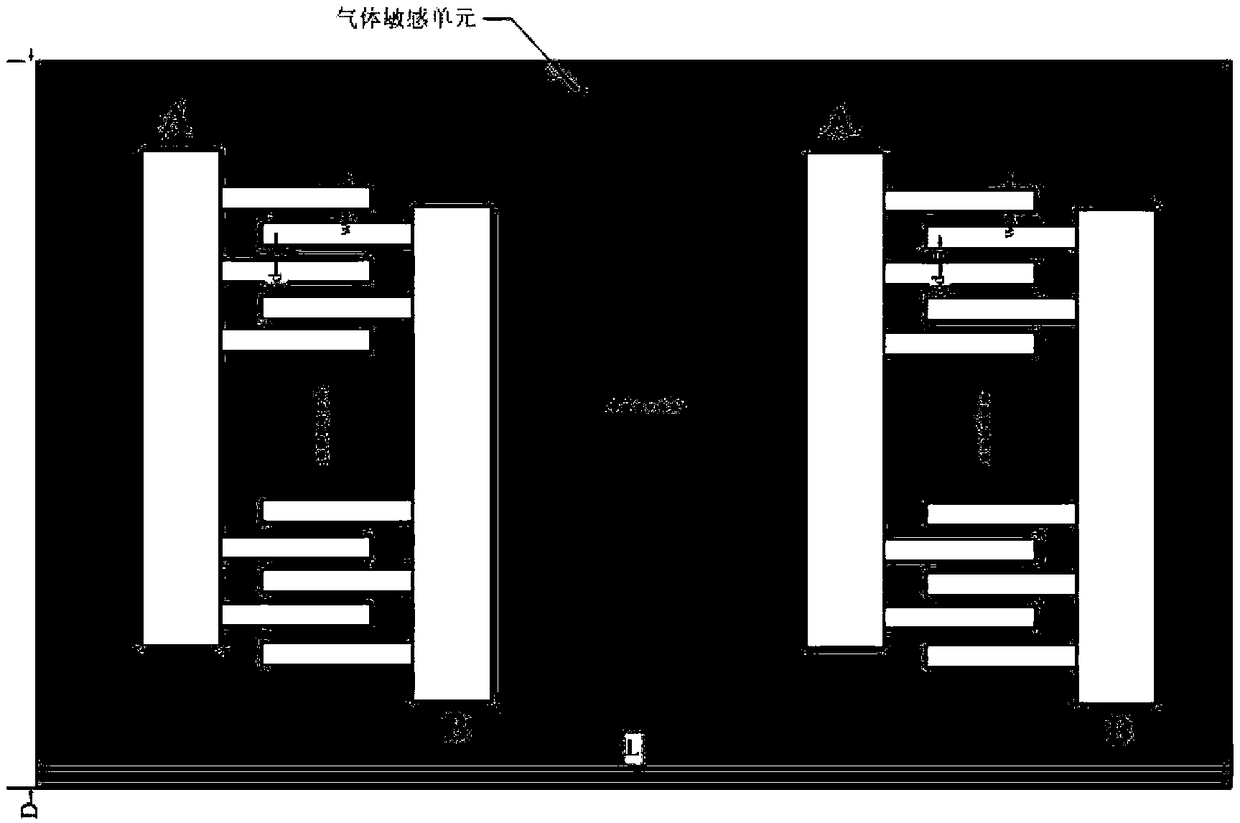

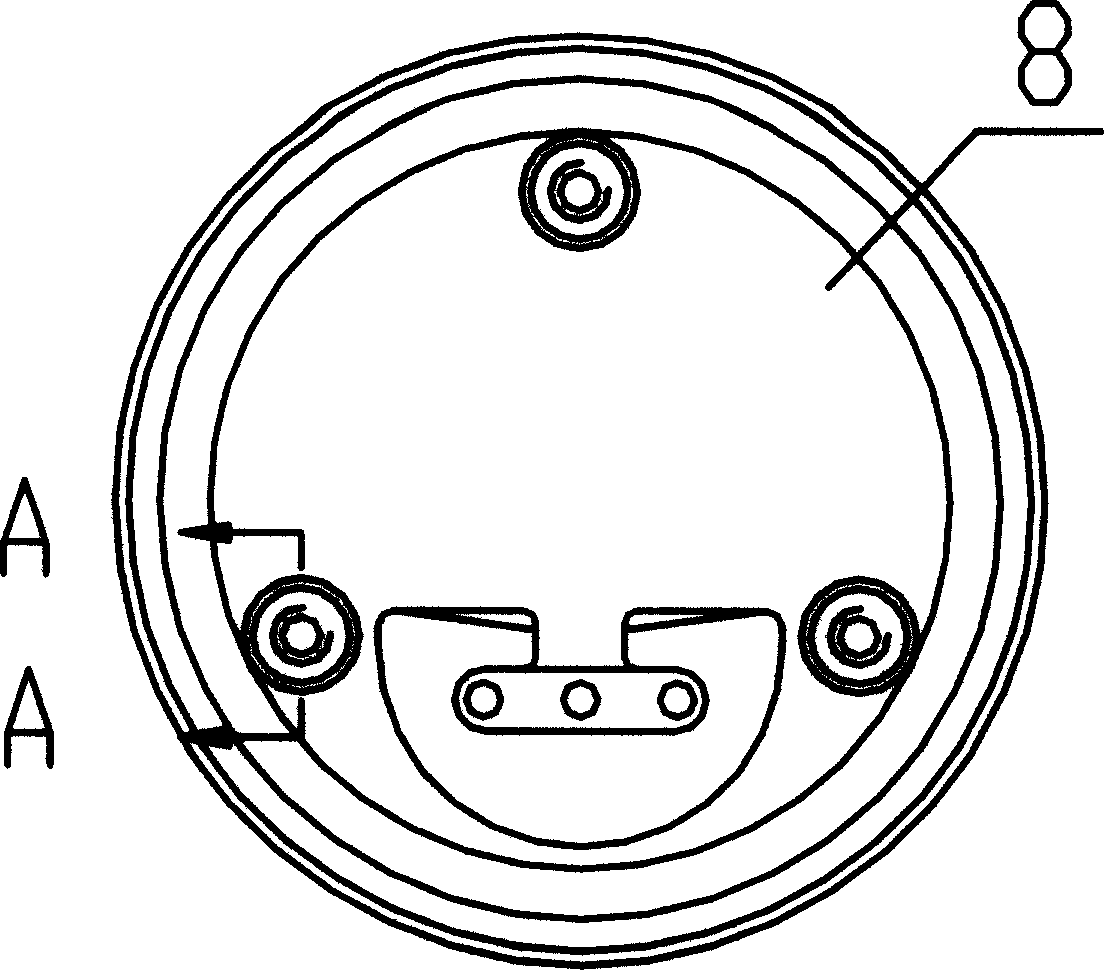

MEMS gas sensor chip and sensor and preparation method of sensor

ActiveCN108844652AShort delivery pathFast balanceTemperatue controlThermometers using electric/magnetic elementsMOSFETTemperature control

The invention relates to an MEMS gas sensor chip and sensor and a preparation method of the sensor, belongs to the technical field of gas detection, and solves the problems of high technical cost, long response time and low environment stability in the prior art. The MEMS gas sensor chip comprises a gas sensitive unit, a temperature sensitive unit, a sensitive structure substrate and a temperaturecontrol unit. The MEMS gas sensor comprises the MEMS gas sensor chip and a control circuit, and the control circuit further comprises a microcontroller, an N type MOSFET, a P type MOSFET and a positive-negative power supply. The microcontroller compares a practical temperature collected by the temperature sensitive unit with a preset temperature, outputs a control signal according to a comparisonresult, controls ON / OFF of the N type MOSFET and the P type MOSFET, and further controls the direction and magnitude of a current through the temperature control unit and changes the surface temperature of the sensitive structure substrate. The MEMS gas sensor is simple in operation and high in versatility, can measure the concentration of different gases simultaneously, saves the cost, and is short in response time and high in environment stability.

Owner:BEIJING MECHANICAL EQUIP INST

Welding process for stainless steel heating tube and stainless steel heating tube

InactiveCN1586782ADoes not affect surface chromaGuaranteed heat transfer effectFluid heatersLaser beam welding apparatusMaterials scienceLaser

The present invention discloses touch welding process between the flange for stainless steel pipe and the electrically heated stainless steel pipe. The flange has at least one raised spot in the notched part to raise the touch welding efficiency and reduce the influence on the surface color of welded stainless steel pipe. Compared with common welding process, the touch welding process is firm, high in welding quality, fast, saving in material. Laser welding may be further used after touch welding. One kind of heating stainless steel pipe for the said technological process is also disclosed.

Owner:李安和 +1

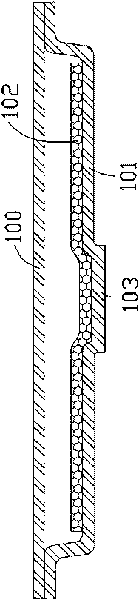

Manufacturing method of capillary structure of flat-sheet heat pipe

InactiveCN101650142AGuaranteed heat transfer performanceNo burningIndirect heat exchangersEngineeringMetal

The invention discloses a manufacturing method of a capillary structure of a flat-sheet heat pipe, comprising the following steps: providing a lower cover board which has a straight heat absorption part and two extension parts extending outwards from the two opposite ends of heat absorption part in a slant way; providing a quantity of metal power; providing a die, which is an inner pore chamber having the outline thereof similar to that of the lower cover board and an opening arranged downwards, and is provided with a first holding section corresponding to the heat absorption part of the lowercover board and a second holding section corresponding to the extension parts with the depth of the first holding section larger than that of the second holding section; filling the metal power intothe die; sintering the lower cover board at high temperature to cause the metal power in the die to be sintered into a continuous capillary structure attached on the upper surface of the lower cover board, wherein the capillary structure comprises a first capillary section attached on the heat absorption part of the lower cover board and a second capillary section attached on the extension parts with the first capillary section being thinner than the second capillary section.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

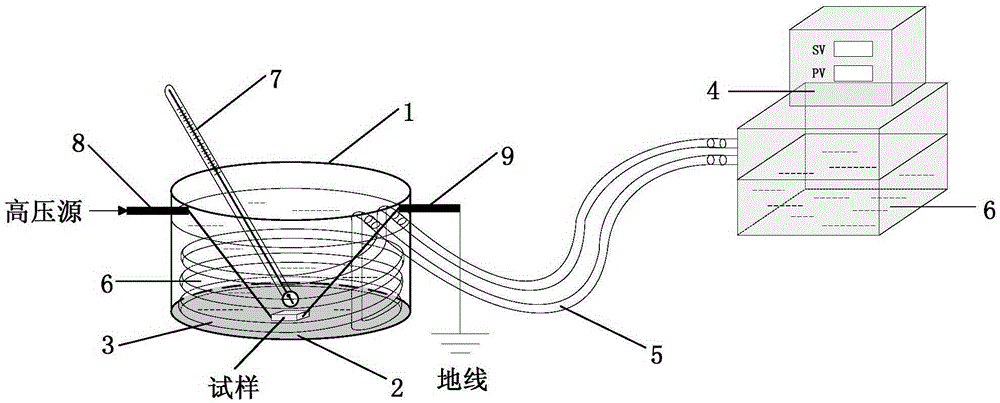

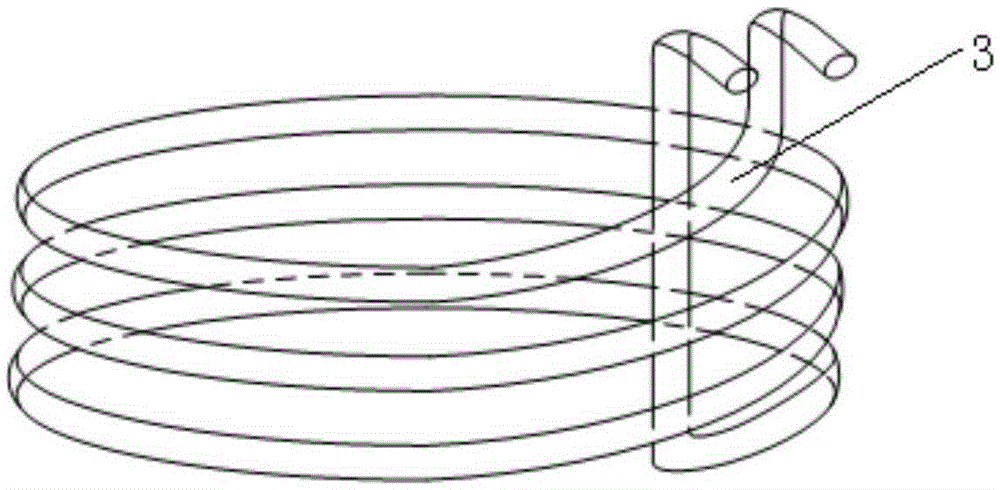

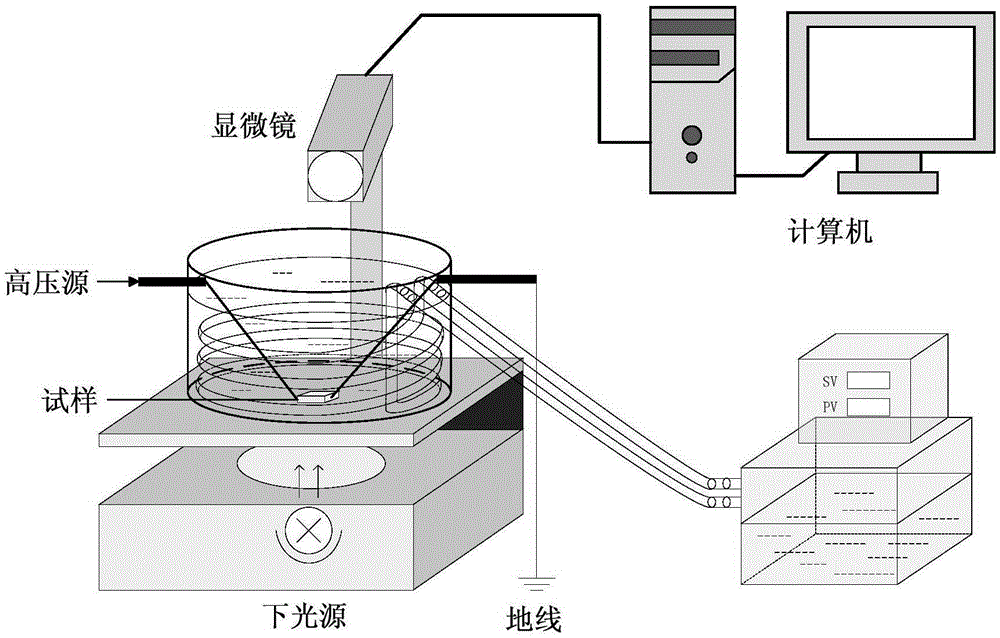

Solid insulation treeing type high temperature test system capable of realizing high efficiency temperature control

ActiveCN105425119AEfficient temperature controlImprove heat resistanceTesting vessel constructionLow voltageMicroscopic observation

The invention relates to a solid insulation treeing type high temperature test system capable of realizing high efficiency temperature control. The system comprises a test vessel formed by a container wall and a glass foundation, wherein the test vessel is internally filled with dimethicone, an annular glass tube surrounds an inner side of the test vessel in a spiral mode, the annular glass tube is connected with a high temperature heating source through a heat circulation tube, the high temperature heating source is internally filled with silicone oil, a sample is arranged at the bottom portion of the test vessel, one end of a high voltage leading wire is connected with an anode of the sample, the other end of the high voltage leading wire is connected with a high voltage power source, one end of a low voltage leading wire is connected with a cathode of the sample, and the other end of the low voltage leading wire is externally in grounding connection. The treeing type test on the solid insulation sample can be carried out under the action of external AC / DC voltages, microscopic observation on electrical tree initiation and growth characteristics can be realized, voltage stress and high temperature thermal stress can be simultaneously applied to the sample, treeing type test and measurement can be prevented from being influenced by a heating system, the system employs enclosed circulation, and the system further has advantages of small heat loss, high heat energy utilization efficiency, simple operation, reliable running, no noise and long service life.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

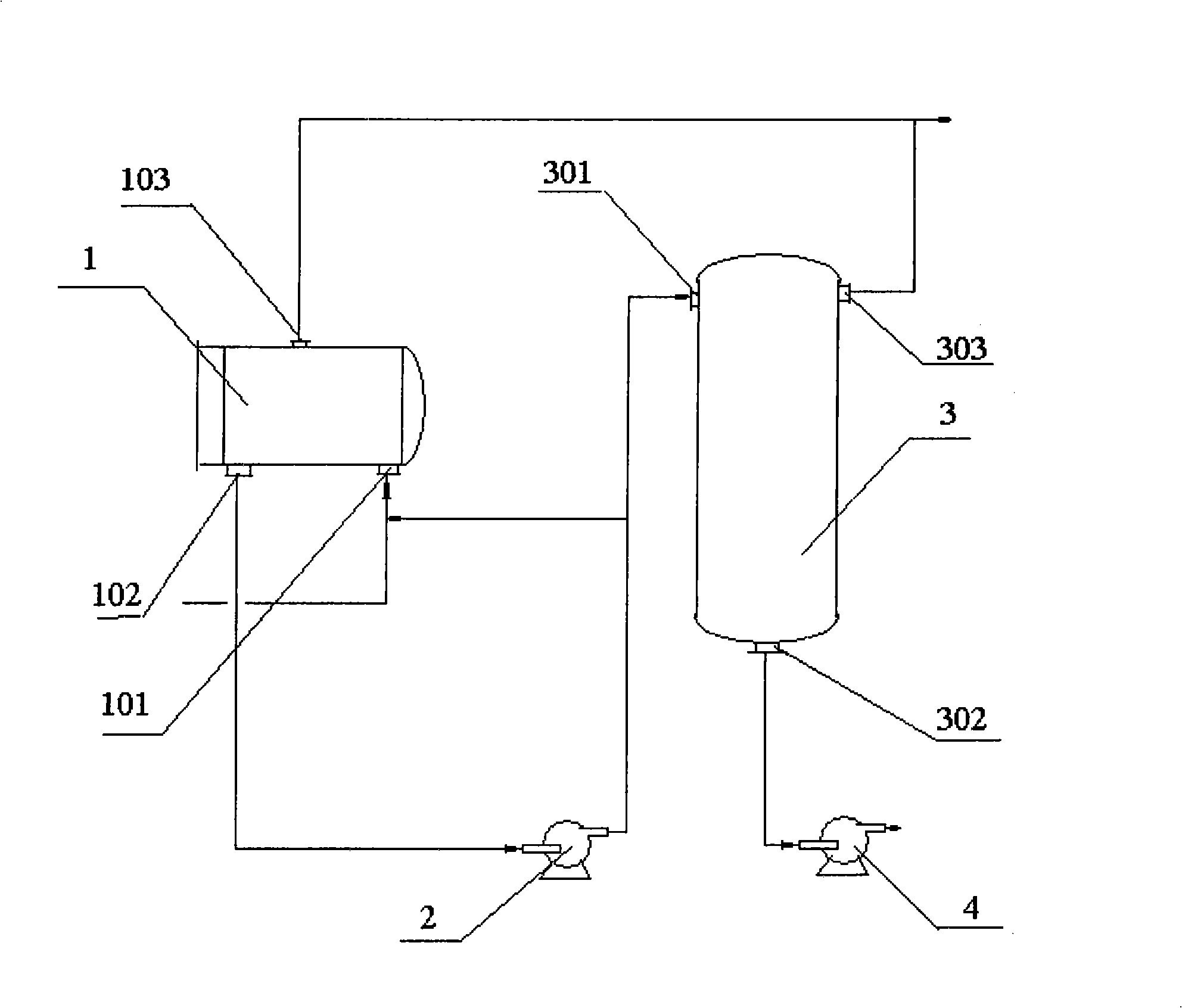

Evaporation method and device easy for polymerizing hydrocarbon solution

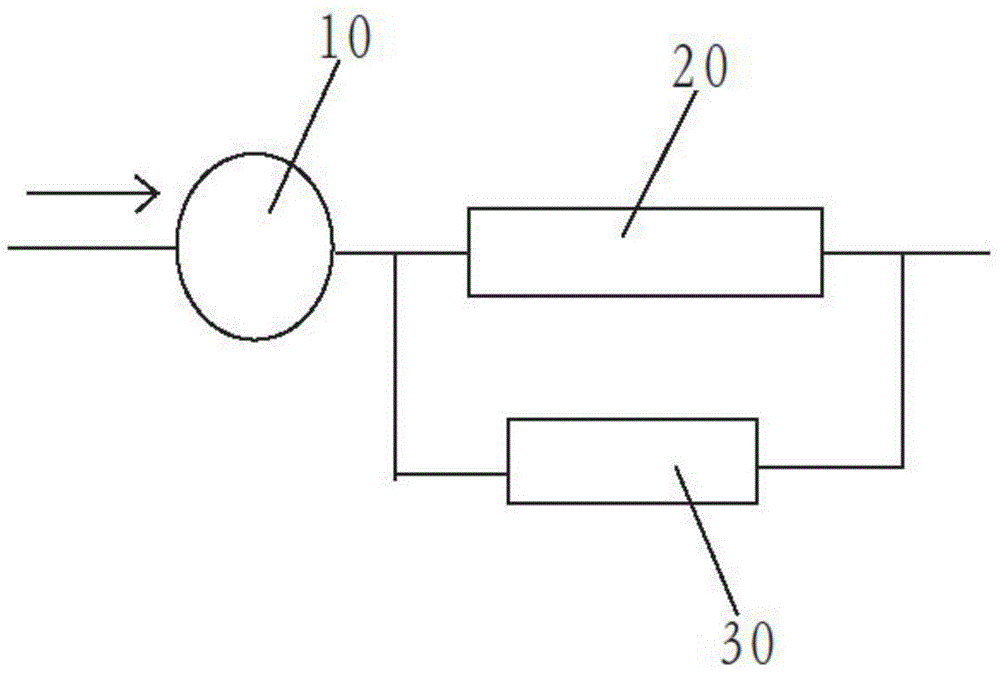

ActiveCN101337131AGuaranteed uptimeEasy to updateDistillation purification/separationEvaporationPolymer scienceCirculator pump

The present invention provides an evaporation method and apparatus for an easily polymerizing hydrocarbon solution, said evaporation method includes processes that: the easily polymerizing hydrocarbon solution is fed into a main evaporator(1),the evaporated hydrocarbon gas is discharged from the top of the main evaporator(1), the evaporated liquid components are drawn out via a cycle pump(2) from the bottom of the main evaporator(1), part of them being circularly fed into the main evaporator(1) and part of them being fed into a film evaporator(3). The evaporated hydrocarbon gas is then discharged from the top of the film evaporator(3) and the remnant liquid after evaporation is forced to be discharged from the film evaporator(3). The forced circulation evaporator and the film evaporator in this invention combines to realize the evaporation process, the polymeric monomer in the easily polymerizing hydrocarbon solution is not subject to polymerization, thereby improving the evaporation efficiency, maintaining the steady operation, lowering the consume of source and energy.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

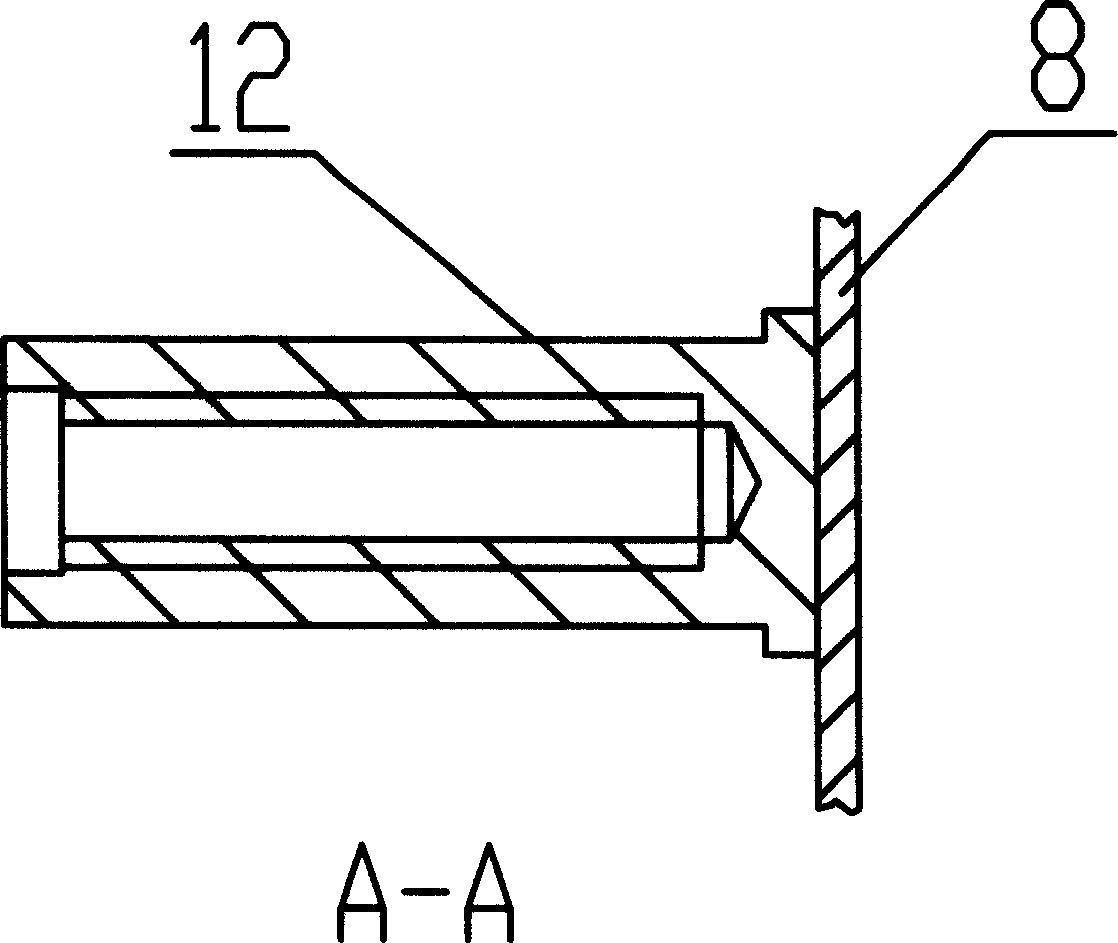

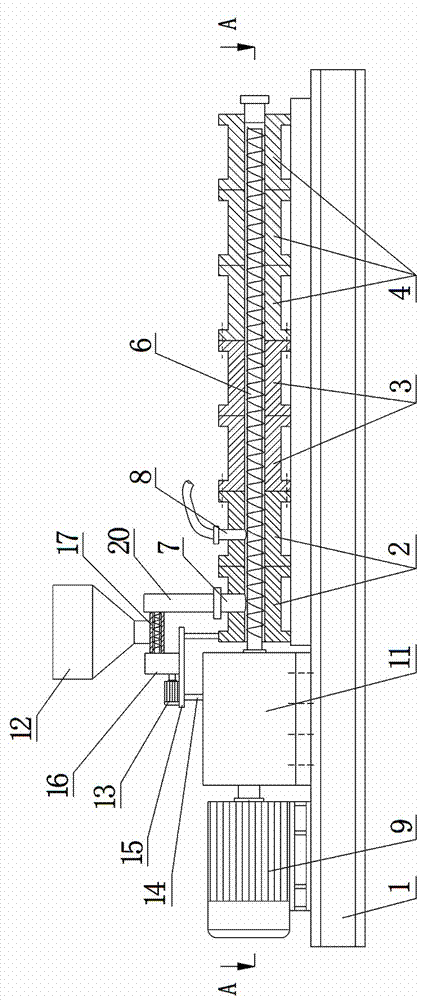

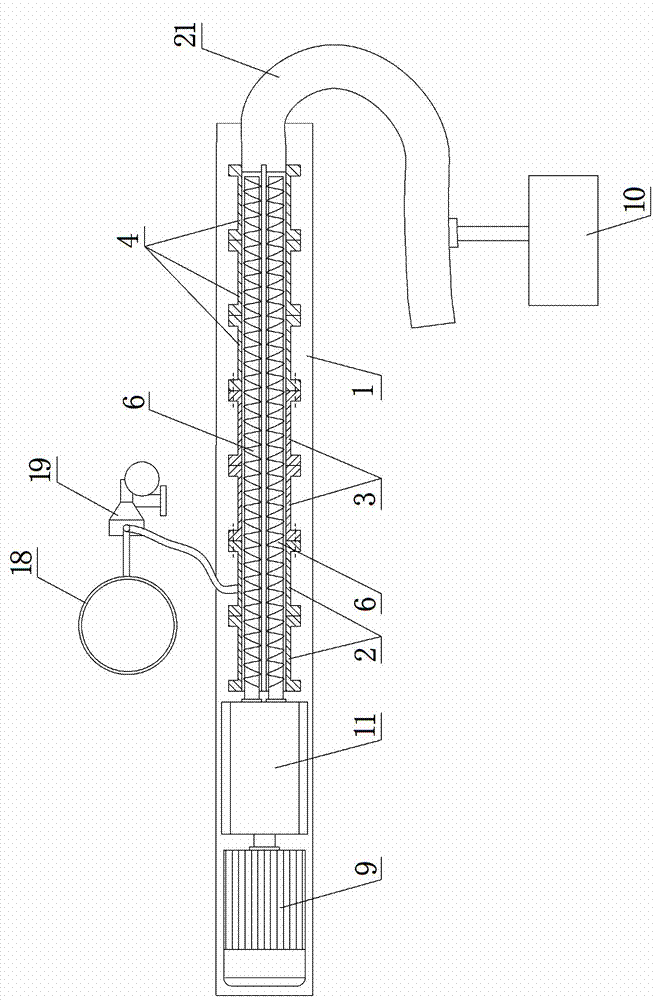

Device and method for preparing foam resin microspheres for physical sensitization of emulsified explosives

The invention discloses a device for preparing foam resin microspheres for physical sensitization of emulsified explosives. The device comprises a frame (1) and a conveying channel cylinder, wherein the conveying channel cylinder is composed of a charging cylinder section (2), a mixing cylinder section (3) and a foaming cylinder section (4) for foaming resin microspheres; the three sections are orderly connected by use of flanges, and a feeding hole A (7) and a feeding hole B (8) both communicated with a conveying channel (5) are formed in the top of the charging cylinder section (2); the device further comprises a charging system, a liquid adding system, a motor I (9), a nitrogen cooling device (10) and a reduction gearbox I (11) with two output ends, wherein the motor I (9), the reduction gearbox I (11) and the conveying channel cylinder are orderly arranged on the frame (1). The invention also discloses a method for preparing the foam resin microspheres. The device for preparing the foam resin microspheres for physical sensitization of the emulsified explosives has the beneficial effects that the production efficiency is high, the dust generated after the foaming of the foam resin microspheres for physical sensitization of the emulsified explosives is effectively reduced, and sticking of the foam resin microspheres for physical sensitization of the emulsified explosives at high temperatures is effectively prevented.

Owner:雅化集团三台化工有限公司

Special continuous casting crystallizer casting powder for ESP low carbon

The invention relates to special continuous casting crystallizer casting powder for ESP low carbon, and belongs to the field of metallurgy accessories. The casting powder comprises chemical componentsincluding, by weight, 28-33 parts of CaO, 22-29 parts of SiO2, 4.5-7.5 parts of MgO, 4.5-7 parts of Al2O3, 7-10 parts of Na2O, 8-11 parts of F, 0.3-1.5 parts of B2O3, 0.5-1 part of Li2O and 1-3.5 parts of C. The casting powder has the low melting temperature, low viscosity and high melting speed, the casting powder can be rapidly consumed when the continuous casting pulling rate is 5-7 m / min, andaccordingly heat transfer and lubricating performance between a continuous casting blank shell and a crystallizer copper plate are guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

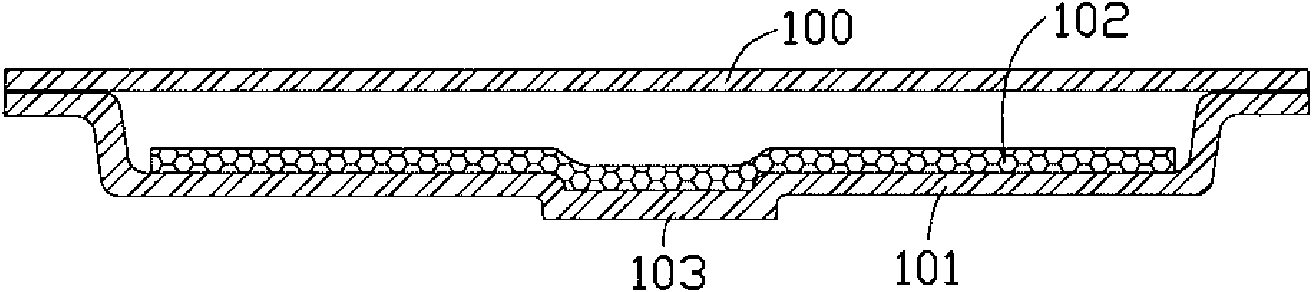

Flat plate type heat pipe and manufacture method thereof

InactiveCN101738114ANo burningGuaranteed heat transfer effectIndirect heat exchangersEngineeringHeat pipe

The invention relates to a flat plate type heat pipe which comprises a lower cover plate, an upper cover plate and a capillary structure, wherein the upper cover plate is matched with the lower cover plate; the capillary structure is attached to the inner surface of the lower cover plate; the lower cover plate comprises a heat absorbing part which is in contact with a heat source and two extending parts which are upwards inclined and extend from two opposite ends of the heat absorbing part; the capillary structure comprises a first capillary section which is attached to the heat absorbing part of the lower cover plate and two second capillary sections which are attached to the extending parts of the lower cover plate; the thickness of the first capillary section is smaller than that of the second capillary sections, and the thickness of the second capillary sections decreases from the middle part to two opposite sides. The first capillary section of the first capillary structure of the flat plate type heat pipe is thinner than the second capillary sections; when the flat plate type heat pipe is used, the working liquid in the first capillary section can rapidly evaporate to carry the heat after the first capillary section absorbs the heat absorbed by the heat absorbing part of the lower cover plate; the working liquid stored in the second capillary sections can rapidly flow to the first capillary section, and the flat plate type heat pipe can not be burnt, thereby ensuring the heat transfer performance of the flat plate type heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

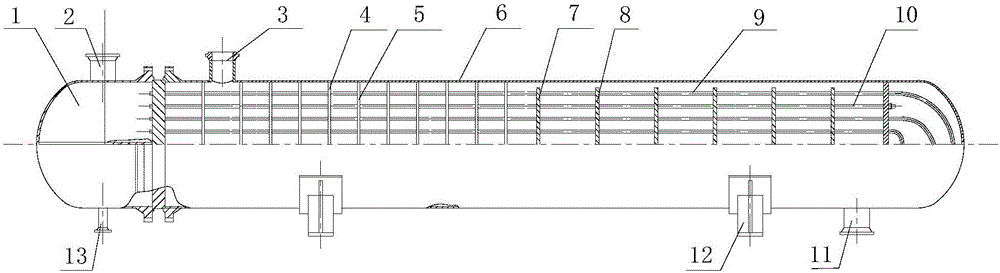

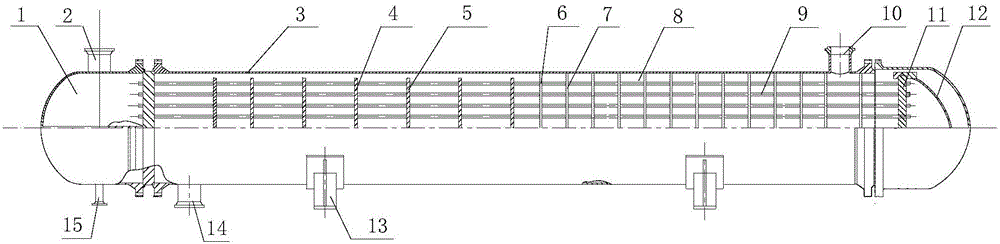

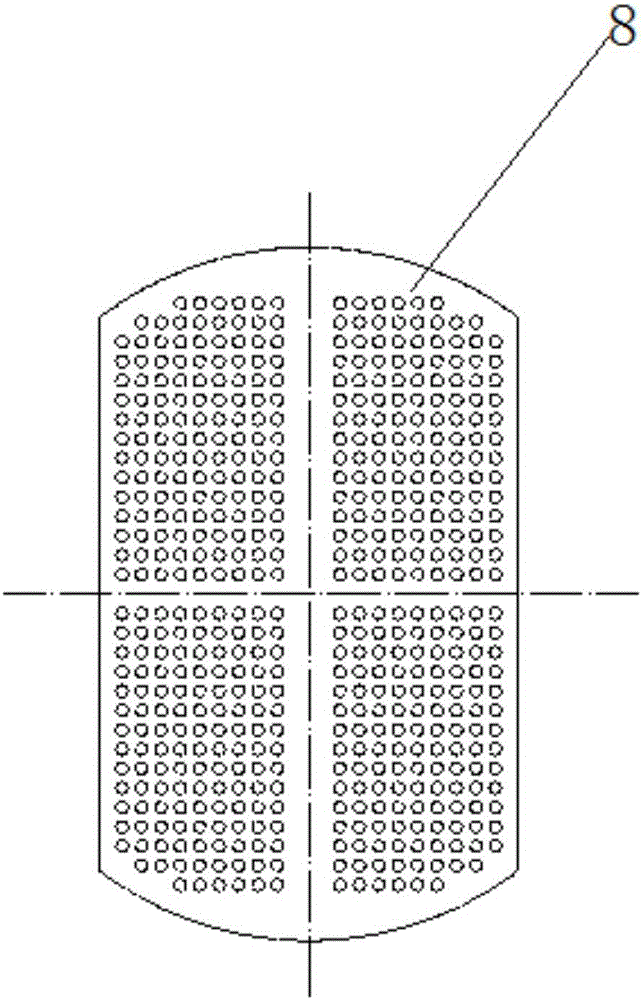

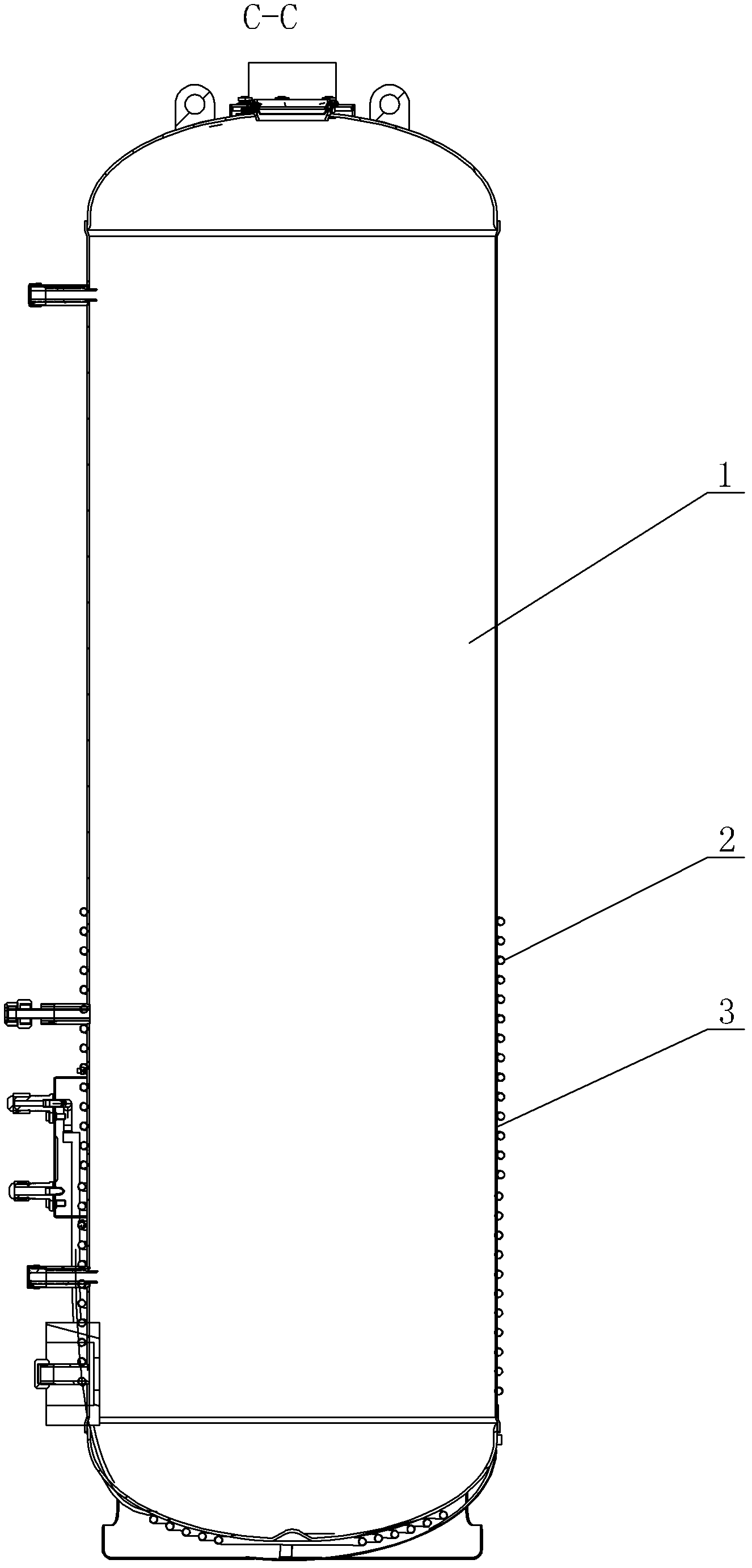

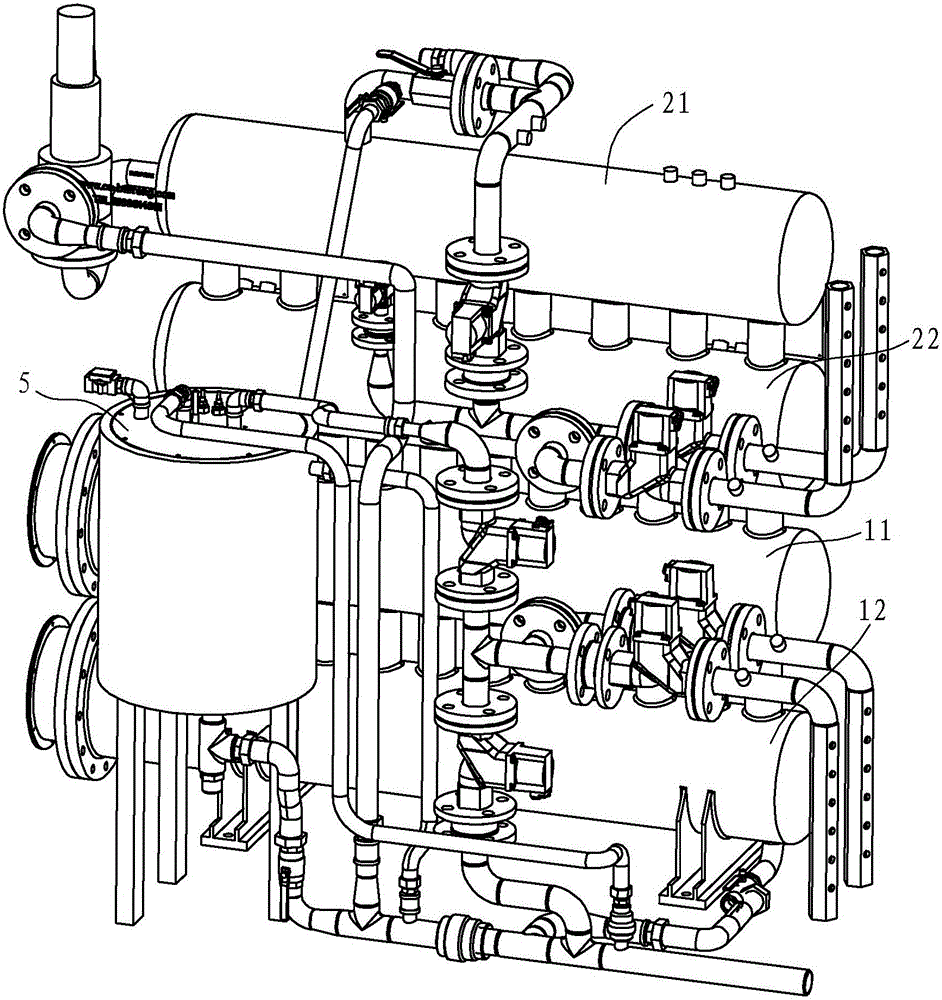

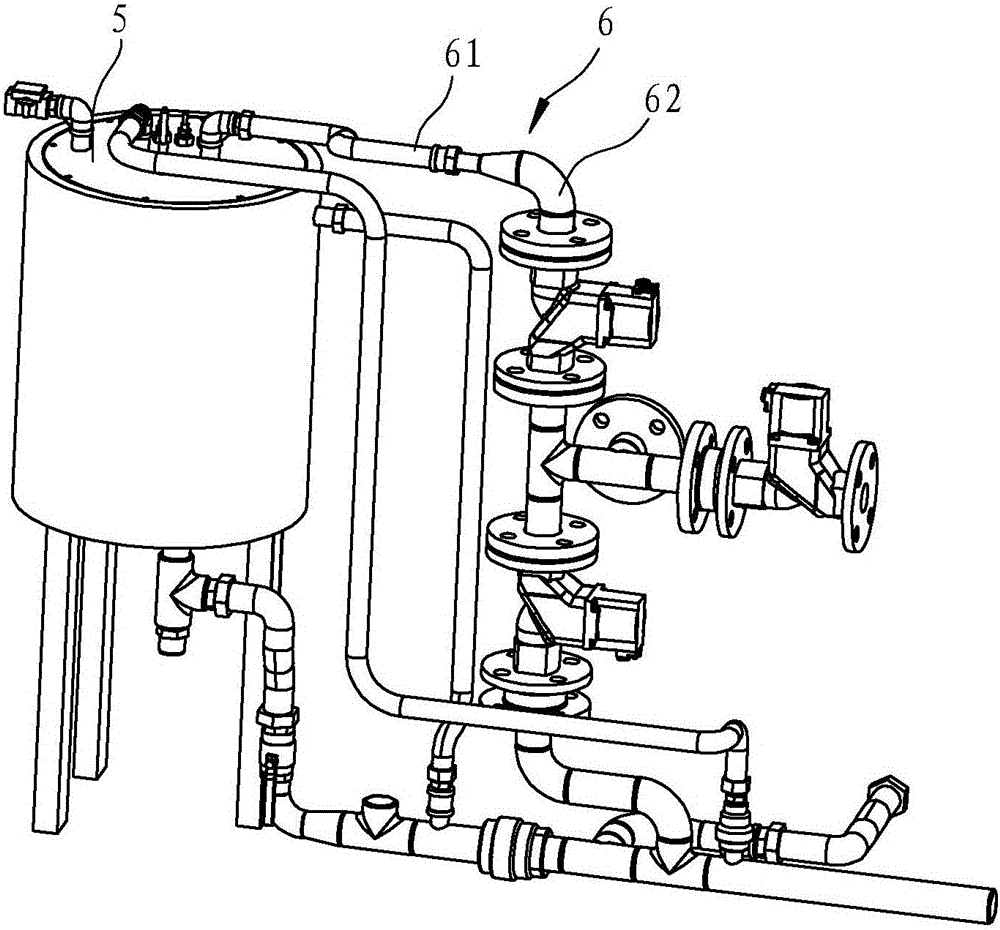

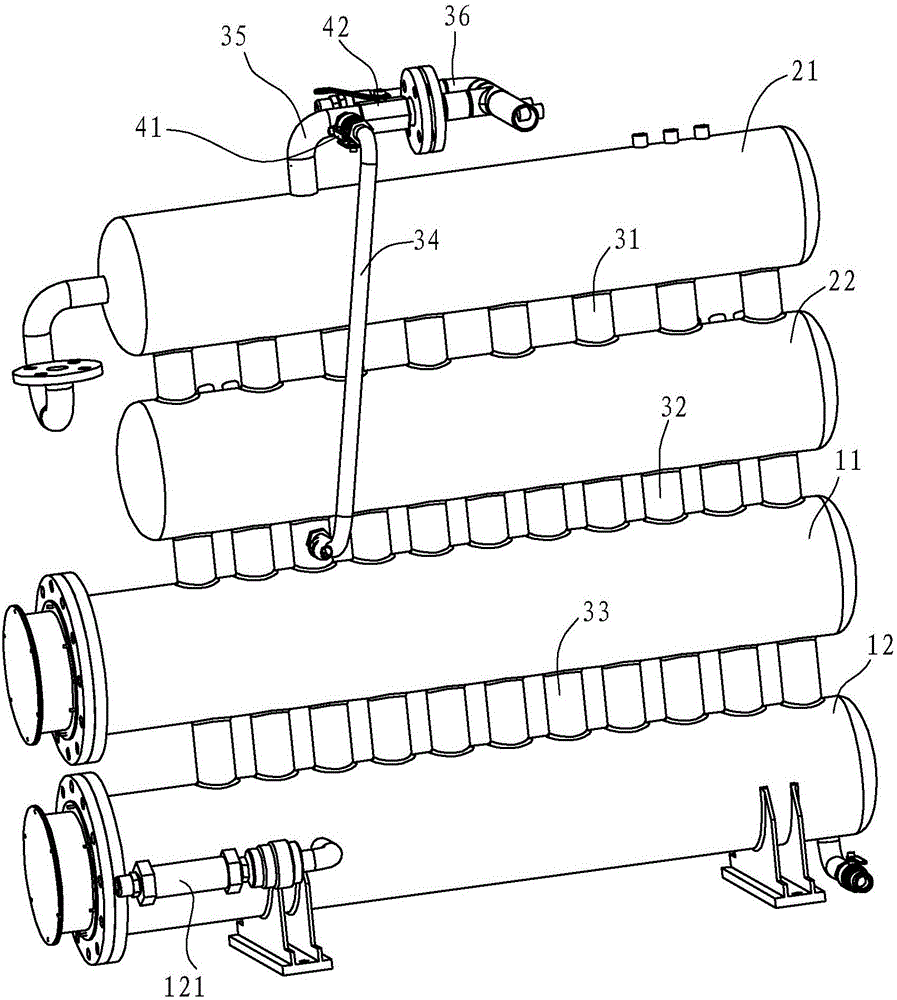

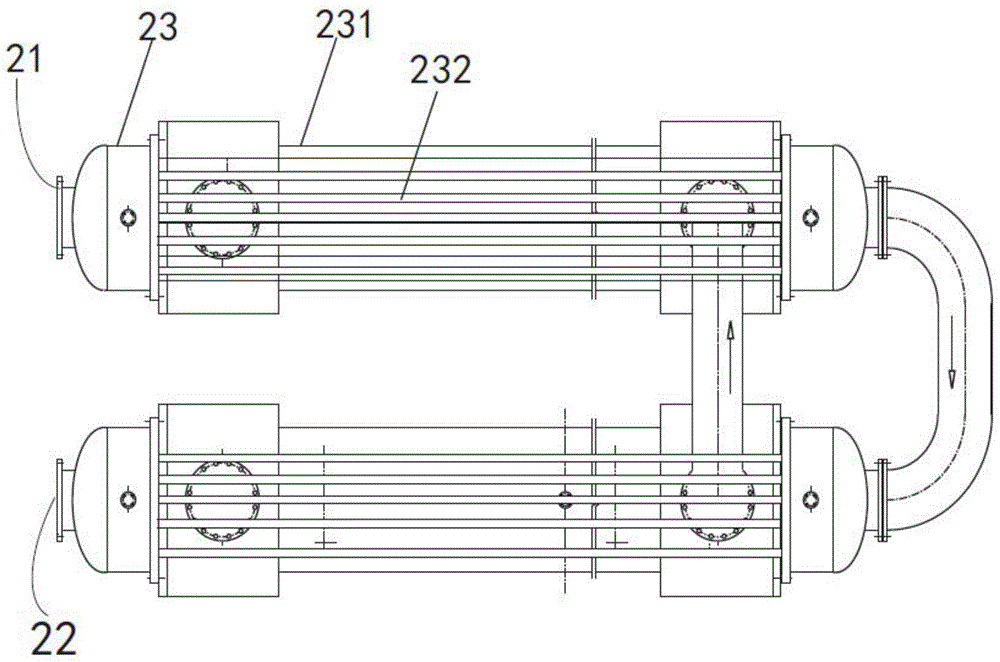

Mixed baffling stream type reboiler

ActiveCN106643227AImprove heat transfer efficiencyLow flow resistanceHeat exchanger casingsStationary tubular conduit assembliesReboilerEngineering

The invention discloses a mixed baffling stream type reboiler. The mixed baffling stream reboiler comprises a shell body and a support which is arranged at the lower part of the shell body and is used for supporting the shell body, shell side in-out ports are correspondingly arranged at two ends of the shell body, multiple groups of tube bundles are arranged at intervals in the axial direction of the shell body in the shell body, baffling stream plates and baffling stream fences are arranged in the radial direction of the tube bundles in the shell body, and the baffling stream plates and the baffling stream fences are used for supporting the tube bundles and conducting stream guidance on shell side fluid. The mixed baffling stream type reboiler is reasonable in structure and safe and efficient in work, and combines an optimal heat transfer property and a minimum flow-induced vibration property.

Owner:XI AN JIAOTONG UNIV

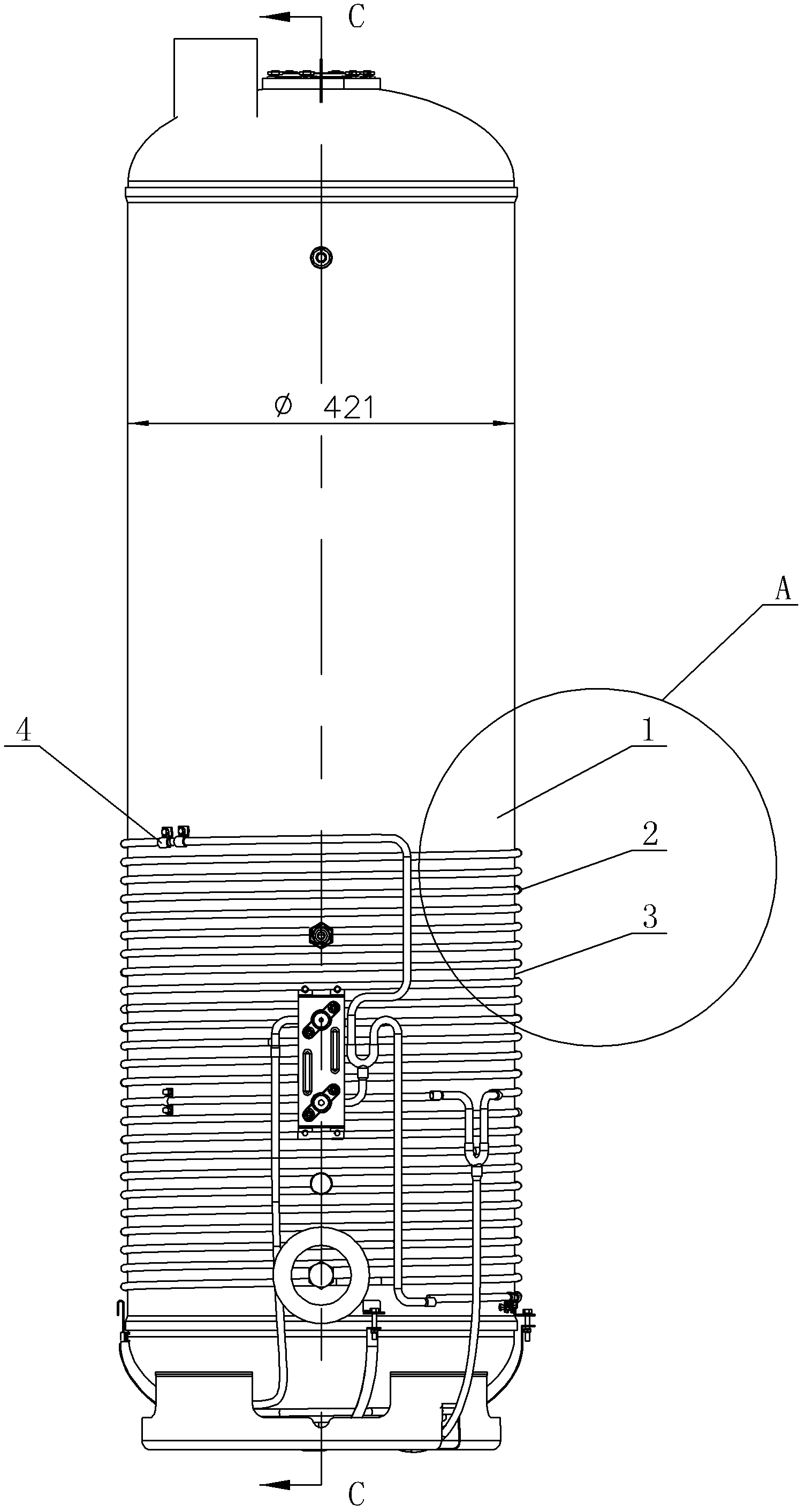

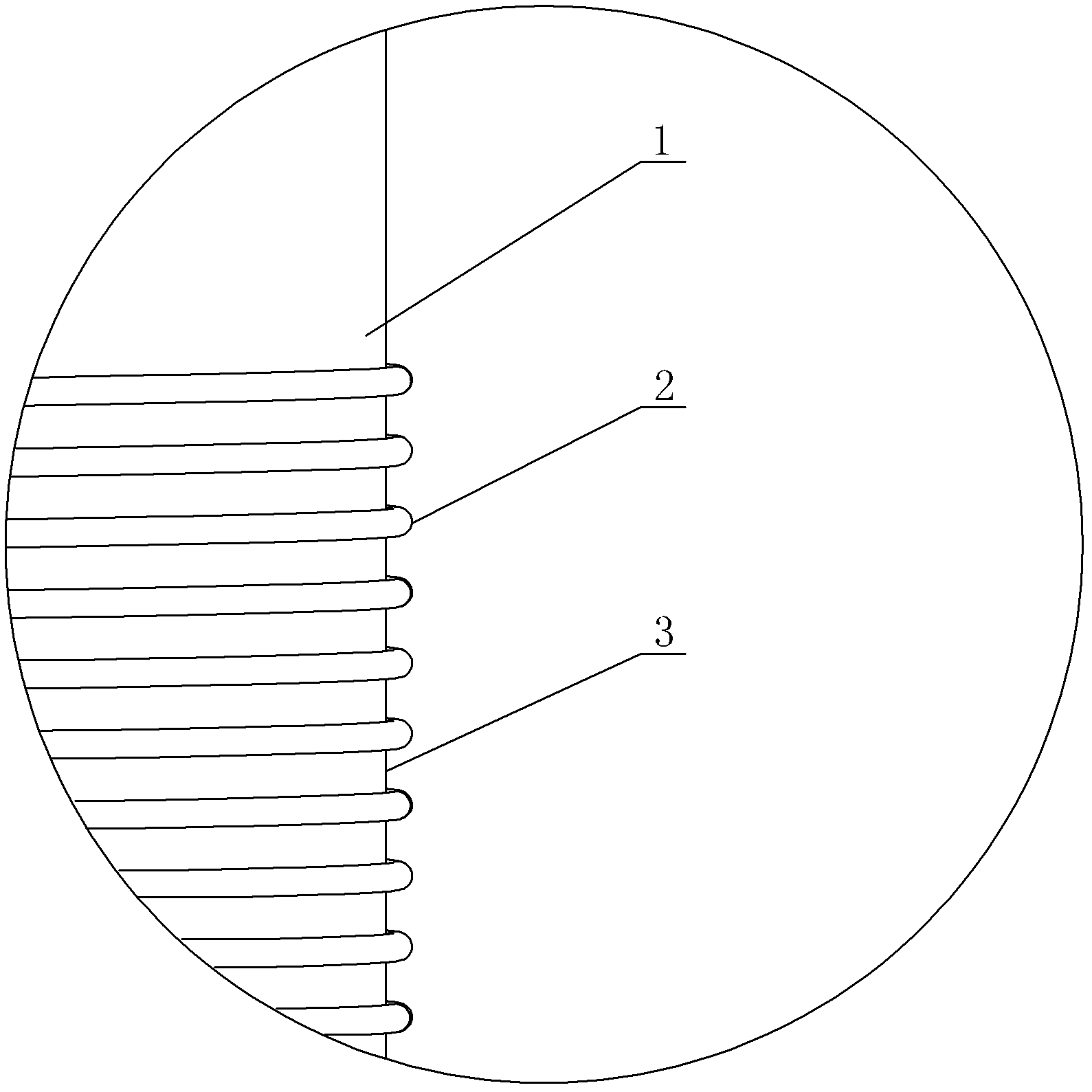

Water tank of heat pump water heater

InactiveCN102589131AGood thermal conductivityGuaranteed heat transfer effectFluid heatersHeat pump water heaterCorrosion

The invention relates to a water tank of a heat pump water heater. The water tank comprises a water tank inner container and a heating coil pipe. The heating coil pipe is wound on the outer surface of the water tank inner container. The water tank is characterized in that: the water tank inner container and the heating coil pipe are made of metal materials; and an isolation dielectric layer is arranged between the water tank inner container and the heating coil pipe. The water tank inner container can be made of the metal materials comprising stainless steel, enamelled pressed steel and cold-roll steel. The heating coil pipe is a copper pipe, or an aluminum pipe, or a Bundy pipe. In the water tank, the isolation dielectric layer is added between the water tank inner container and the heating coil pipe so that physical contact between the water tank inner container and the heating coil pipe can be effectively prevented by the isolation layer and the isolation layer has good heat conductivity. Potential corrosion caused by potential difference between two metals is effectively prevented, meanwhile, the heat transfer effect of the water tank is ensured, and the performance of the complete machine of a heat pump is ensured. With the adoption of the water tank, the safe reliability of the heat pump water heat can be improved, and the water tank is convenient to be popularized.

Owner:MIDEA GRP CO LTD

Vulcanization molded single-component high-thermal-conductivity interstitial interface material with moisture and preparation method of interface material

InactiveCN107828386AGuaranteed heat transfer effectEfficient heat transfer effectHeat-exchange elementsPolymer scienceVulcanization

The invention discloses a vulcanization molded single-component high-thermal-conductivity interstitial interface material with moisture and a preparation method of the interface material, relates to the technical field of materials, and in particular relates to the high-thermal-conductivity interface material. The vulcanization molded single-component high-thermal-conductivity interstitial interface material with moisture is mainly prepared from the following components in parts by weight: 100 parts of alkoxy silicone oil, 100-1500 parts of thermal conductive powder, 0-10 parts of a chain extender, and 1-10 parts of a catalyst. The interface material provided by the invention takes the alkoxy silicone oil as a matrix, and the thermal conductive powder and the chain extender are added, so that the product has the advantages of good thermal conductivity, curing performance, low stress, good pressure absorption performance, a thin adhesive layer, high adhesion performance, convenient production, low costs, convenient sizing, on-line shaping and the like.

Owner:SHANGHAI ALLIED PLASTIC IND

Mold temperature control device

A mold temperature control device comprises steam storage tanks, heating tanks and a heat exchanger. A steam guide pipe for steam output is arranged on one steam storage tank. The heating tanks are provided with water inlets, heating pipes are arranged in the heating tanks, and the heating tanks are connected and communicated with the steam storage tanks through steam conveying pipes. The heat exchanger is provided with a cold water inlet, a hot water outlet, a steam recovery opening and a condensate water drainage opening. The hot water outlet is connected with the water inlet of the heating tanks. The mold temperature control device is characterized in that the steam storage tanks and the heating tanks are all in strip shapes and are arranged in a vertically spaced mode, the number of the steam conveying pipes is at least three, and the steam conveying pipes are arranged at the two ends and the middles of the steam storage tanks. Compared with the prior art, the mold temperature control device has the advantages that by means of multi-channel design, enough steam in the heating tanks can enter the steam storage tanks at the same time, the saturability of the steam output out of the steam storage tanks is relatively high, and therefore the heat transfer effect of the output steam is guaranteed.

Owner:NINGBO BAIGE INTELLIGENT TECH

Comprehensive anti-scaling system for mine cooling engineering

A comprehensive anti-scaling system for a mine cooling engineering sequentially comprises a multistage multi-channel filter, a heat exchange tube section and a physical descaling device from the upstream of a water route to the downstream of the water route, wherein the multistage multi-channel filter is used for filtering large particles, the heat exchange tube section for recovering heat energy of mine water is provided with a heat exchanger, and the physical descaling device is parallelly connected between two ends of the heat exchange tube section. The physical descaling device comprises a ball catching device, a ball transmitting tube and a transmitting water pump, the ball catching device is arranged at the water outlet tube end of the heat exchange tube section and used for recovering cleaning small balls passing the heat exchange tube section, the recovered cleaning small balls are collectively stored in a small ball collector, one end of the ball transmitting tube is connected at the water inlet tube end of the heat exchange tube section, the other end of the ball transmitting tube is connected with the small ball collector, so that small balls in the small ball collector pass and enter the water inlet tube end of the heat exchange tube section, the transmitting water pump is connected with a circulating pipeline through two groups of water-intake paths and two groups of water return paths, the cleaning small balls are washed into the heat exchange tube section by the aid of high-pressure and high-speed water flow according to an angle to form turbulent flow, so that the cleaning small balls rapidly collide with the tube wall of the heat exchange tube section, and descaling efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

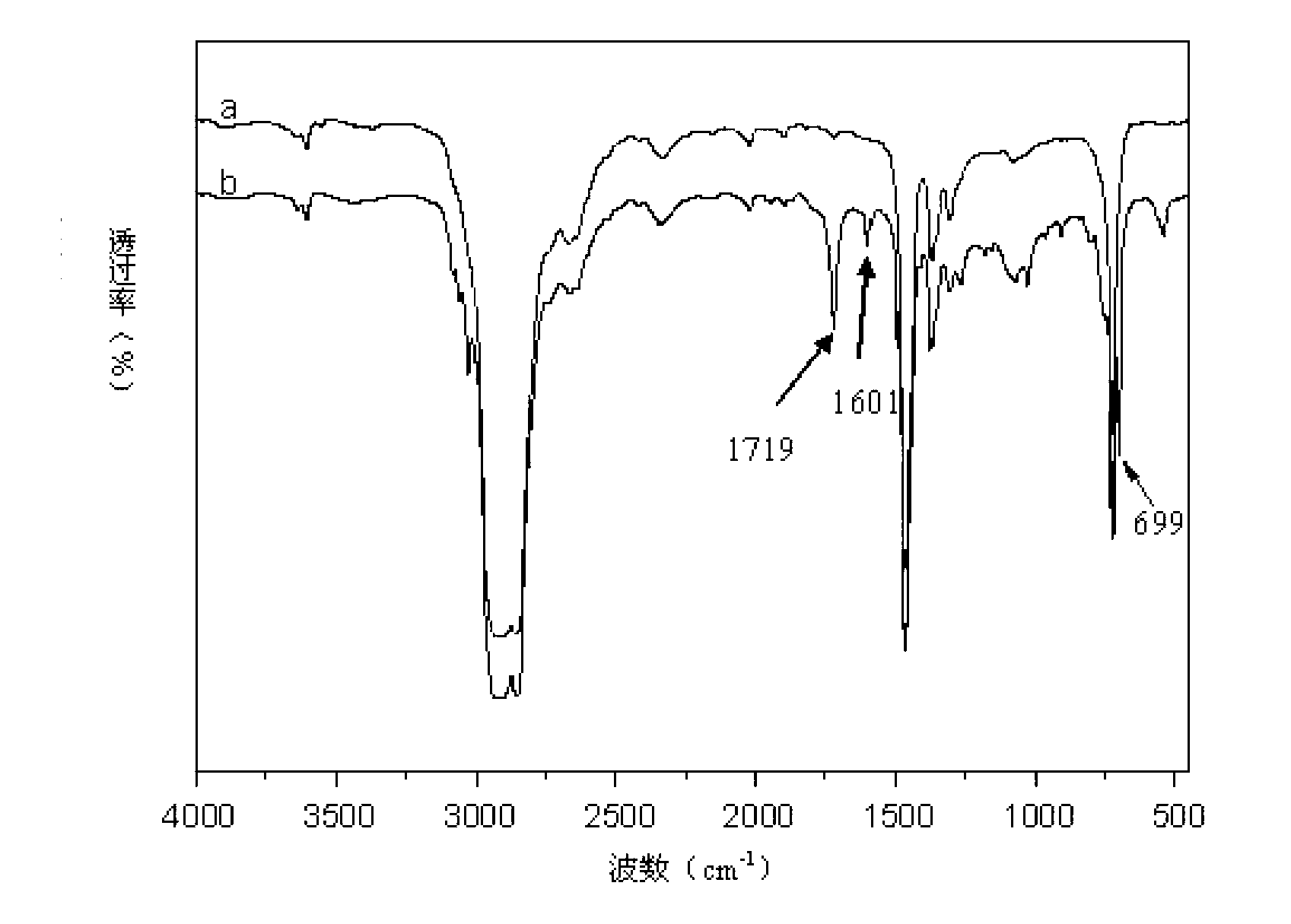

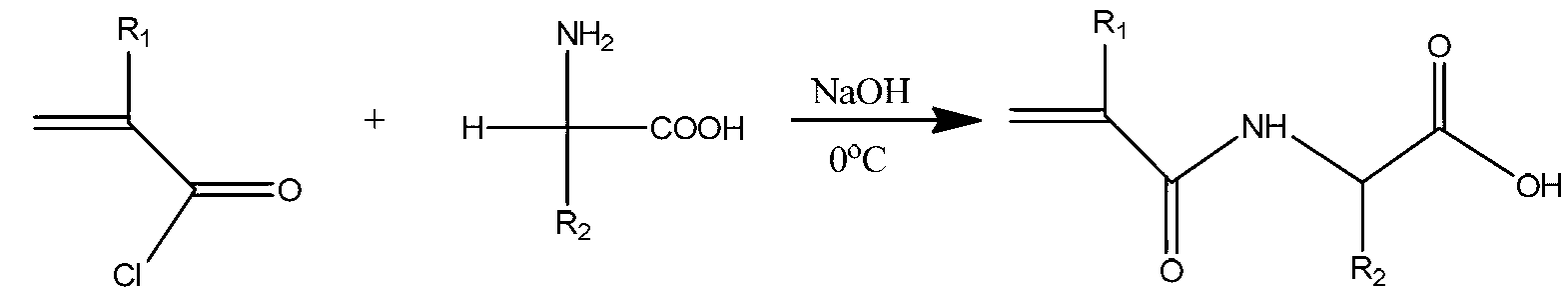

Method for grafting linear low density polyethylene to polar monomer

InactiveCN103224593AHigh grafting rateGood biocompatibilityLow-density polyethyleneLinear low-density polyethylene

The invention provides a method for grafting linear low density polyethylene to a polar monomer. The method includes: dissolving 5-25 parts of an unsaturated carboxylic acid monomer in 60 parts of N, N-dimethyl formamide, and dissolving 2-10 parts of benzoyl peroxide in 10-50 parts of an interface agent dimethylbenzene; placing 100 parts of linear low density polyethylene particles and 5-50 parts of a second grafting monomer styrene in a reaction vessel containing 300 parts of water, conducting stirring to make the linear low density polyethylene particles uniformly suspended in water; adding the unsaturated carboxylic acid monomer solution and the benzoyl peroxide solution into the reaction vessel, stirring them at 60DEG C for 1.5h under a nitrogen atmosphere to perform swelling, raising the temperature to 80-95DEG C to let the materials react for 2-6h, and then carrying out cooling, washing, filtering and drying, thus obtaining the product. The linear low density polyethylene grafted product obtained in the invention contains amino acid residues, thus having good biocompatibility and being able to maintaining the excellent mechanical properties of the linear low density polyethylene raw material.

Owner:HARBIN ENG UNIV

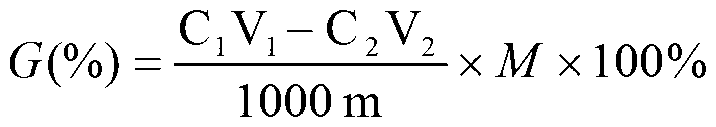

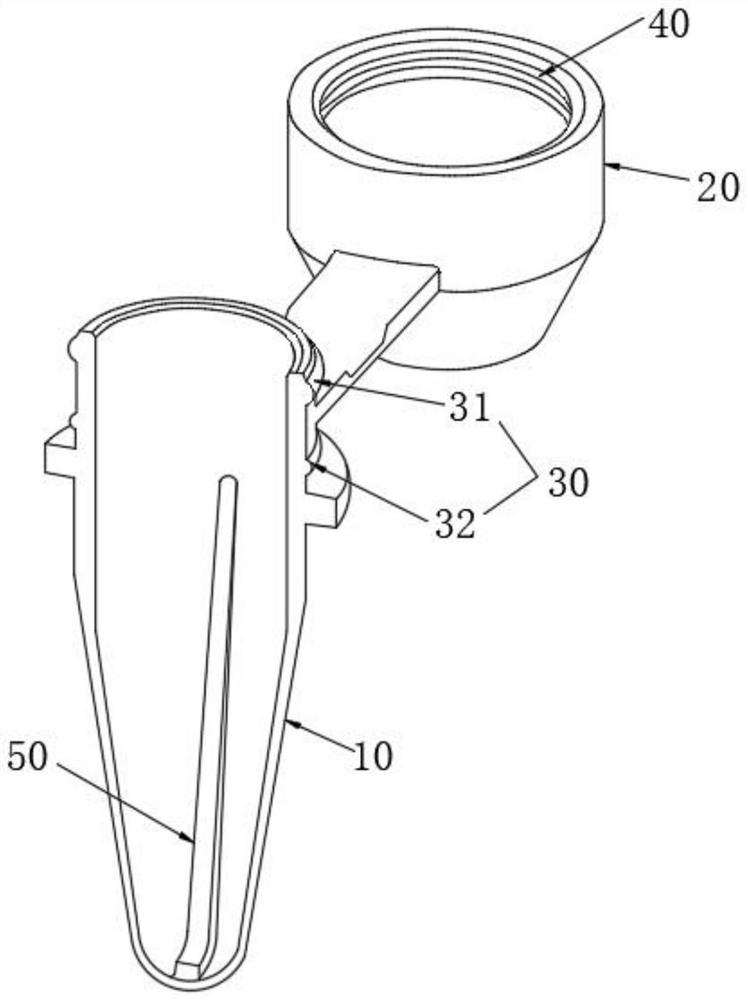

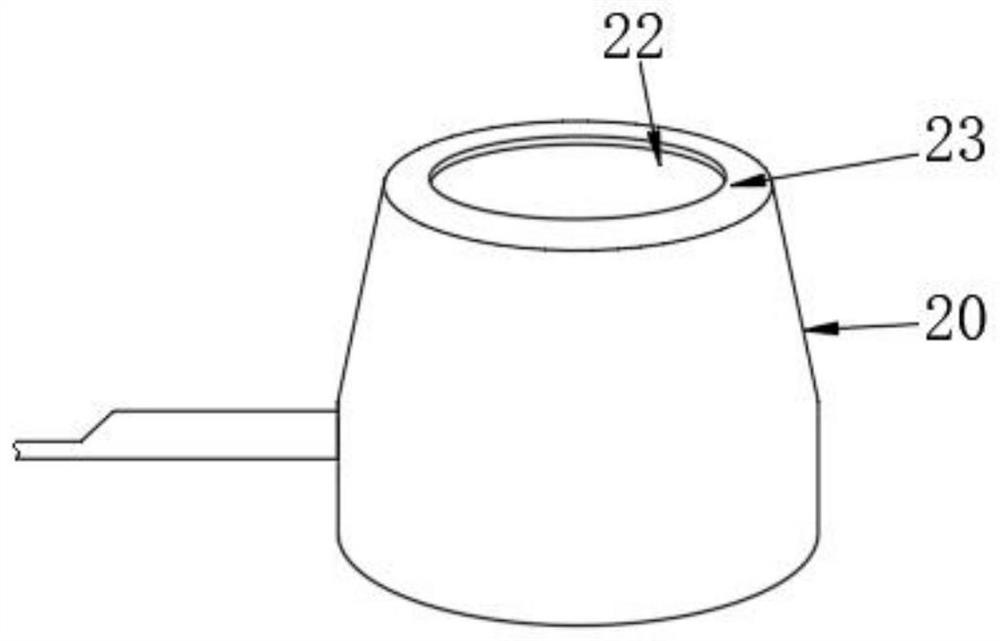

Reagent tube

PendingCN114874886AAvoid LeakageImprove liquidityBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringPhysics

The invention discloses a reagent tube. The reagent tube comprises a tube body and a tube cover connected with the tube body, wherein the pipe body comprises a cylinder part and a cone-shaped body part, and the wall thickness delta of the cone-shaped body part is smaller than 0.22 mm; a sealing component is arranged at the joint of the tube cover and the tube body so that the tube cover can seal the tube body. Due to the fact that the groove and the protruding ring which can be mutually embedded are arranged on the tube cover and the tube body, and the protruding ring is attached to the inner wall of the tube cover to form secondary sealing, the sealing effect is greatly improved, and the situation that a solution in the tube body leaks is avoided.

Owner:AMAZING BIOTECH SHANGHAI CO LTD +1

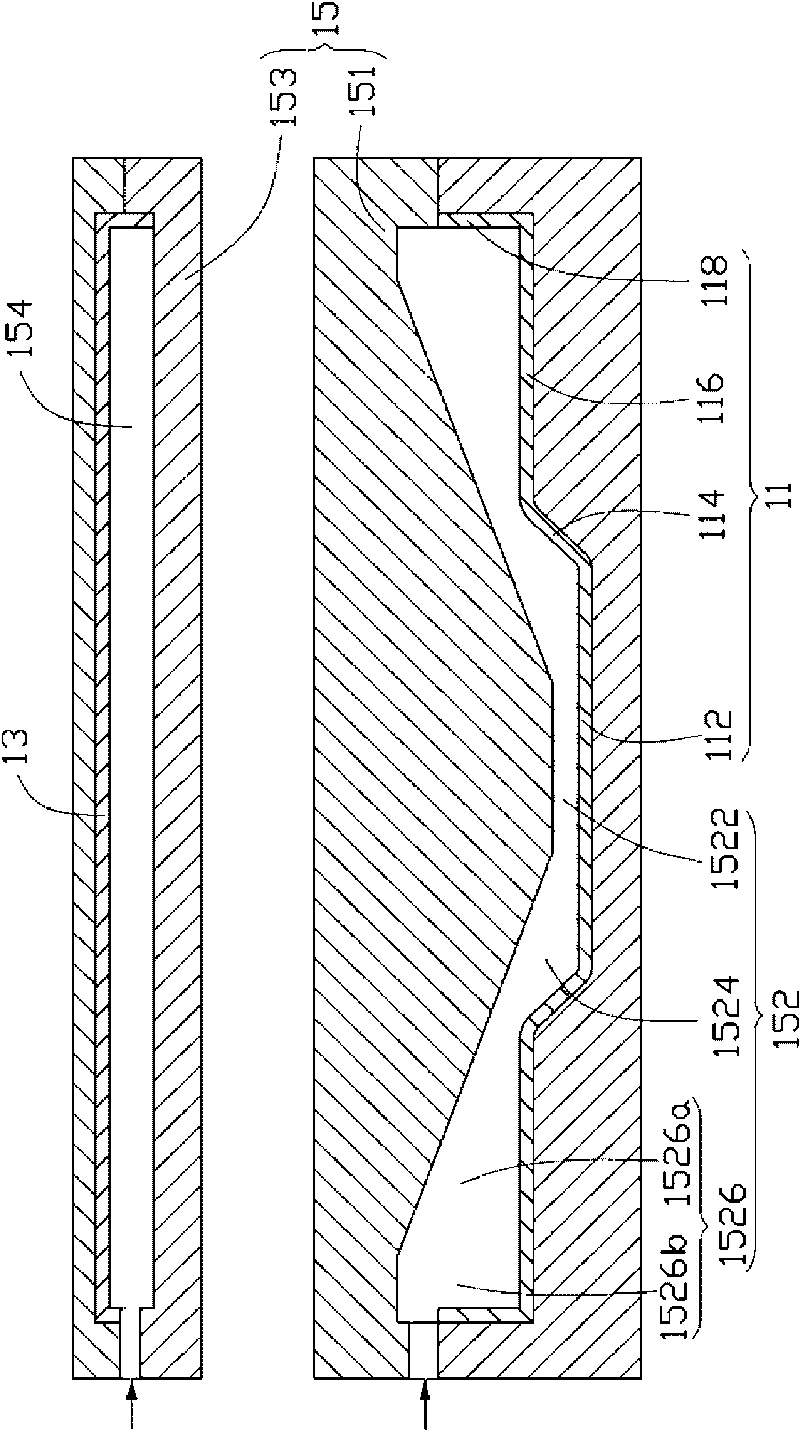

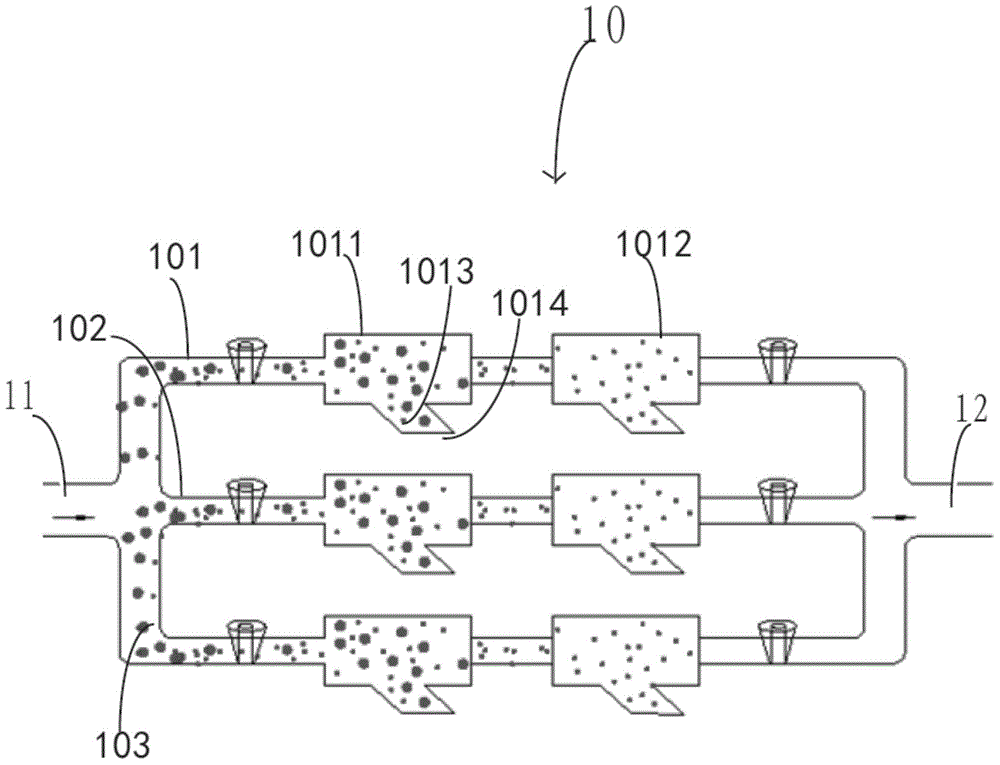

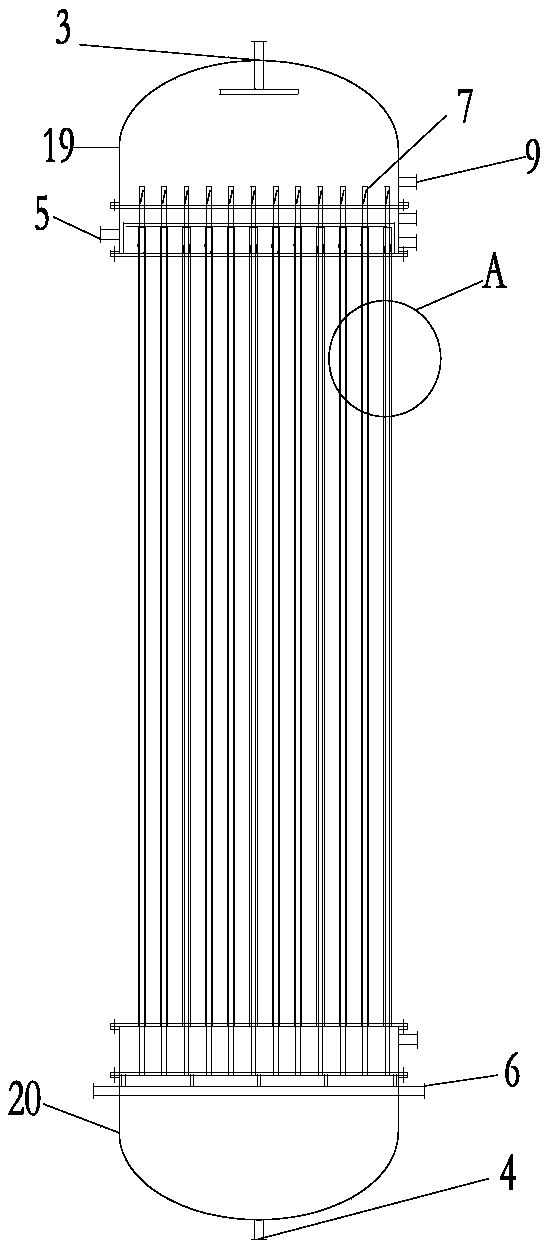

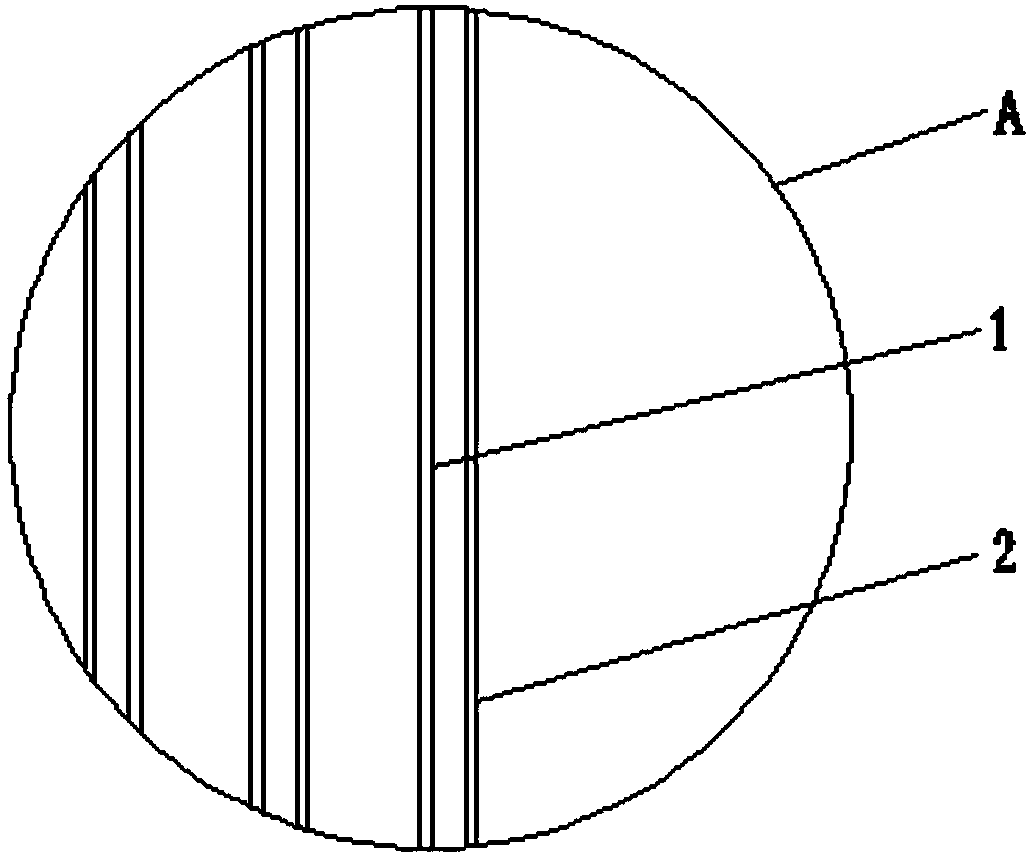

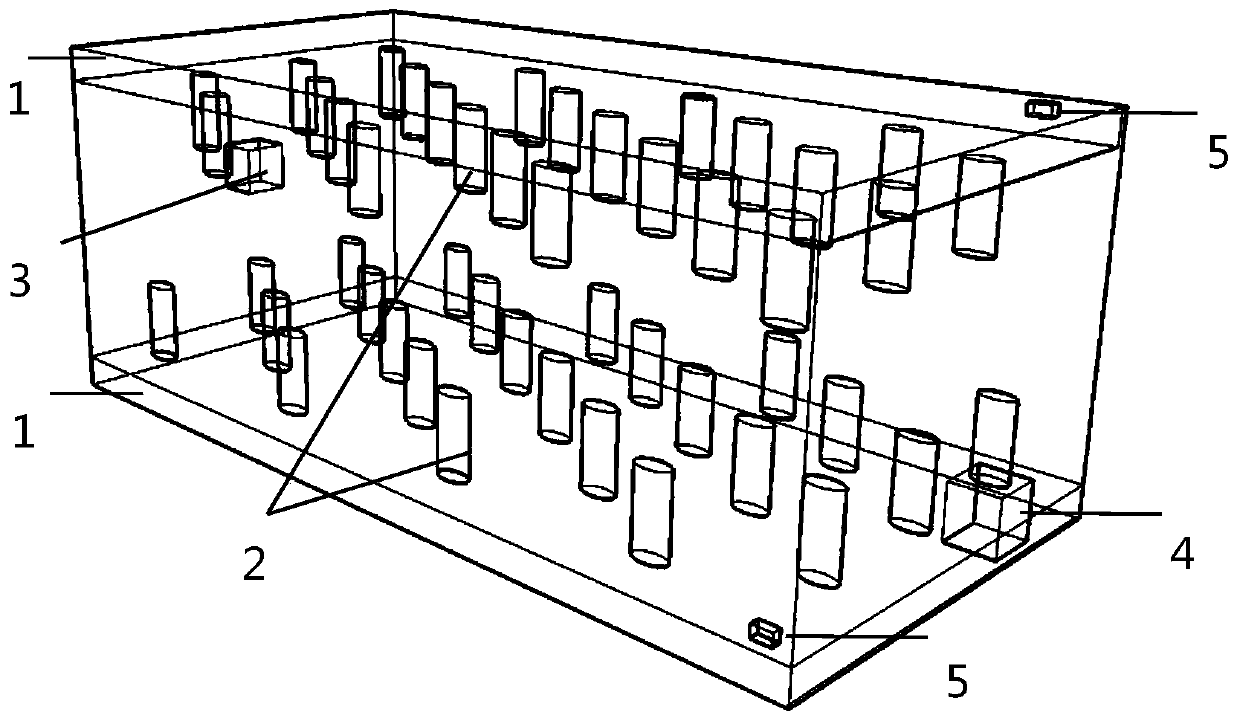

Novel double falling film melting crystallizer and substance separation process thereof

PendingCN109045743AAvoid unevennessGuaranteed heat transfer effectSolution crystallizationHeat exchange cooling cystallizationEngineeringCrystallization

The invention relates to a novel double falling film melting crystallizer and a substance separation process thereof, relating to the technical field of substance purification through melting and crystallizing. The top of an upper shell is communicated with a purified substance inlet and an overflow release outlet separately, the bottom of a lower shell is communicated with a purified substance outlet, an outer tube is communicated between the upper shell and the lower shell, an inner tube is sheathed in the outer tube, cold and holt mediums flow between the outer tube and the inner tube, theouter tube is internally provided with an outer tube pull rod, the outer tube is further provided with an outer tube filming head, the outer tube filming head is provided with an outer tube filming hole, the inner tube is internally provided with an inner tube pull rod, the inner tube is provided with an inner tube filming head, and the inner tube filming head is provided with an inner tube filming hole. Through adoption of the novel double falling film melting crystallizer, liquid not forming a film can be redistributed, so as to avoid uneven filming caused by crystallization, a heat transfereffect of the formed film is ensured, and constant temperature is controlled accurately in separation, crystallization and melting of substances.

Owner:JIANGSU DUBLE ENG +2

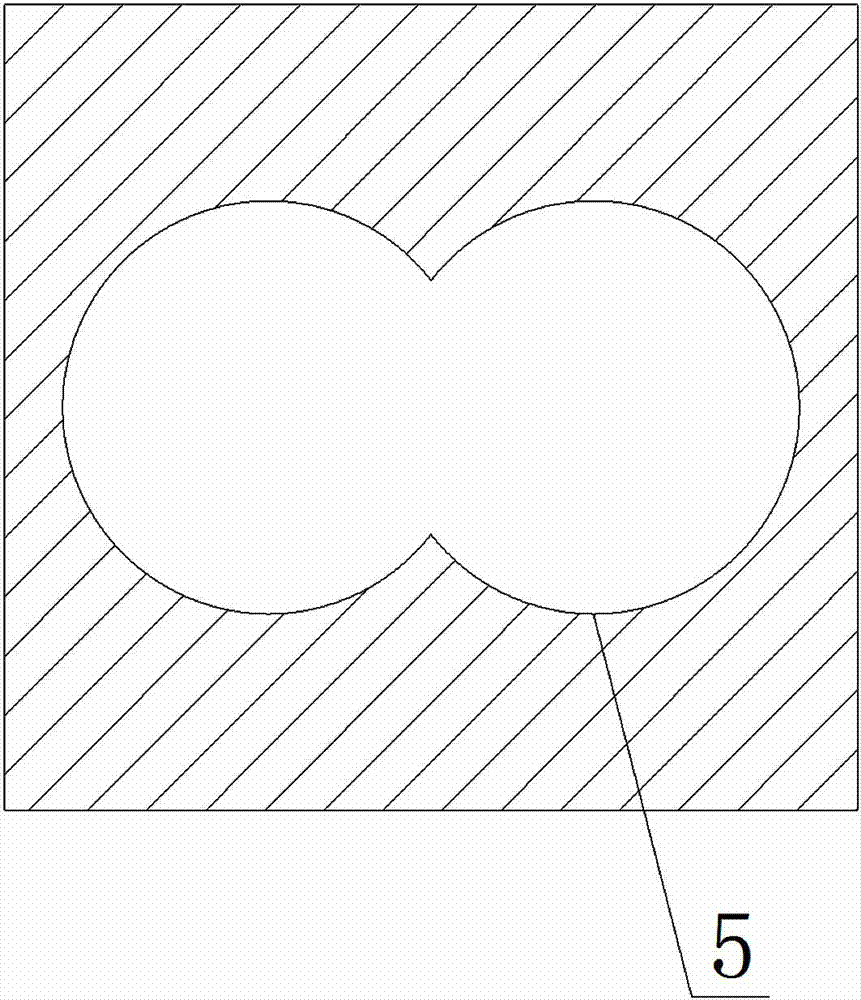

Amorphous crystallizer

The invention provides a crystallizer which is mainly used for preparing amorphous alloy. The amorphous crystallizer is composed of a copper sleeve 5, a copper sleeve support 3 and a rotary spindle 1; when the crystallizer works, cold water flows in from a water inlet end of the rotary spindle and flows into the copper sleeve 5 along the pore channels in the rotary spindle 1 and the copper sleeve support 3; the cold water absorbs the heat of molten steel transferred from the outer surface of the copper sleeve; and then the hot water returns to a water outlet end in the rotary spindle from the copper sleeve support 3 at the other end of the copper sleeve 5 along the path opposite to the cold water and flows out so as to circularly cool the molten steel. The crystallizer provided by the invention has the advantages that: the cooling efficiency is high, the surface temperature of the copper sleeve is uniform, a water flow dead angle does not exist in the copper sleeve, the axial cooling of the copper sleeve is uniform, the mechanical performance is good, and the working precision is high; and the heat transfer effect of applying the amorphous crystallizer to cool the molten steel is guaranteed.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Finned phase change energy storage heat exchanger

InactiveCN110822970AGuaranteed heat transfer effectLarge cooling capacityHeat storage plantsHeat storage materialMechanical engineering

The invention discloses a finned phase change energy storage heat exchanger which comprises a closed heat exchanger shell. A plurality of elliptical hollow column fins are respectively fixed on the top wall and the bottom wall in the heat exchanger shell, an air inlet is formed in the left wall of the heat exchanger shell, an air outlet is formed in the right wall of the heat exchanger shell, andthe heat exchanger shell and the elliptical hollow column fins are filled with phase change heat storage materials correspondingly. A eutectic mixture comprising 95% by mass of n-decanoic acid and 5%by mass of dodecanol is adopted as the phase change heat storage materials. Filling holes are formed in the top wall and the bottom wall of the heat exchanger shell correspondingly. The phase change heat exchanger can be used as a pre-cooling device in cooperation with various cooling systems to ensure the heat transfer effect.

Owner:TIANJIN UNIV +1

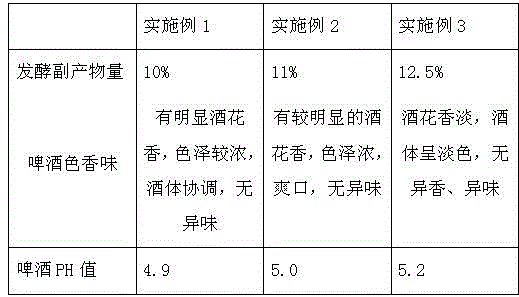

Beer production technology

InactiveCN104560477ATake advantage ofAchieve reuseBeer fermentationMicroorganism based processesRipeningTreated water

The invention discloses a beer production technology which is characterized in that the technology comprises the following processing steps: (1) raw material pretreatment; (2) gelatinization and filtration; (3) sewage treatment: after gelatinization and filtration, sewage for washing a rice-cooker and a knockout tower is collected through pipelines into a sewage tank and then undergoes UASB+CASS treatment process, and the water obtained is used in industry and agriculture; (4) boiling; (5) sedimentation and cooling; (6) fermentation: beer yeast is added into wort and the mixture is fermented in a fermentor, temperature is controlled to 7-15 DEG C, fermentation time is 8-10 days, and then storage is carried out for about 6 days after fermentation; and (7) ripening and filtration. During the beer production process, a lot of sewage is produced, and sewage for washing equipment after gelatinization and filtration is the main source of sewage. Degree of pollution is high. By the beer production technology provided by the invention, pollution caused by washing sewage is treated, influence of beer production on the environment is reduced, and treated water is fully utilized to realize reuse of water.

Owner:丹阳恒安化学科技研究所有限公司

Built-in heat pipe dual-medium heat transfer pipe

InactiveCN103123233AImprove reliabilityAchieve deliveryIndirect heat exchangersEngineeringMechanical engineering

Disclosed is a built-in heat pipe dual-medium heat transfer pipe. The built-in heat pipe dual-medium heat transfer pipe comprises sleeve pipes and heat pipes. Each heat pipe is installed in the sleeve pipe through a support. The heat pipes and the sleeve pipes are concentric. A channel is formed between each heat pipe and each sleeve pipe. A first type of medium is injected into each channel. A second type of medium is filled into each heat pipe. The heat transfer pipe is filled with the inner media and the outer media. The first type of medium in each channel between the heat pipe and the sleeve pipe can achieve rapid heat transfer of the inner side and the outer side of each sleeve pipe, and heat transfer effect is guaranteed. The second type of medium in each heat pipe can achieve the heat transfer through evaporation and condensation. Due to the fact that materials and wall thickness of the sleeve pipes are decided according to actual working conditions and free from limitation of the materials of the heat pipes, reliability of the heat transfer pipe is improved greatly, and the built-in heat pipe dual-medium heat transfer pipe can totally meet the safety requirement on a high dangerous occasion that a severe reaction can generate when cold fluid and hot fluid in a heat exchanger are mixed.

Owner:山东中和热工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com