Comprehensive anti-scaling system for mine cooling engineering

An anti-scaling and engineering technology, applied in the direction of damage protection, non-rotating equipment cleaning, heat exchange equipment, etc., can solve the problems of reducing the service life of the pipeline, the structure of the descaling system is complex, and the descaling efficiency is not high, so as to achieve the goal of increasing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments, all of which do not depart from the scope of the present invention, and the descriptions and drawings therein are essentially for illustrative purposes, rather than limiting this invention.

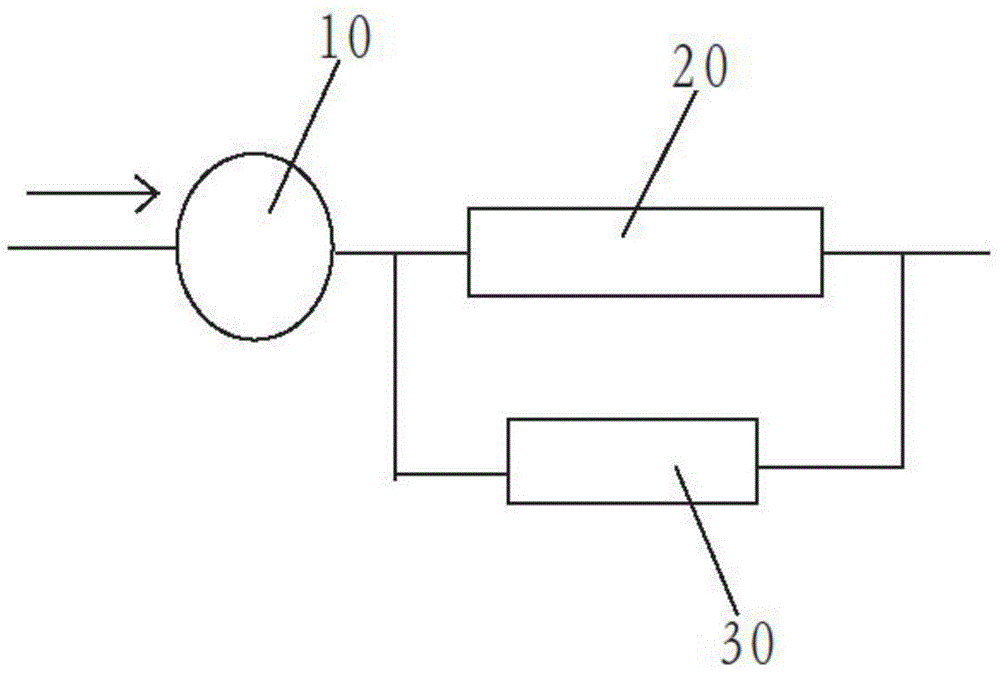

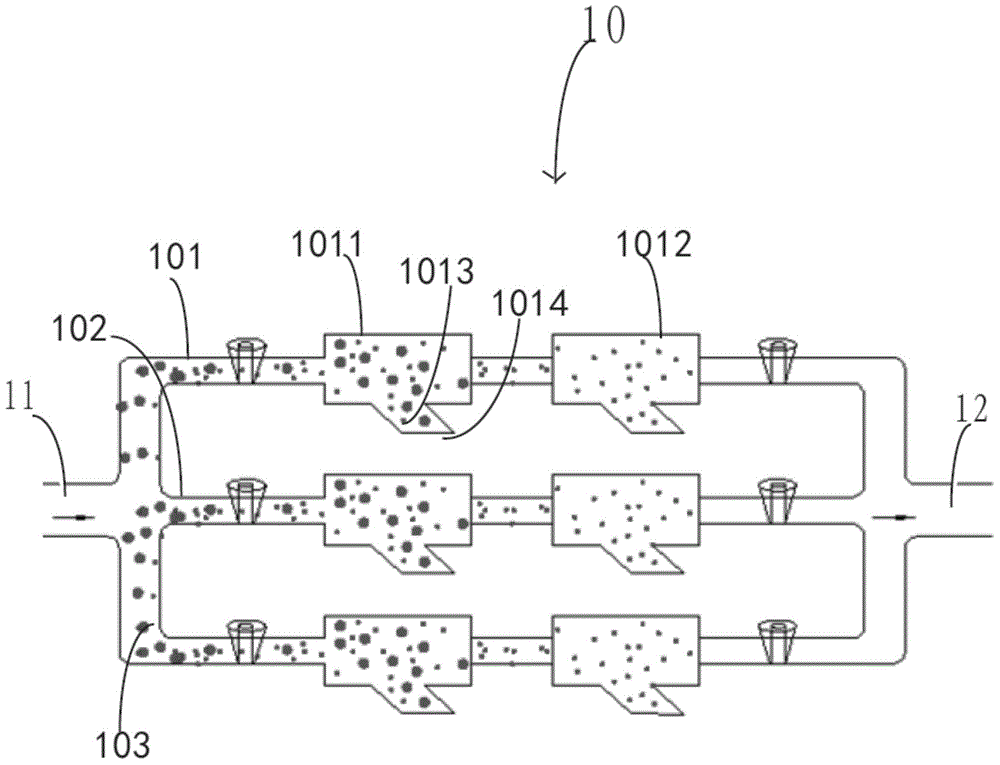

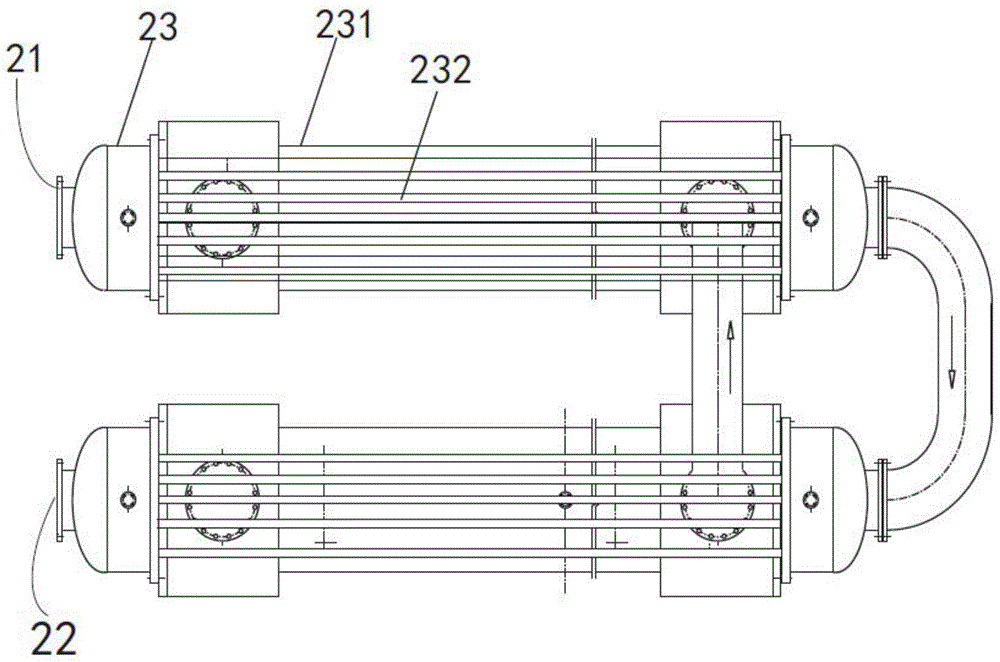

[0039] Such as figure 1 Shown is a block diagram of the solution of the present invention. It includes a multi-stage multi-channel filter 10 located upstream of the mine water flow. The mine water from the multi-stage multi-channel filter 10 is filtered to remove large solid minerals, and then enters the heat exchange pipe section 20. After the heat exchange with the circulating cooling water, the mine water temperature is reduced and the heat energy of the mine is recovered. A physical descaling device 30 is connected in parallel between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com