Cu-W/Cu-Cu composite board preparation method

A composite plate, cu-cu technology, applied in the field of composite plate preparation, to achieve good process compatibility, small residual deformation and stress, and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a 3mm Cu-W / Cu-Cu composite plate with a layer thickness ratio of 1:1:1 and a Cu volume fraction of 50% in the W / Cu plate 2 is prepared. The preparation process includes the following steps:

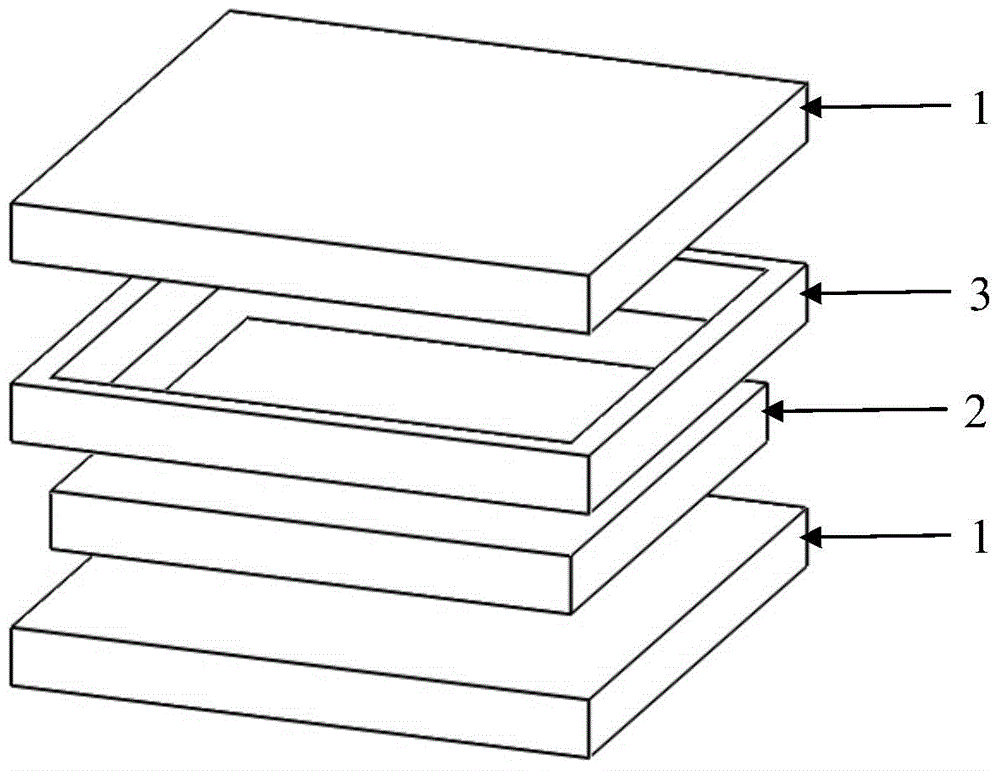

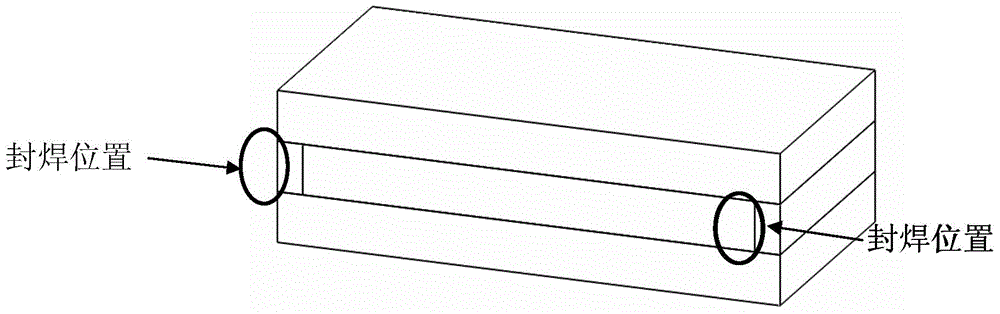

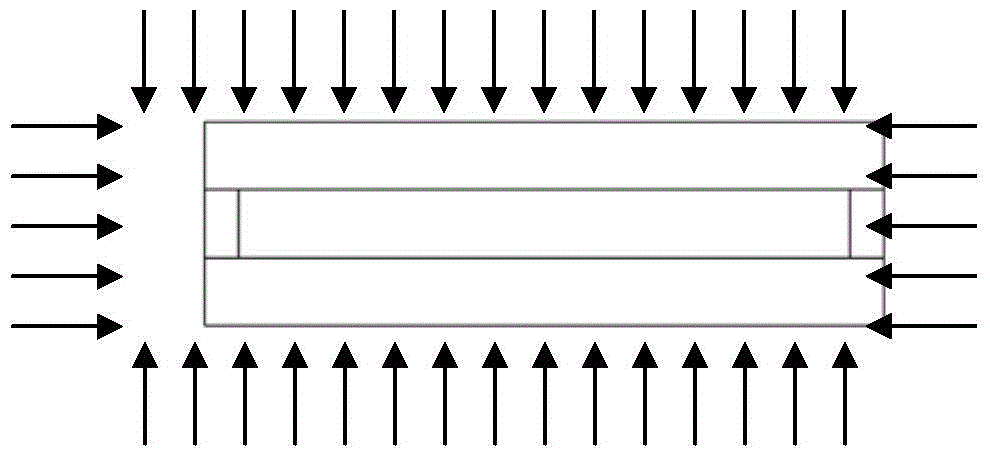

[0024] Step 1: select the oxygen-free copper Cu plate 1 that two thicknesses are 1.1mm (leave 0.1mm processing residue), select a 1mm W / Cu plate 2 that the Cu volume fraction is 50% for use (due to heat isostatic The pressure medium is a gas phase uniform pressure, which basically does not affect the final size of the dense material), and the Cu skin 3 for coating is 0.1mm. The oxygen-free copper Cu plate 1 on the upper and lower surfaces is closely attached to the Cu skin 3, completely wrapping the tungsten copper ( figure 1 ), fix the outer layer copper and tungsten copper core by tooling. Use high-temperature-resistant BNi2 solder to vacuum braze the Cu skin 3 on the side of the W / Cu plate 2 and the Cu plate 1 that is attached to the top and bottom to form a...

Embodiment 2

[0029] In this embodiment, a 15mm Cu-W / Cu-Cu composite plate with a layer thickness ratio of 1:3:1 and a Cu volume fraction of 30% in the W / Cu layer is prepared. The preparation process includes the following steps:

[0030] Step 1: select the oxygen-free copper Cu sheet material 1 that two thicknesses are 3.1mm (leaving 0.1mm processing residue), select a 9mm W / Cu sheet material 2 that the volume fraction of Cu is 30% (due to heat isostatic The pressure medium is a gas phase uniform pressure, which basically does not affect the final size of the dense material), and the Cu skin 3 for coating is 0.1mm. The oxygen-free copper Cu plate 1 on the upper and lower surfaces is closely attached to the Cu skin 3, completely wrapping the tungsten copper ( figure 1 ), fix the outer layer copper and tungsten copper core by tooling. Use high-temperature-resistant BNi2 solder to vacuum braze the Cu skin 3 on the side of the W / Cu plate 2 and the Cu plate 1 that is attached to the top and bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com