High-precision temperature controlling and energy saving stewing cabinet intelligently and automatically removing scale

A high-precision, scaling technology, applied in the field of kitchen utensils, can solve the problems of reducing the steam generation capacity of heating devices and water tanks, low effective utilization of energy, waste of labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

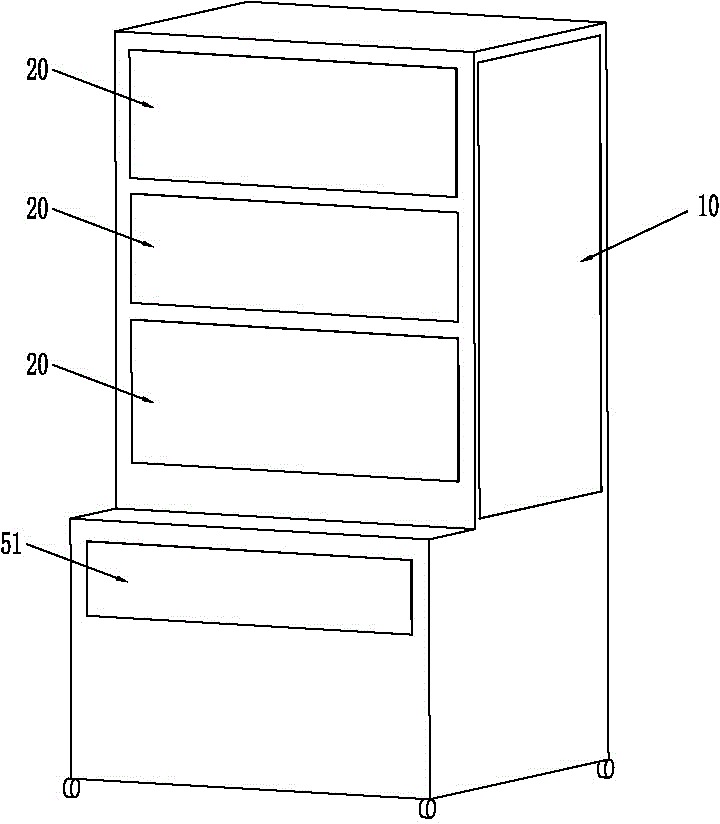

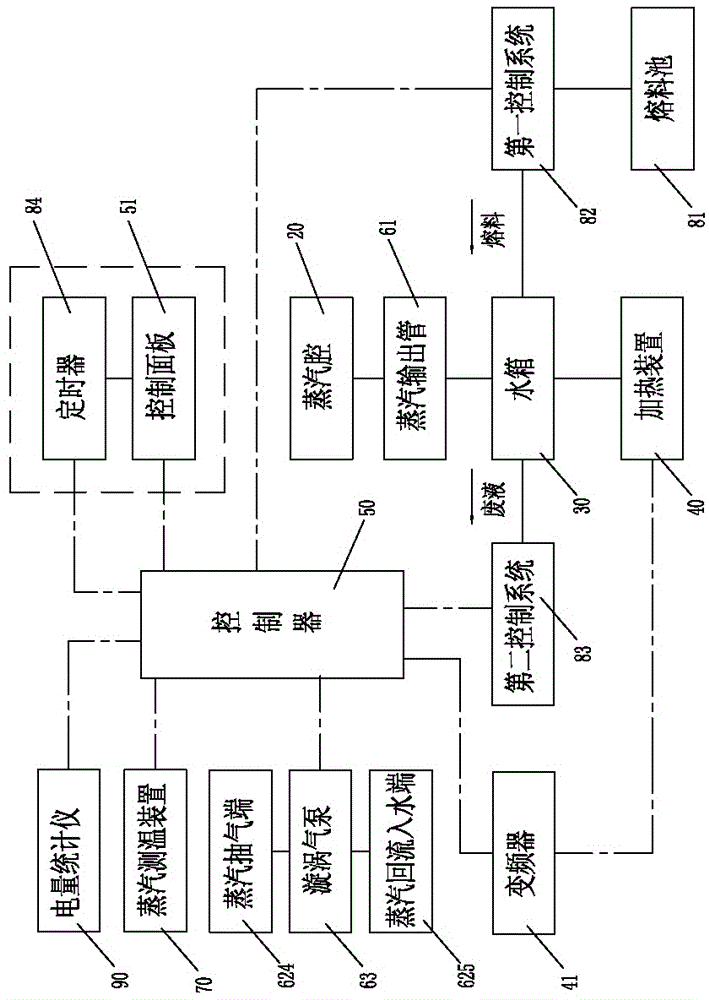

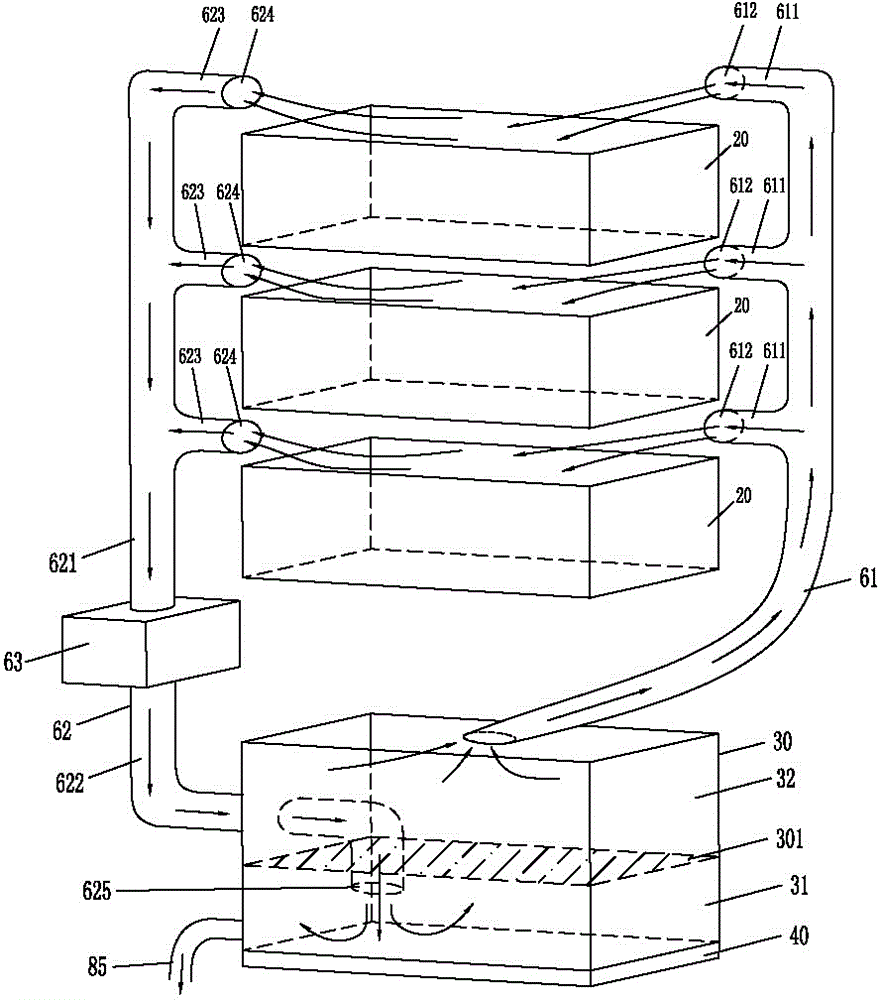

[0039] Please refer to Figure 1 to Figure 3 As shown, it shows the general structure of the embodiment of the present invention, including a steaming cabinet body 10, which is provided with a steam chamber 20 for cooking food, a water tank 30 for generating steam, and a steaming tank 30 Heated heating device 40, steam circulation delivery system for ensuring uniform steam and temperature stability, segmented temperature control and energy-saving control system for improving food cooking effect, automatic descaling system for cleaning water tank 30, for intelligent control The controller 50 and the control panel 51 of the cooking operation are connected to the controller 50.

[0040] Wherein, the steam circulation delivery system includes a steam output pipe 61, a steam return pipe 62 and a vortex pump 63; the lower end of the steam output pipe 61 is connected to the aforementioned water tank 30, and the upper section of the steam output pipe 61 has a plurality of The steam outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com