Solid insulation treeing type high temperature test system capable of realizing high efficiency temperature control

A solid insulation and high temperature test technology, applied in the direction of test ship construction, test dielectric strength, measurement devices, etc., can solve the problems that the temperature is not easy to meet the test requirements, hinder the effective transfer of heat, and the test temperature range is narrow, so as to ensure the heating performance and heat transfer effect, reducing heat loss, and the effect of small heating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

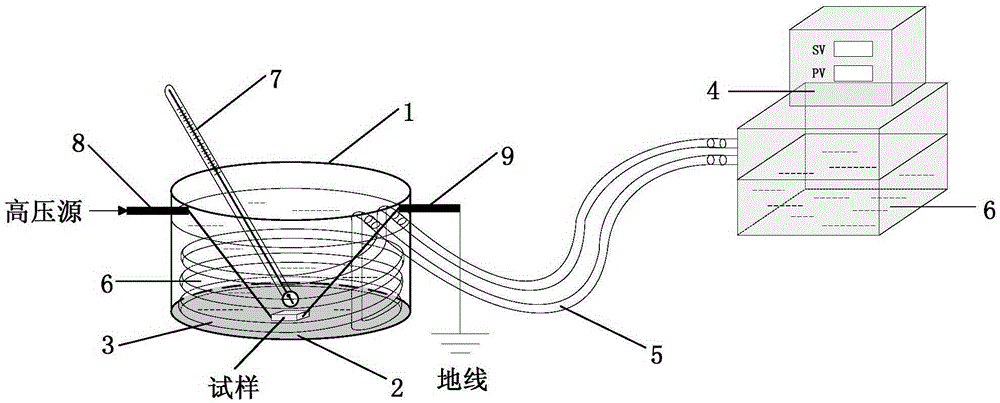

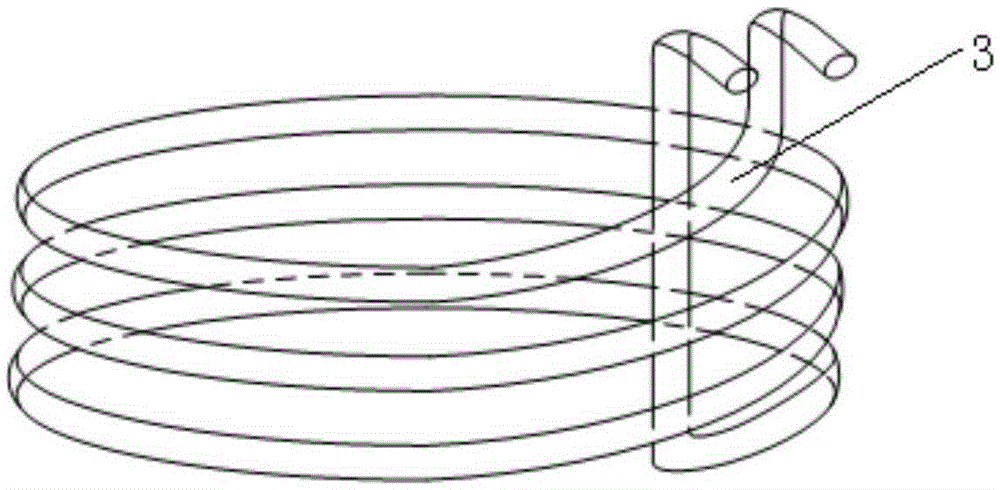

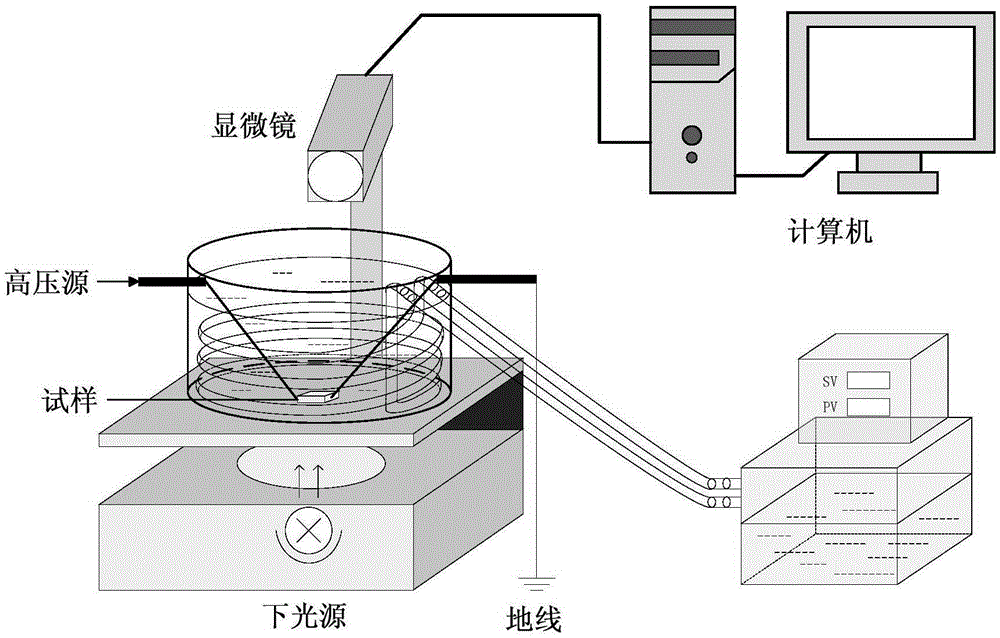

[0027] like figure 1 As shown, the solid insulation dendritic high-temperature test system capable of efficient temperature control of the present invention adopts an experimental vessel composed of a polytetrafluoroethylene container wall 1 and a thickened tempered glass base 2, and an annular glass tube 3 surrounds the experimental vessel. On the inner side, its inlet and outlet are connected to the inlet and outlet of the high-temperature heating source 4 through the thermal circulation tube 5. Both the high-temperature heating source 4 and the annular glass tube 3 are filled with silicone oil 6 to form a closed cycle. The thermometer 7 is placed in the experimental vessel for real-time measurement. temperature. The high-temperature heating source 4 is connected to the annular glass tube 3 in the experimental vessel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com