Patents

Literature

61results about How to "Fast balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

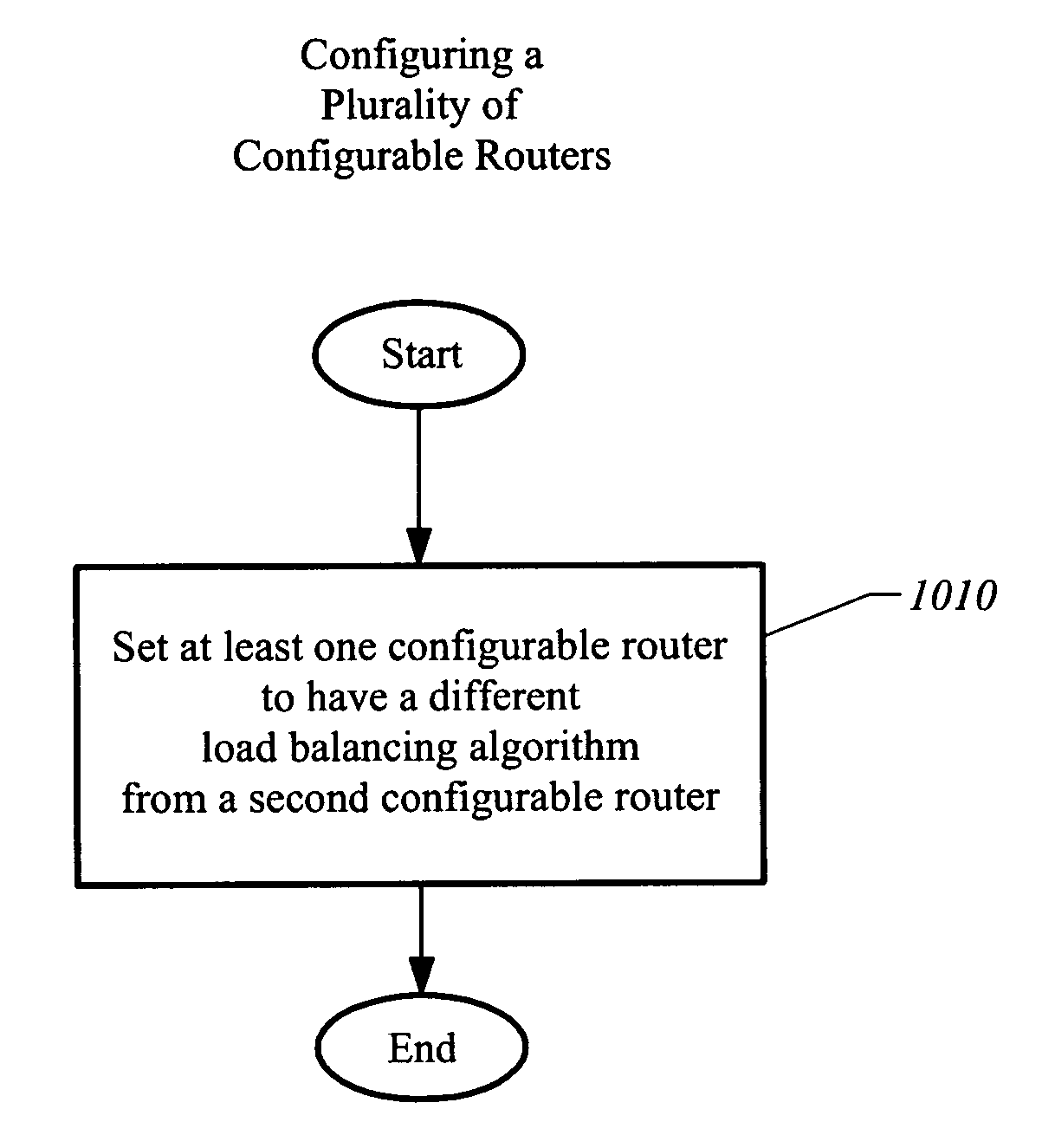

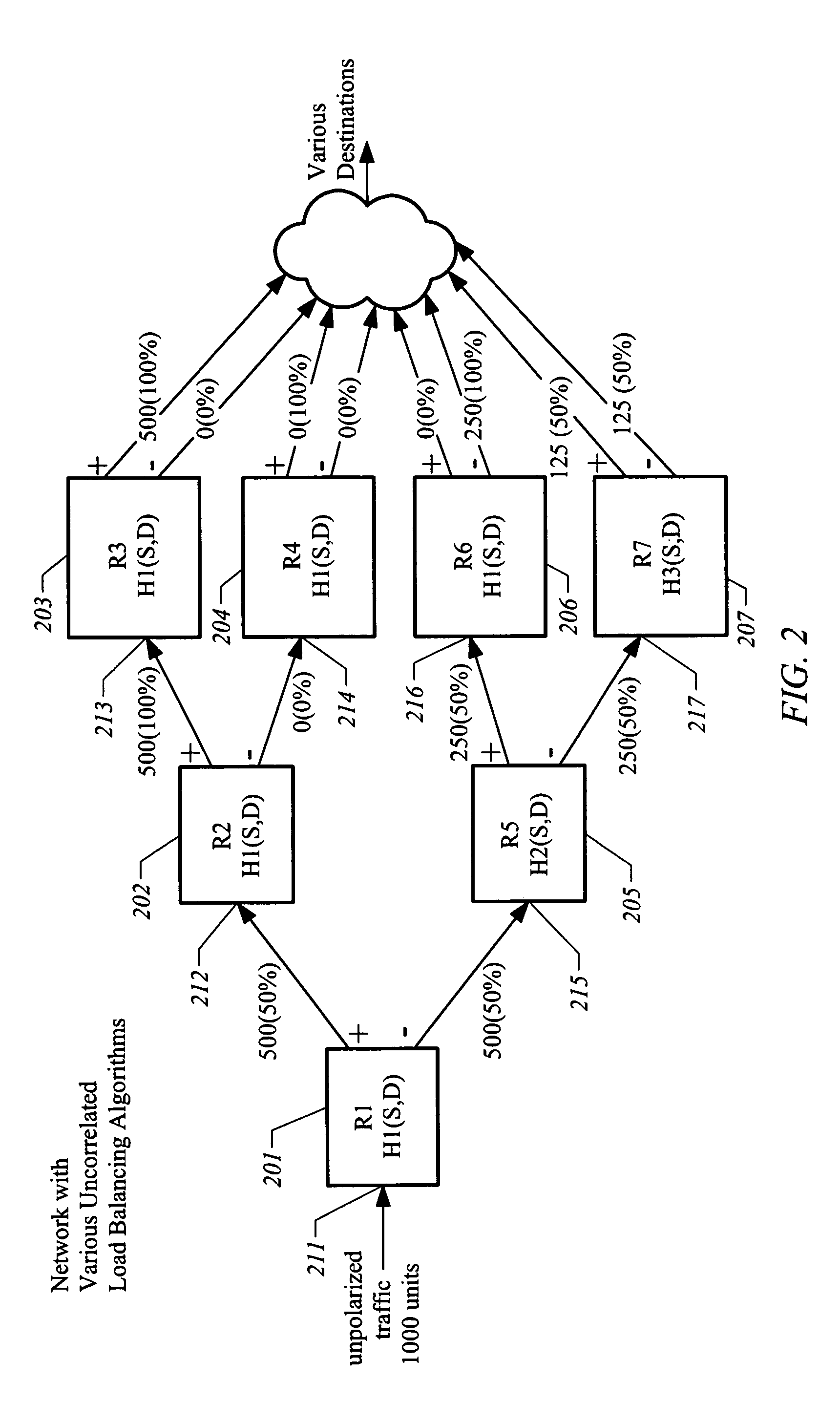

Method and apparatus for per session load balancing with improved load sharing in a packet switched network

InactiveUS6980521B1Increase traffic sharingReduce systematic unequal distribution of trafficMultiplex system selection arrangementsError preventionTraffic capacityAlgorithm Selection

Systems and methods for implementing per-session load balancing of packets that increase traffic sharing and reduce systematic unequal distribution of traffic are provided by virtue of one embodiment of the present invention. A method for operating a selected router is provided that uses a load balancing algorithm that is configured to de-correlate distribution of sessions among the active paths at the selected router relative to distributions of sessions of other algorithms at other routers of said network. Packets arriving at the selected router are assigned to an output path according to the load balancing algorithm. A method of routing a packet received at a router having an associated identifier is provided. The source address and a destination address of the packet are obtained. An output path is selected according to a load balancing algorithm that uses the associated identifier, the source address, and the destination address as inputs, and the packet is routed to the output interface associated with the selected output path. A look-up table that is configured using the identifier can be used in selecting the output path. A router storing an identifier assigned to the router is provided; the identifier is used in determining per-session routing of incoming packets.

Owner:CISCO TECH INC

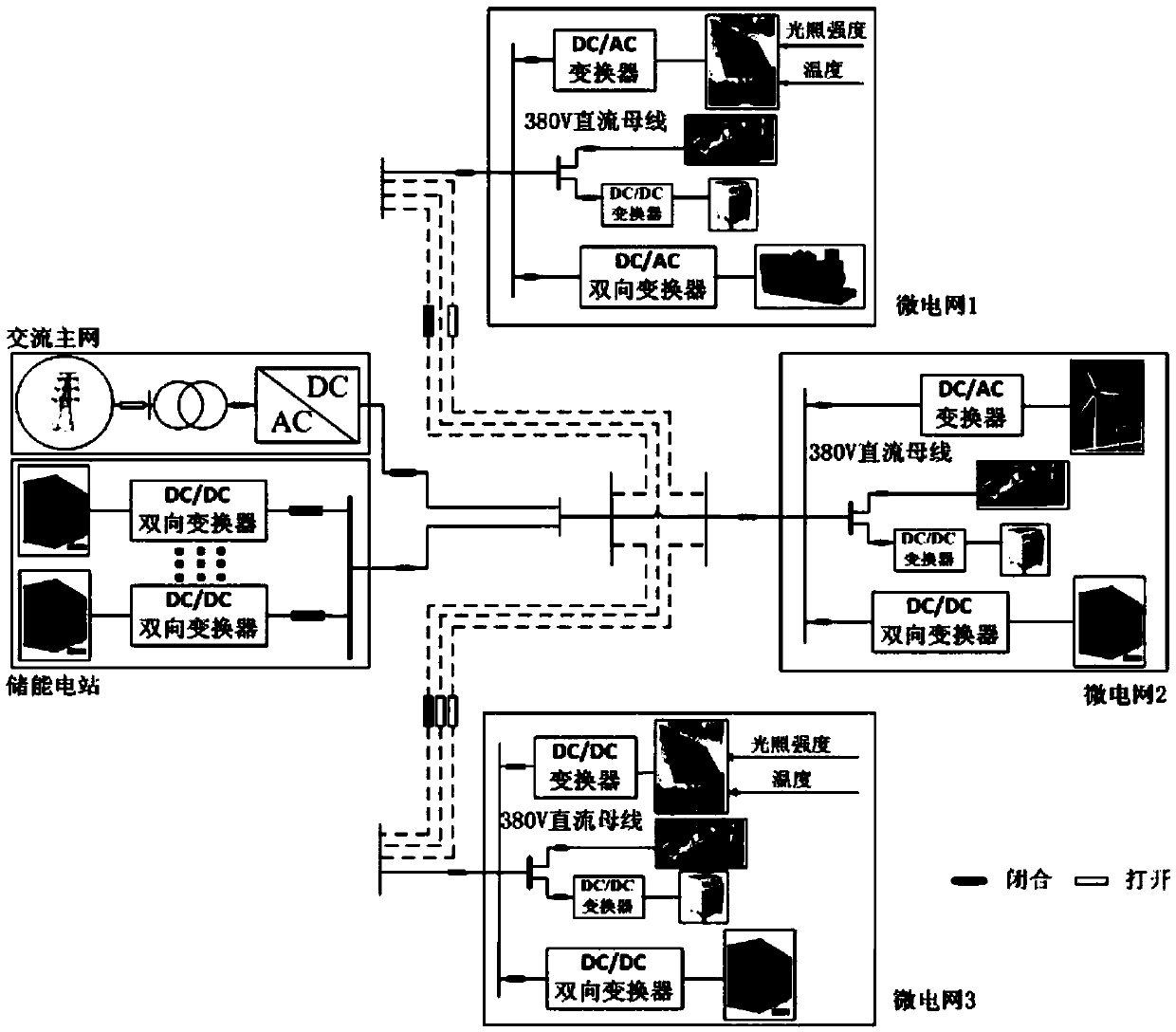

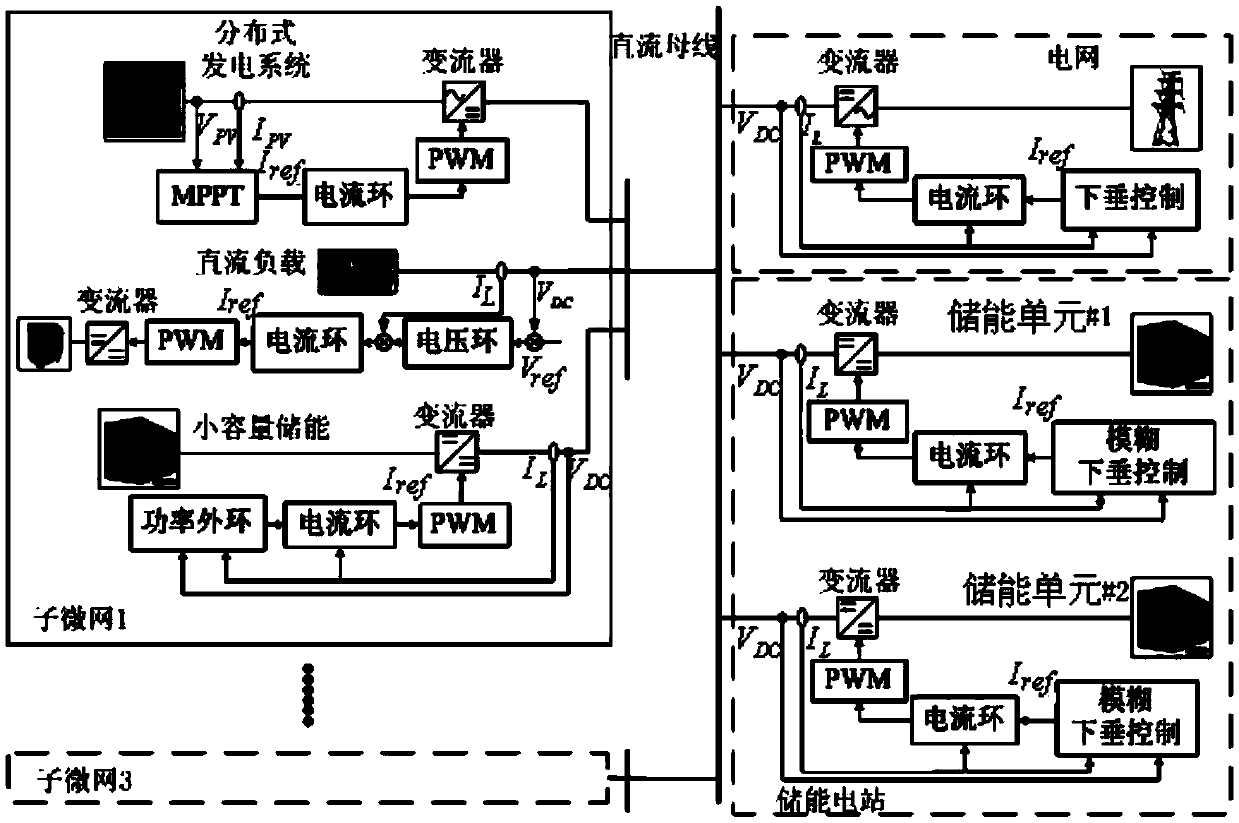

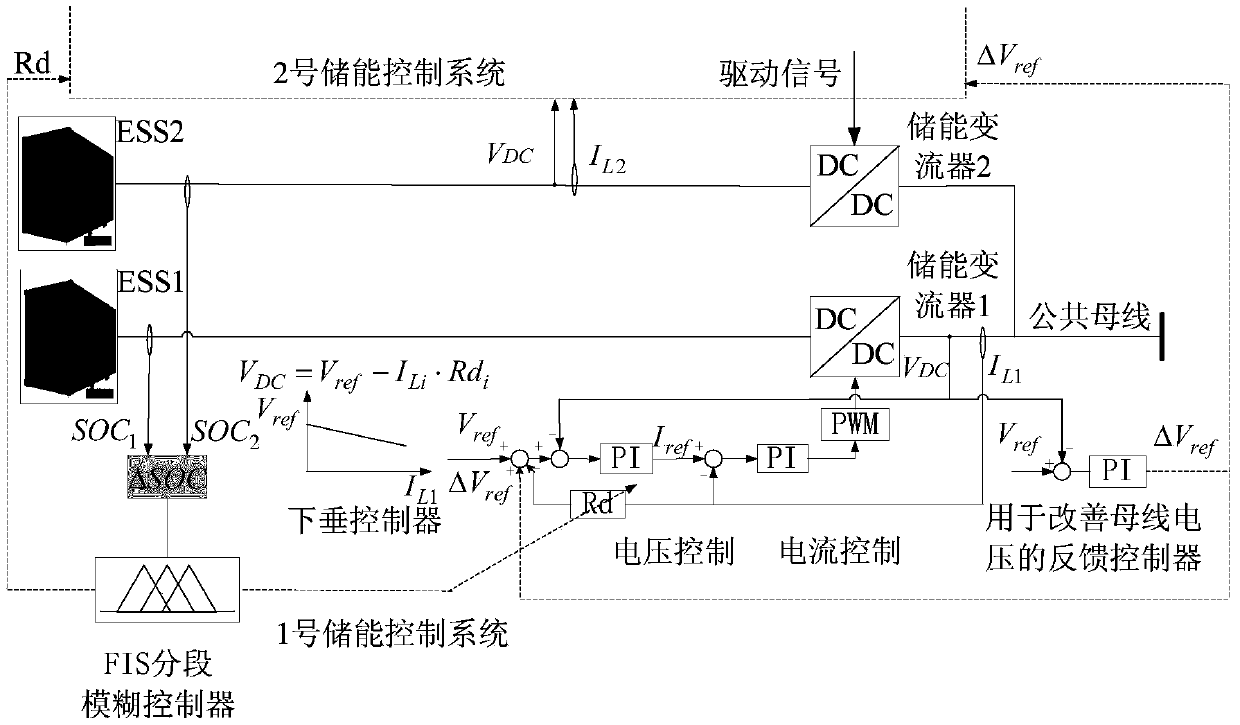

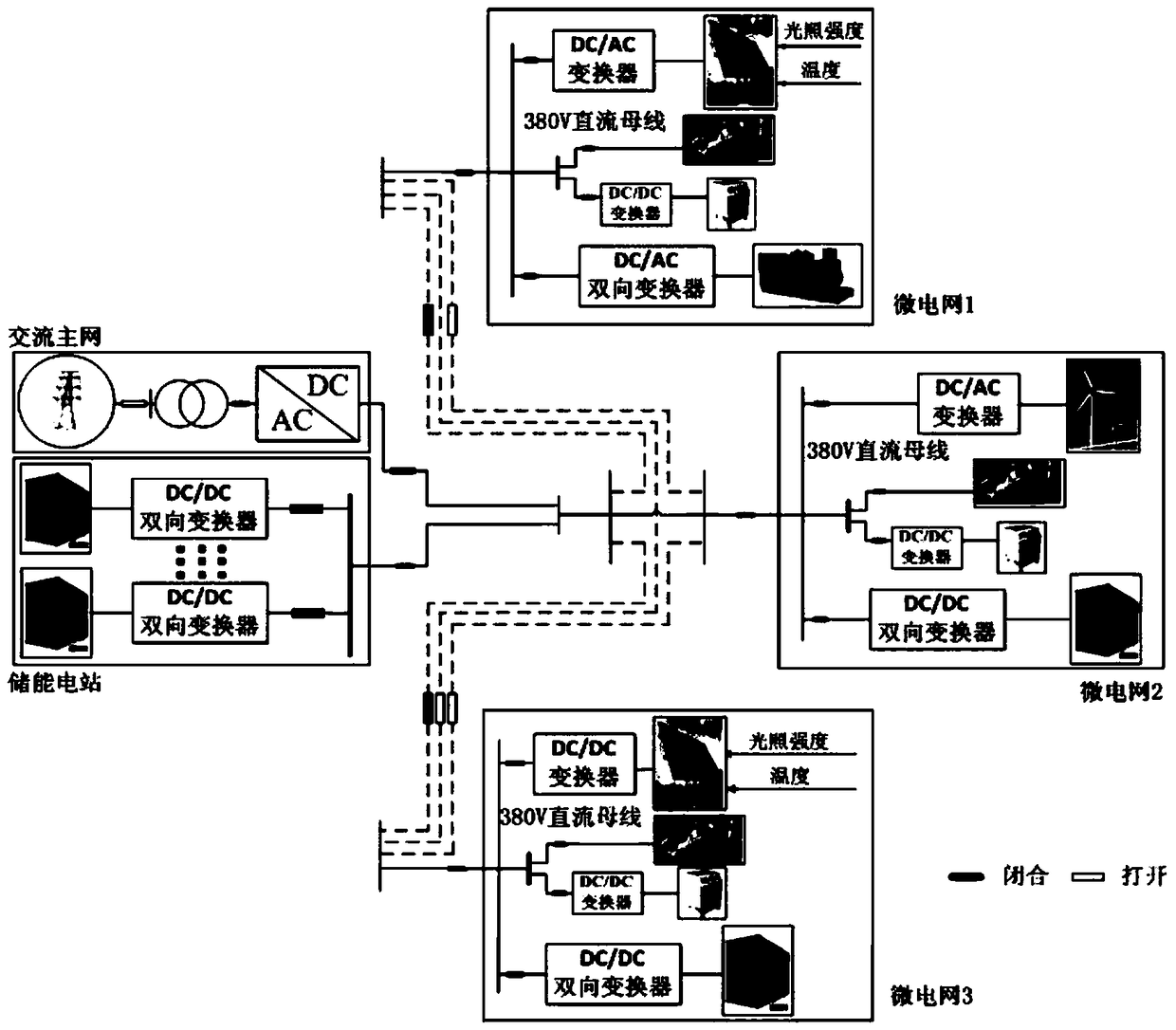

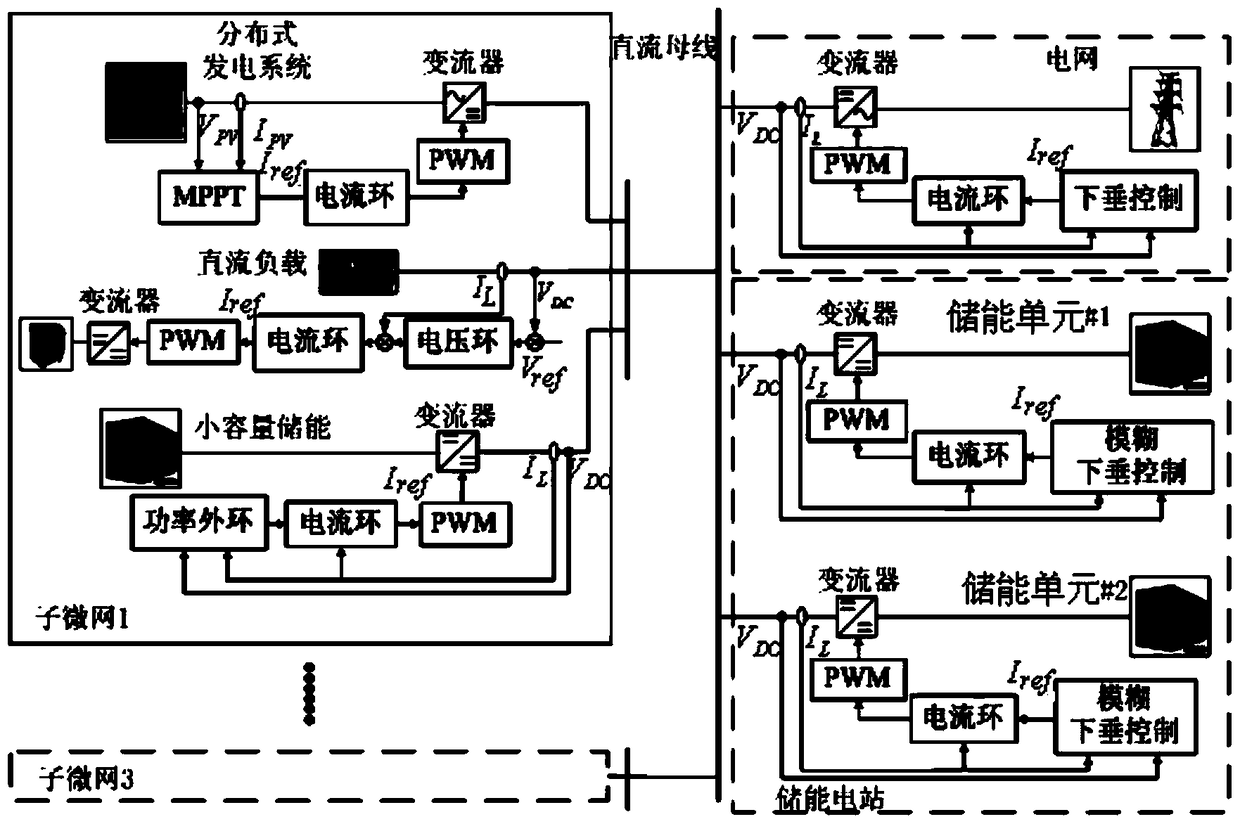

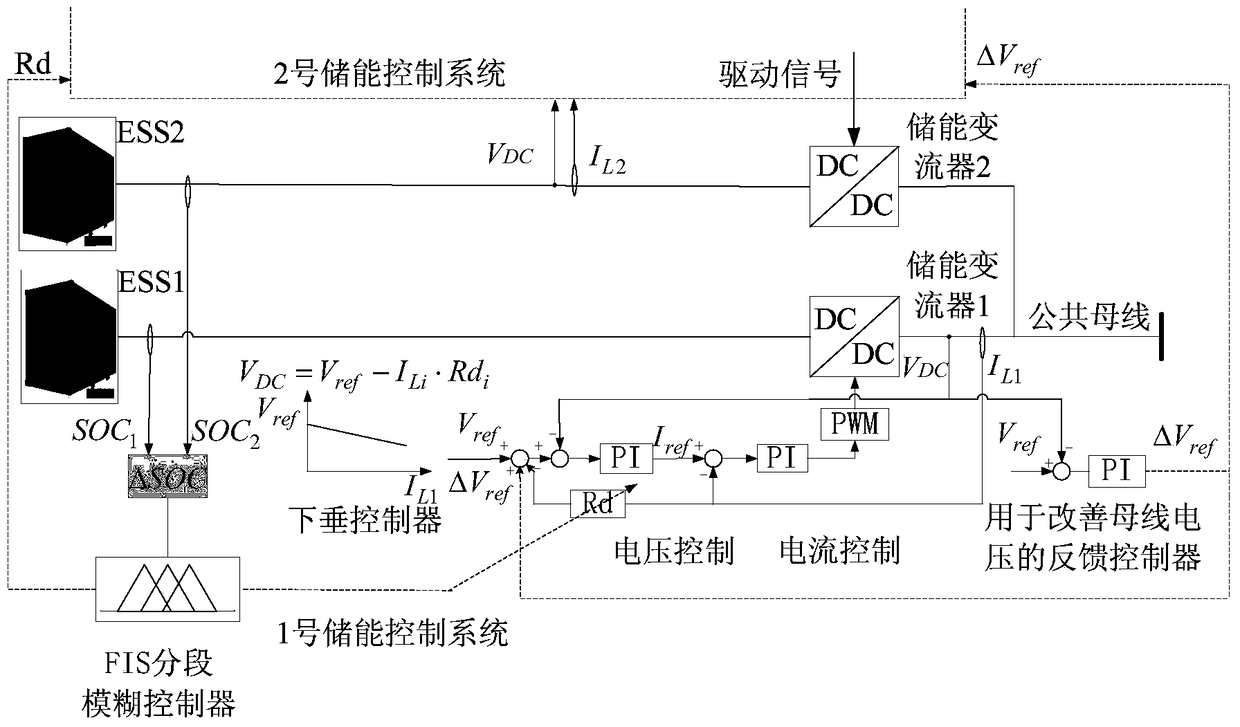

Energy storage optimization and coordination control method for direct-current micro grid group

ActiveCN105514966AImprove securityImprove voltage qualityLoad balancing in dc networkDc source parallel operationPower stationState of charge

The invention relates to an energy storage optimization and coordination control method for a direct-current micro grid group. When multiple sub micro grids are operated in parallel, an energy storage system in each sub micro grid automatically adjusts power distribution according to the maximum charging and discharging power and the state of charge (SOC) of the corresponding energy storage system, and therefore the safety of the energy storage systems is improved while distributed generated power fluctuation can be smoothed and the bus voltage quality can be improved; when the energy storage systems of all the sub micro grids cannot effectively buffer the system power supply and demand, an energy storage power station needs to be connected to control stabilization of the bus voltage. According to the energy storage optimization and coordination control method for the direct-current micro grid group, the virtual impedance of droop controllers of all energy storage units in the energy storage power station is adjusted by adopting fuzzy control to achieve automatic distribution of the power among the different energy storage units and SOC balance, fuzzy input is segmented, the SOC balancing speed of the fuzzy input in different ranges is increased by adopting fuzzy control, bus voltage drop caused by droop control is compensated by adopting a bus voltage feedback control method, and the bus voltage quality is improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

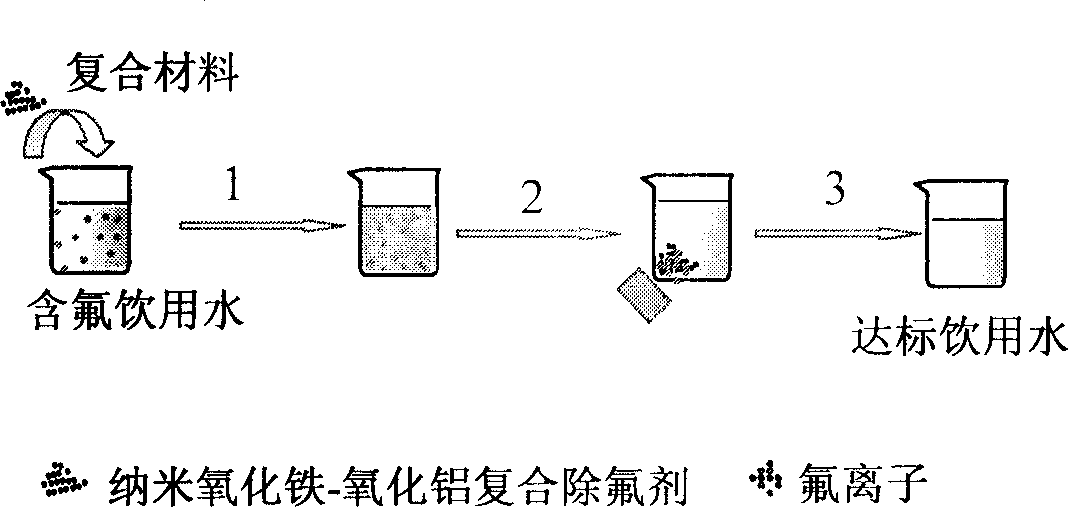

Preparing and applications of ferric oxide-alumina compound nanophase defluoridation material

InactiveCN101229504AReduce dosageImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentAlumina composite

The invention pertains to the field of chemical analysis test equipment, relating to a novel composite material of nano iron oxide-alumina which is used as an sorbent for removing fluoride from water to remove the fluoride from the large amount of drinking water; the fluorin content after the treatment is lower than the content of national standard; compared with the traditional defluorinating agent, the invention has the advantages of simple structure, low cost, high sorption capacity and fast removing speed. As a novel magnetic nano material, the defluorinating agent can realize the separation of extraction agent and base solution under the condition of external magnetic field. The surface of the nano iron oxide is coated with a layer of Al(OH)3; F<-> and Al<3+> in the water to form a complex compound which settles down to realize the effect of defluorination; 1L of water sample only consumes the defluorinating agent of 0.1g; to high fluorin content water with concentration of 20mg / L, the concentration after defluorination can be less than 1mg / L, which can well meet requirement with the reproducibility of analysis result RSD being less than 7 percent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

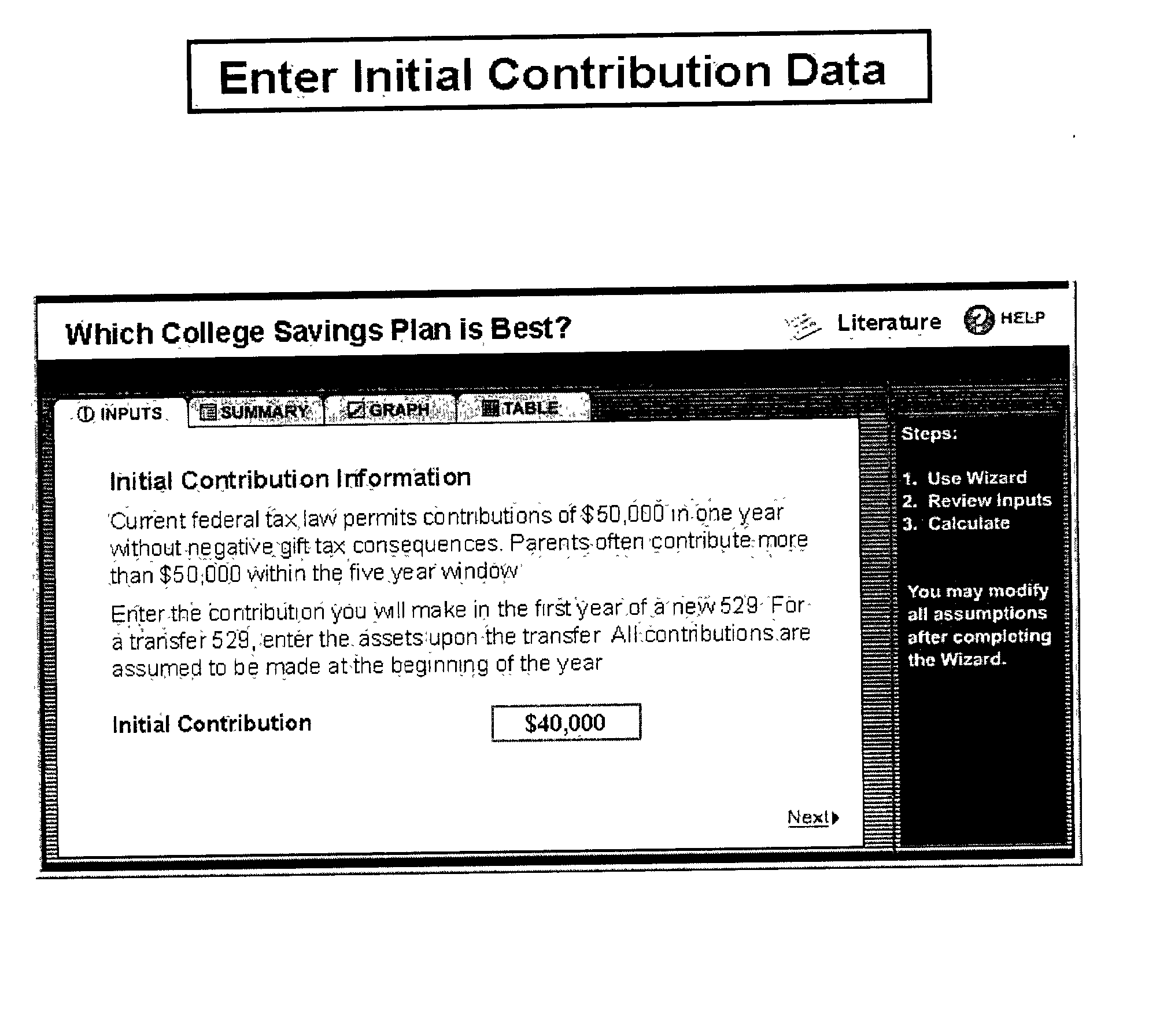

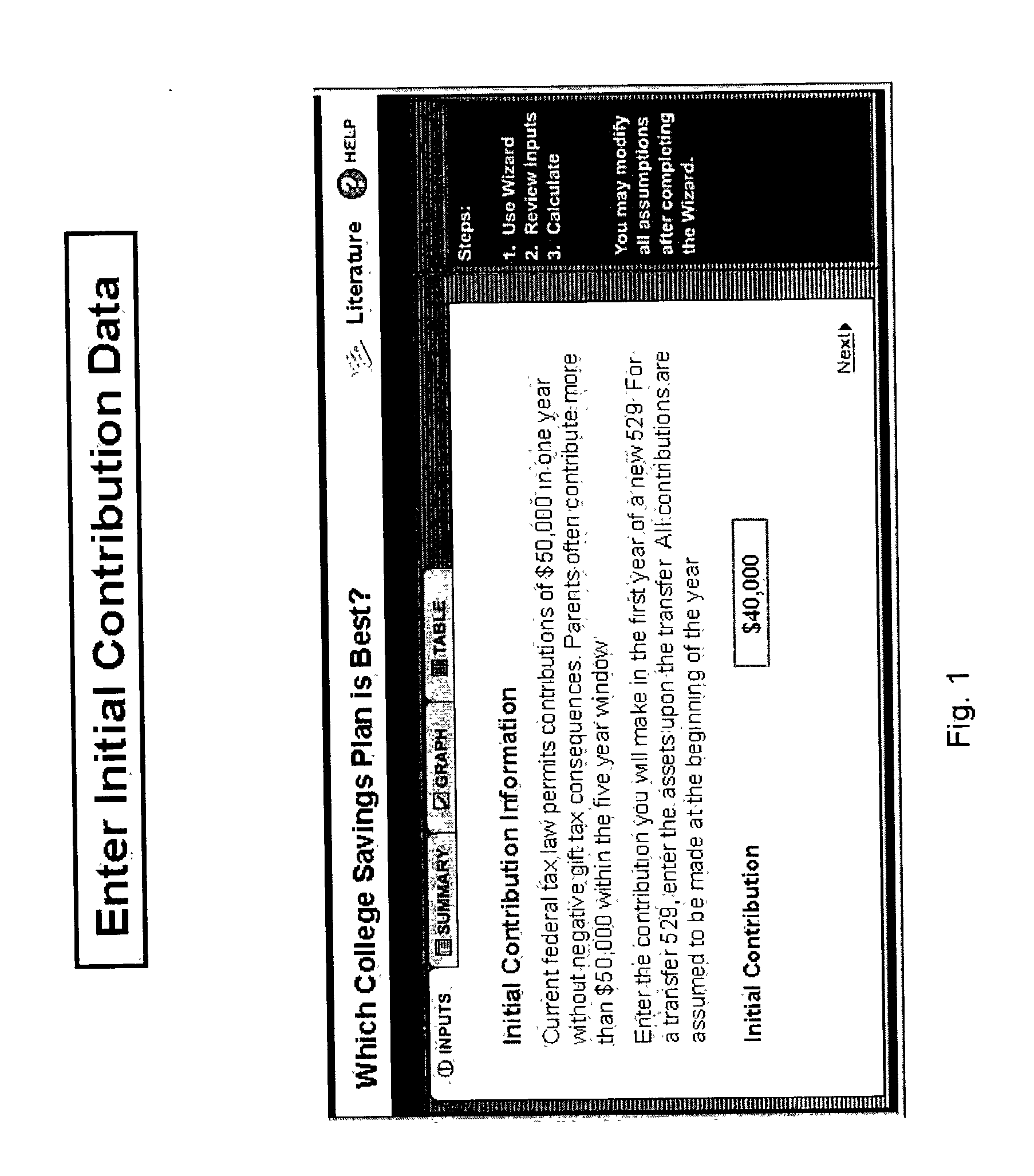

Tool for analyzing investment plans

InactiveUS20030097324A1Good decisionSmall sizeFinanceSpecial data processing applicationsProgram planningComputer science

A method, computer based or otherwise, for comparing a plurality of investment plans by accessing investor-specific information and investment-specific information and generating a plurality of investment plans based on said investor-specific and investment-specific information. These plans are compared, and the comparisons displayed, to determine which investment plan is best for the investor.

Owner:SPECKMAN STUART JULIAN

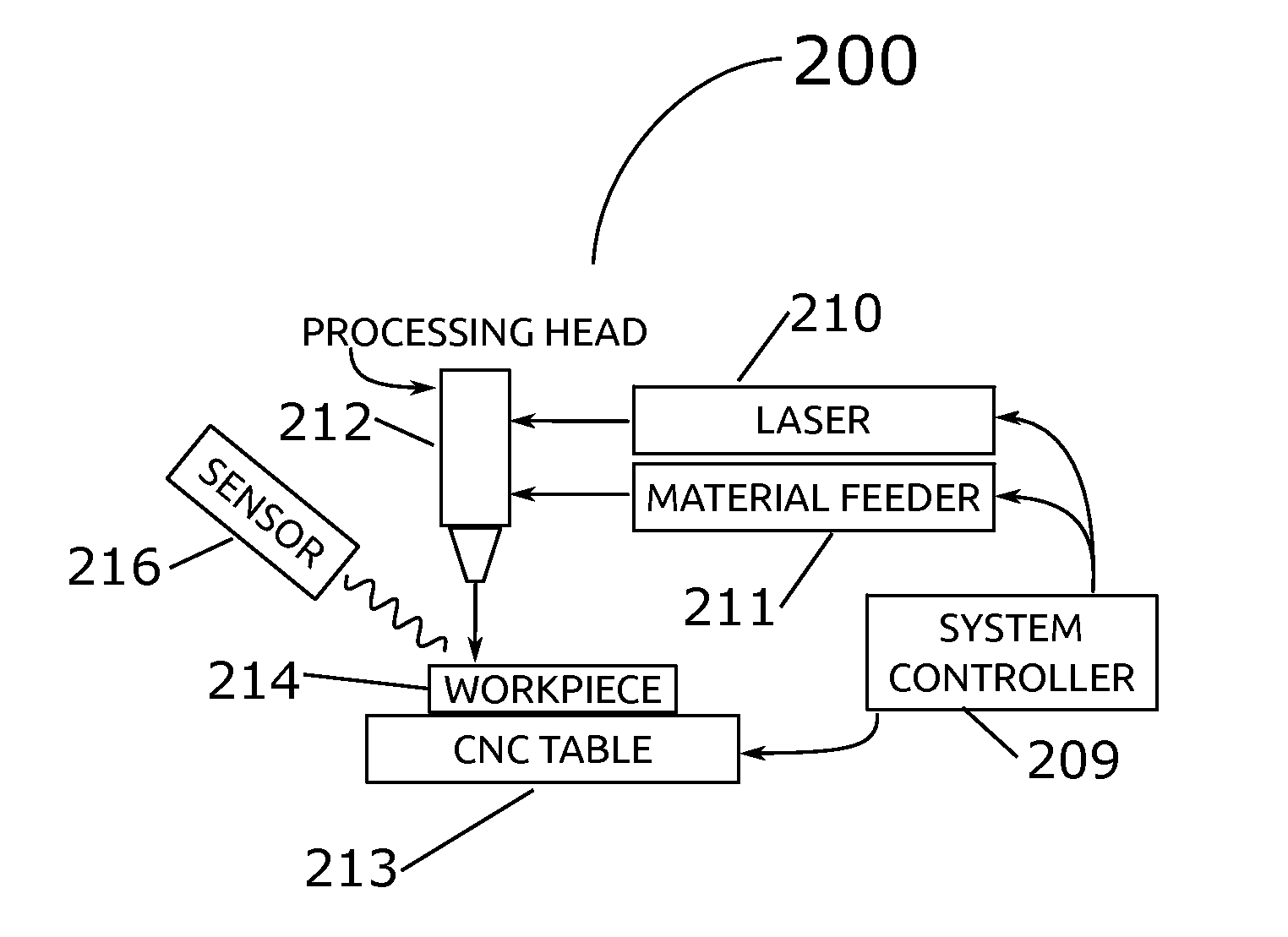

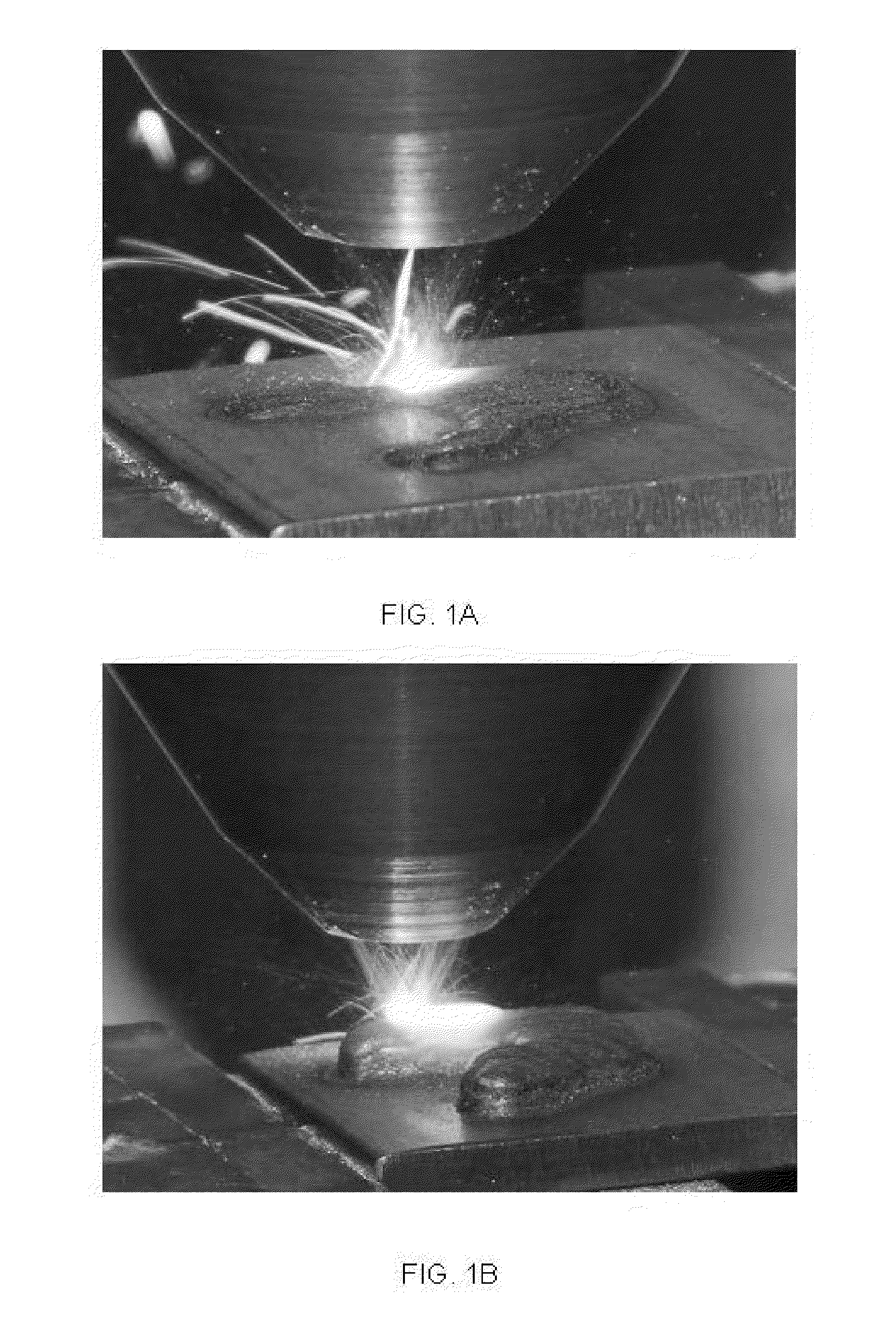

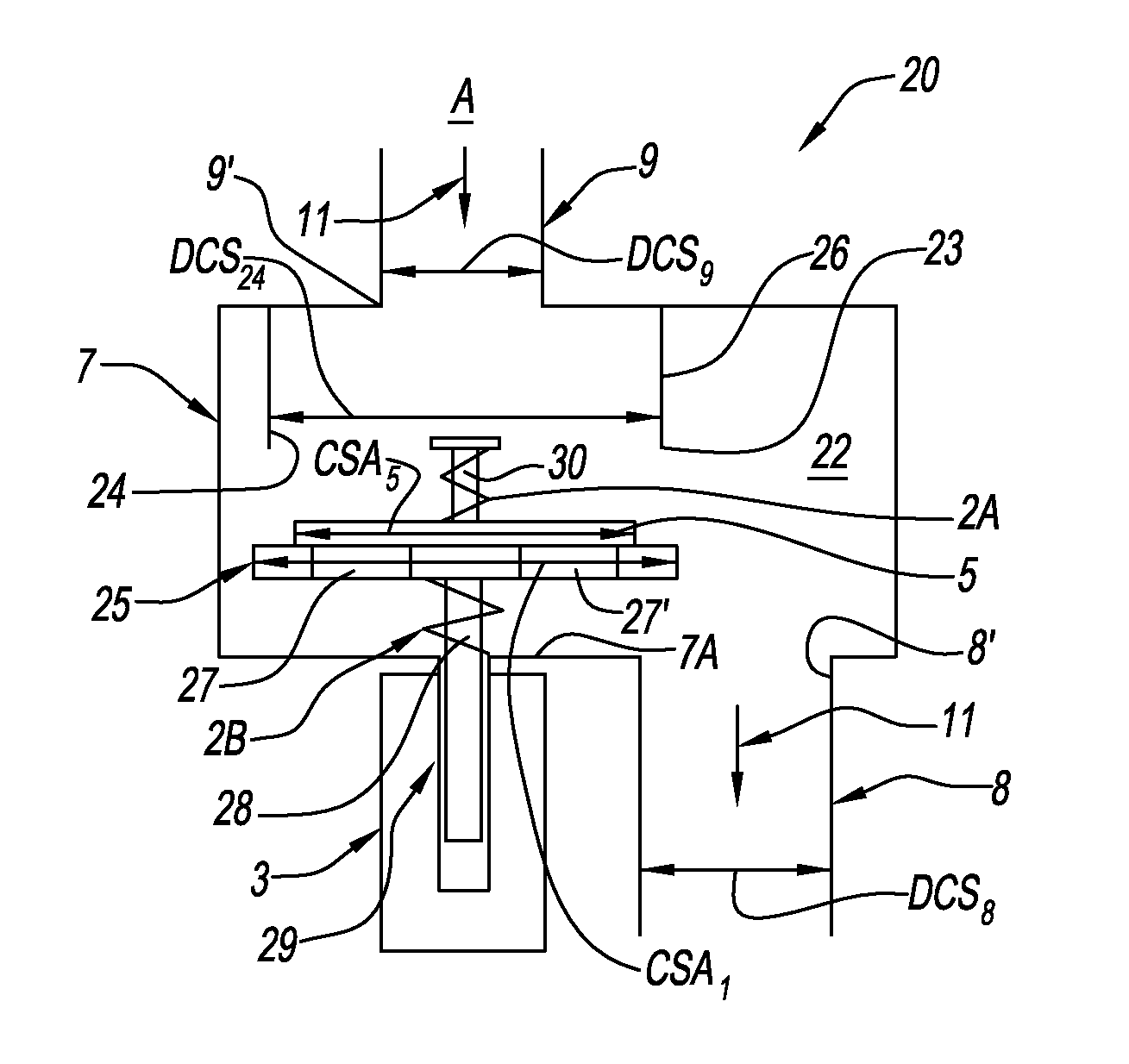

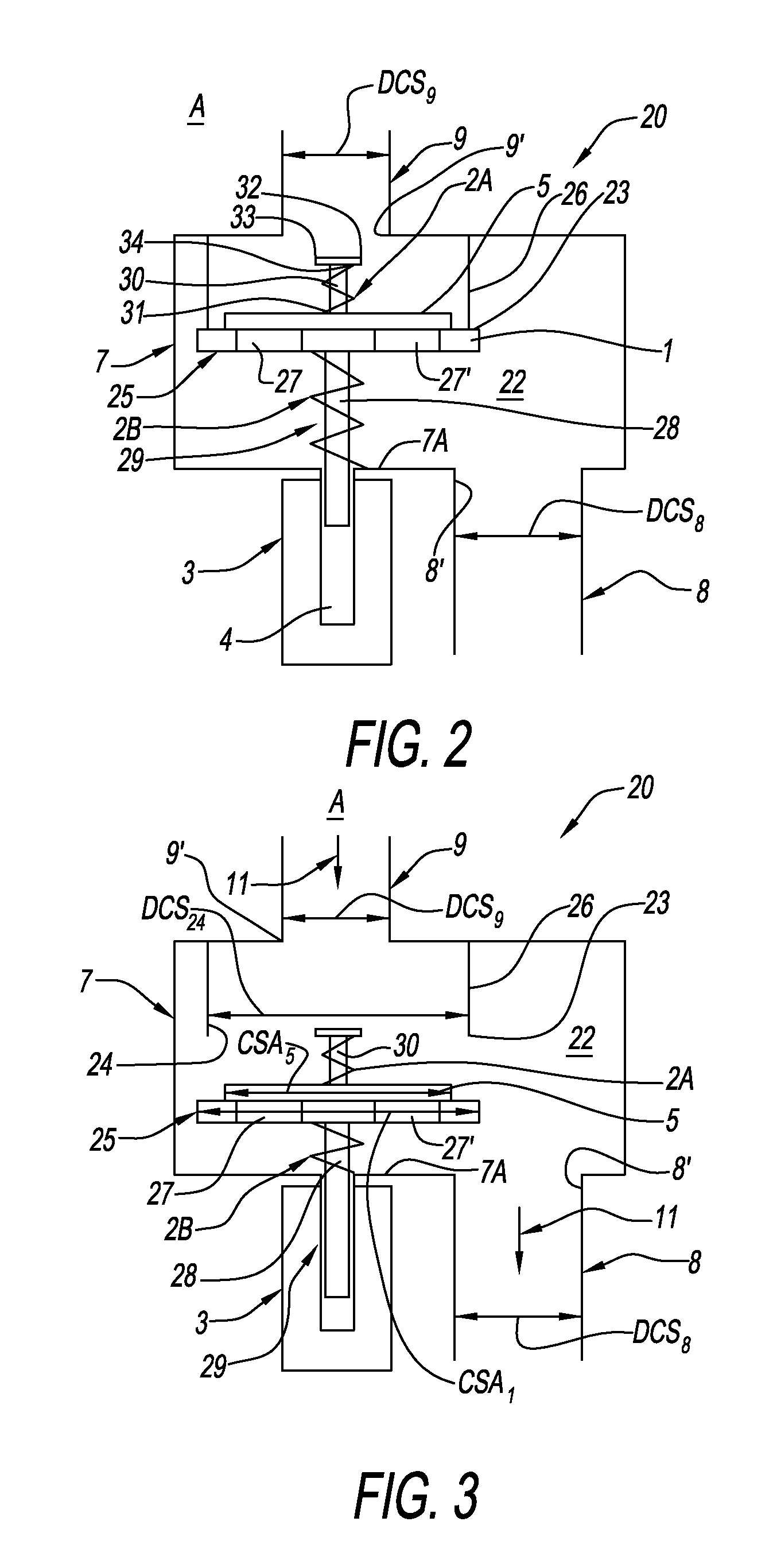

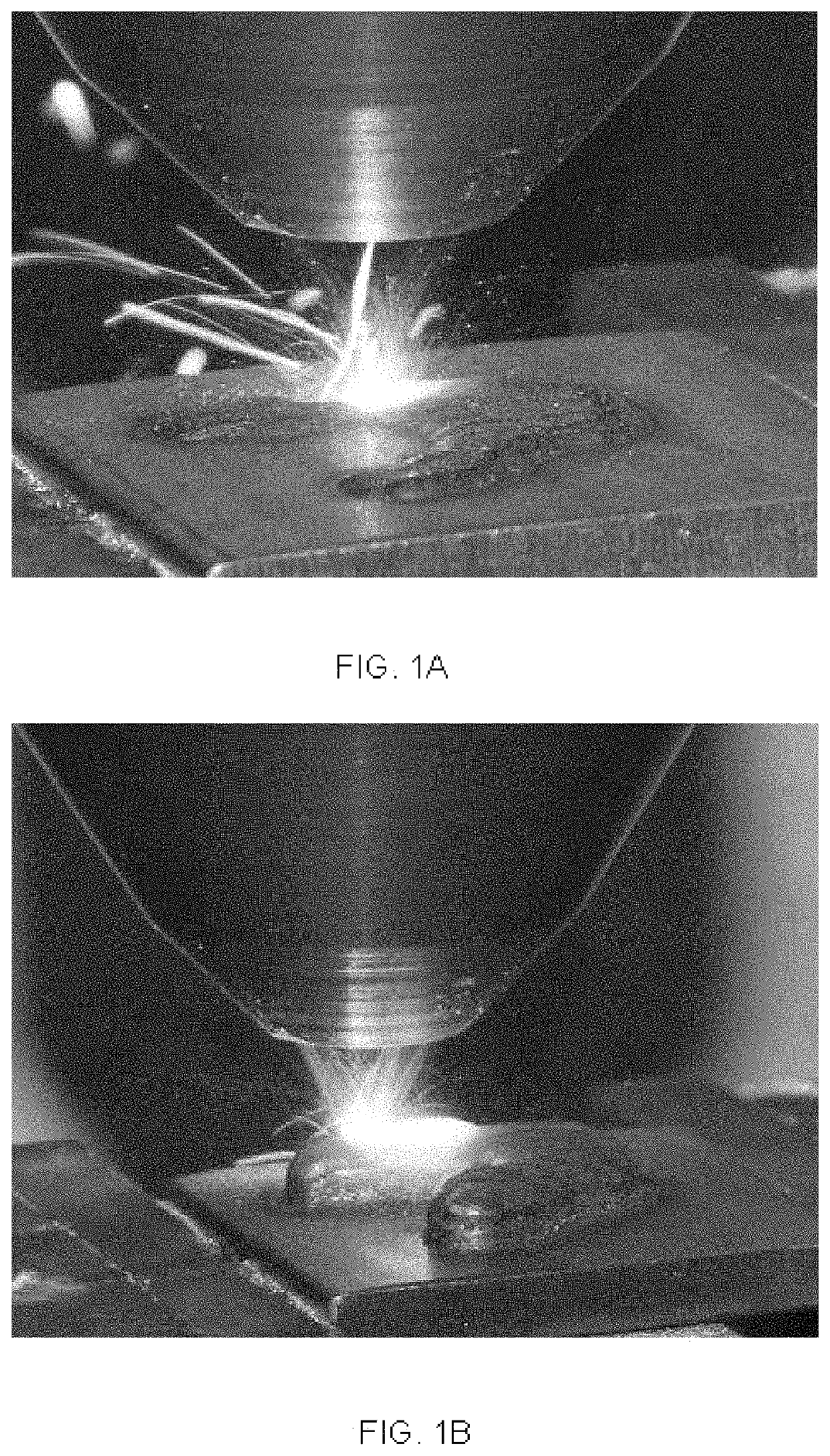

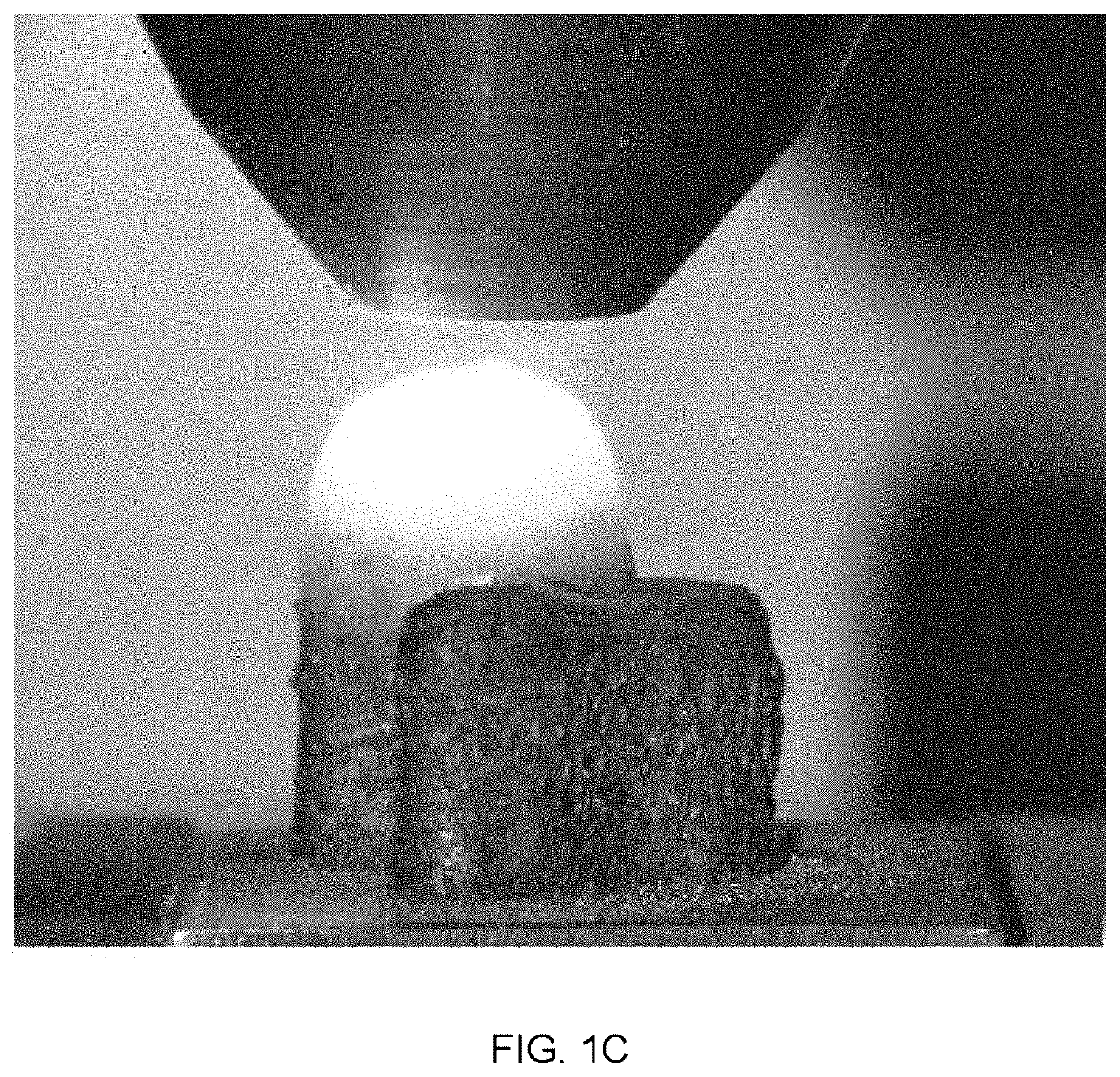

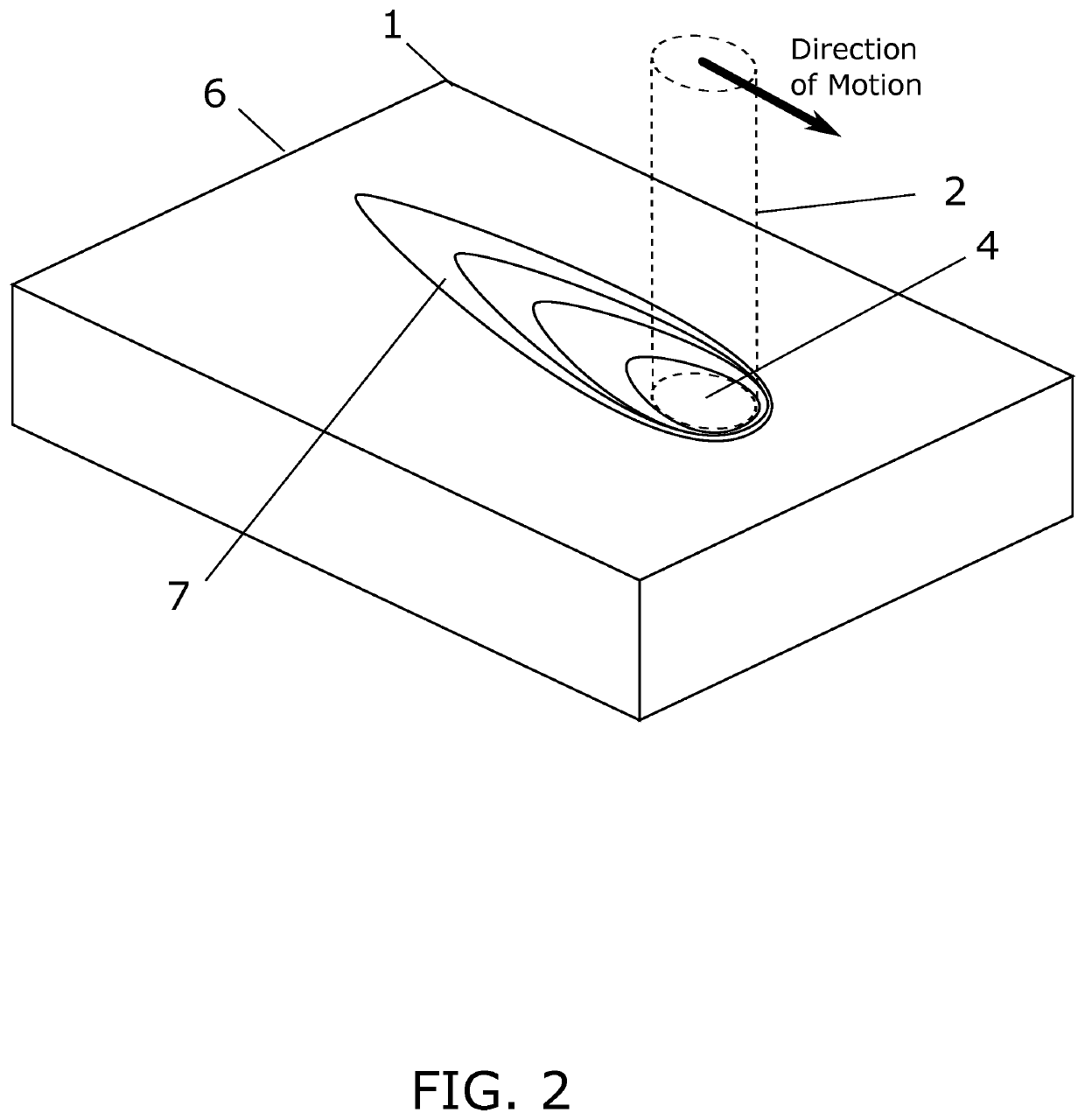

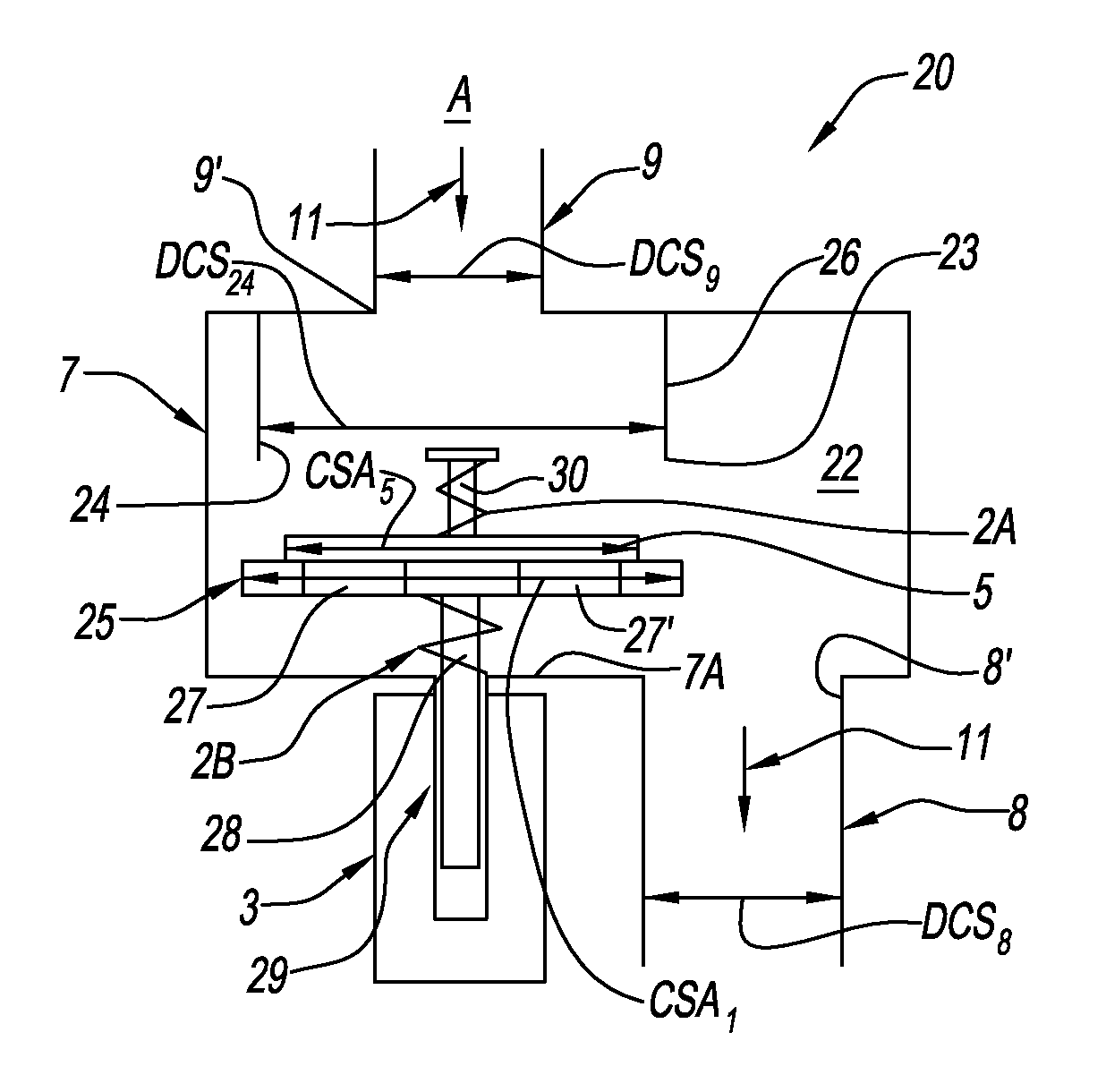

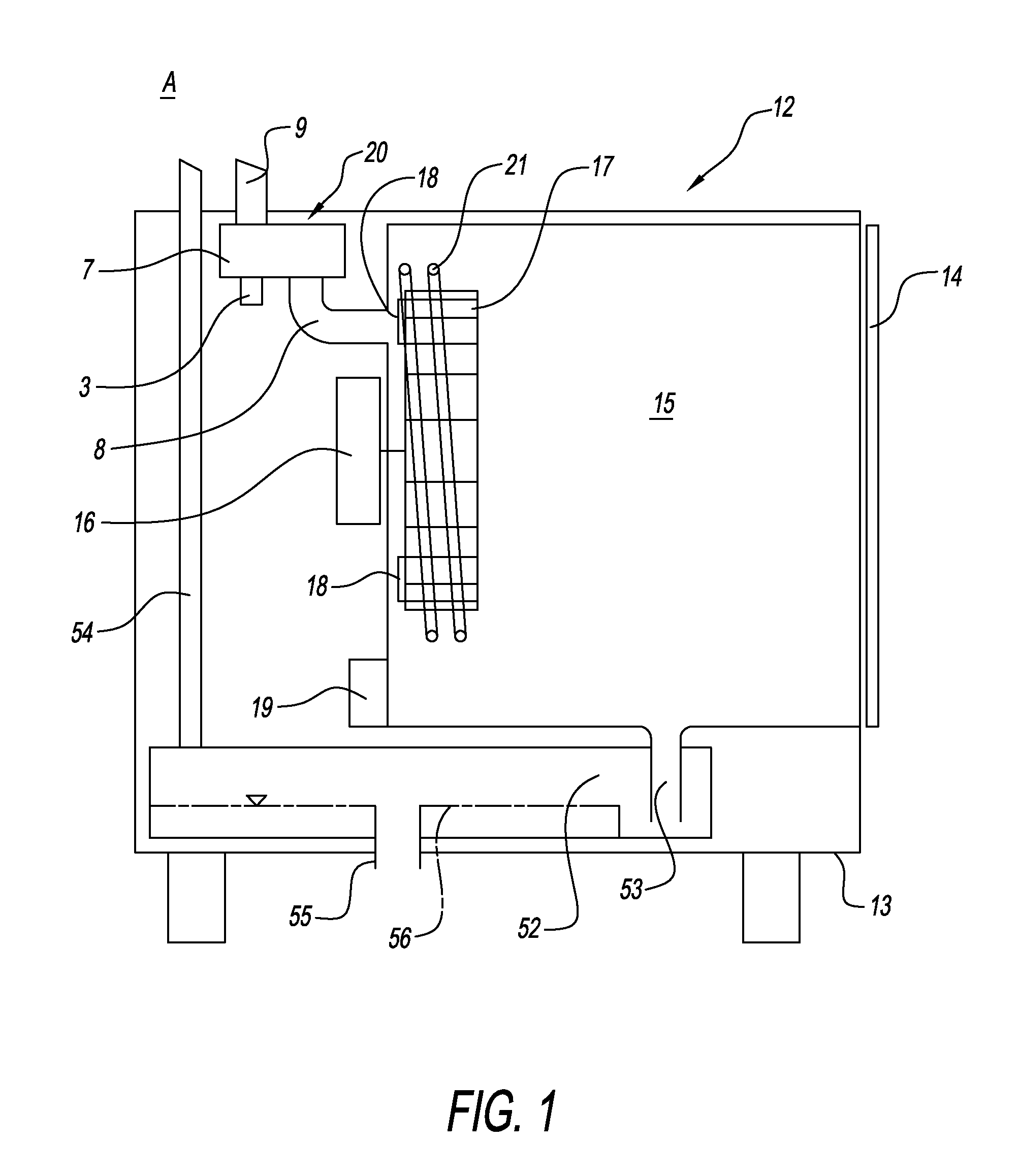

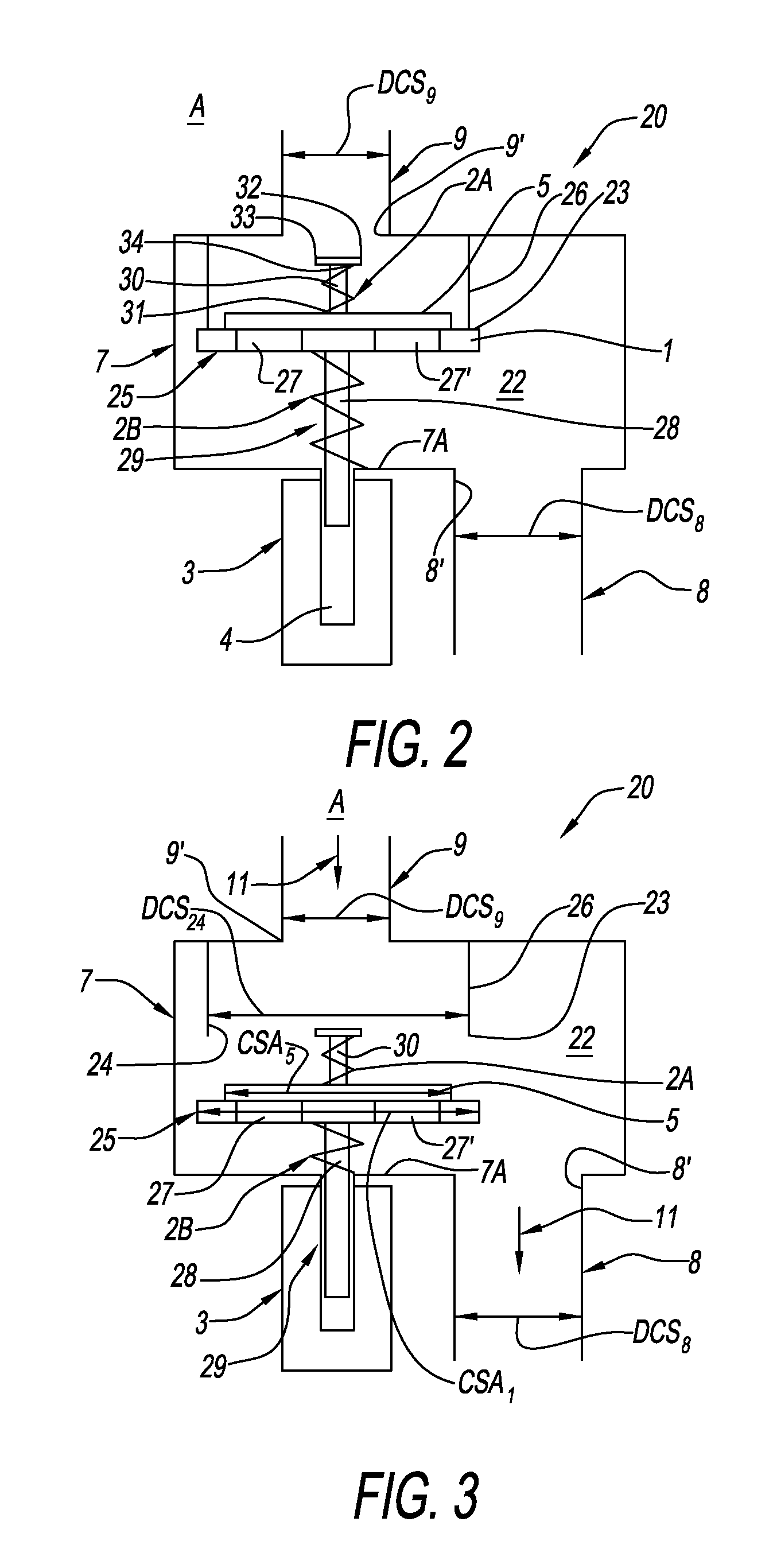

System and method for controlling the input energy from an energy point source during metal processing

ActiveUS20160151859A1Fast balanceFast inferenceAdditive manufacturing apparatusArc welding apparatusPhysicsWavelength range

A method for controlling, during metal processing, the input energy from an energy point source that directs focused emitted energy onto a metal workpiece having a geometry, wherein the directed focused emitted energy creates a melt pool and hot zone on the workpiece that emit radiation during the process. The method comprises determining a wavelength range for the emitted radiation that is within a spectral range of radiation emitted by the hot zone during processing that is comparatively high in amount in relation to the amount of radiation emitted by the melt pool in that spectral range during processing; directing the beam onto the workpiece to generate a melt pool and hot zone on the structure; measuring the intensity of radiation within the determined wavelength range; and adjusting the input energy from the energy point source based upon the measured intensity of radiation within the determined wavelength range.

Owner:PROD INNOVATION & ENG L LC

Lithographic fountain solution composition containing complex surfactants

ActiveCN104309350AFast ink balanceFast balancePrinting pre-treatmentActive agentSurface-active agents

A lithographic fountain solution composition containing complex surfactants is composed of the complex surfactants, buffering electrolytes, water-soluble high-molecular compounds, aqueous germicide and algicide, aqueous antifoaming agents and water. The complex surfactants include two or more nonionic surfactants, anionic surfactants, cationic surfactants or ampholytic surfactants. The lithographic fountain solution composition containing the complex surfactants has the advantages of excellent dynamic ink-water balance performance, low requirements on quality of water for working solution preparation, high adaptability to changes of temperature conditions and the like; using the lithographic fountain solution composition can evidently improve quality of prints, improve printing efficiency and reduce production cost; in addition, the lithographic fountain solution composition contains no poisonous and harmful substances and is high in stability and long in storage time.

Owner:HUNAN NORMAL UNIVERSITY

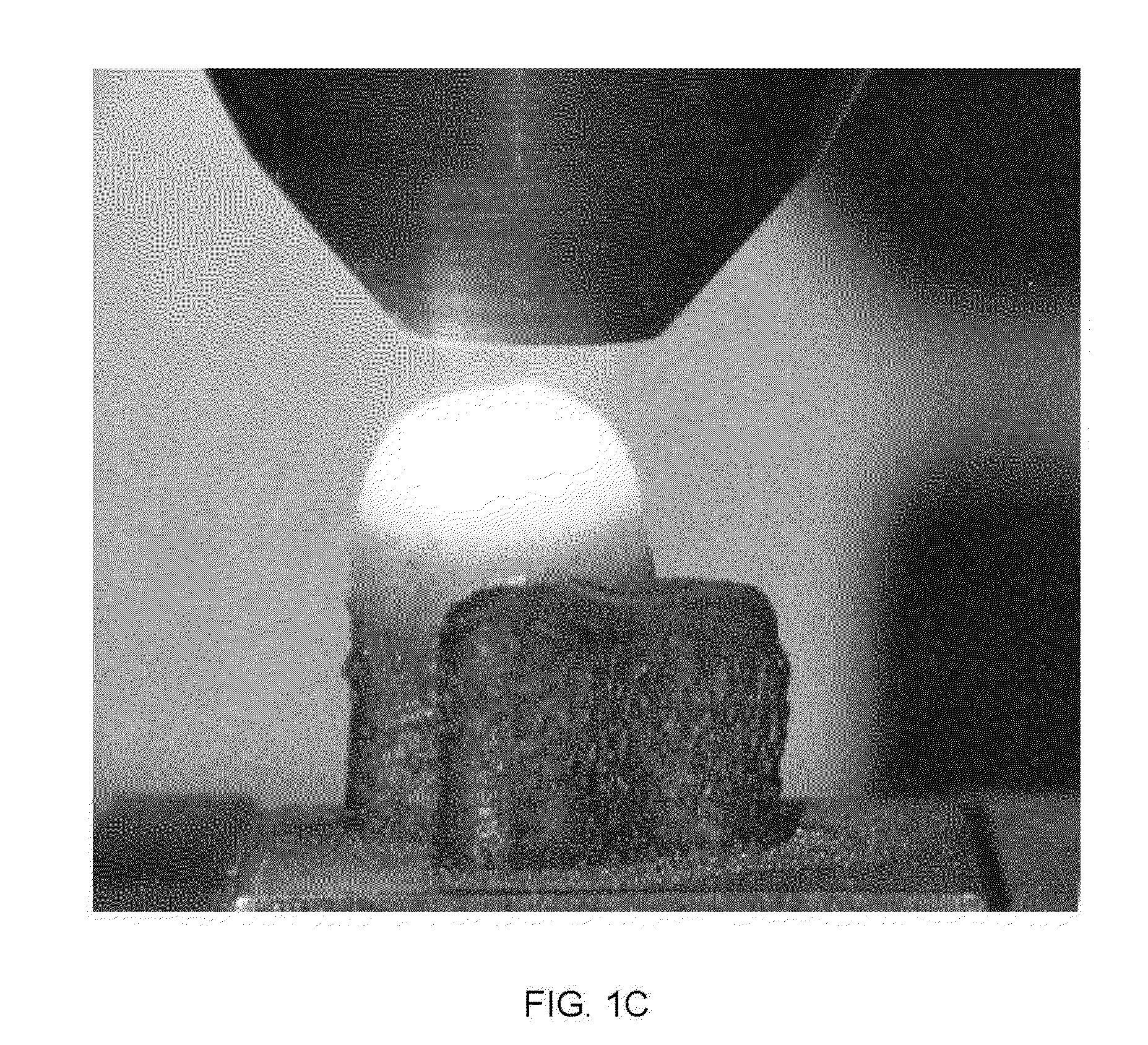

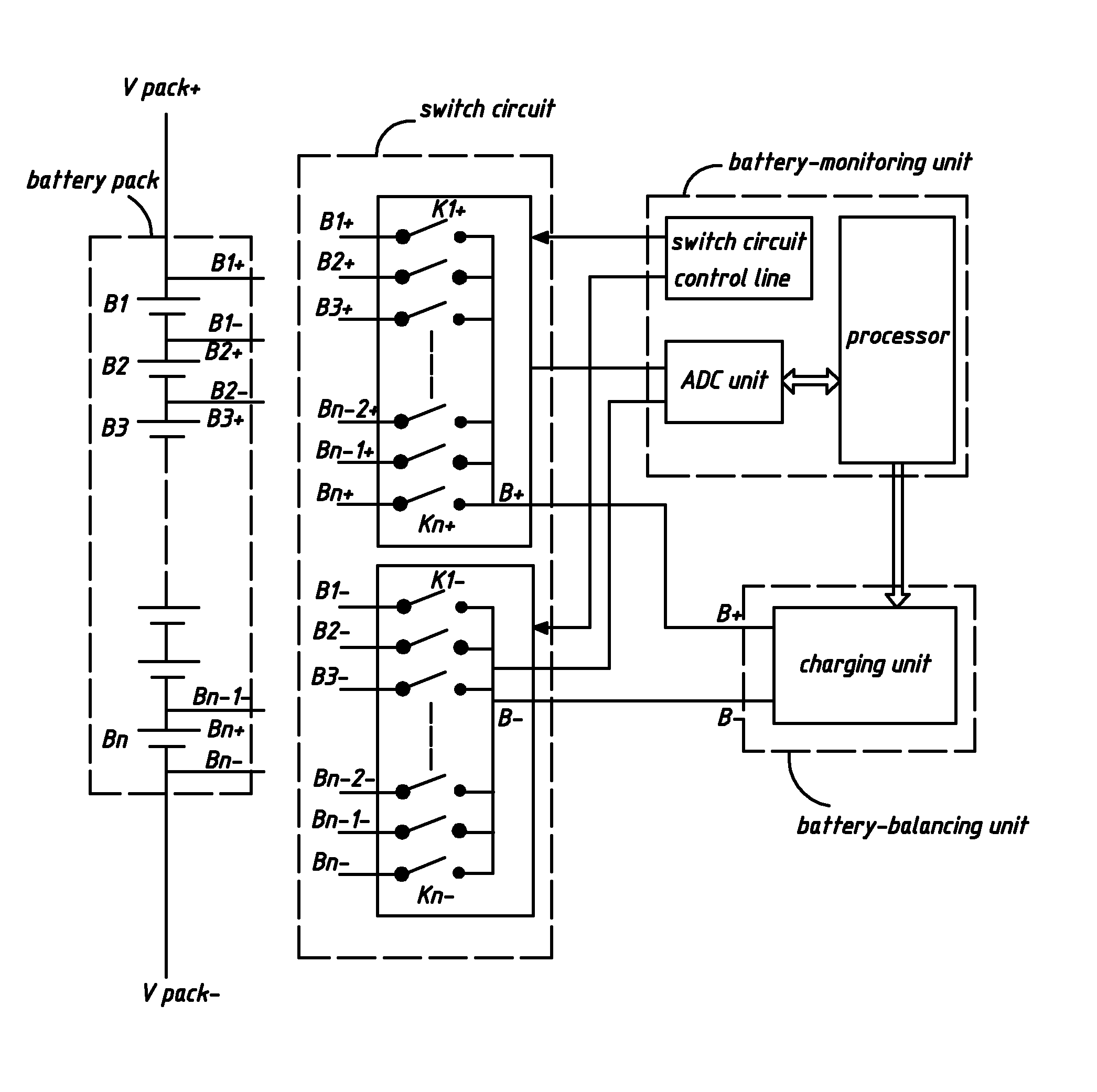

System and method for balancing a battery pack

InactiveUS20110187325A1Improve performanceExtended service lifeCharge equalisation circuitCircuit monitoring/indicationLow voltageEngineering

A system and method for balancing a battery pack is disclosed. The method includes the step of monitoring voltages for all batteries in the battery pack and if the voltages of any two batteries are out of balance, then, issuing a balancing command to charge the battery that is relatively lower in voltage between the two until the voltage of the battery attaining a preset voltage. The battery-pack balancing system includes a battery-monitoring unit and a battery-balancing unit. The battery-monitoring unit monitors the voltage of all the batteries in the battery pack and, when the voltages of any of the two batteries in the battery pack is out of balance, issues a balancing command to charge the battery that is relatively lower voltage in the battery pack.

Owner:LIN PO CHANG +1

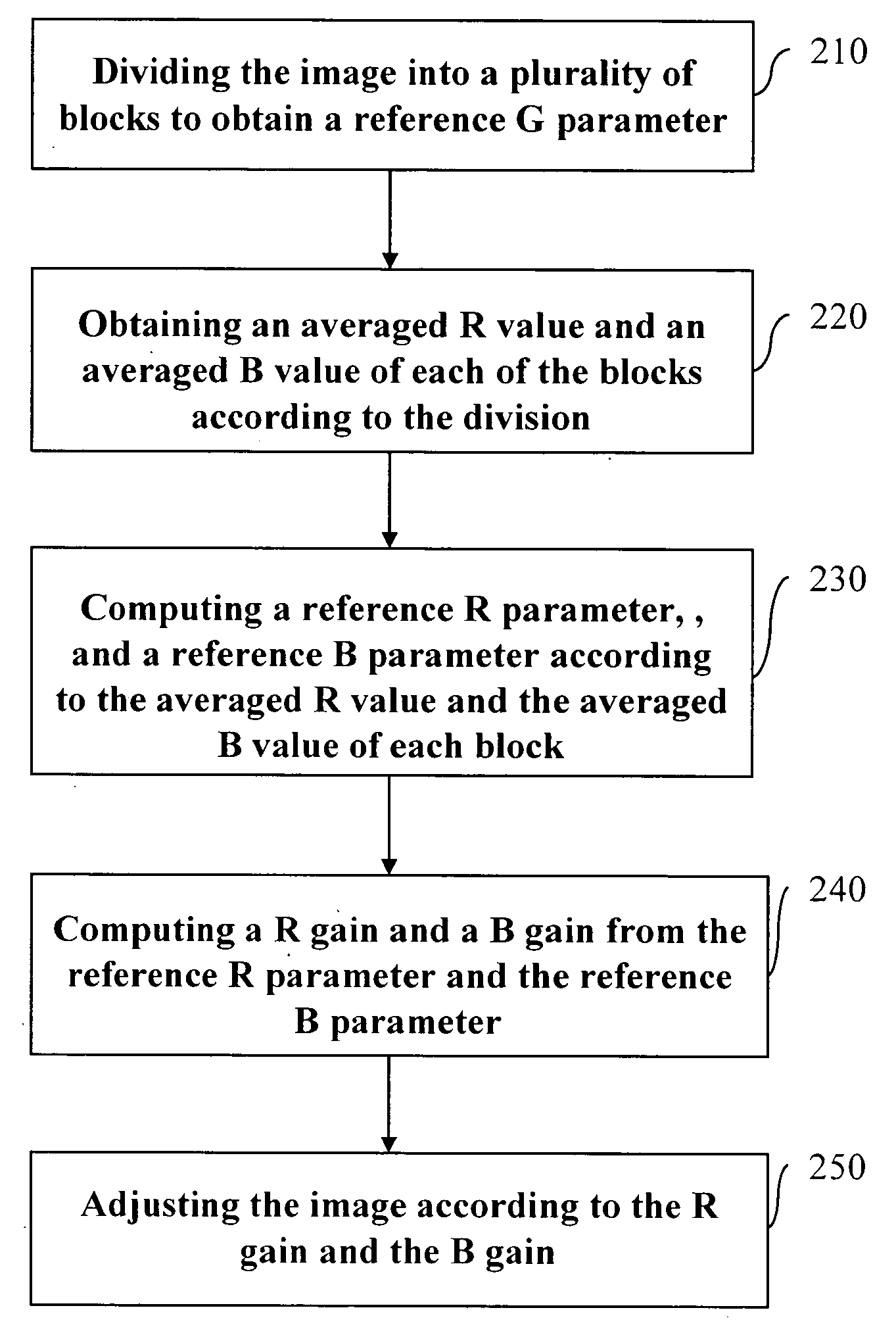

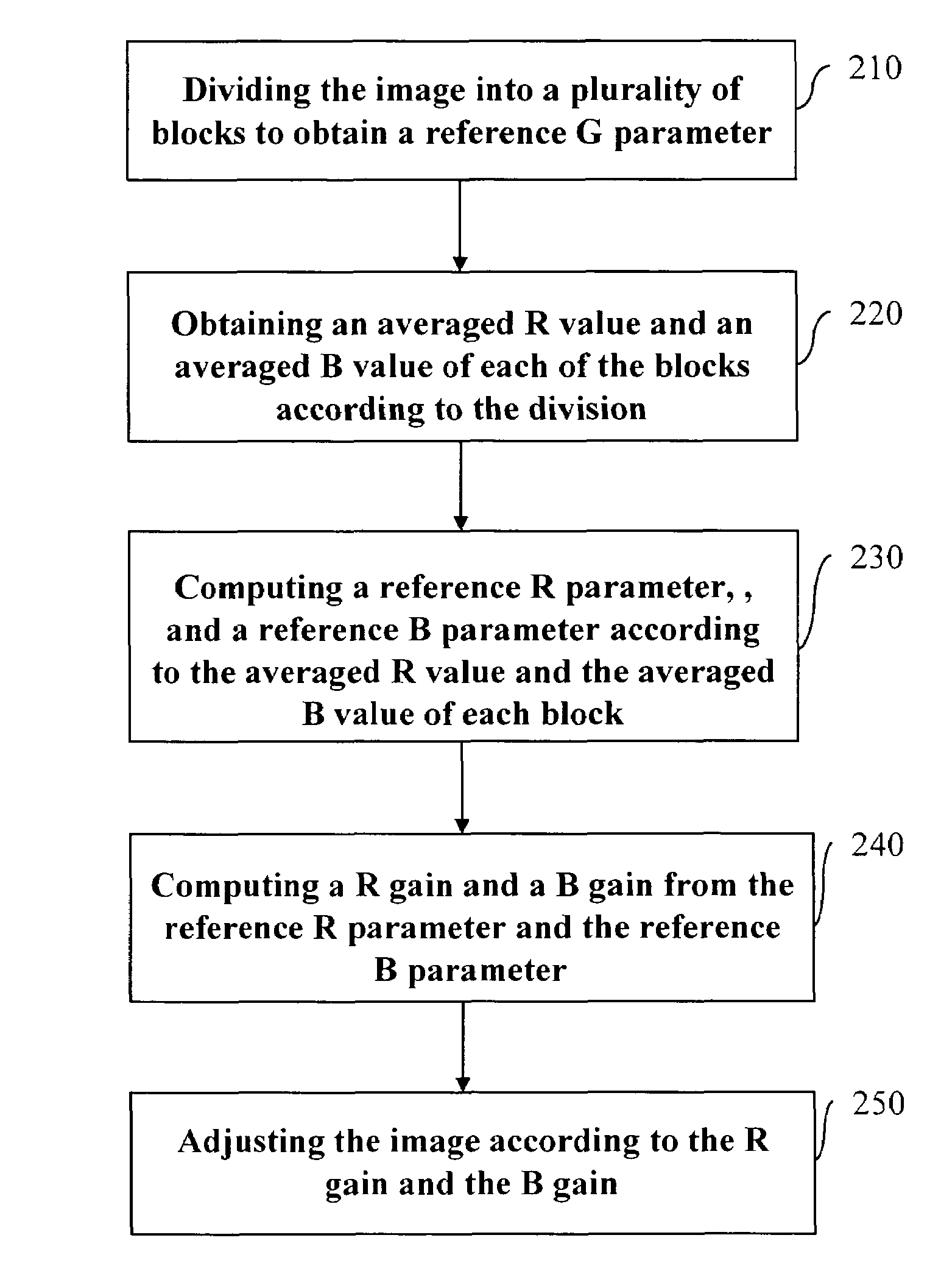

Rapid white balance method for color digital images

InactiveUS20050007463A1Reduce processing timeImprove image qualityTelevision system detailsColor signal processing circuitsDigital imageImage quality

A rapid white balance method for color digital image is disclosed. This method is applied to RGB color regions in an image. First, the image is divided into several blocks to obtain the G parameter, then the averaged R and B parameters of each block, thereby obtaining the R and B parameters of the whole image. Using the R and B parameters, the method obtains an R gain and a B gain. Finally, the image is adjusted. The method only uses one RGB value for each pixel. The processing time is reduced, while the quality of the image is increased.

Owner:PRIMAX ELECTRONICS LTD

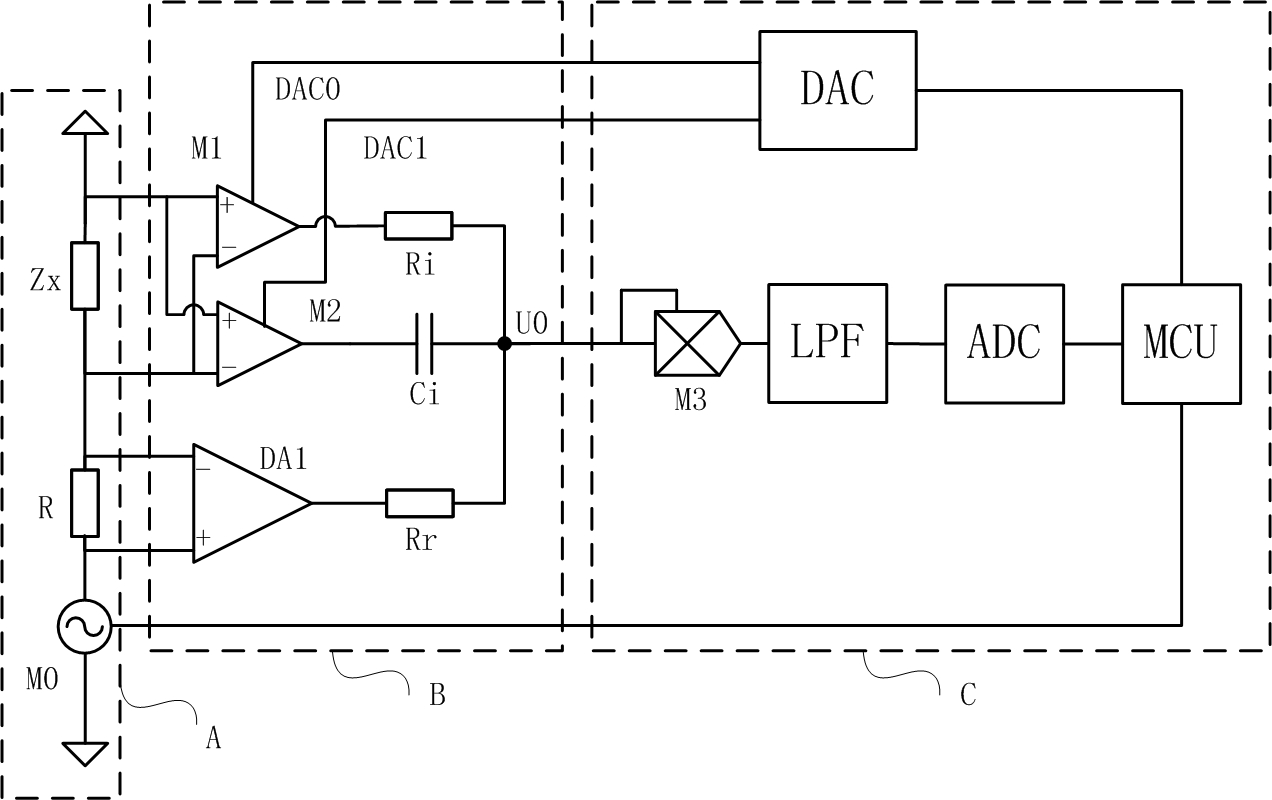

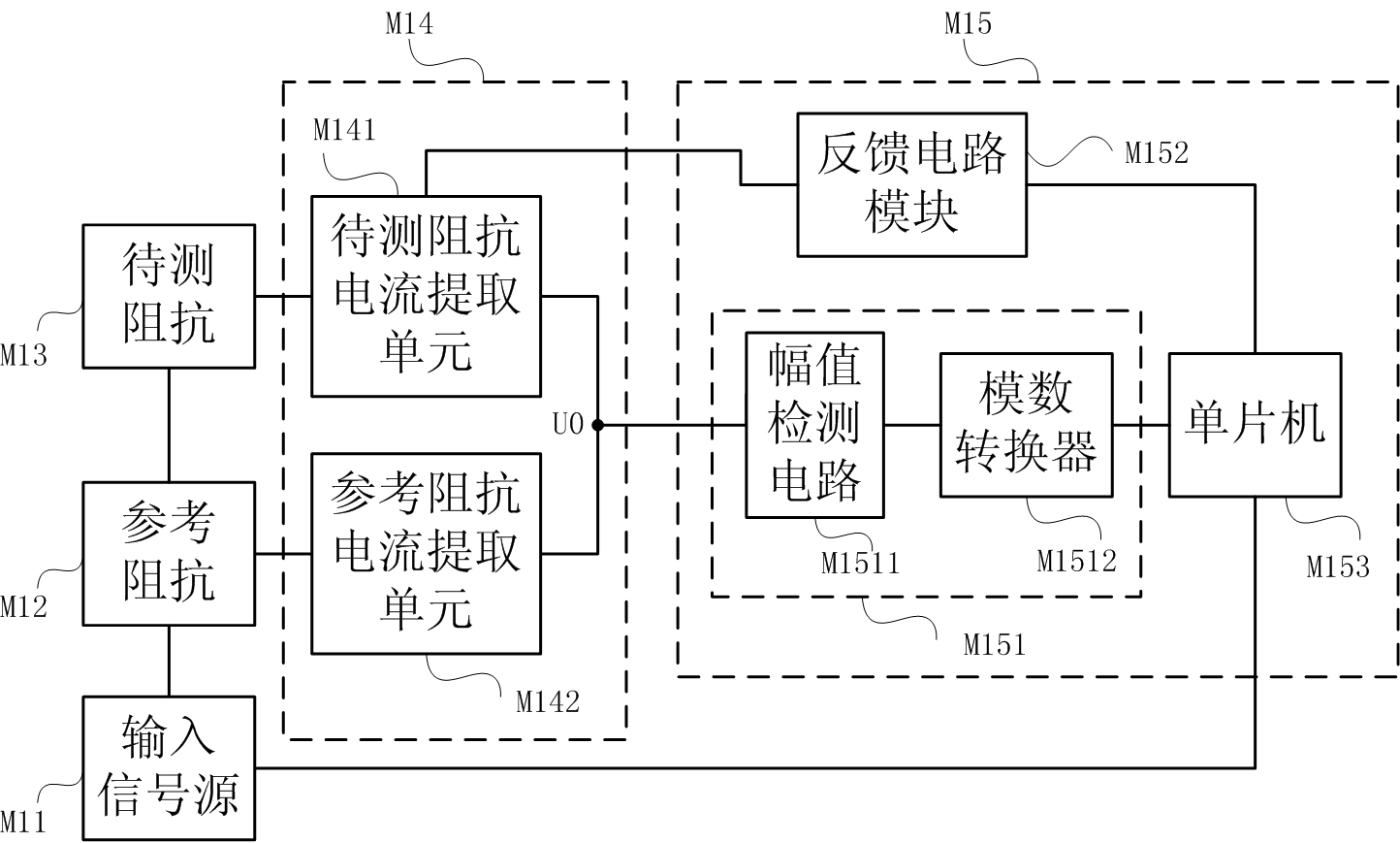

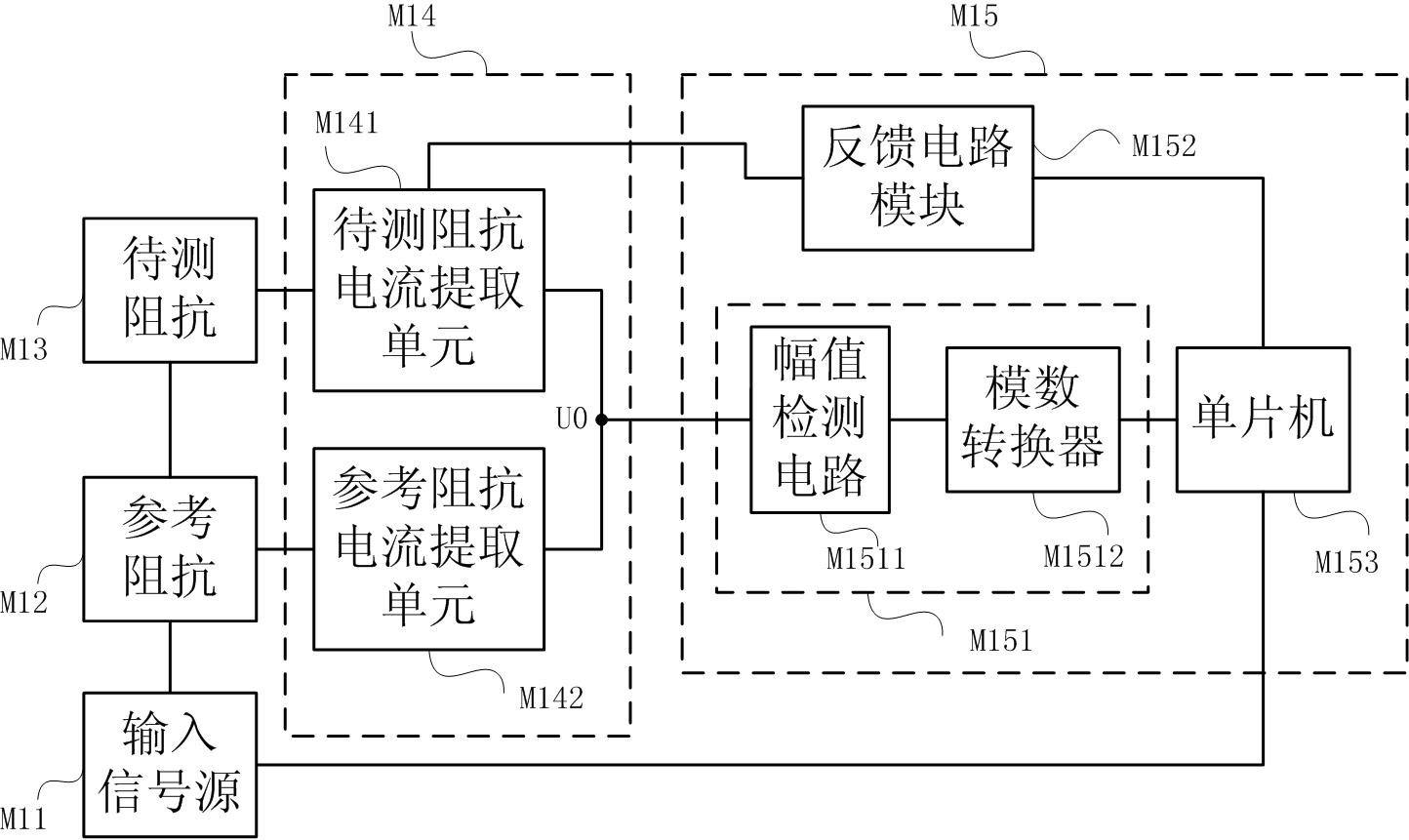

Balanced bridge

InactiveCN102662109ASuitable for different applicationsBalance, stability and fast realizationResistance/reactance/impedenceReference comparisonMicrocomputerMicrocontroller

A balanced bridge comprises an input signal source, a reference impedance, an impedance to be tested, a bridge balancing module and a balance control module. The reference impedance is serially connected with the impedance to be tested and connected with the input signal source and is used for obtaining current vectors. The bridge balancing module comprises a reference impedance current extraction unit and an impedance to be tested current extraction unit and is used for providing bridge output pressure for the balance control module. The reference impedance current extraction unit is coupled to two ends of the reference impedance, the impedance to be tested current extraction unit is coupled to two ends of the impedance to be tested, and an output port of the bridge balancing module is an output port of bridge output pressure. The balance control module comprises a pressure detection module, a feedback circuit module and a single chip microcomputer, wherein one end of the pressure detection module is connected with the output port of bridge output pressure, the other end of the pressure detection module is connected with the single chip microcomputer, the other end of the single chip microcomputer is connected with the feedback circuit module, and the feedback circuit module is coupled to the impedance to be tested current extraction unit.

Owner:SHANGHAI DIANJI UNIV

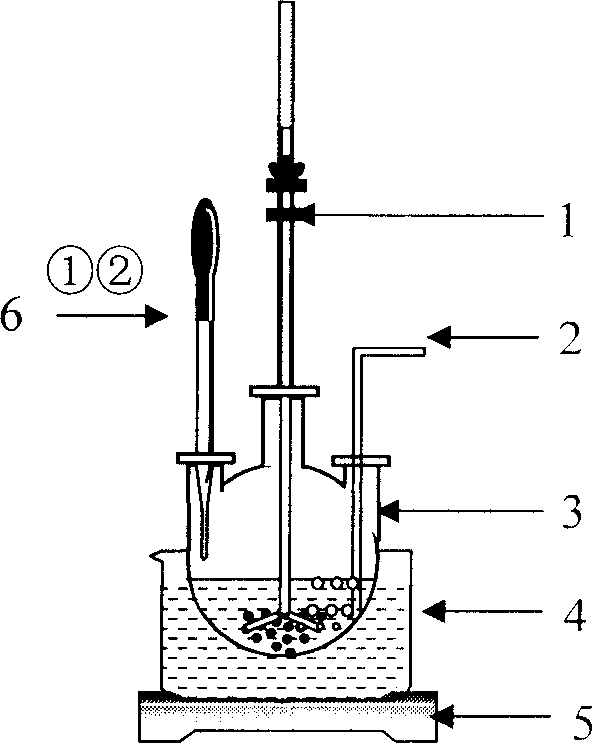

Method for separating boron-10 isotopic element using reducing tower

InactiveCN101502758AIncreased chance of convective exposureIncrease exposureIsotope separationFractional distillationRefluxGas phase

The invention discloses a method for separating boron-10 isotopes by a reducing tower. Chemical exchange distillation is carried out on complex compound of boron triflouride by three rectifying towers which have the same height and progressively decreased diameters and are connected with each other in series; the operating condition of each rectifying tower is that the vacuum degree of the tower system is 20-200mmHg, the temperature at the top of the towers is 50-100DEG C, the temperature of a still is 60-120DEG C, the reflux ratio is 400-150:1. The rectifying towers with progressively decreased diameters directly change the flow of liquid phase and gas phase, effectively increase chances of convection contact between the liquid phase and the gas phase, increase the speed so that the system achieves balance in 72-75 hours, and increase the separation efficiency of products simultaneously, the abundance ratio of boron-10 in the final product is up to 90%. The invention has the advantages of simple structure, easy operation, rapid speed for achieving balance, high separation efficiency and little energy consumption.

Owner:DALIAN TAIRUI CHEM IND

Rapid white balance method for color digital images

InactiveUS7126644B2Fast balanceQuality improvementColor signal processing circuitsDigital imageImage quality

A rapid white balance method for color digital image is disclosed. This method is applied to RGB color regions in an image. First, the image is divided into several blocks to obtain the G parameter, then the averaged R and B parameters of each block, thereby obtaining the R and B parameters of the whole image. Using the R and B parameters, the method obtains an R gain and a B gain. Finally, the image is adjusted. The method only uses one RGB value for each pixel. The processing time is reduced, while the quality of the image is increased.

Owner:PRIMAX ELECTRONICS LTD

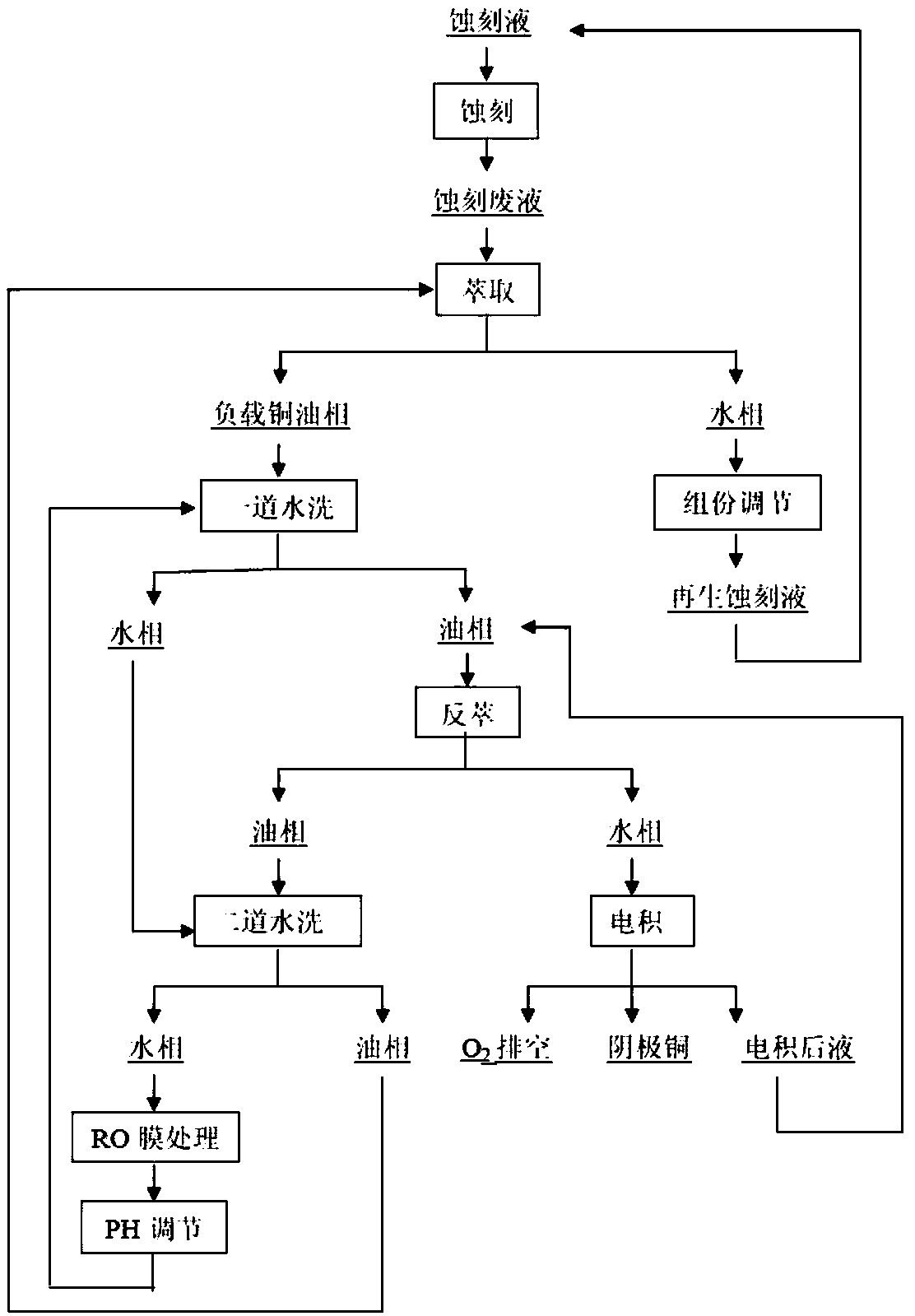

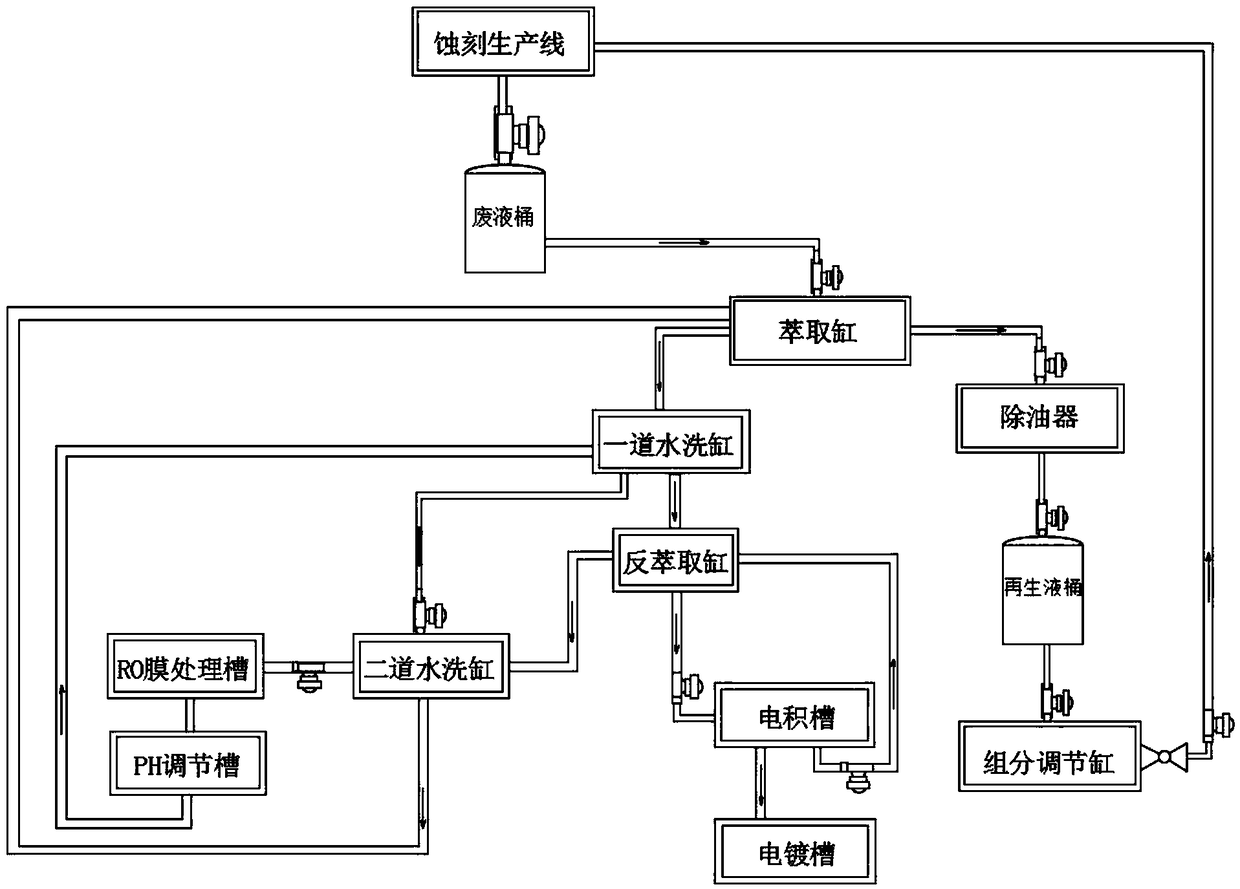

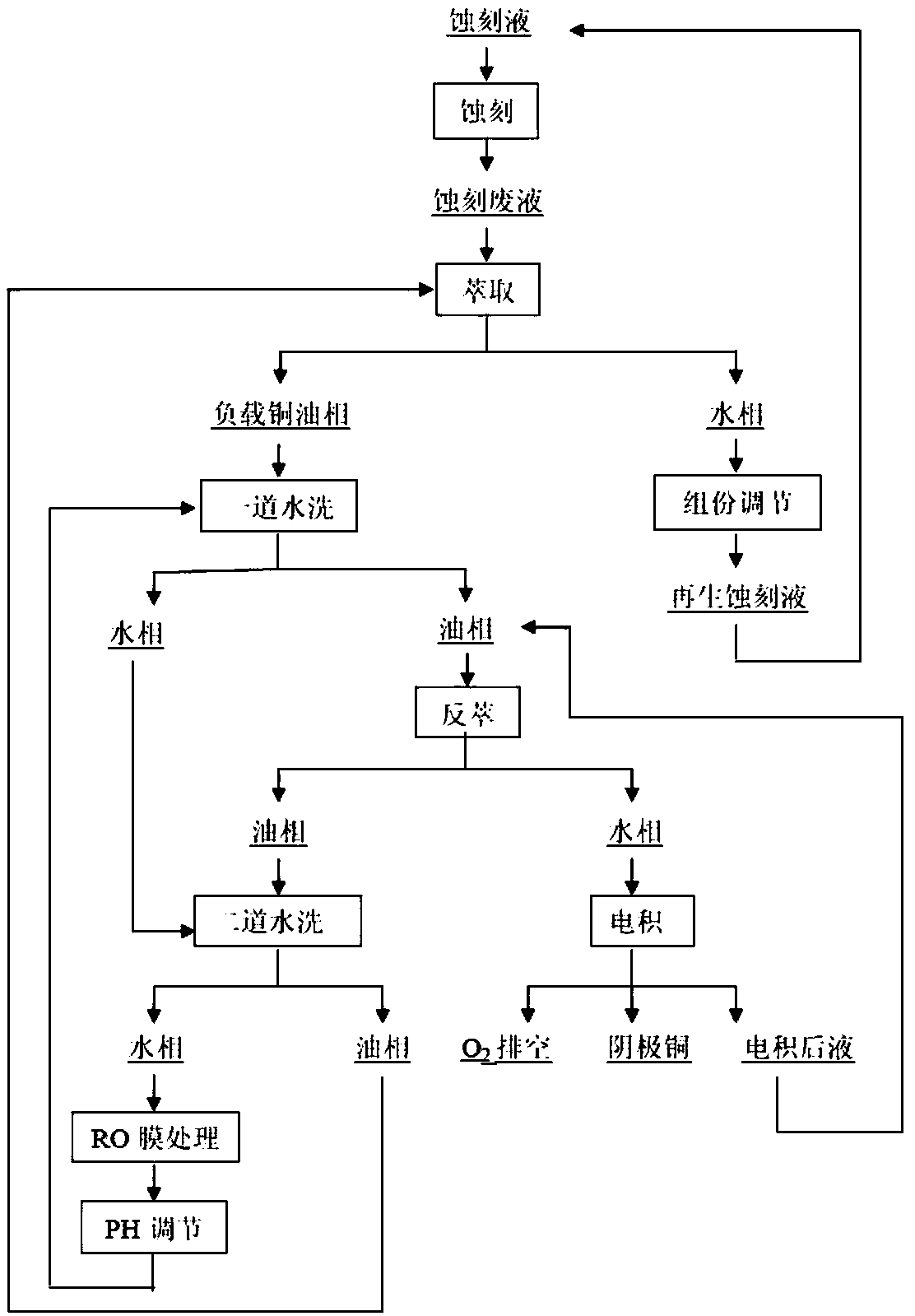

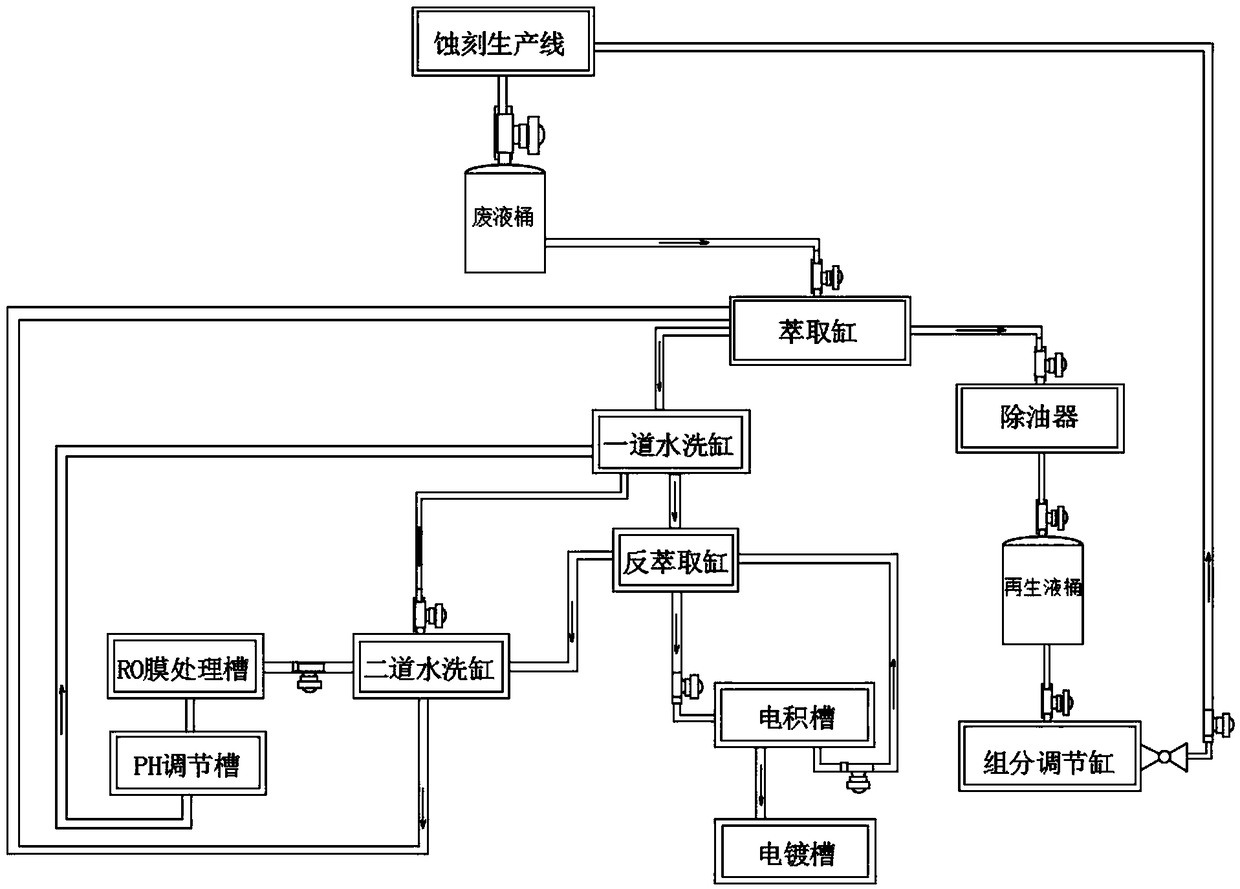

Alkaline etching solution circulation regeneration system and method thereof

InactiveCN108914129ARealize closed loopThe process can be continuously automatedLiquid wasteProduction line

The invention discloses an alkaline etching solution circulation regeneration method. The method comprises the following steps that (1) etching waste liquid is produced; (2) extracting is conducted, the etching waste liquid is mixed with an extraction agent, copper ions are separated from the etching waste liquid, a copper-loaded oil phase is formed, and regeneration liquid is stored in a regeneration liquid barrel; (3) components are adjust, and tests of Cu<2+>, NH4<+>, Cl<-> and PH value are conducted on the regeneration liquid, amount of ammonia and ammonium chloride needed to be added is determined according to the test results so as to make the regeneration liquid flow back to an etching production line; (4) first water washing is carried out, and the copper-loaded oil phase is subjected to the first water washing to separate a aqueous phase from the copper-loaded oil phase; (5) back extracting is conducted, the copper-loaded oil phase is transferred into back-extraction liquid, the loaded extraction agent in the copper-loaded oil phase contact with and reacts with H2SO4 solution, so that the copper ions are separated from the extraction agent, and a CuSO4 solution is generated to enter the aqueous phase; and (6) electrodeposition is conducted, the CuSO4 solution is added into an electrolyte, the CuSO4 solution is subjected to electrolysis by the electrolyte, crude copperis deposited by a cathode, the anode generates oxygen, and the CuSO4 solution after electrodeposition is returned to a back-extraction cylinder.

Owner:德雅(深圳)环境科技有限公司

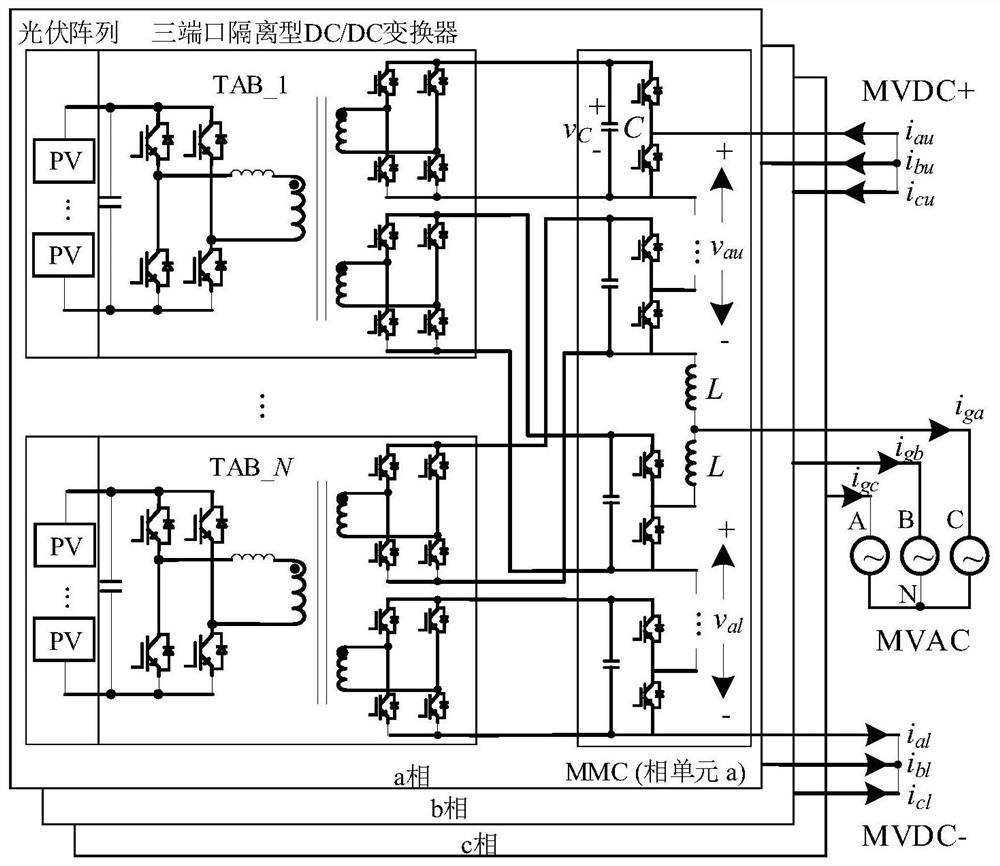

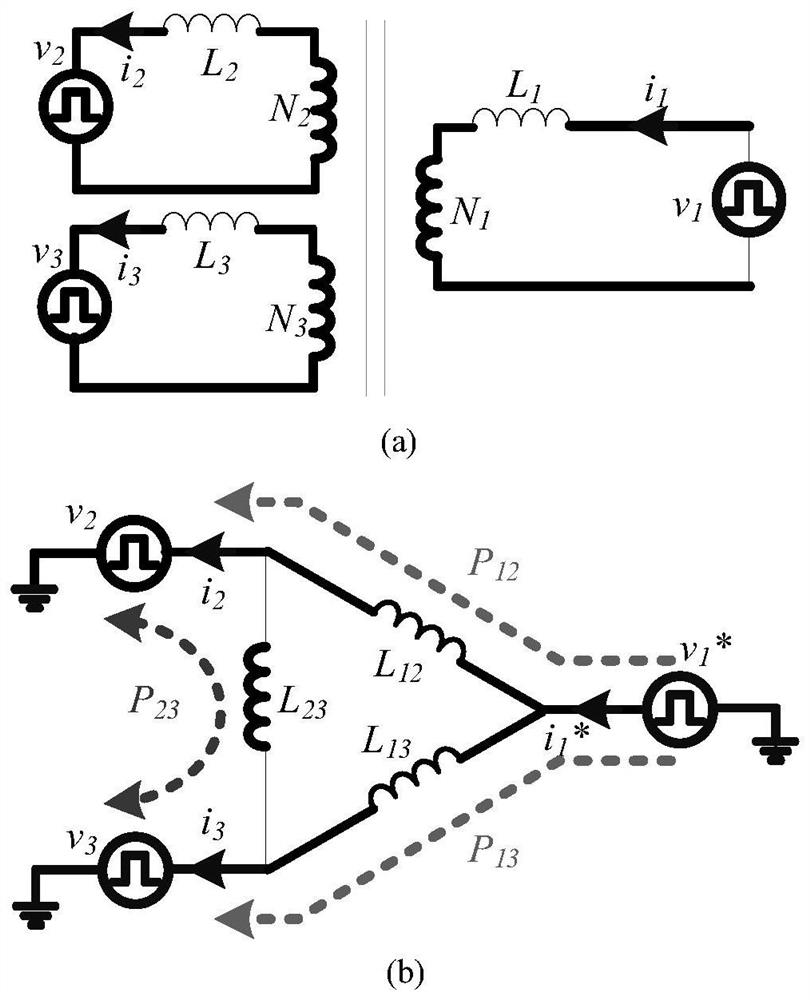

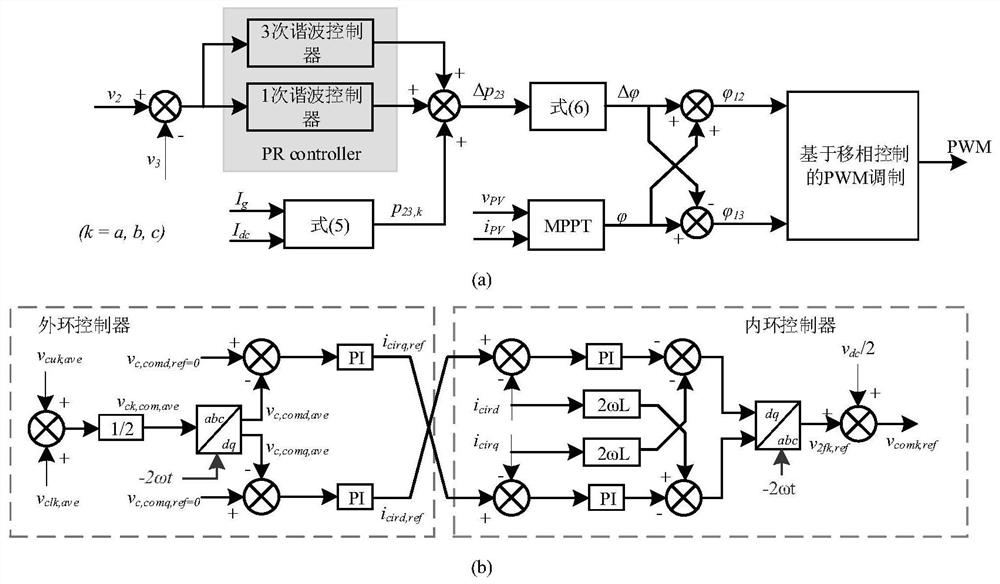

Novel modularized photovoltaic grid-connected system based on three-port power channel and control method

ActiveCN113078674AAvoiding the problem of local power maximaImplement redundant controlDc-dc conversionSingle network parallel feeding arrangementsCapacitanceTransformer

The invention discloses a novel modularized photovoltaic grid-connected system based on a three-port power channel and a control method. The system comprises a front-stage three-port isolation type DC / DC photovoltaic converter, a rear-stage three-phase half-bridge cascade MMC and a combination thereof. The front-stage three-port DC / DC converter adopts a three-winding high-frequency transformer for isolation, an input port is connected with a photovoltaic array, and two output ports are respectively connected to two sub-modules of upper and lower bridge arms of each phase unit of the MMC. The half-bridge cascade structure of the MMC enables the output voltage to be the superposition of the output voltage of each sub-module, and the output current harmonic wave is greatly reduced through carrier phase-shifting modulation, so that the MMC can be directly connected with a medium-voltage AC power grid and a medium-voltage DC power grid. According to the topology, through power decoupling control, the capacity of a power decoupling capacitor can be reduced by dozens of times, and the size of a system is greatly reduced. In addition, the photovoltaic power among the topological phase units is balanced in the form of direct-current circulating current through a direct-current link, so that the problem of mismatch of the photovoltaic power is well solved.

Owner:WUHAN UNIV

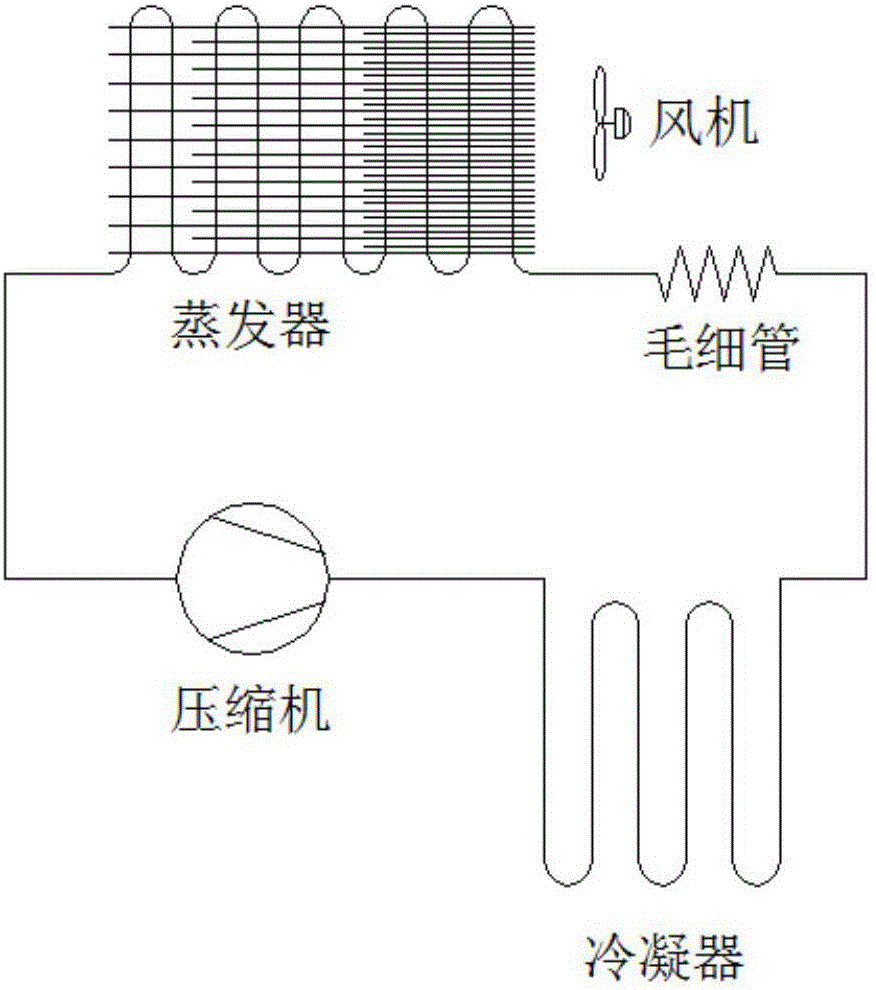

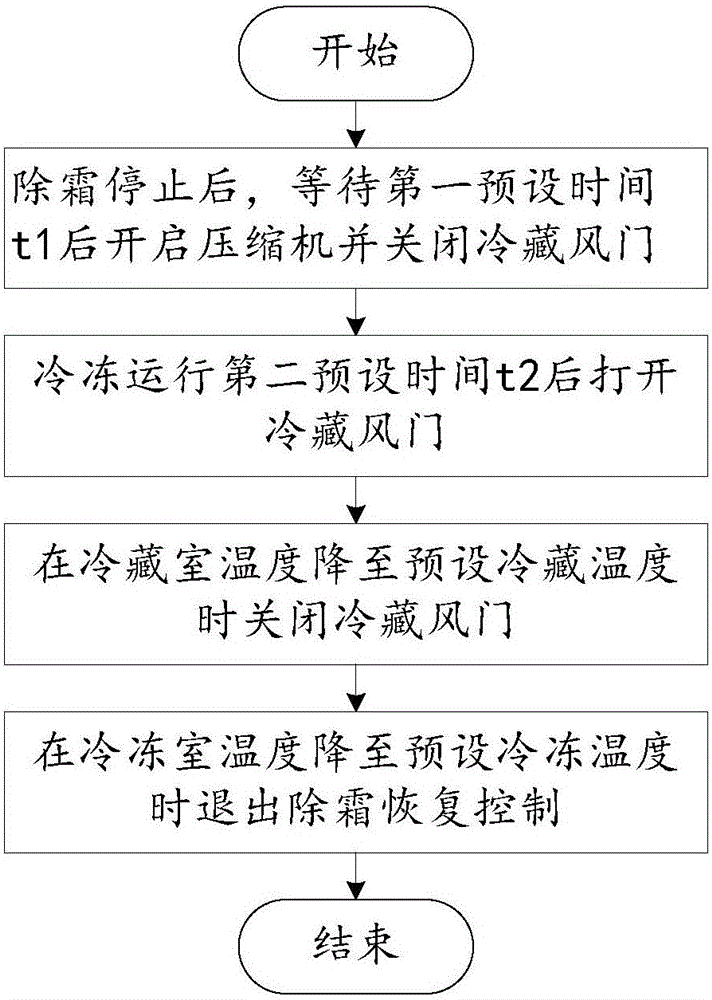

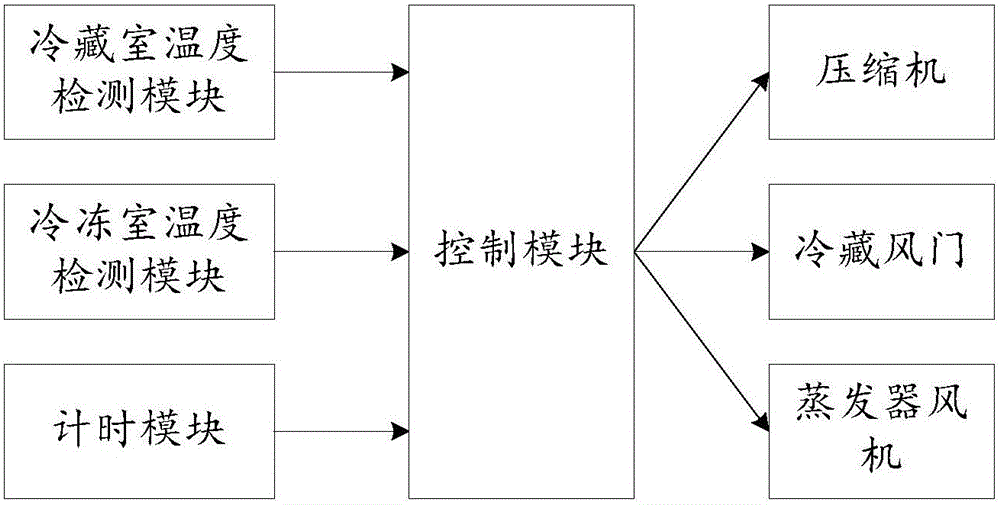

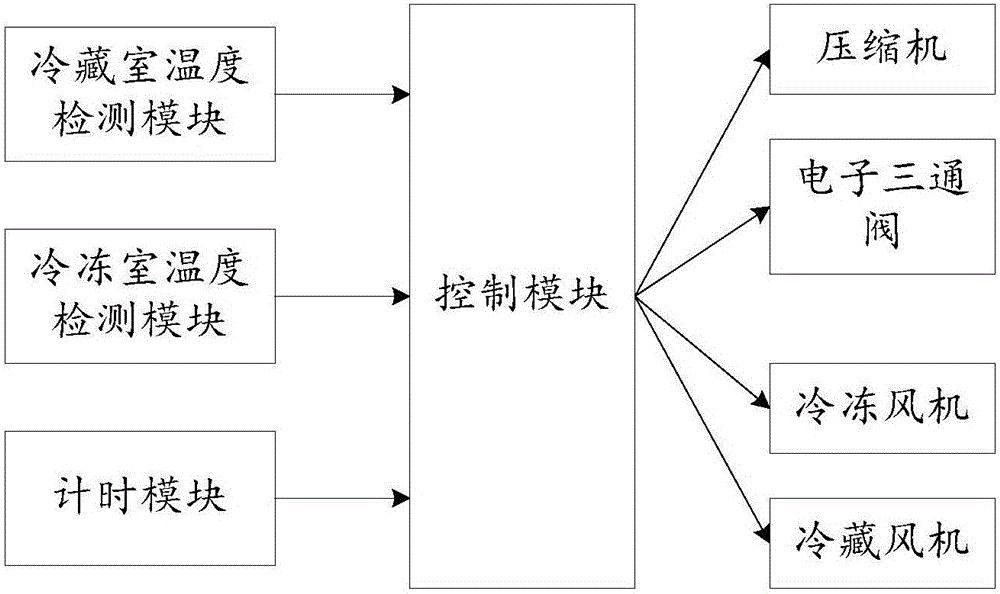

Single-system air-cooling refrigerator defrosting recovery period control method and system and refrigerator

InactiveCN106016954ATo achieve the purpose of running time-sharing controlTo achieve the purpose of time-sharing controlLighting and heating apparatusCooling fluid circulationTemperature controlRecovery period

The invention relates to a single-system air-cooling refrigerator defrosting recovery period control method and system and a refrigerator. The method comprises the following steps: starting a compressor and closing a refrigeration air door a first preset time t1 later after defrosting stops; opening the refrigeration air door after a second preset time t2 of refrigeration; when the temperature of a refrigeration chamber is lowered to a preset refrigeration temperature, closing the refrigeration air door; and when the temperature of a freezing chamber is lowered to a preset freezing temperature, stopping defrosting recovery control. According to the invention, the purpose of time-sharing control of refrigeration and freezing is achieved by controlling the opening / closing state of the refrigeration air door after defrosting; and after time control is over, both the refrigeration chamber and the freezing chamber are finally enabled to reach the preset temperatures by controlling the opening / closing state of the refrigeration air door. Through the control method provided by the invention, the defrosting recovery period is effectively shortened, power consumption in the defrosting recovery period is reduced, and refrigeration and freezing are recovered as soon as possible to a normal stable operation state.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

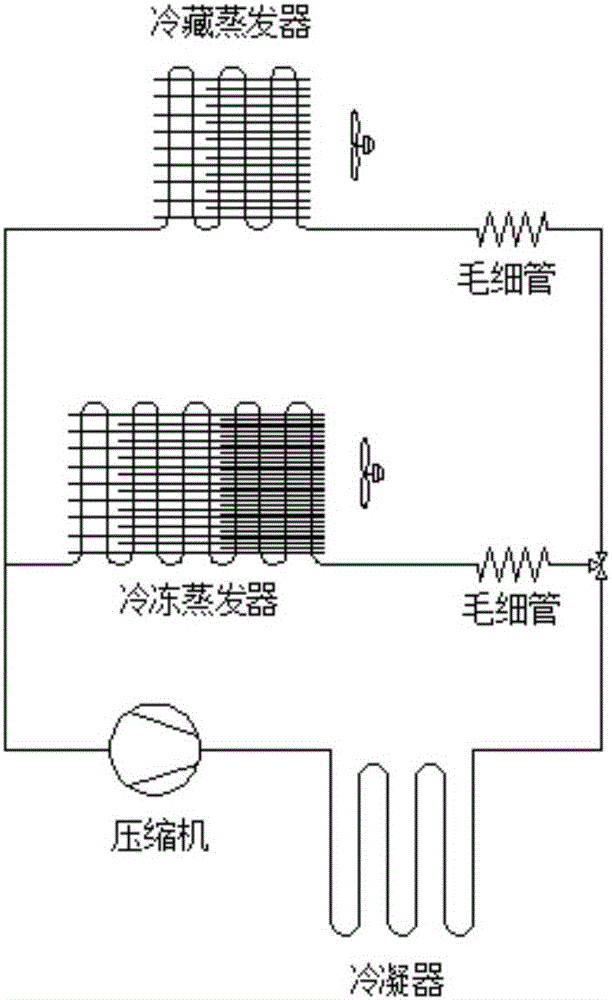

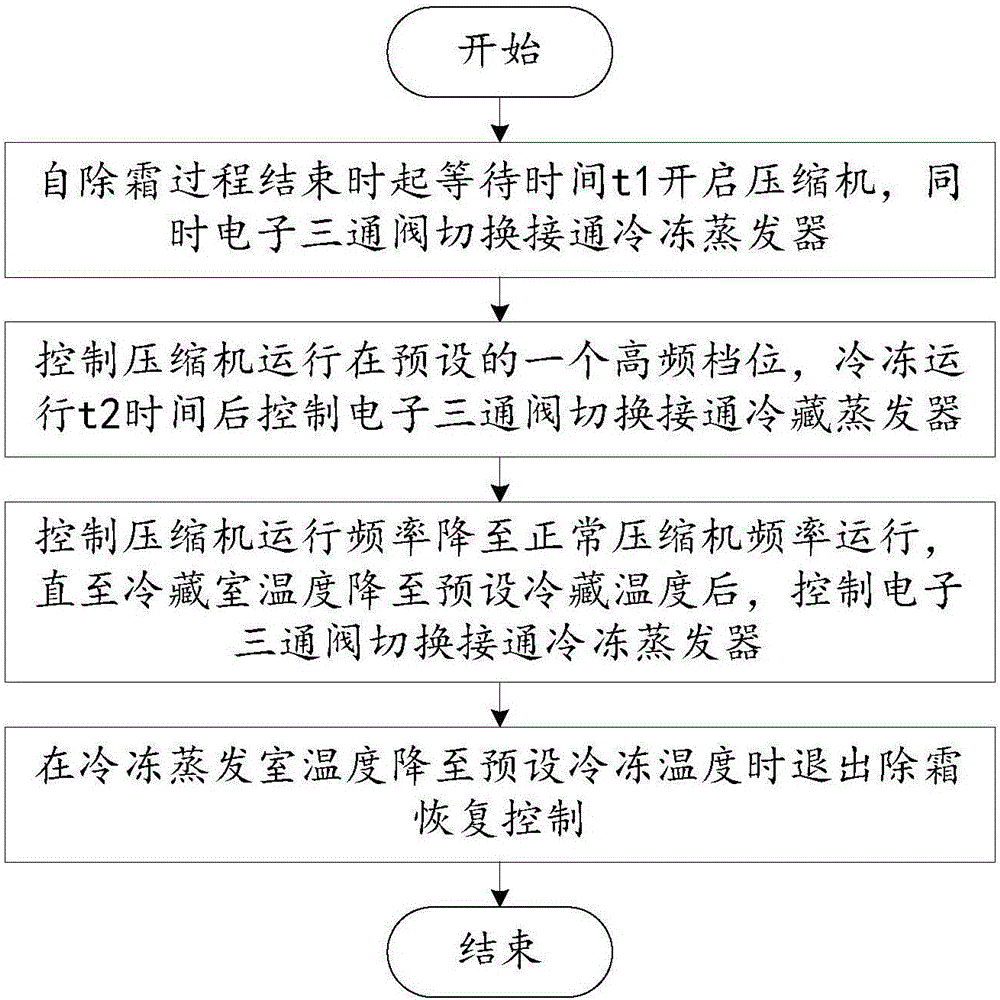

Control method and system for dual system refrigerator and dual system refrigerator

ActiveCN106123478AShorten defrost cycle timeSpend less timeLighting and heating apparatusDomestic refrigeratorsTime controlControl theory

The invention relates to the technical field of refrigerators, in particular to a control method and system for a dual system refrigerator and the dual system refrigerator. The control method for the dual system refrigerator comprises the steps that after the defrosting process is completed, high-frequency operation freezing time control is conducted firstly, and then low-frequency operation temperature control is conducted. According to the control method for the dual system refrigerator, the defrosting recovery phase duration can be shortened, power consumption in the recovery phase can be reduced, and the refrigerating and freezing modes are rapidly recovered to the normal and stable operation states.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

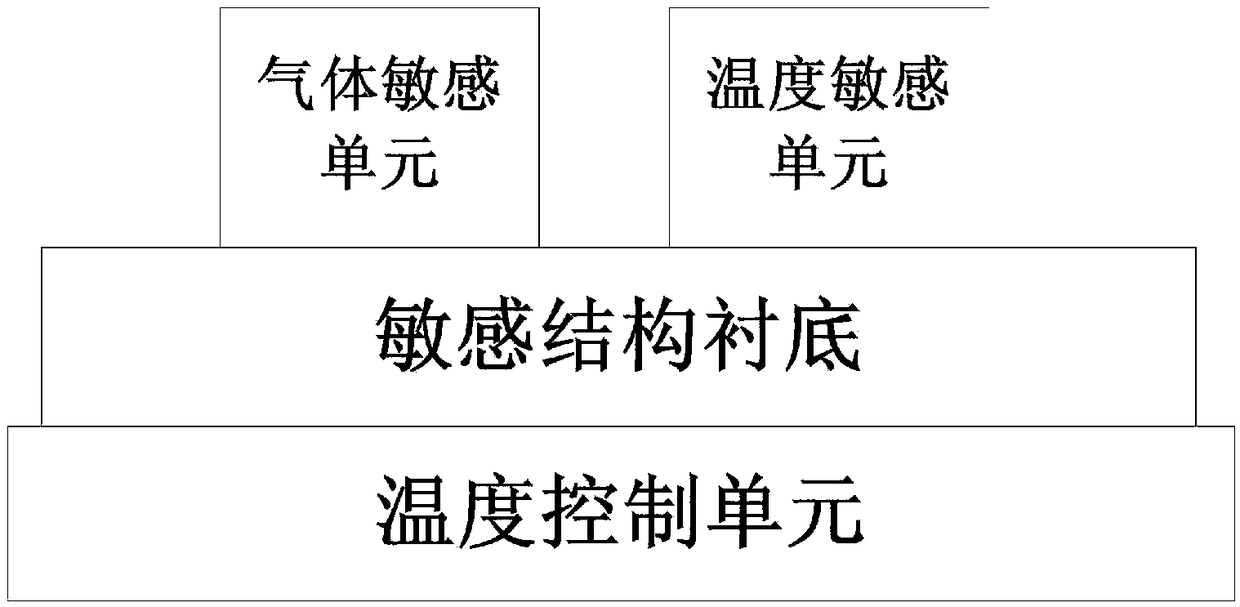

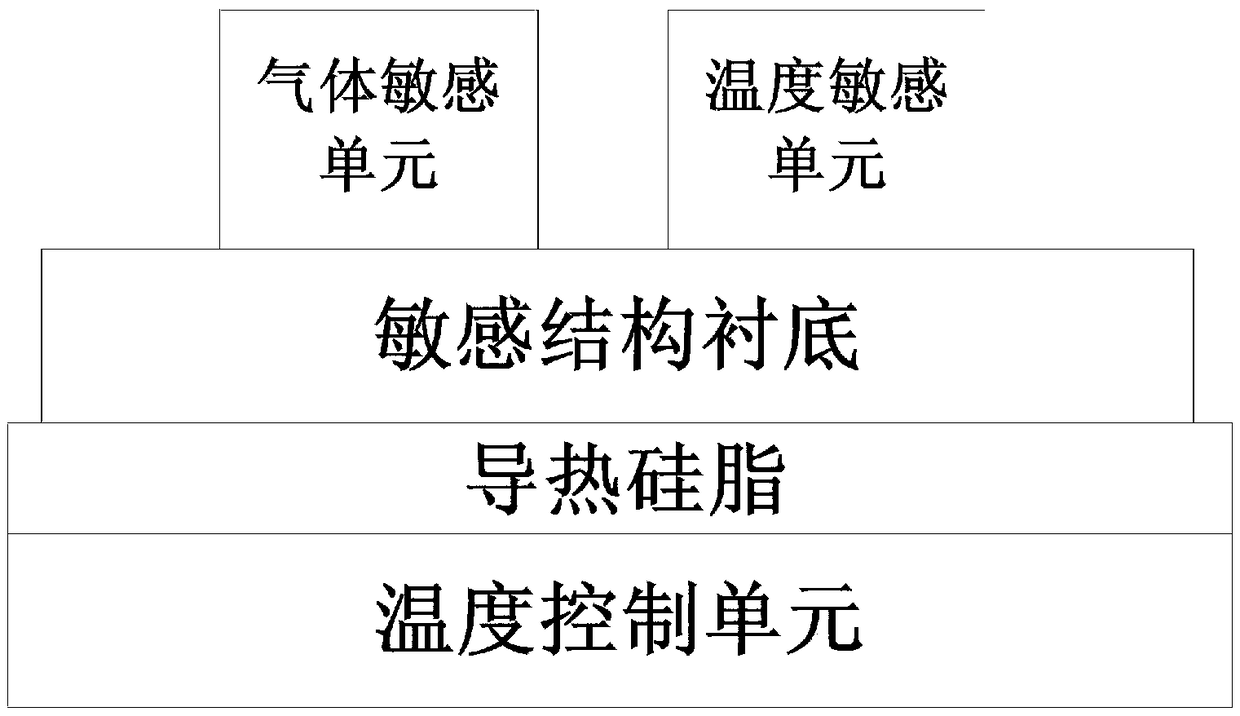

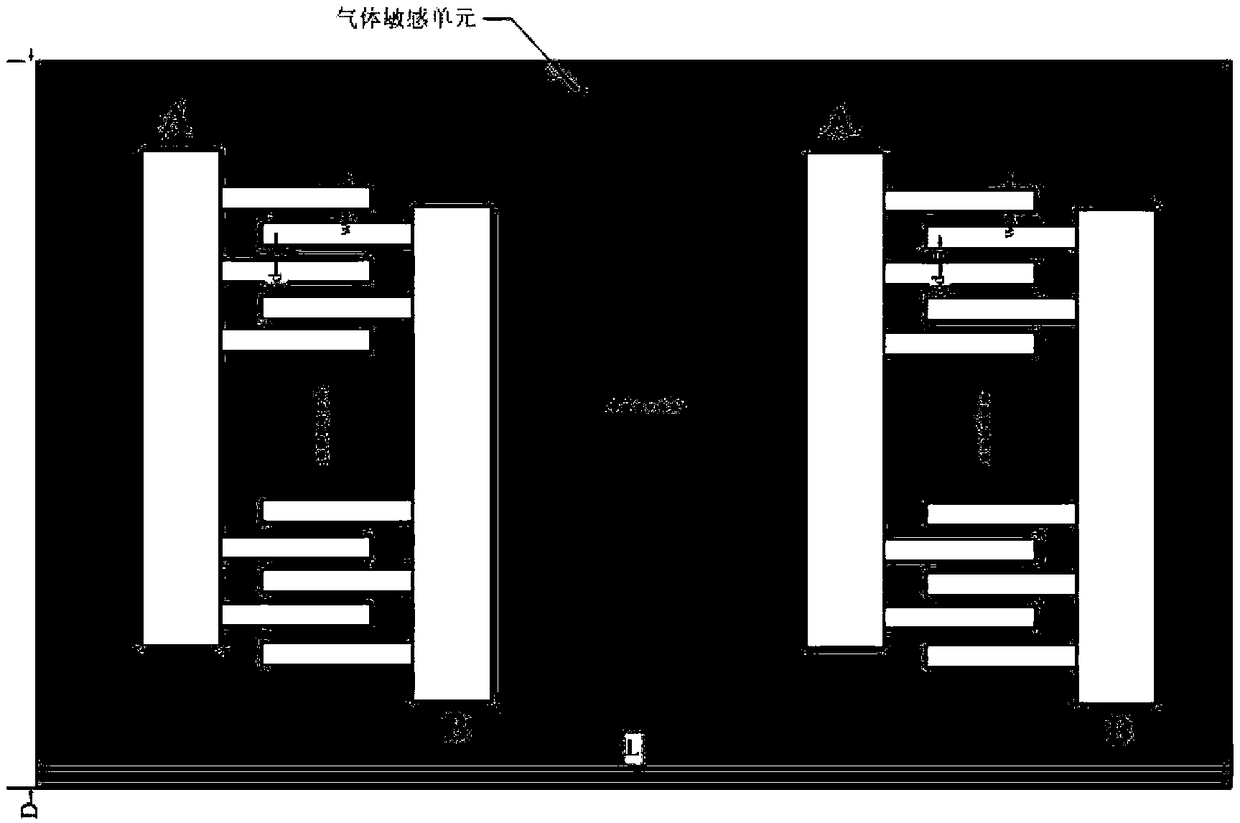

MEMS gas sensor chip and sensor and preparation method of sensor

ActiveCN108844652AShort delivery pathFast balanceTemperatue controlThermometers using electric/magnetic elementsMOSFETTemperature control

The invention relates to an MEMS gas sensor chip and sensor and a preparation method of the sensor, belongs to the technical field of gas detection, and solves the problems of high technical cost, long response time and low environment stability in the prior art. The MEMS gas sensor chip comprises a gas sensitive unit, a temperature sensitive unit, a sensitive structure substrate and a temperaturecontrol unit. The MEMS gas sensor comprises the MEMS gas sensor chip and a control circuit, and the control circuit further comprises a microcontroller, an N type MOSFET, a P type MOSFET and a positive-negative power supply. The microcontroller compares a practical temperature collected by the temperature sensitive unit with a preset temperature, outputs a control signal according to a comparisonresult, controls ON / OFF of the N type MOSFET and the P type MOSFET, and further controls the direction and magnitude of a current through the temperature control unit and changes the surface temperature of the sensitive structure substrate. The MEMS gas sensor is simple in operation and high in versatility, can measure the concentration of different gases simultaneously, saves the cost, and is short in response time and high in environment stability.

Owner:BEIJING MECHANICAL EQUIP INST

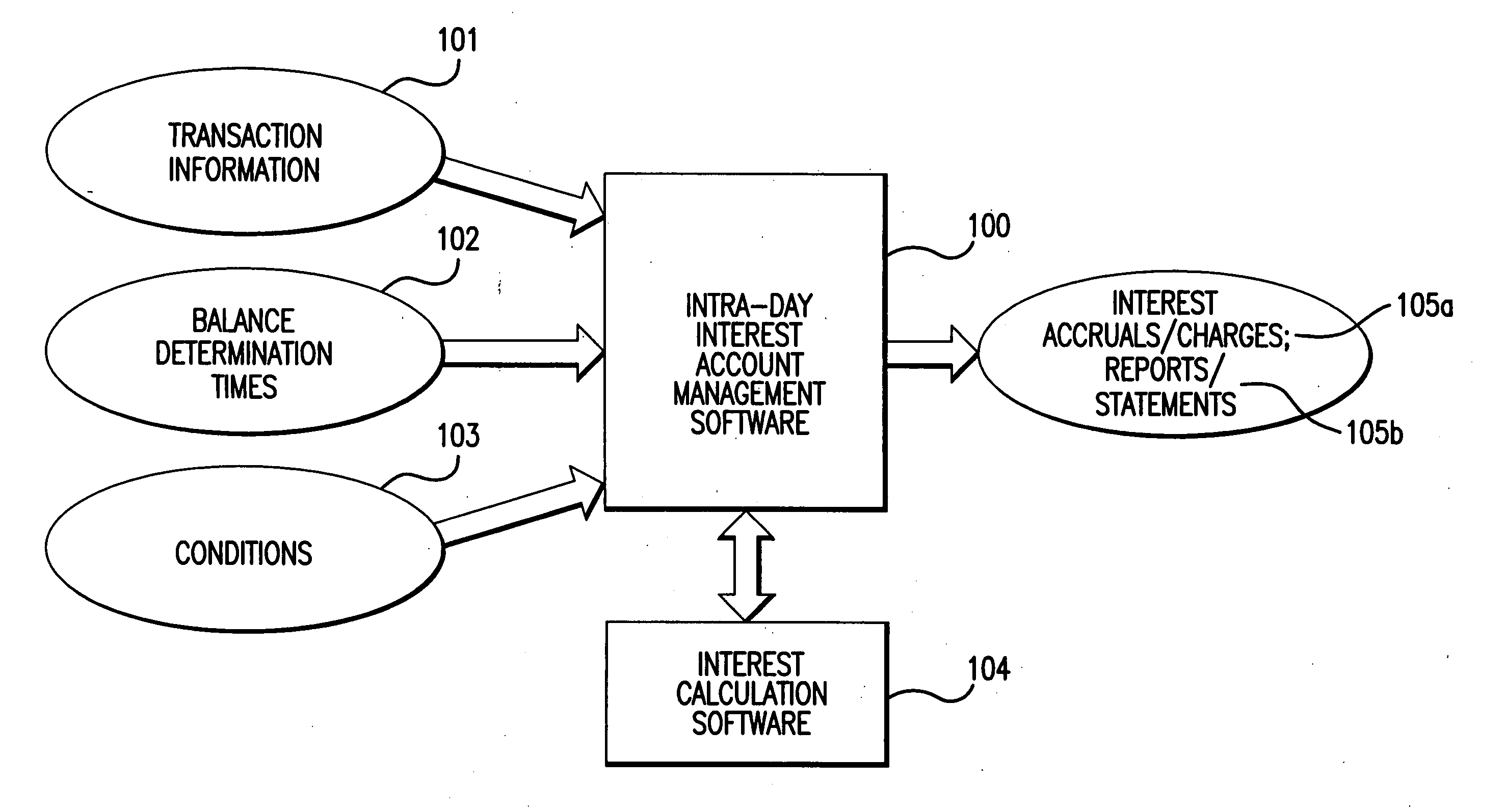

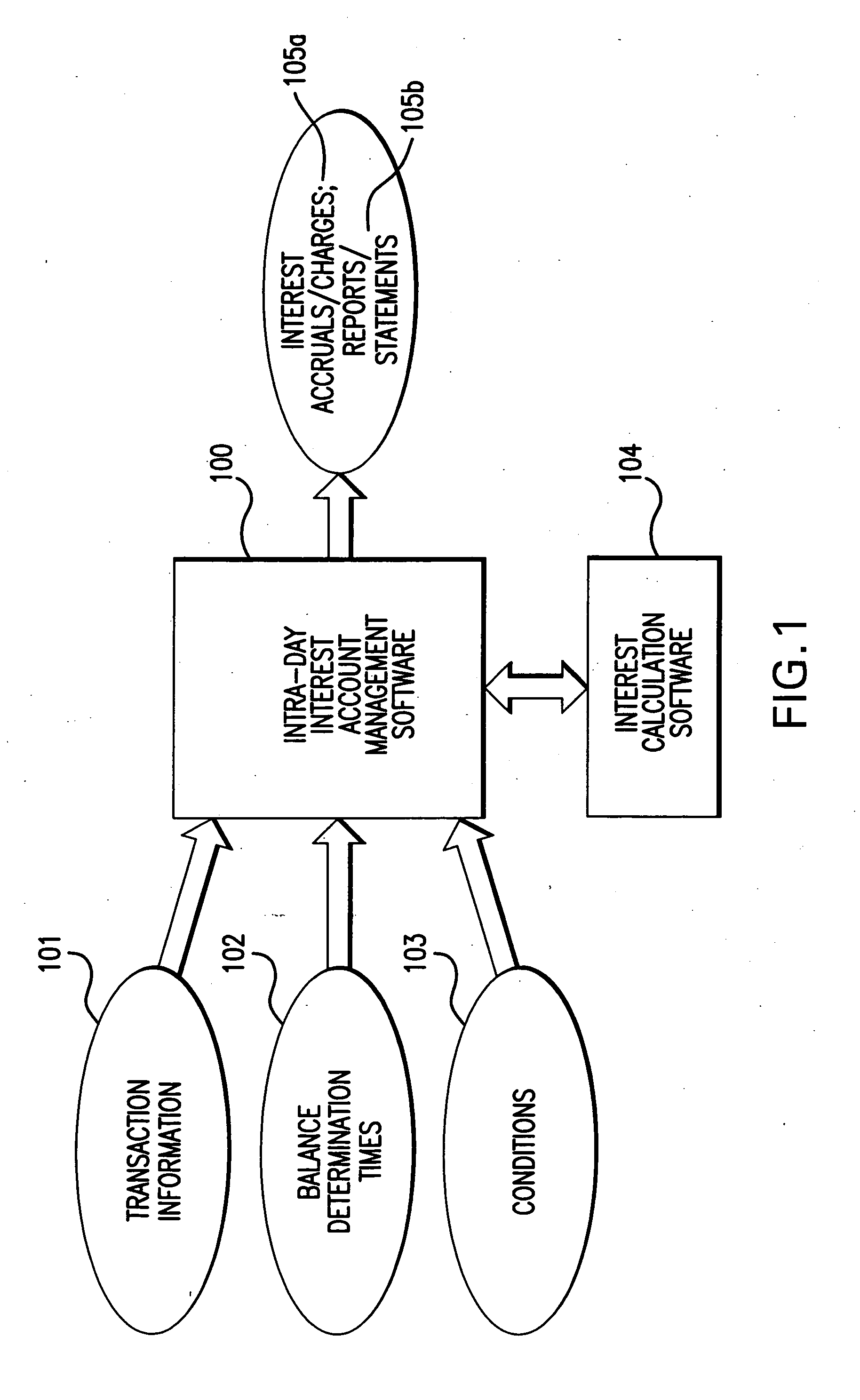

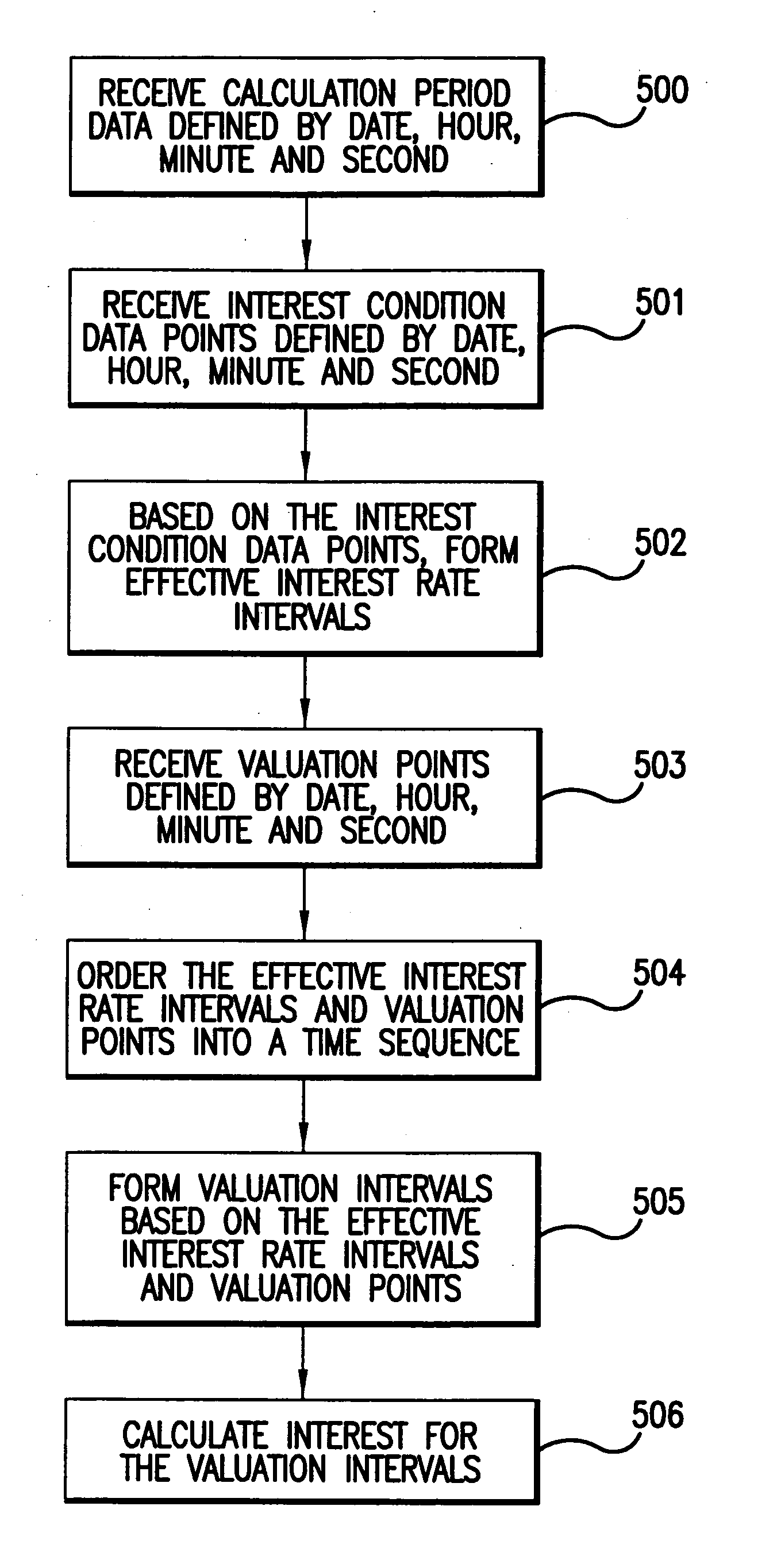

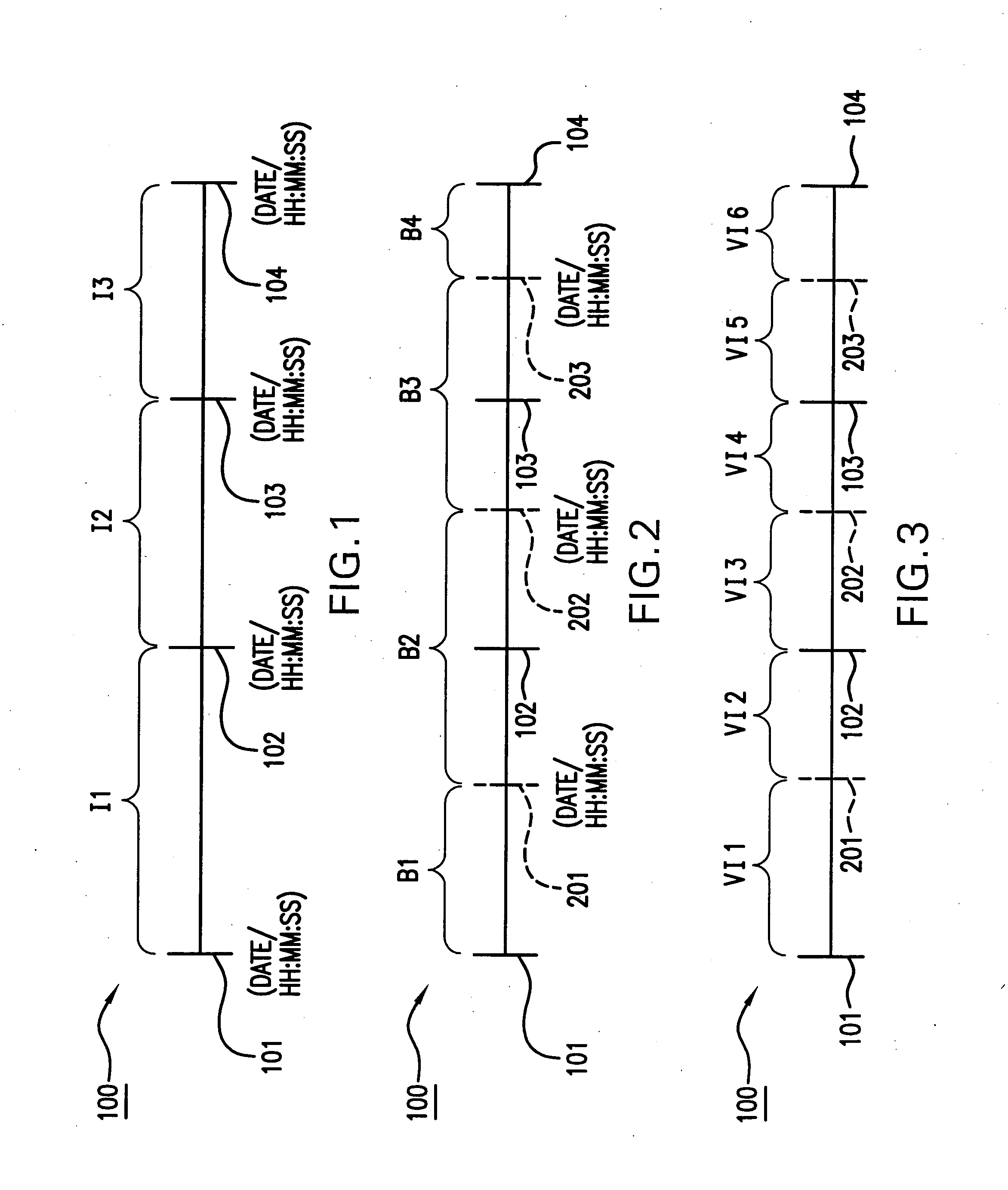

Management of intra-day interest calculations for bank accounts

ActiveUS20050080694A1Good precisionRapid in account balanceFinancePayment architectureBank accountSimulation

Embodiments of the present invention relate to a computer-implemented method and system for managing intra-day interest calculation on a bank account. The embodiments provide for control of and support for interest calculations that, instead of being based on daily end-of-day account balances, are based on a plurality of net account balances as determined for a plurality of points in time within a day.

Owner:SAP AG

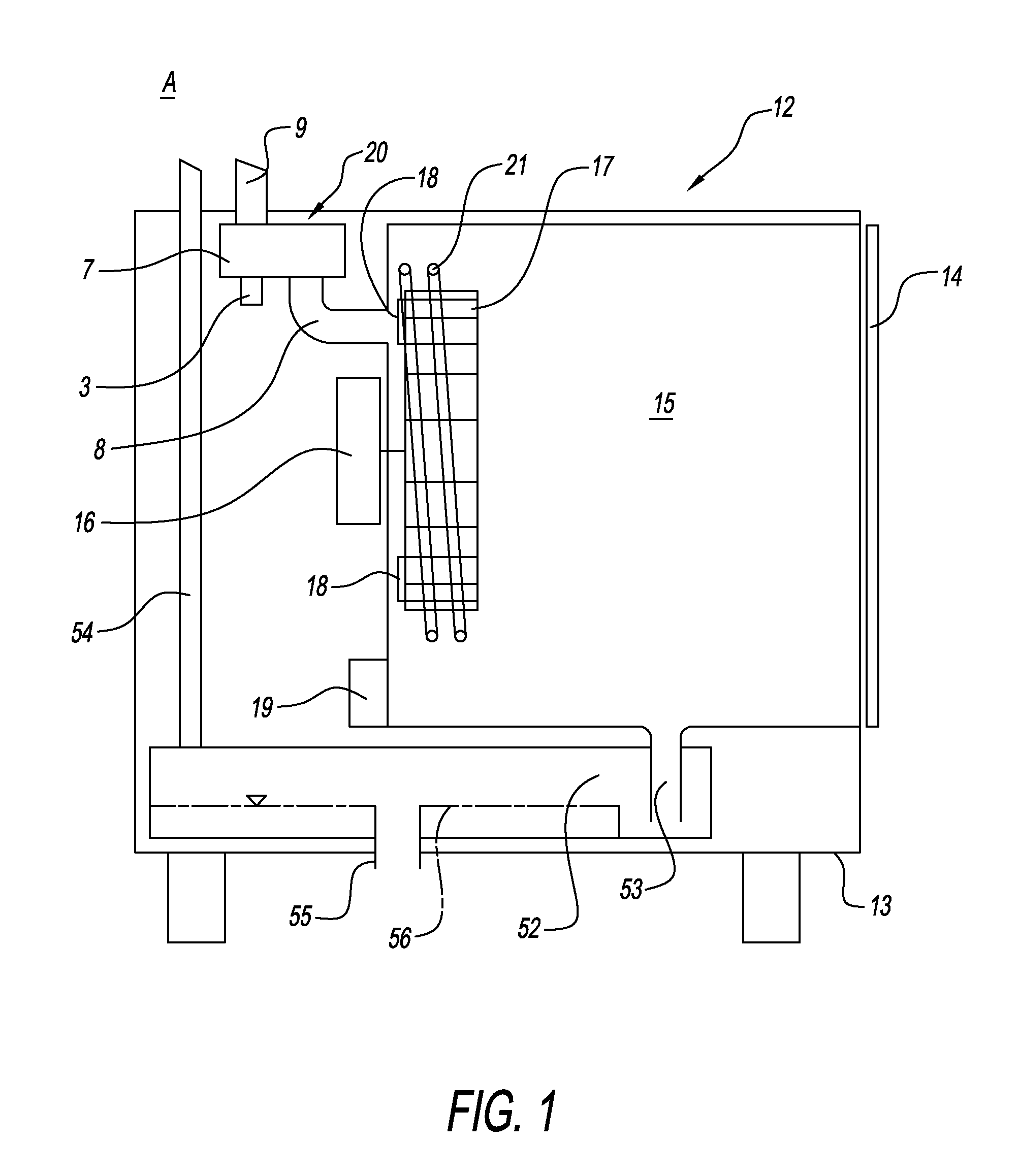

Valve arrangement of a commercial cooking device and commercial cooking device

ActiveUS20130192473A1Low flow resistanceQuick releaseDomestic stoves or rangesOperating means/releasing devices for valvesValve openingEngineering

Disclosed is a valve arrangement which includes a housing having a first conduit having a first discharge cross-section, a second conduit having a second discharge cross-section, and at least one valve seat within the interior chamber of the housing having at least one valve seat opening which cooperates with at least one valve disc. The valve disc is moveable between a closed position seated on the valve seat opening, and an open position spaced apart from the valve seat opening. There can be also provided an actuator for moving the valve disc between the open and closed positions. The valve seat opening has a cross-section that is larger than the discharge cross-section of the first conduit and / or the discharge cross-section of the second conduit. The cross-section of the valve disc is greater than the valve seat opening.

Owner:WELBILT DEUT GMBH

Alkaline etching solution recycling regeneration system and method thereof

PendingCN109440111ARealize closed loopThe process can be continuously automatedElectrolytic agentAlkaline etching

The invention discloses an alkaline etching solution recycling regeneration method. The alkaline etching solution recycling regeneration method comprises the following steps that (1) an etching wastesolution is produced; (2) extraction is carried out, specifically, the etching waste solution is mixed with an extraction agent, copper ions are separated from the etching waste solution to form a loaded copper oil phase, and a regenerated solution is stored in a regenerated solution bucket; (3) component adjustment is carried out, specifically, Cu2+, NH4+, Cl- and PH value are assayed for the regenerated solution, the amount of ammonia and ammonium chloride to be added is determined by the assayed results, and then the regenerated solution flows back to an etching production line; (4) primarywashing is carried out, specifically, primary washing is carried out on the loaded copper oil phase, and an aqueous phase is separated from the loaded copper oil phase; (5) back extraction is carriedout, specifically, the loaded copper oil phase is transferred into a back extraction solution, and a loaded extractant in the loaded copper oil phase has a contact reaction with a H2SO4 solution, thecopper ions are separated from the extractant, and a CuSO4 solution is formed and enters the aqueous phase; (6) an electrodeposition is carried out, specifically, the CuSO4 solution is added to an electrolyte, the CuSO4 solution is electrolyzed by the electrolyte, the coarse copper is deposited at a cathode, oxygen is generated at an anode, and after the CuSO4 solution is electrodeposited, the solution flows back into a back extraction cylinder.

Owner:广州德雅新环境科技有限公司

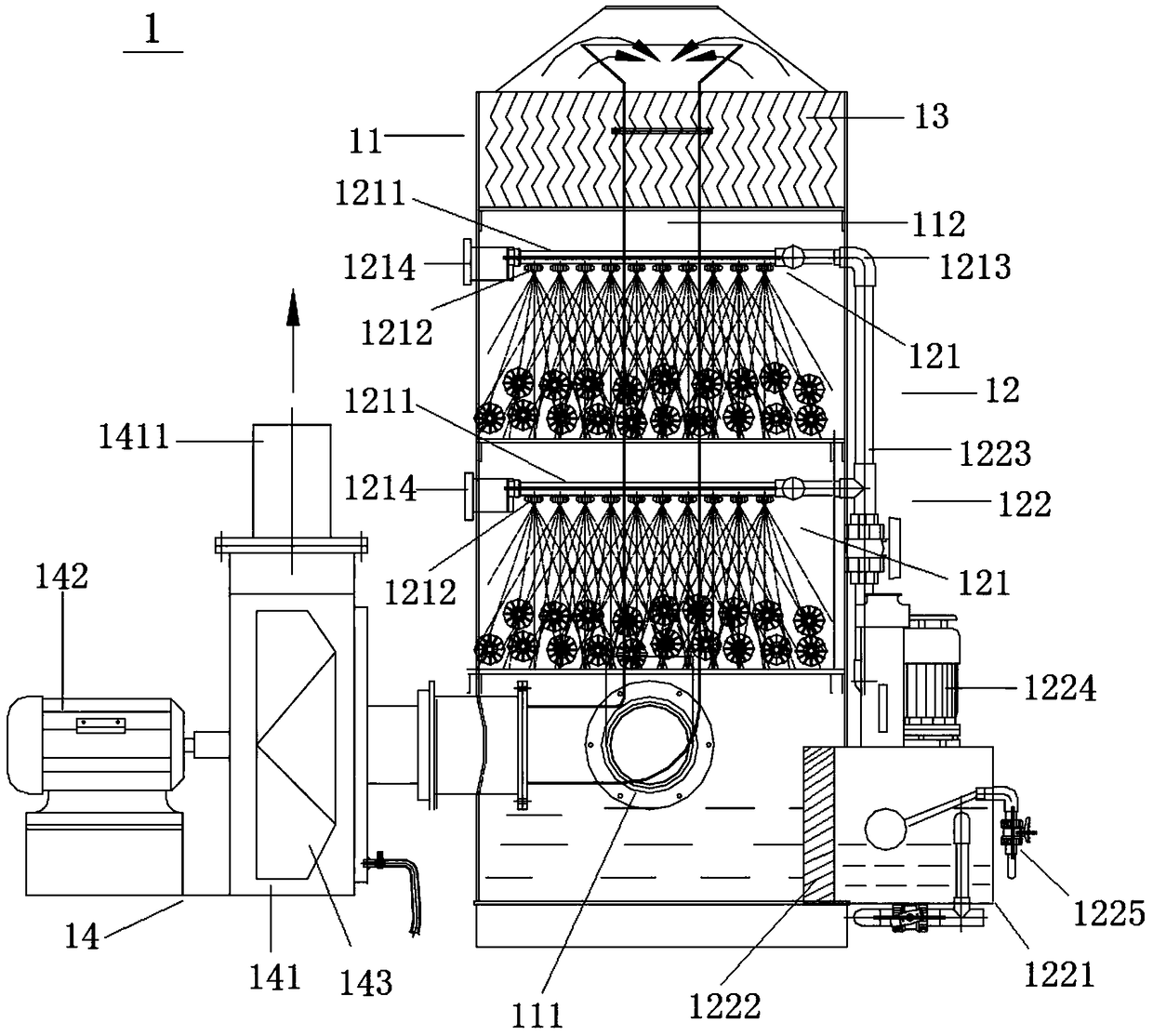

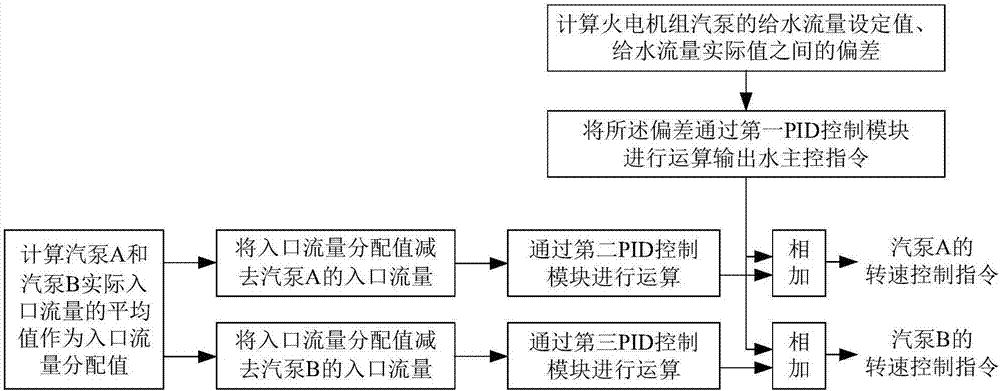

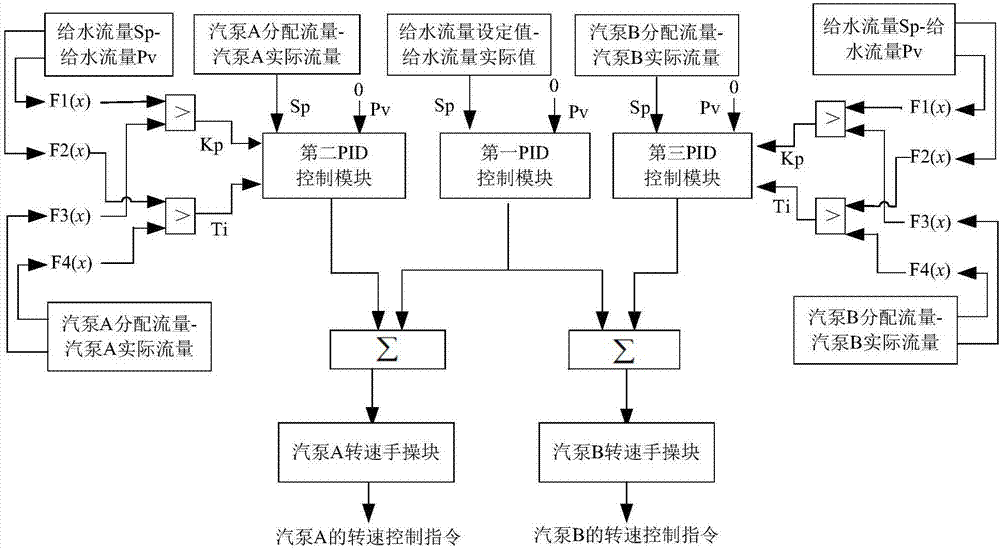

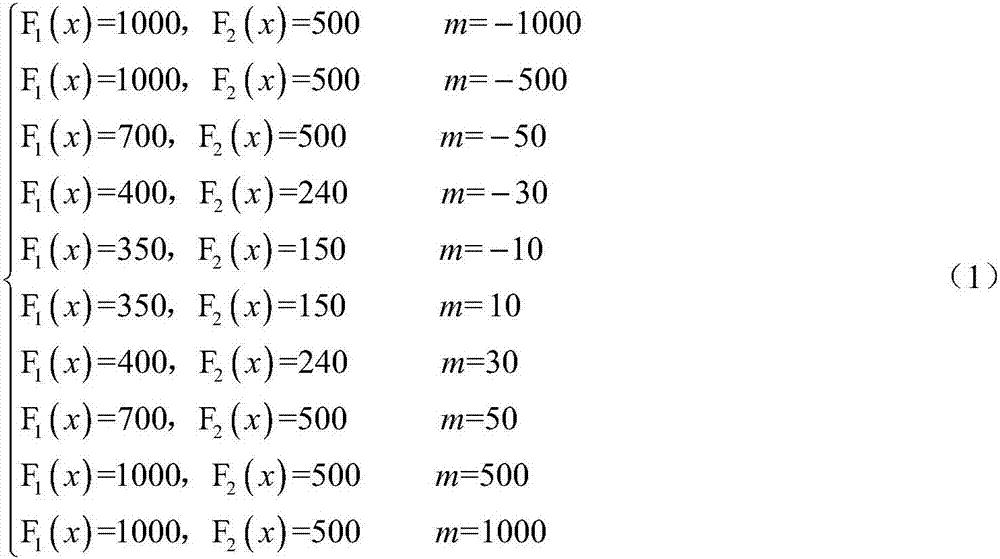

Automatic adjusting method for steam pump power output balance of thermal power generating unit

ActiveCN106870341AReduce labor intensityEliminate human errorPump controlPump installationsEngineeringGenerating unit

The invention discloses an automatic adjusting method for steam pump power output balance of a thermal power generating unit. The method includes the implementation steps that the deviation between a feed water flow set value and a feed water flow actual value of each thermal power generating unit steam pump is calculated and then is output to a water master control instruction through a first PID control module; the average value of the actual inlet flow of the steam pump A and the actual inlet flow of the steam pump B of the thermal power generating unit is calculated to serve as an inlet flow assigned value of each steam pump; the inlet flow of the steam pump A is subtracted from the corresponding inlet flow assigned value, a first control instruction is output through a second PID control module, and the water master control instruction and the first control instruction are added to control the rotating speed of the steam pump A; and meanwhile, the inlet flow of the steam pump B is subtracted from the corresponding inlet flow assigned value, a second control instruction is output through a third PID control module, and the water master control instruction and the second control instruction are added and then control the rotating speed of the steam pump B. By the adoption of the automatic adjusting method, output power can be made automatic, fast and balanced when the steam pumps are in parallel operation, and feed water flow stability in the adjusting process of steam pump power output balance can be guaranteed.

Owner:STATE GRID CORP OF CHINA +2

A DC microgrid group energy storage optimization and coordinated control method

ActiveCN105514966BImprove securityImprove voltage qualityLoad balancing in dc networkDc source parallel operationMicrogridFeedback control

The invention relates to an energy storage optimization and coordination control method for a direct-current micro grid group. When multiple sub micro grids are operated in parallel, an energy storage system in each sub micro grid automatically adjusts power distribution according to the maximum charging and discharging power and the state of charge (SOC) of the corresponding energy storage system, and therefore the safety of the energy storage systems is improved while distributed generated power fluctuation can be smoothed and the bus voltage quality can be improved; when the energy storage systems of all the sub micro grids cannot effectively buffer the system power supply and demand, an energy storage power station needs to be connected to control stabilization of the bus voltage. According to the energy storage optimization and coordination control method for the direct-current micro grid group, the virtual impedance of droop controllers of all energy storage units in the energy storage power station is adjusted by adopting fuzzy control to achieve automatic distribution of the power among the different energy storage units and SOC balance, fuzzy input is segmented, the SOC balancing speed of the fuzzy input in different ranges is increased by adopting fuzzy control, bus voltage drop caused by droop control is compensated by adopting a bus voltage feedback control method, and the bus voltage quality is improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

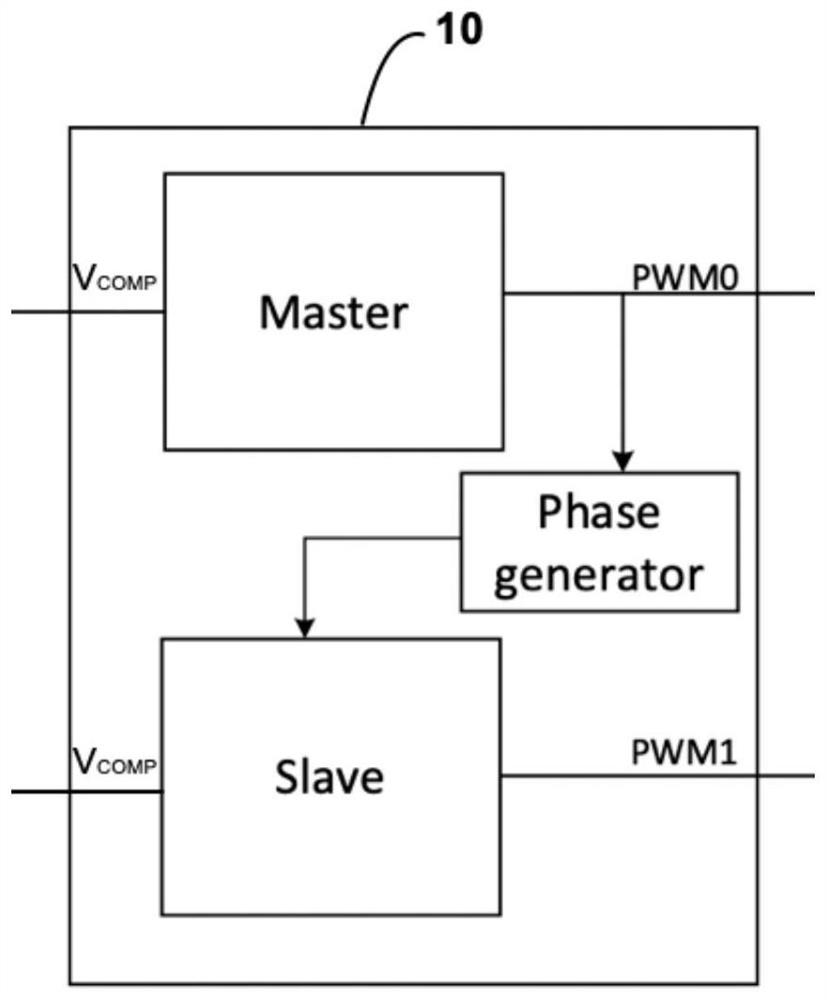

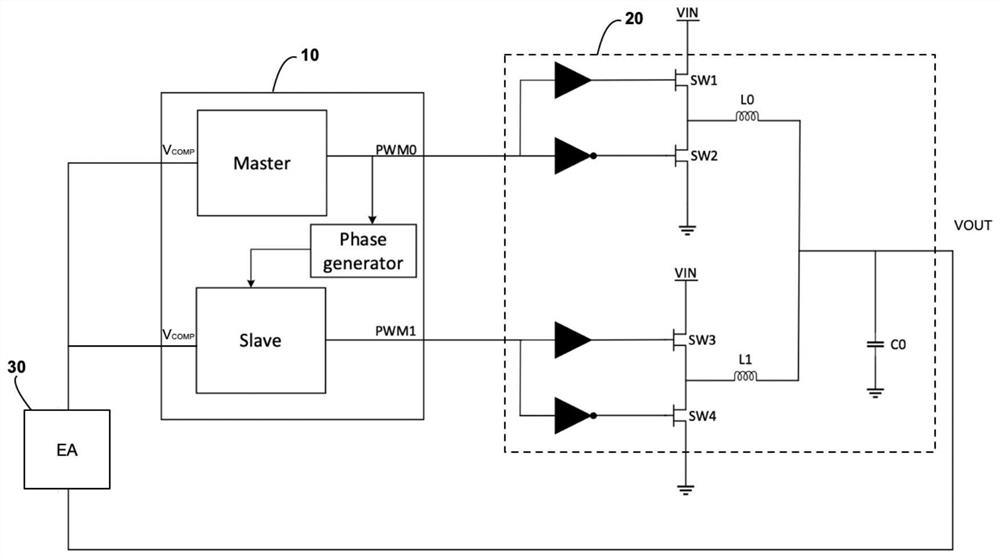

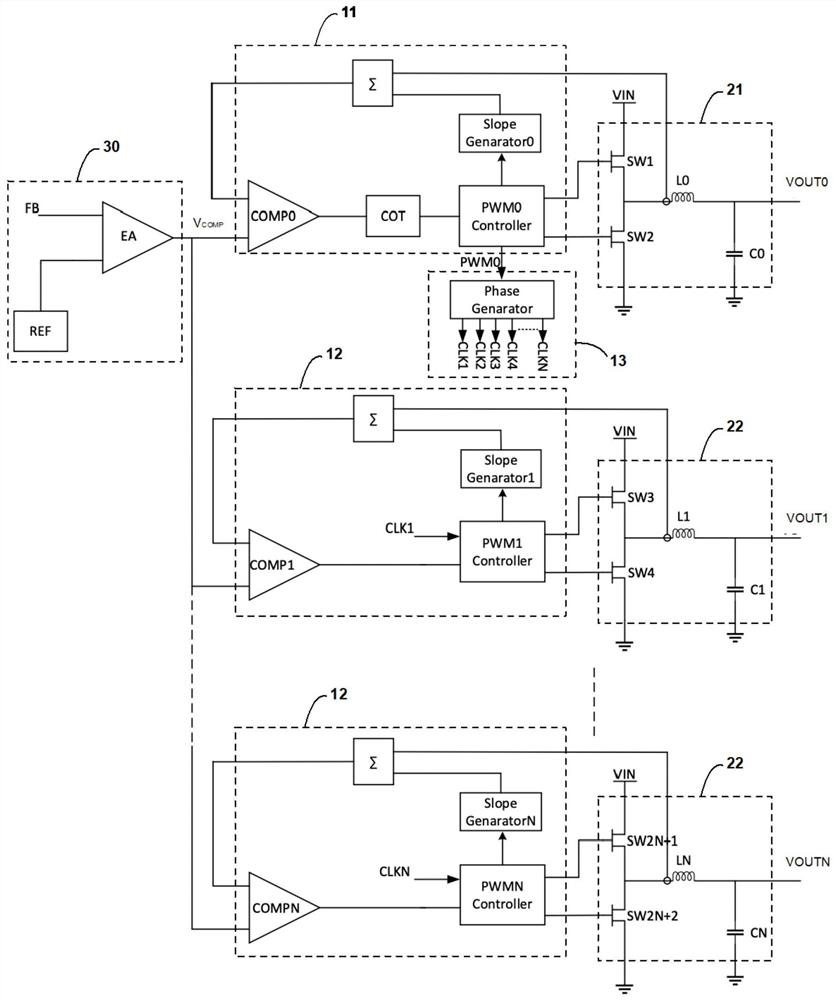

Multi-phase DCDC control system and multi-phase DCDC conversion circuit

ActiveCN112737334AFast dynamic responseFast balanceDc-dc conversionElectric variable regulationCurrent mode controlControl signal

The invention discloses a multi-phase DCDC control system and a DCDC converter. The system comprises a main unit which generates a first PWM signal based on a COT control mode, and converts the first PWM signal into a first control signal, a phase generation unit used for carrying out phase shift on the first PWM signal to generate a plurality of clock signals, and a plurality of slave units used for generating a plurality of second PWM signals based on a current mode control mode and the plurality of clock signals and converting the second PWM signals into second control signals. A main-slave structure is adopted for multi-phase control, the main unit generates the first PWM signal in the COT control mode, the phase generation unit generates a multi-phase clock signal needed by the slave units, the slave units generate the second PWM signals in a current mode control mode, and rapid dynamic response and current balance in the DCDC conversion circuit can be achieved at the same time.

Owner:3PEAK INC

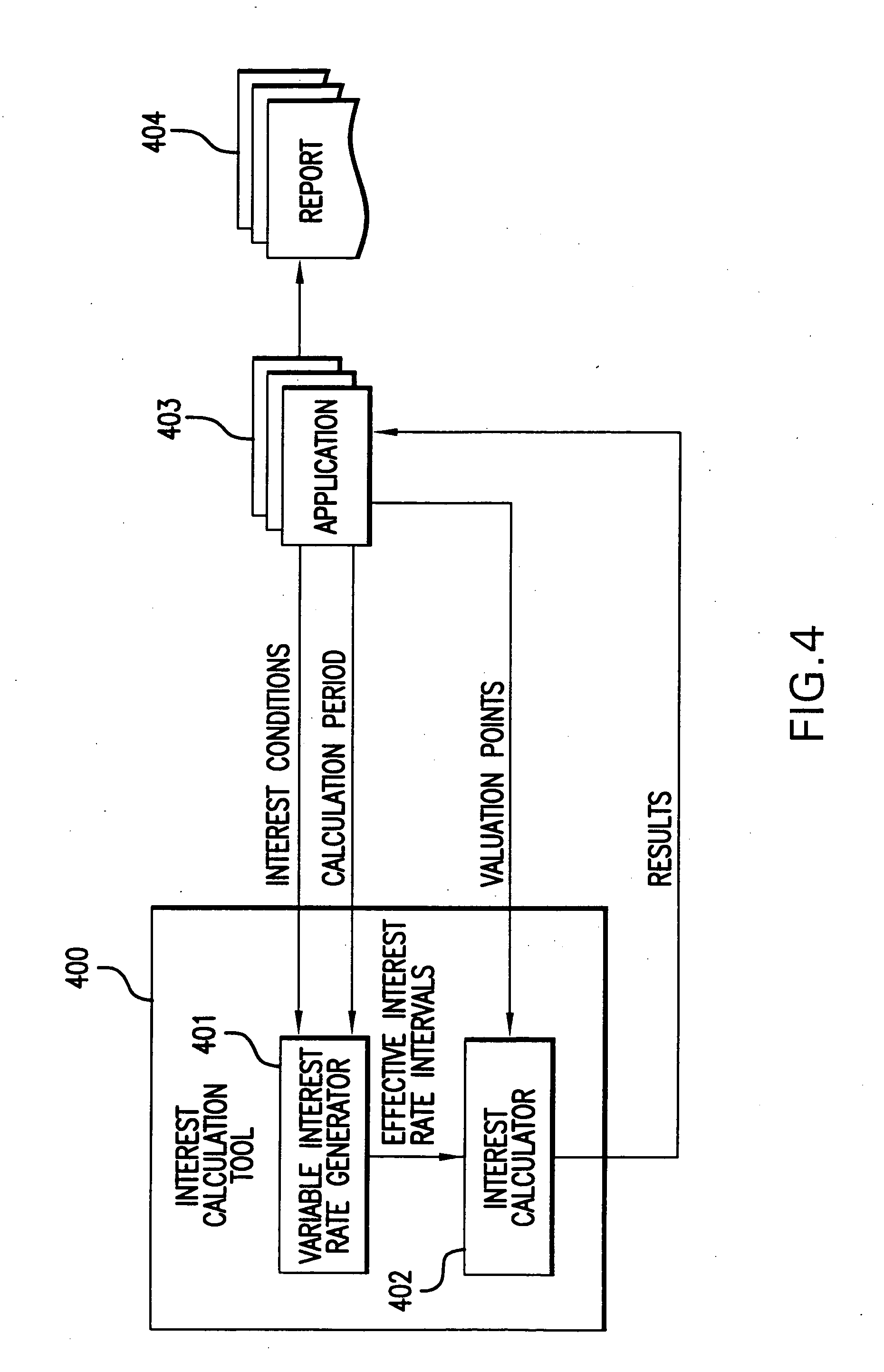

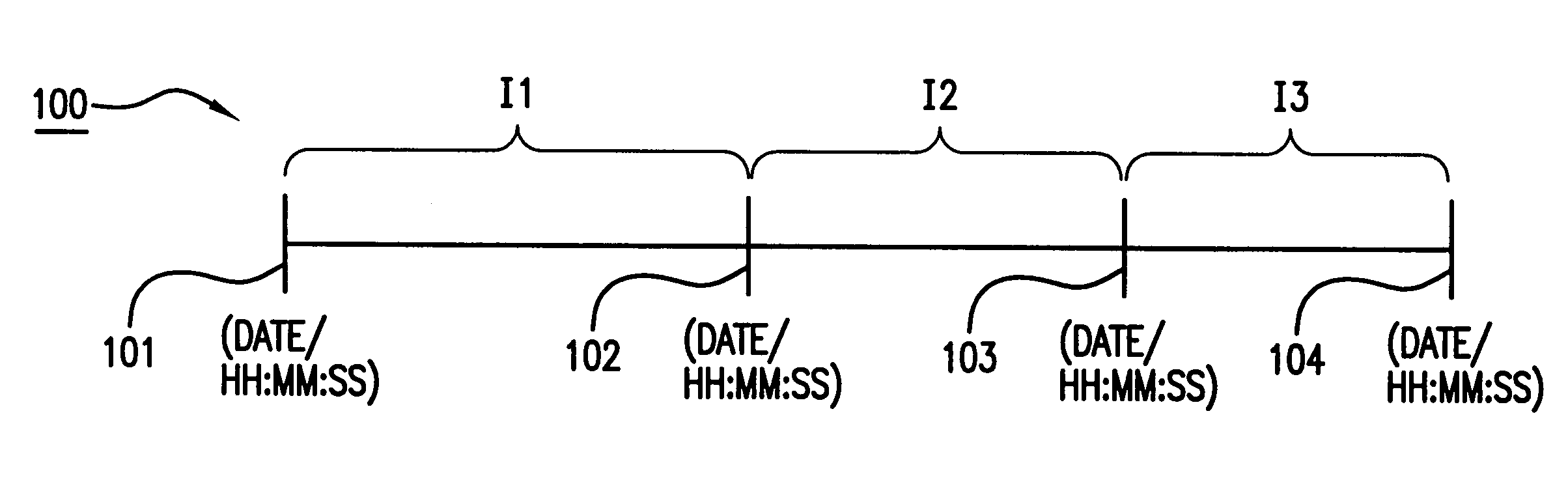

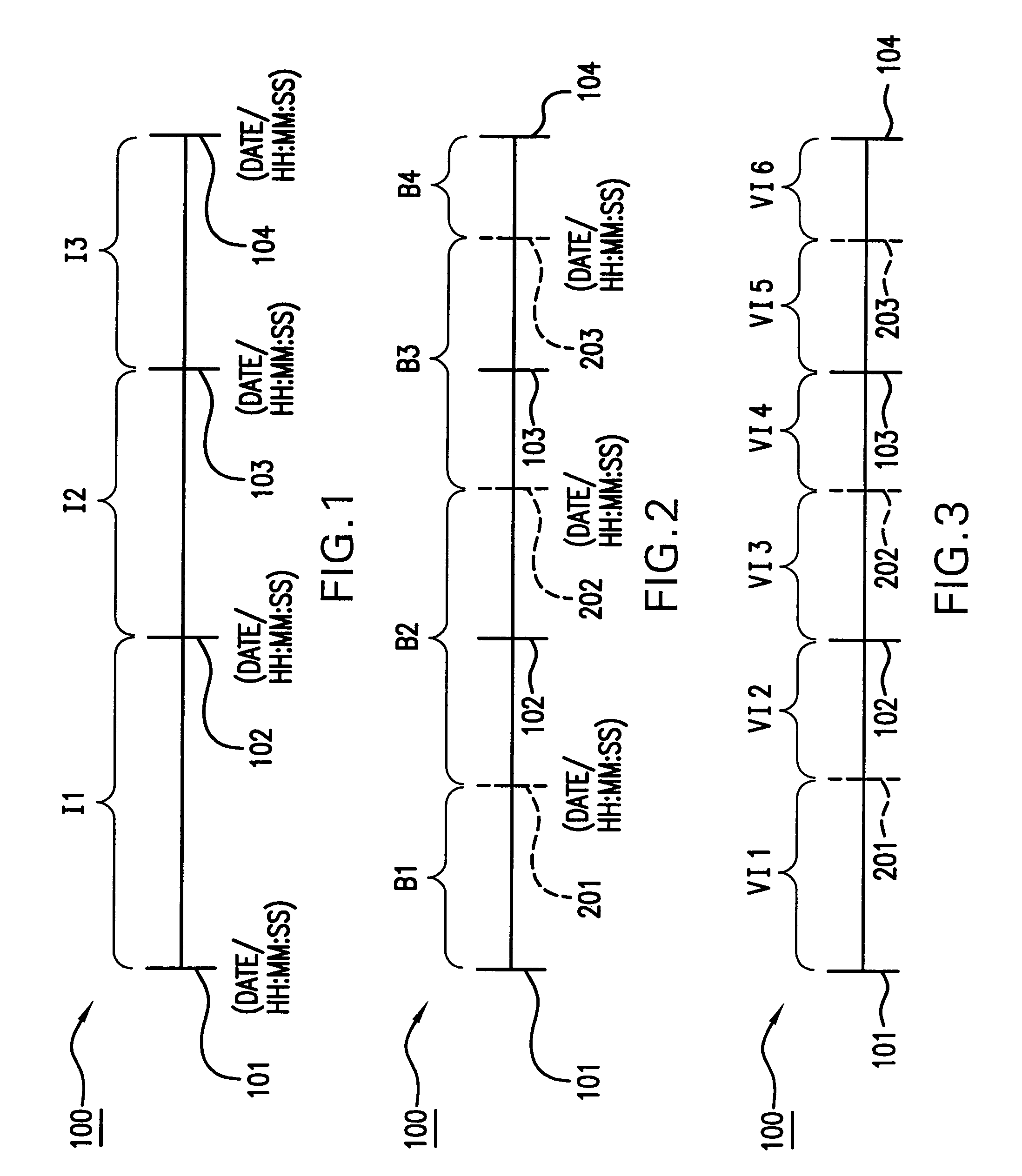

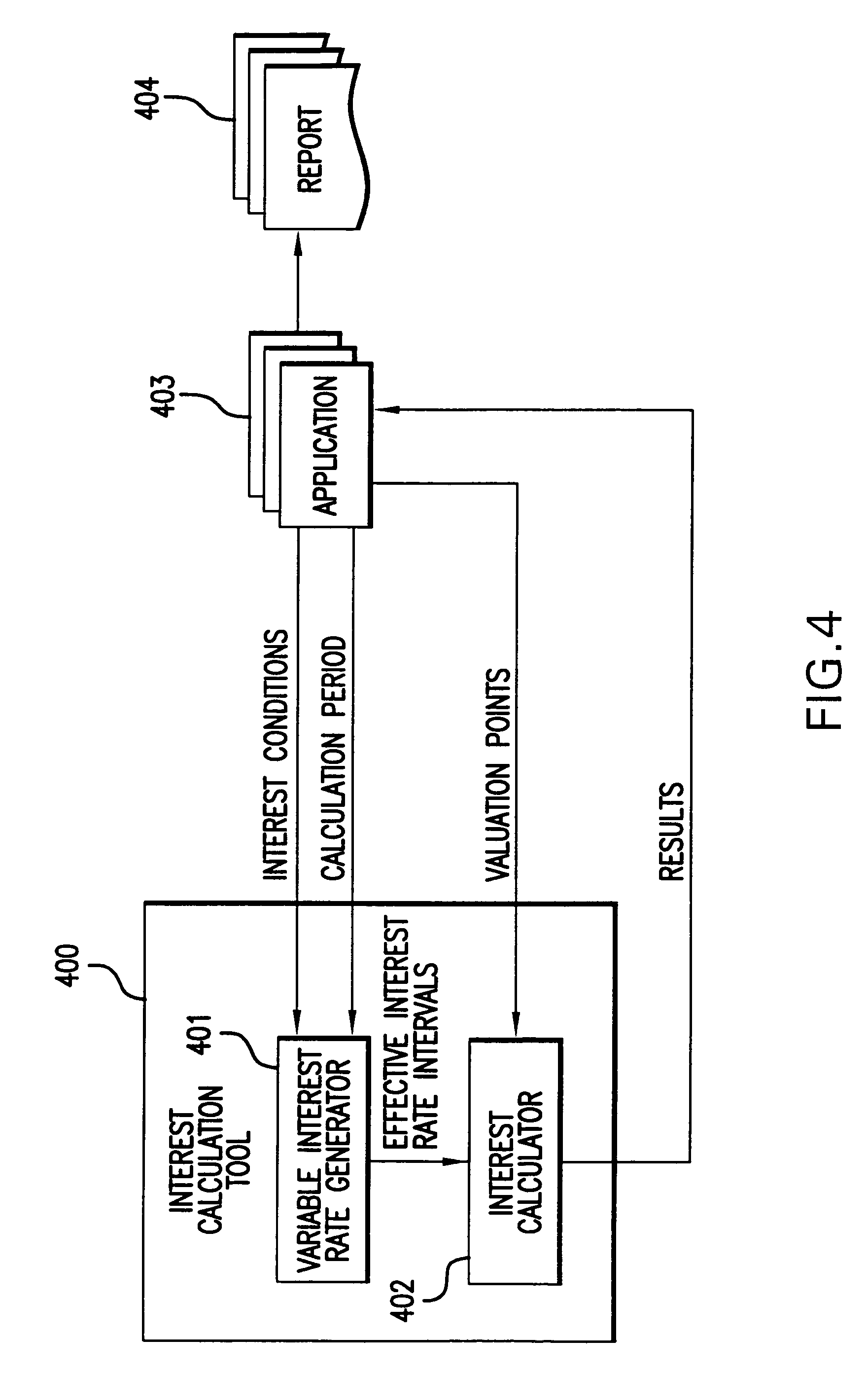

Interest calculation tool

ActiveUS20050071398A1Good precisionRapid in account balanceFinanceInput/output processes for data processingSimulationTime parameter

Embodiments of the present invention relate to a computer-implemented method and system for performing interest calculations on account balances. The calculations may be based on time intervals of less than a day, and using time parameters defined in terms of seconds.

Owner:SAP AG

Interest calculation tool

ActiveUS7499884B2Fast balanceAccurate calculationFinanceInput/output processes for data processingSimulationTime parameter

Embodiments of the present invention relate to a computer-implemented method and system for performing interest calculations on account balances. The calculations may be based on time intervals of less than a day, and using time parameters defined in terms of seconds.

Owner:SAP AG

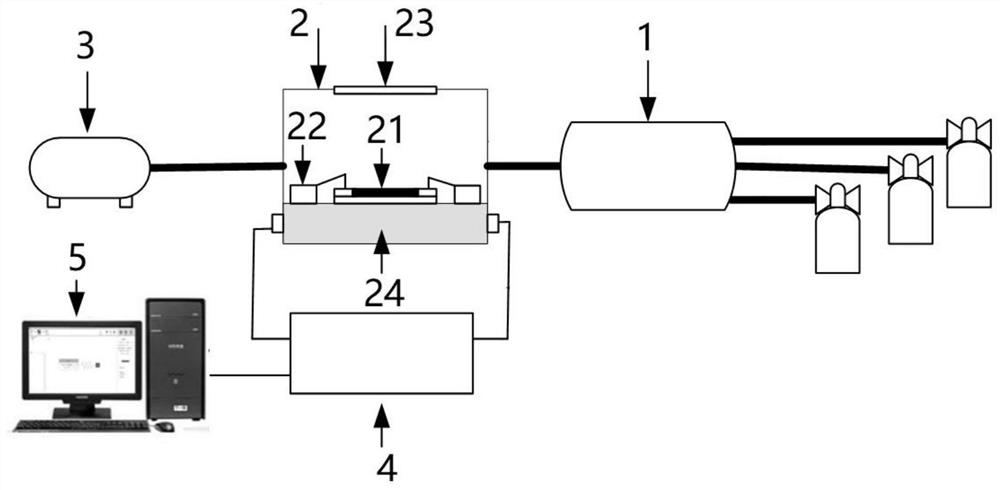

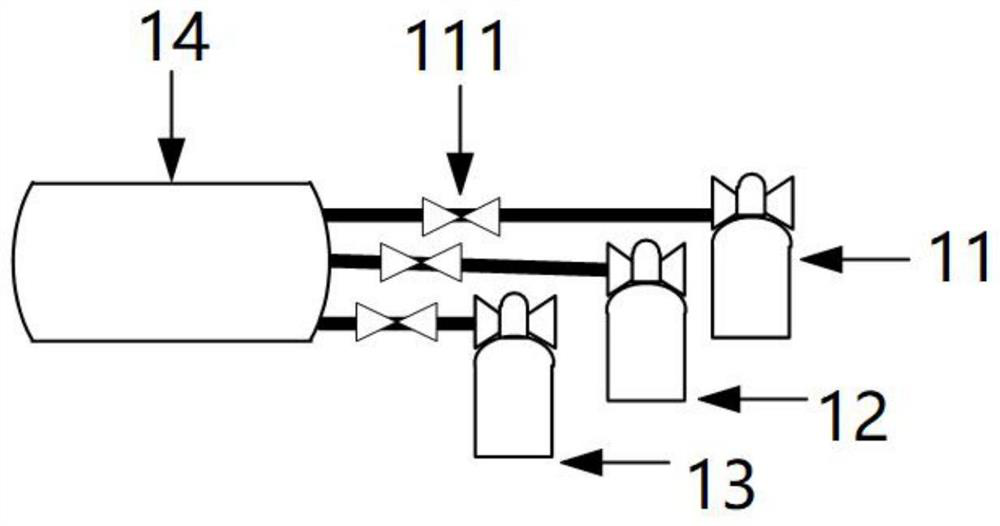

Dynamic test platform and test method for gas sensor

ActiveCN112834572ASimple structureVersatileMaterial analysis by electric/magnetic meansSulfur hexafluorideData analysis system

The invention belongs to the technical field of gas sensors. The invention provides a dynamic test platform and test method for a gas sensor. High-precision testing environments with different types of gases, different flow rates and different gas concentrations can be provided through the dynamic gas distribution system, and are closer to the actual application conditions of sulfur hexafluoride and decomposition product gases thereof, so that the accuracy of gas-sensitive testing is improved. According to adsorption and desorption of gas molecules on the gas-sensitive sensor, gas signals are collected in the gas-sensitive response chamber, and rapid replacement and balance of atmosphere concentration in the chamber in the testing process are guaranteed. The collecting device can be used for collecting waste gas. And the electrical detection system and the data analysis system are respectively used for realizing conversion of gas signals and receiving and processing of electrical signals. The dynamic test platform of the gas sensor is simple in structure, complete in function, convenient to operate and high in detection accuracy. According to the test method of the gas sensor, rapid gas-sensitive detection and comprehensive evaluation of the gas-sensitive sensing performance can be realized.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

System and method for controlling the input energy from an energy point source during metal processing

ActiveUS10632566B2Fast balanceFast inferenceAdditive manufacturing apparatusIncreasing energy efficiencyHot zoneLight beam

Owner:PROD INNOVATION & ENG L LC

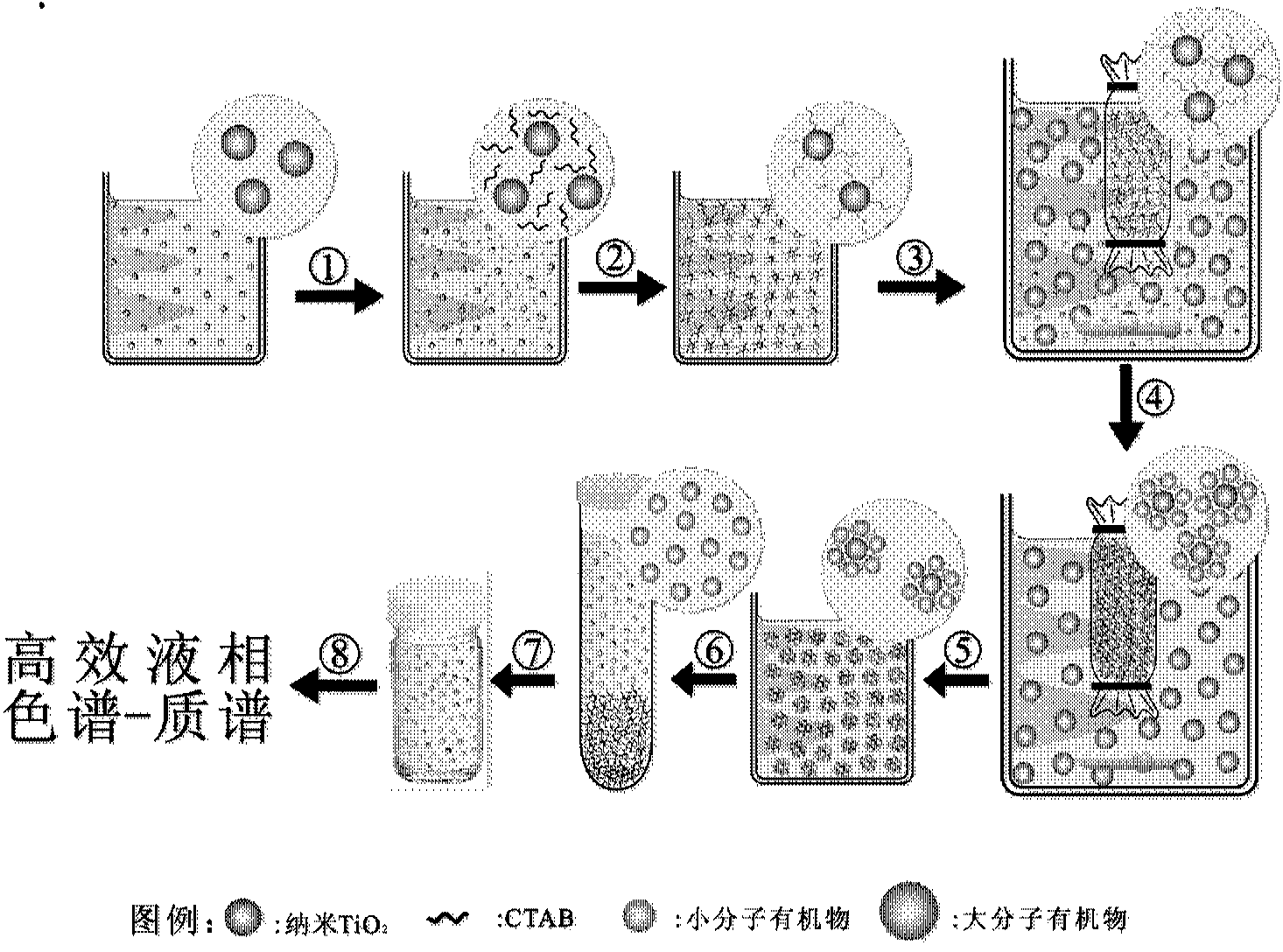

Surfactant modified nano TiO2 semi-permeable membrane water sample pretreatment method

InactiveCN103674618AGood choiceImprove adsorption capacityMaterial nanotechnologyWithdrawing sample devicesDiffusionPretreatment method

The invention discloses a surfactant modified nano TiO2 semi-permeable membrane water sample pretreatment method which comprises the following steps: nano TiO2 particles modified by the surfactant are embedded into a semi-permeable membrane dialysis bag, sealed and put into water, stirring is performed until adsorption equilibrium is reached, and organic pollutants in water enter the semi-permeable membrane dialysis bag in a passive diffusion and transmembrane manner so as to isolate natural organic matters outside the semi-permeable membrane dialysis bag. The method can be used for pretreatment of an environment water sample containing high content of organic matters.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

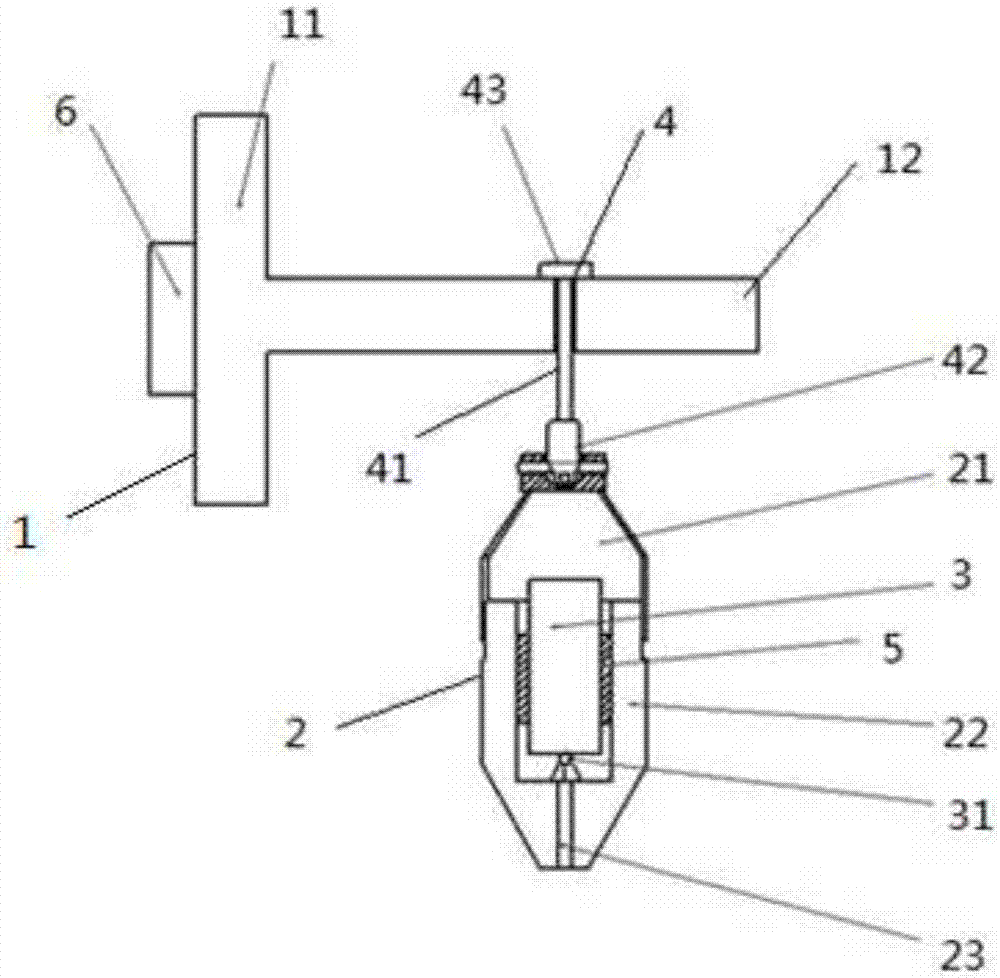

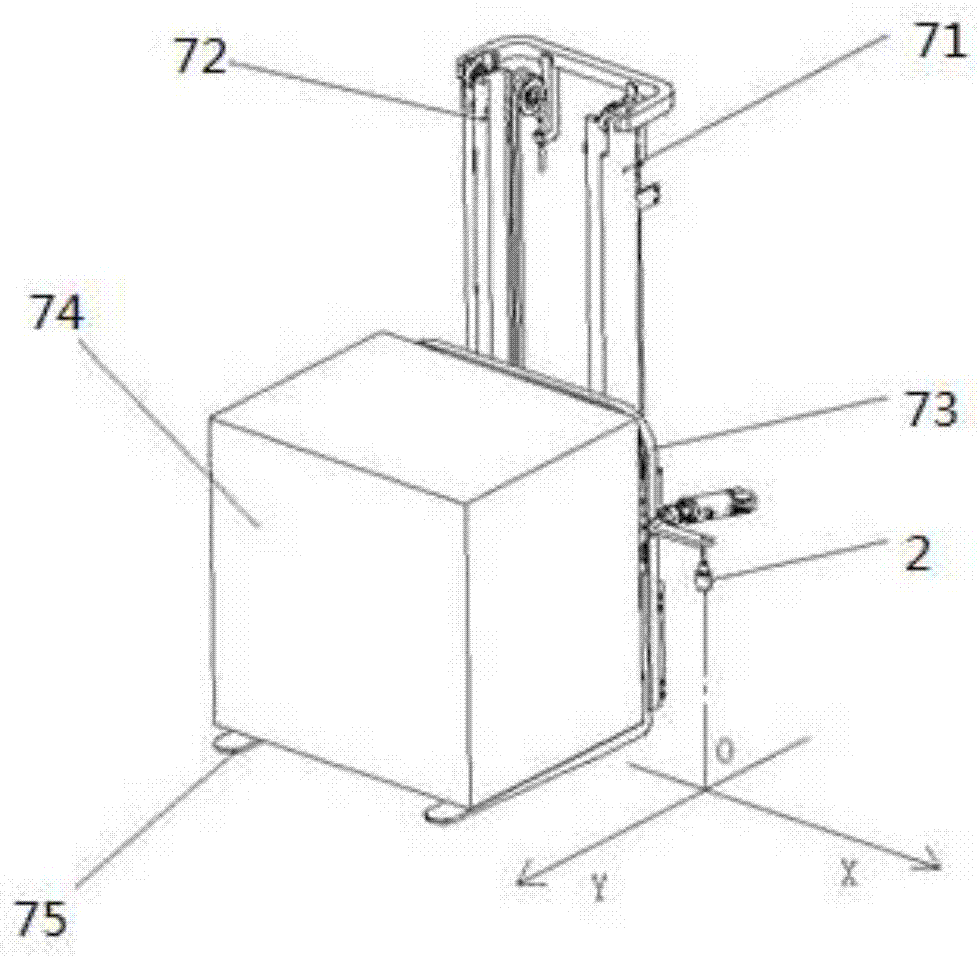

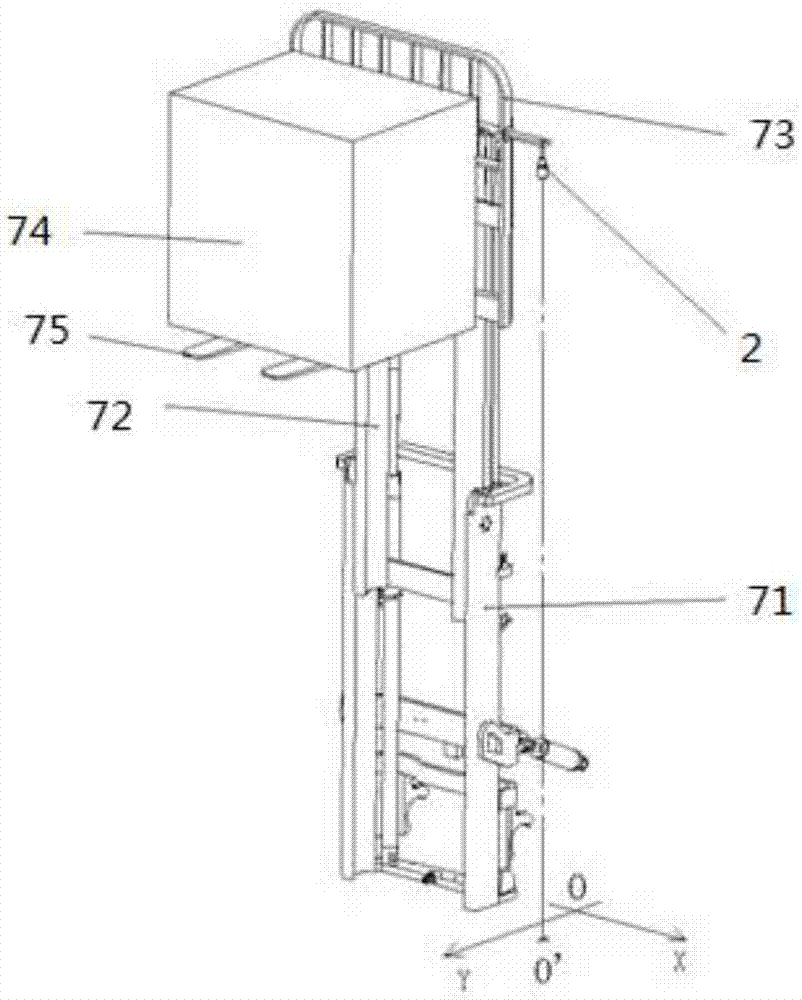

Fork trunk mast deflection measurement detection device

PendingCN107290116ASolve the problem that the deflection is affected by the wind speed environmentSimple structureUsing optical meansElasticity measurementLight spotEngineering

The invention relates to a fork trunk mast deflection measurement detection device comprising a support and a plumb body which is installed on the support and arranged along a plumb direction. A laser generator is fixedly arranged in the plumb body. The laser head of the laser generator is vertically and downwardly arranged. The bottom part of the plumb body is provided with a guide hole corresponding to the laser head along the plumb direction. According to the fork trunk mast deflection measurement detection device, the characteristics of plumb self-vertical and laser light spot linear projection can be combined, the structure is simple and operation is convenient so that self-vertical and self-balancing can be rapidly realized, the detection efficiency can be enhanced in the aspect of time, and the problem of the influence of the wind speed environment in measuring fork trunk mast deflection through the plumb can be solved.

Owner:ANHUI HELI CO LTD

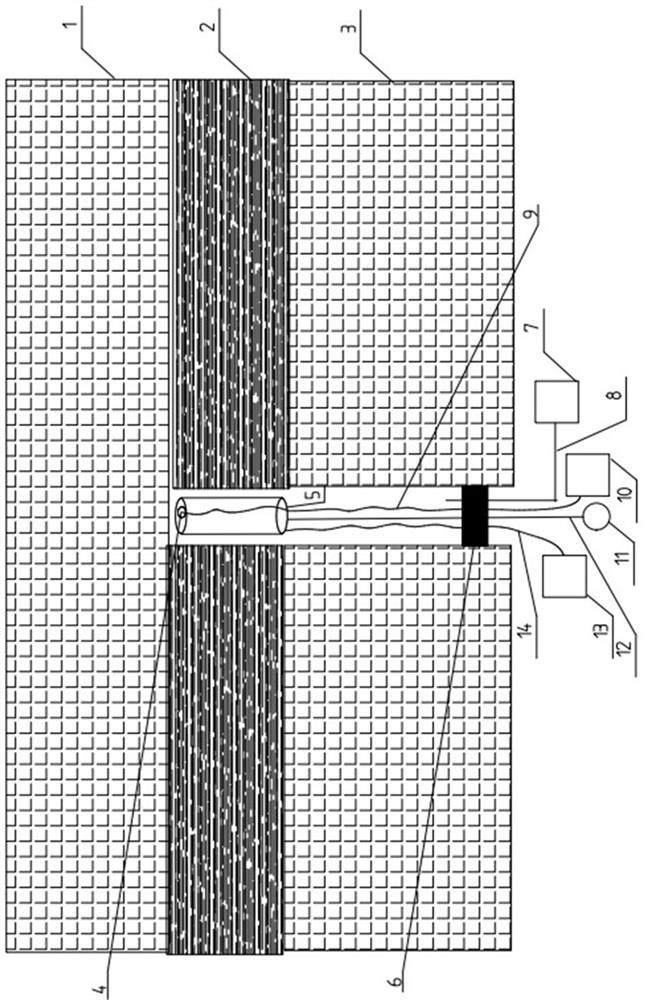

Device and method for shortening coal seam gas pressure measurement observation time

ActiveCN113818921AReduce volumeFast balanceFluid pressure measurementGas removalThermodynamicsMeasurement device

The embodiment of the invention discloses a device and a method for shortening coal seam gas pressure measurement observation time, relates to the technical field of coal seam gas pressure measurement, and mainly aims to solve the problems of low gas flow field balance speed and long observation time in the conventional coal seam gas pressure measurement device and method. The device comprises a grouting mechanism, a capsule located in a drill hole, a pressure measuring mechanism, a water conveying mechanism and an expansion liquid conveying mechanism, wherein the surface of the capsule is wrapped with a light, flexible and water-absorbing material, a plurality of sprayers are arranged at the top end of the capsule, and a pressure measuring pipe in the pressure measuring mechanism is fed into the capsule at the front end of the drill hole, so that not only can the pipe be tightly attached to the coal wall around the drill hole before the pressure measuring drill hole is sealed, to hinder flowing of gas in the coal seam around the drilled hole towards the drilled hole, but also can occupy most space of a pressure measuring chamber after the pressure measuring drill hole is sealed, and therefore, the size of the pressure measuring chamber is reduced, the amount of gas flowing into the pressure measuring chamber from the coal wall around the drill hole is reduced, the balance speed of a gas flow field can be increased, and the observation time is shortened.

Owner:NORTH CHINA INST OF SCI & TECH

Valve arrangement of a commercial cooking device and commercial cooking device

ActiveUS9326632B2Quick releaseLow flow resistanceDomestic stoves or rangesOperating means/releasing devices for valvesEngineeringValve seat

A valve structure includes a housing having an interior chamber, a first conduit connecting the interior chamber with a cooking chamber of a cooking device and having a first discharge cross-section, a second conduit connecting the interior chamber with the outside environment and having a second discharge cross-section, and at least one valve seat within the interior chamber having at least one valve seat opening which cooperates with at least one valve disc. The at least one valve disc moves between a closed position on the valve seat opening, and an open position spaced apart from the valve seat opening by changes in pressure in the cooking chamber. The valve operates to allow bidirectional flow of fluid to relieve over pressure and underpressure conditions, and enables automatic balancing of low pressure or vacuum in the cooking chamber.

Owner:WELBILT DEUT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com