Automatic adjusting method for steam pump power output balance of thermal power generating unit

A thermal power unit, automatic adjustment technology, applied in the direction of machine/engine, pump, pump control, etc., can solve problems such as inappropriate parameter setting, reversed sequence of commands, main water flow fluctuations, etc., to improve the level of automatic control and eliminate artificial The effect of misoperation and stable water supply flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

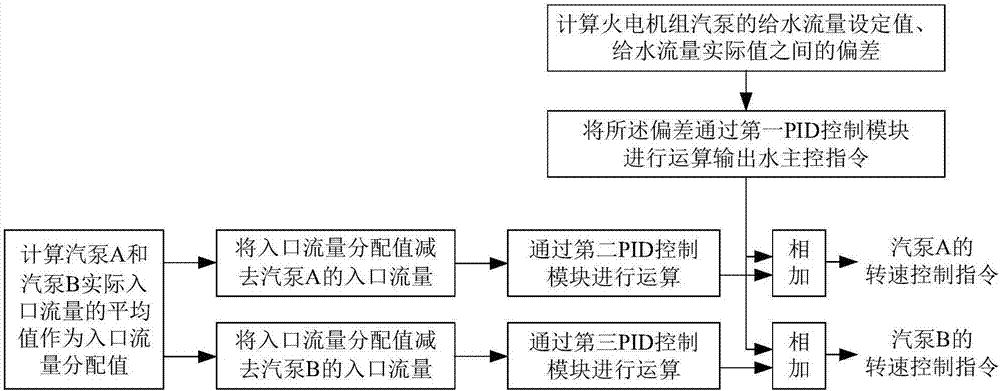

[0031] Such as figure 1 As shown, the implementation steps of the method for automatically adjusting the output balance of the steam pump of the thermal power unit in this embodiment include:

[0032] 1) Calculate the deviation between the set value of the water supply flow rate of the thermal power unit and the actual value of the water supply flow rate, and calculate the deviation through the first PID control module to output the water supply master control command;

[0033] 2) Calculate the average value of the actual inlet flow of the two steam pumps of steam pump A and steam pump B of the thermal power unit, and use the average value of the actual inlet flow as the inlet flow distribution value of each steam pump;

[0034] 3) Subtract the inlet flow rate of the steam pump A from the inlet flow distribution value, and calculate the difference obtained through the second PID control module to output the first control command, and add the main water supply control command a...

Embodiment 2

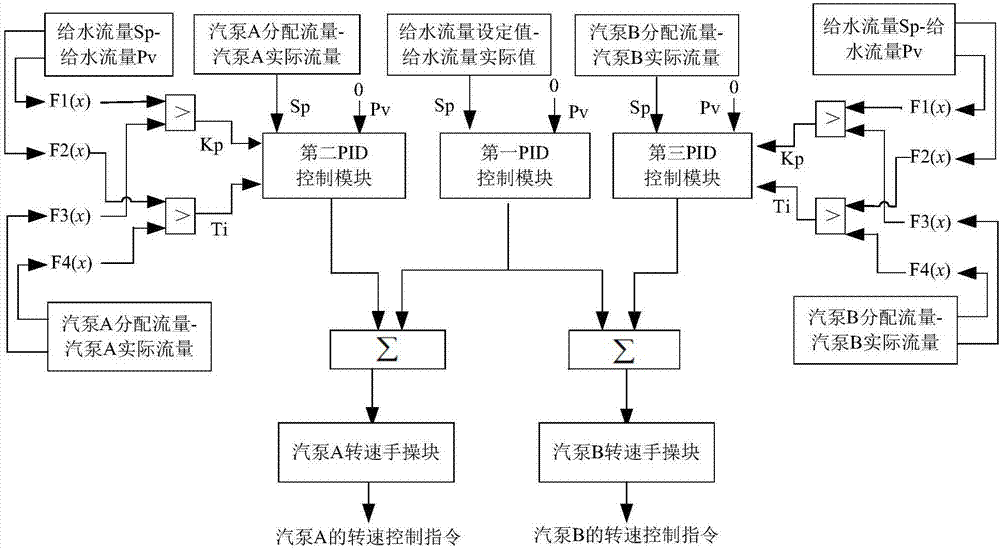

[0041] This embodiment is basically the same as Embodiment 1, and the main difference is that the control parameters of the second PID control module and the third PID control module among the three sets of PID control modules are further optimized.

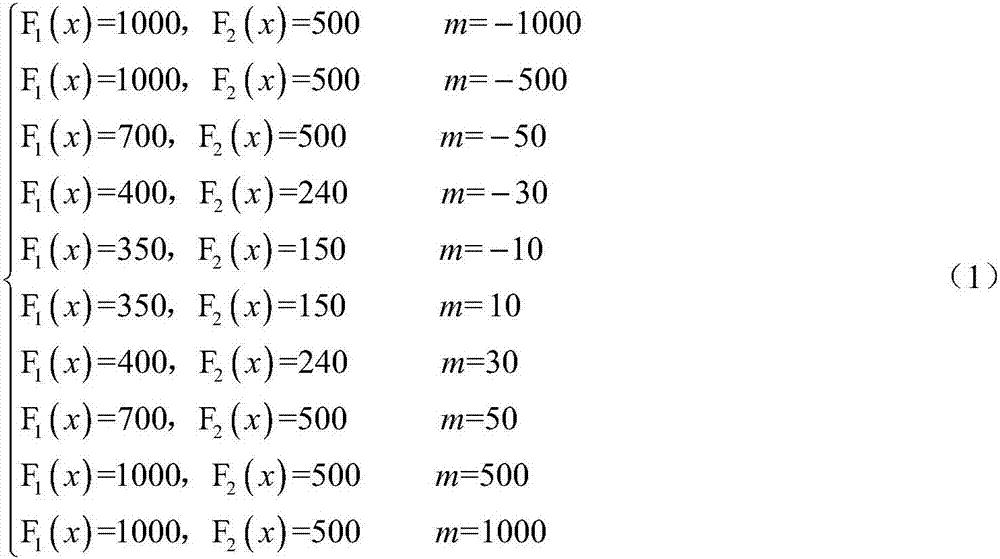

[0042] Such as figure 2 As shown, in this embodiment, when the set value is calculated by the second PID control module, a different broken line function F is constructed in advance based on the first difference obtained by subtracting the feed water flow process value Pv from the feed water flow set value Sp 1 (x) and F 2 (x), the second difference obtained by subtracting the actual flow from the inlet flow distribution value of each steam pump to construct a different broken line function F 3 (x) and F 4 (x); determine the broken line function F according to the first difference obtained by subtracting the feedwater flow process value Pv from the feedwater flow set value Sp 1 (x) and F 2 The value of (x); subtract the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com