Alkaline etching solution circulation regeneration system and method thereof

A technology of regeneration system and etching waste liquid, which is applied in the field of etching, can solve the problems that the whole system cannot be recycled and reused, zero discharge, waste liquid discharge, etc., and achieve the effect of continuous automation of operation, high efficiency and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

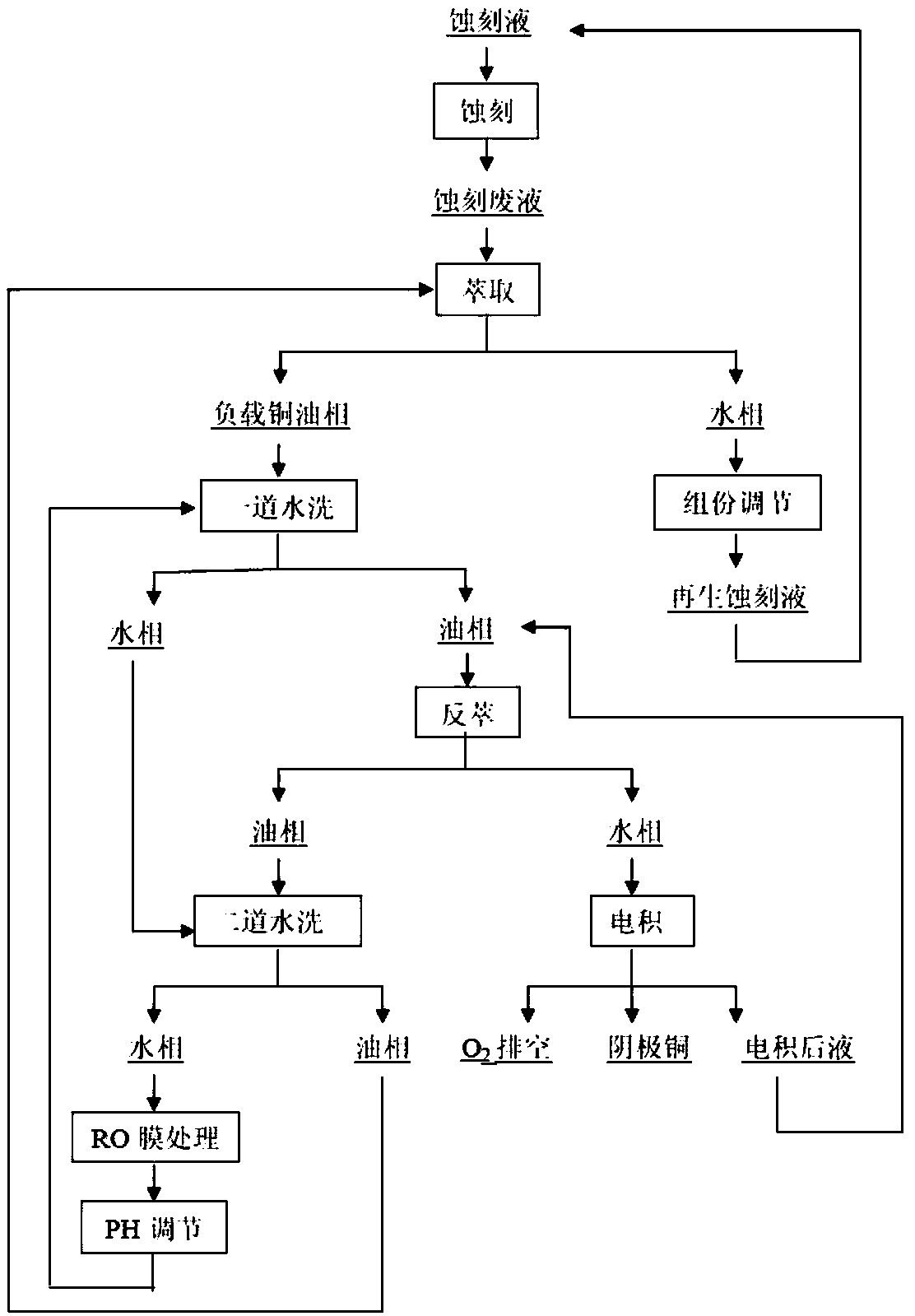

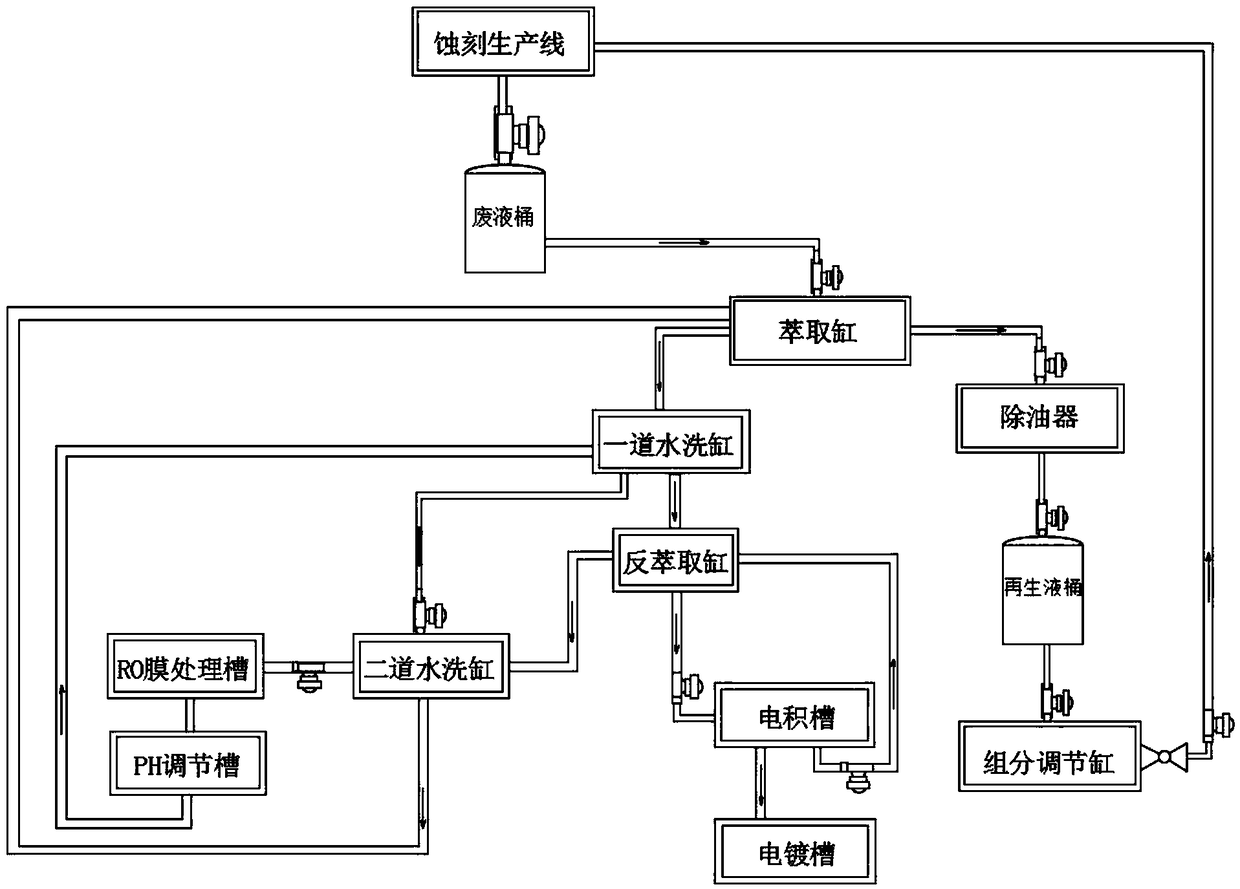

[0038] Please refer to figure 1 , the present embodiment provides a method for recycling alkaline etching solution, comprising the following steps:

[0039] (1) Generation of etching waste liquid: the etching waste liquid produced by the etching production line is stored in the waste liquid barrel, and the etching waste liquid in the waste liquid barrel is added to the extraction cylinder;

[0040] (2) Extraction: The etching waste liquid added to the extraction tank is mixed with the extractant in the extraction tank, the concentration of the extractant is 40%, the ratio is O / A=2, and most of the copper ions are separated from the etching waste liquid , and react with the extractant to generate a loaded extractant, then clarified and stratified, oil and water are separated to form a copper-loaded oil phase, and the regeneration solution whose copper concentration is reduced to 25g / L is stored in the regeneration solution bucket as an aqueous phase;

[0041] (3) Component adj...

Embodiment 2

[0046] This embodiment provides a method for circulating and regenerating alkaline etching solution, comprising the following steps:

[0047] (1) Generation of etching waste liquid: the etching waste liquid produced by the etching production line is stored in the waste liquid barrel, and the etching waste liquid in the waste liquid barrel is added to the extraction cylinder;

[0048] (2) Extraction: The etching waste liquid added to the extraction tank is mixed with the extractant in the extraction tank, the concentration of the extractant is 60%, the ratio is O / A=2, and most of the copper ions are separated from the etching waste liquid , and react with the extractant to generate a loaded extractant, then clarified and stratified, oil and water are separated to form a copper-loaded oil phase, and the regeneration solution whose copper concentration is reduced to 35g / L is stored in the regeneration solution bucket as an aqueous phase;

[0049] (3) Component adjustment: Cu 2+ ...

Embodiment 3

[0054] This embodiment provides a method for circulating and regenerating alkaline etching solution, comprising the following steps:

[0055] (1) Generation of etching waste liquid: the etching waste liquid produced by the etching production line is stored in the waste liquid barrel, and the etching waste liquid in the waste liquid barrel is added to the extraction cylinder;

[0056] (2) Extraction: The etching waste liquid added to the extraction tank is mixed with the extractant in the extraction tank, the concentration of the extractant is 50%, the ratio is O / A=2, and most of the copper ions are separated from the etching waste liquid , and react with the extractant to generate a loaded extractant, then clarified and stratified, oil and water are separated to form a copper-loaded oil phase, and the regeneration solution whose copper concentration is reduced to 30g / L is stored in the regeneration solution bucket as an aqueous phase;

[0057] (3) Component adjustment: Cu 2+ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com