Wet processing method for tin-copper slag

A wet processing, tin-copper technology is applied in the field of tin refining and sulfur removal and copper slag treatment. Production cost, the effect of improving the direct yield of tin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

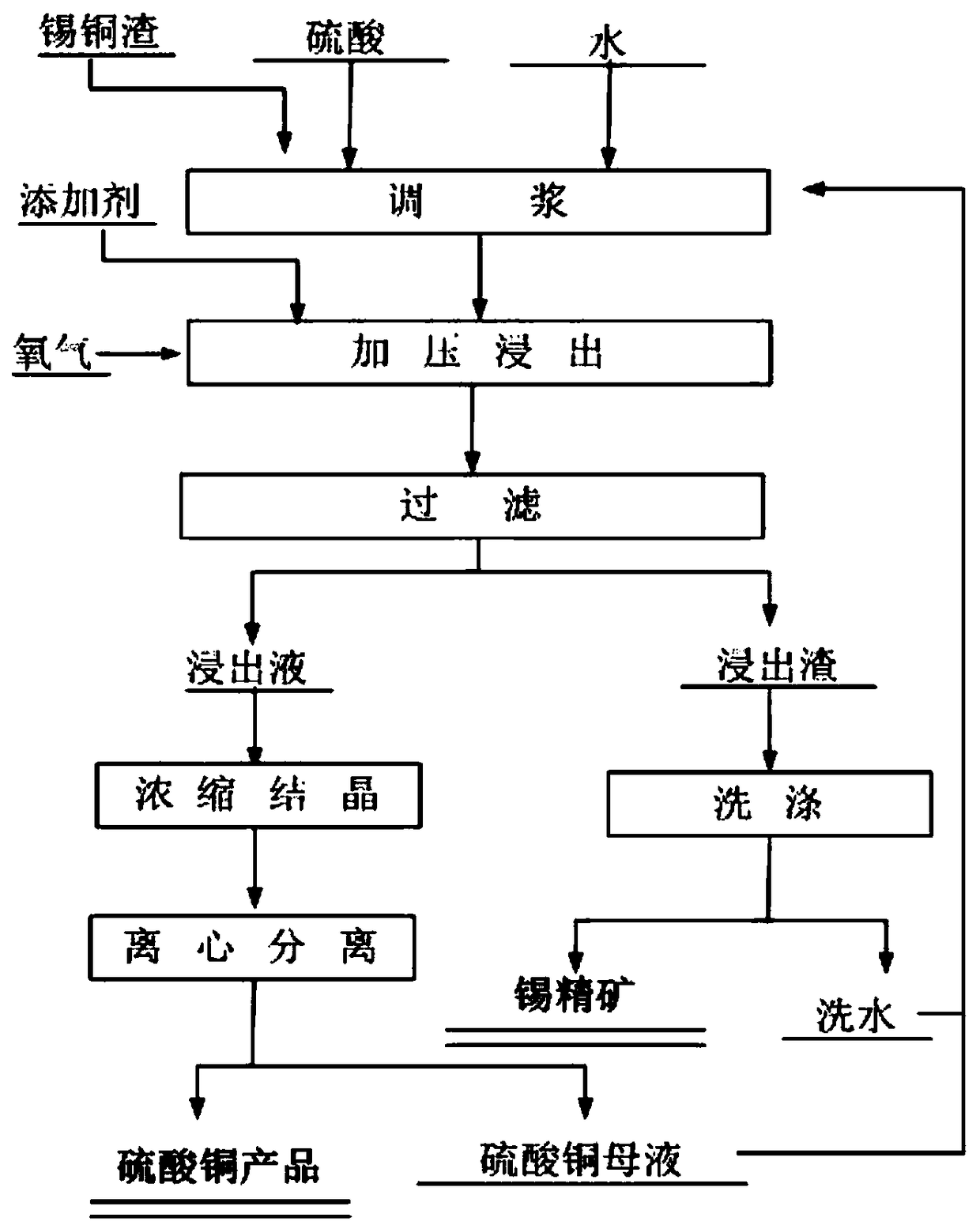

Image

Examples

Embodiment 1

[0020] (1) With 10.03% of copper, 500g of tin-copper slag containing 58.36% of tin, adopt sulfuric acid pressure leaching, leaching condition: add cupric chloride by 2% of tin-copper slag quality, sulfuric acid initial acidity 100g / l, sulfuric acid and The liquid-solid mass ratio of tin-copper slag is 4:1, the reaction temperature is 120-130°C, oxygen is passed through the reaction process, the kettle pressure is 0.8MPa, and the reaction time is 6 hours to obtain 1.85L containing Cu22.46g / l and Sn0.042g / l Copper sulfate solution and 466g leaching residue containing Sn62.14%, Cu1.92%;

[0021] (2) the copper sulfate solution of leaching is returned airtight container again with new tin-copper slag material, feeds oxygen again and pressurization, heating repeats leaching twice, obtains the copper sulfate solution of 1.8L copper 65.14g / l, will Copper sulfate solution is evaporated and concentrated, cooled and crystallized, and centrifuged to obtain 402g of copper sulfate product ...

Embodiment 2

[0023] (1) 500g of tin-copper slag containing 18.23% of copper and 50.31% of tin is used for pressure leaching with sulfuric acid, and the leaching conditions are: add copper chloride according to 5% of the mass of tin-copper slag, the initial acidity of sulfuric acid is 150g / l, liquid-solid The mass ratio is 5:1, the reaction temperature is 140-150°C, oxygen is passed through the reaction process, the kettle pressure is 1.5MPa, and the reaction time is 4 hours, 2.32L copper sulfate solution containing Cu36.85g / l, Sn0.023g / l and 446g The leaching residue containing Sn54.14%, Cu1.62%.

[0024] (2) Return the copper sulfate solution to leaching once to obtain 2.3L copper sulfate solution containing 59.38g / l of copper. After evaporation and concentration, cooling and crystallization, centrifugation obtains 488g of copper sulfate product and 500ml of crystallization mother liquor. The crystallization mother liquor can be returned to oxygen Pressure leaching, the obtained copper su...

Embodiment 3

[0026] (1) 500g of tin-copper slag containing 30.23% of copper and 59.25% of tin is leached under pressure with sulfuric acid. The solid ratio is 8:1, the reaction temperature is 190-200°C, oxygen is passed through the reaction process, the kettle pressure is 2MPa, and the reaction time is 2 hours, 3.72L copper sulfate solution containing Cu39.41g / l, Sn0.018g / l and 424g containing Sn68.82%, Cu1.42% leaching residue.

[0027] (2) Return the copper sulfate solution to leaching once again to obtain 3.7L copper sulfate solution containing 65.34g / l of copper. After evaporation and concentration, cooling and crystallization, centrifugation obtains 844g of copper sulfate product and 500ml of crystallization mother liquor. The crystallization mother liquor can be returned to oxygen pressure Leaching, the obtained copper sulfate product contains copper sulfate pentahydrate 97.24%, Sn0.001%, Pb0.0011%, As0.002%, Fe0.025%, free acid 0.058%, water insoluble matter 0.016%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com