Device and method for shortening coal seam gas pressure measurement observation time

A technology of coal seam gas pressure and observation time, which is applied to measurement devices, gas discharge, safety devices, etc., to achieve the effects of speeding up the balance speed, reducing the volume, and solving the problem of long observation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

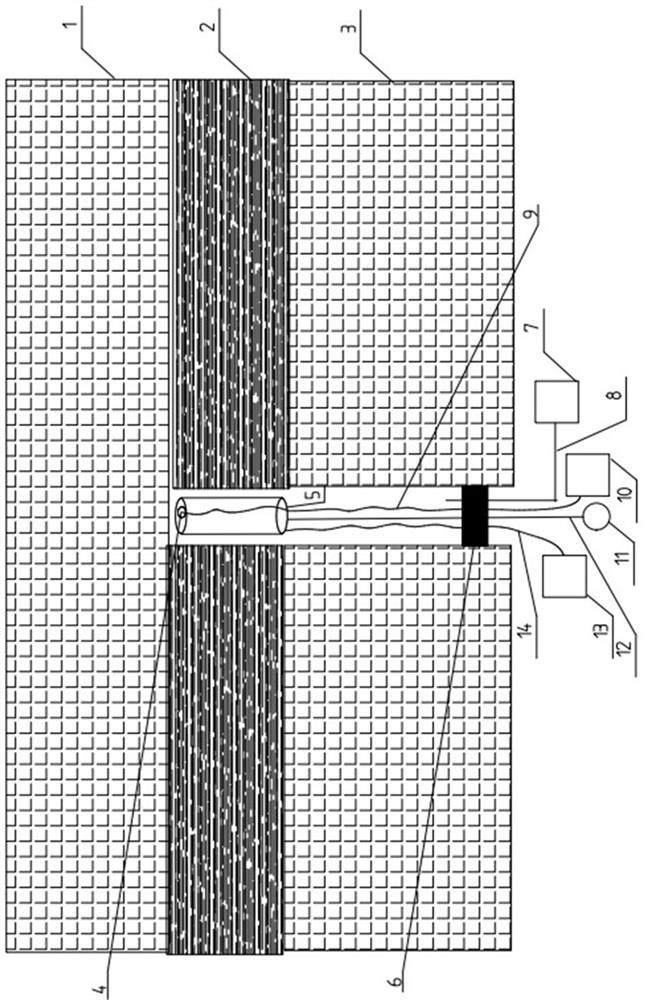

[0031] The technical solution in the embodiment of the application will be clearly and completely described below in conjunction with the accompanying drawings in the embodiment of the application, please refer to figure 1 , this embodiment provides a device for shortening the observation time of coal seam gas pressure measurement, including a grouting mechanism, and also includes:

[0032] A capsule 5 located in the borehole, the surface of the capsule 5 is wrapped with light, flexible, water-absorbing materials, and the top of the capsule 5 is provided with several spray heads 4; and

[0033] A pressure measuring mechanism, the pressure measuring mechanism is provided with a pressure measuring tube 12 for pushing the capsule 5 to move in the borehole; and

[0034] A water delivery mechanism, the water delivery mechanism is provided with a water injection pipe 9, the water outlet end of the water injection pipe 9 is connected to the lower end of the capsule 5, and is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com