Method for grafting linear low density polyethylene to polar monomer

A linear low-density, polyethylene grafting technology, applied in the field of linear low-density polyethylene graft modification, can solve the problems of operator eye and skin damage, difficult production process, easy volatilization or sublimation, etc., to ensure uniformity and heat transfer effect, good biocompatibility, and the effect of overcoming material bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

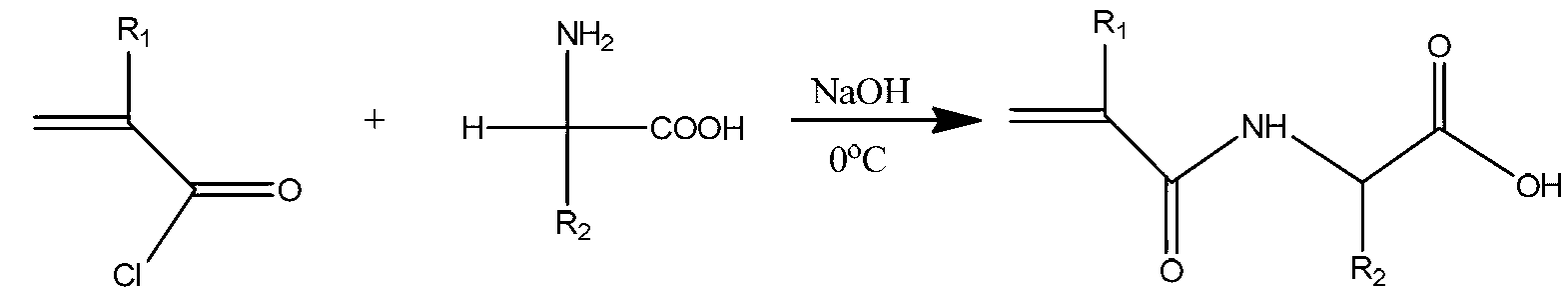

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 5 parts by weight of unsaturated carboxylic acid monomer 1-methacryloylpyrrolidine-2-carboxylic acid in 60 parts of N,N-dimethylformamide (DMF), 2 parts of diphenyl peroxide Acyl (BPO) was dissolved in 10 parts of interface agent xylene; 100 parts of LLDPE particles and 15 parts of the second graft monomer styrene (St) were placed in a reaction vessel containing 300 parts of water, and stirred to make the LLDPE particles evenly Suspend in water; Add the unsaturated carboxylic acid monomer solution and BPO solution into the reaction vessel through a syringe, stir at 60°C under a nitrogen atmosphere for 1.5h, react at 95°C for 2 hours, then cool, wash, filter, and use methanol Extracted with acetone and dried in vacuum to obtain the final grafted product with a grafting rate of 2.1%.

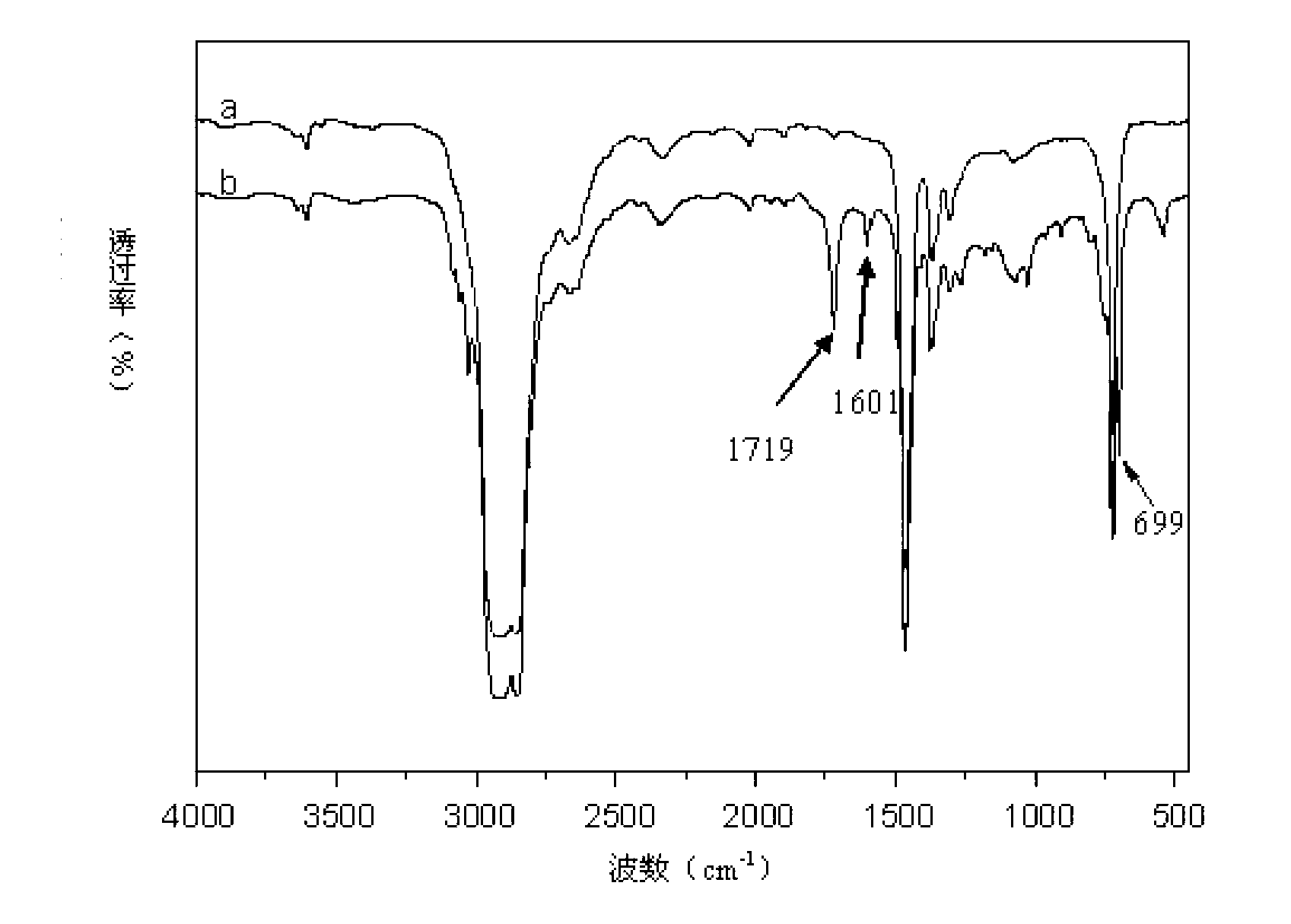

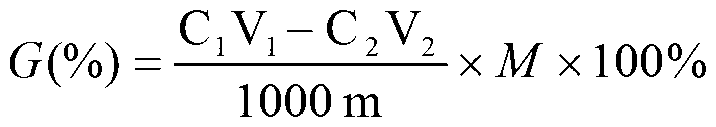

[0028] The invention uses a chemical titration method to measure the grafting rate of unsaturated carboxylic acid monomer grafted LLDPE. The specific method is as follows: firstly...

Embodiment 2

[0033] Dissolve 10 parts by weight of unsaturated carboxylic acid monomer 1-methacryloylpyrrolidine-2-carboxylic acid in 60 parts of N,N-dimethylformamide (DMF), 2 parts of diphenyl peroxide Acyl (BPO) is dissolved in 10 parts of interface agent xylene; 100 parts of LLDPE particles and 10 parts of the second graft monomer styrene (St) are placed in a reaction vessel containing 300 parts of water, and stirred to make the LLDPE particles evenly Suspend in water; Add the unsaturated carboxylic acid monomer solution and BPO solution into the reaction vessel through a syringe, stir at 60°C under a nitrogen atmosphere for 1.5h, react at 95°C for 2 hours, then cool, wash, filter, and use methanol and acetone extraction, vacuum drying, the final grafted product can be obtained, and its grafting rate is 5.3%.

Embodiment 3

[0035] Dissolve 15 parts by weight of unsaturated carboxylic acid monomer 1-methacryloylpyrrolidine-2-carboxylic acid in 60 parts of N,N-dimethylformamide (DMF), 2 parts of diphenyl peroxide Acyl (BPO) is dissolved in 10 parts of interface agent xylene; 100 parts of LLDPE particles and 5 parts of the second graft monomer styrene (St) are placed in a reaction vessel containing 300 parts of water, and stirred to make the LLDPE particles evenly Suspend in water; Add the unsaturated carboxylic acid monomer solution and BPO solution into the reaction vessel through a syringe, stir at 60°C under a nitrogen atmosphere for 1.5h, react at 95°C for 2 hours, then cool, wash, filter, and use methanol and acetone extraction, vacuum drying, the final grafted product can be obtained, and its grafting rate is 11.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com