Ultraviolet radiation two-step grafting method on surface of polyethylene fiber with ultrahigh molecular weight

A polyethylene fiber and ultra-high molecular weight technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of easy attenuation of fiber surface bonding performance, attenuation of modification effect, and impact on mechanical properties, so as to improve the bonding performance , Improve the effect of surface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

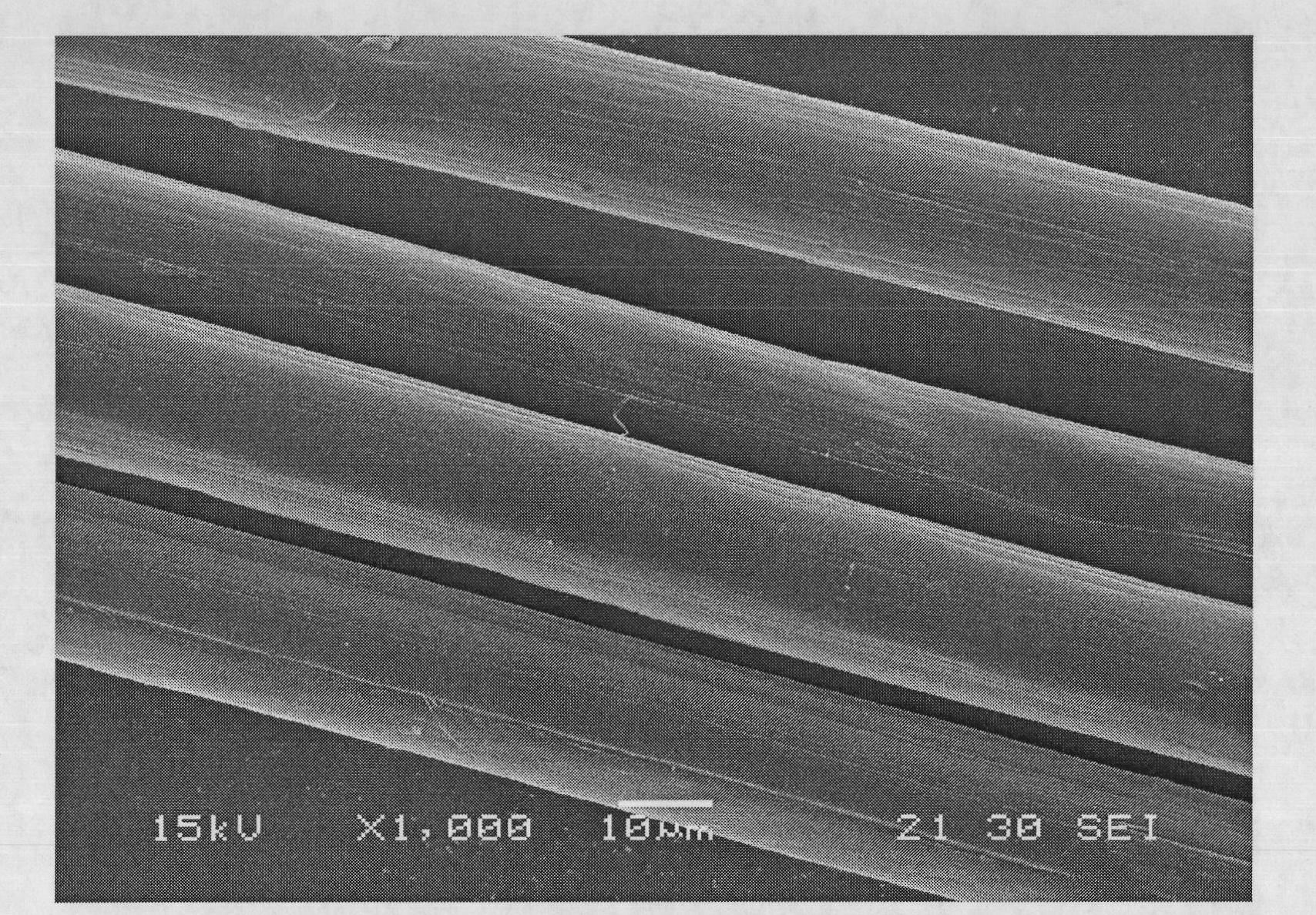

[0047] Soak ultra-high molecular weight polyethylene fibers in n-heptane for 12 hours, then extract them with acetone for 2 hours to obtain pretreated ultra-high molecular weight polyethylene fibers, mix 5wt% benzophenone (BP) with 1.0wt% Polyvinyl acetate was dissolved in tetrahydrofuran solution to prepare a coating solution, and then the swollen pretreated ultra-high molecular weight polyethylene fibers were soaked in the coating solution for 2 hours and protected by nitrogen gas, and then taken out and placed in a vacuum dryer. Vacuum dry, take out after 30min.

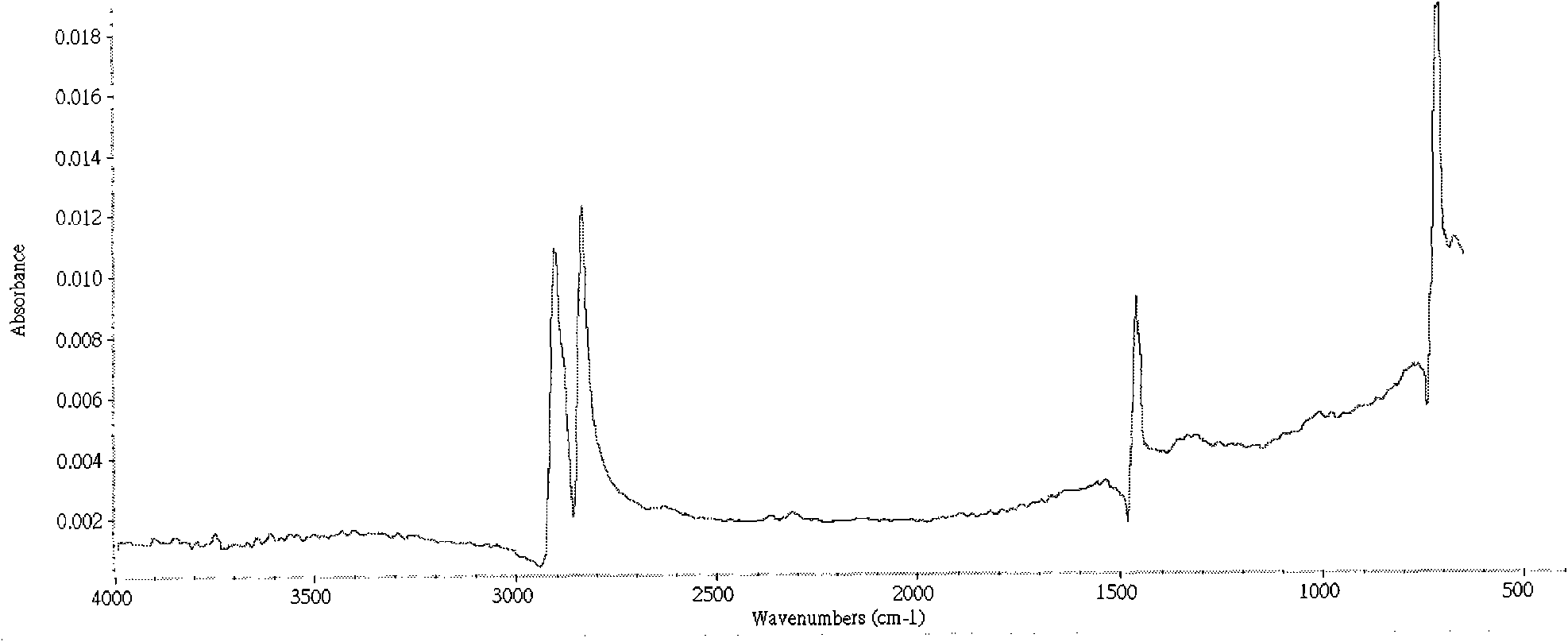

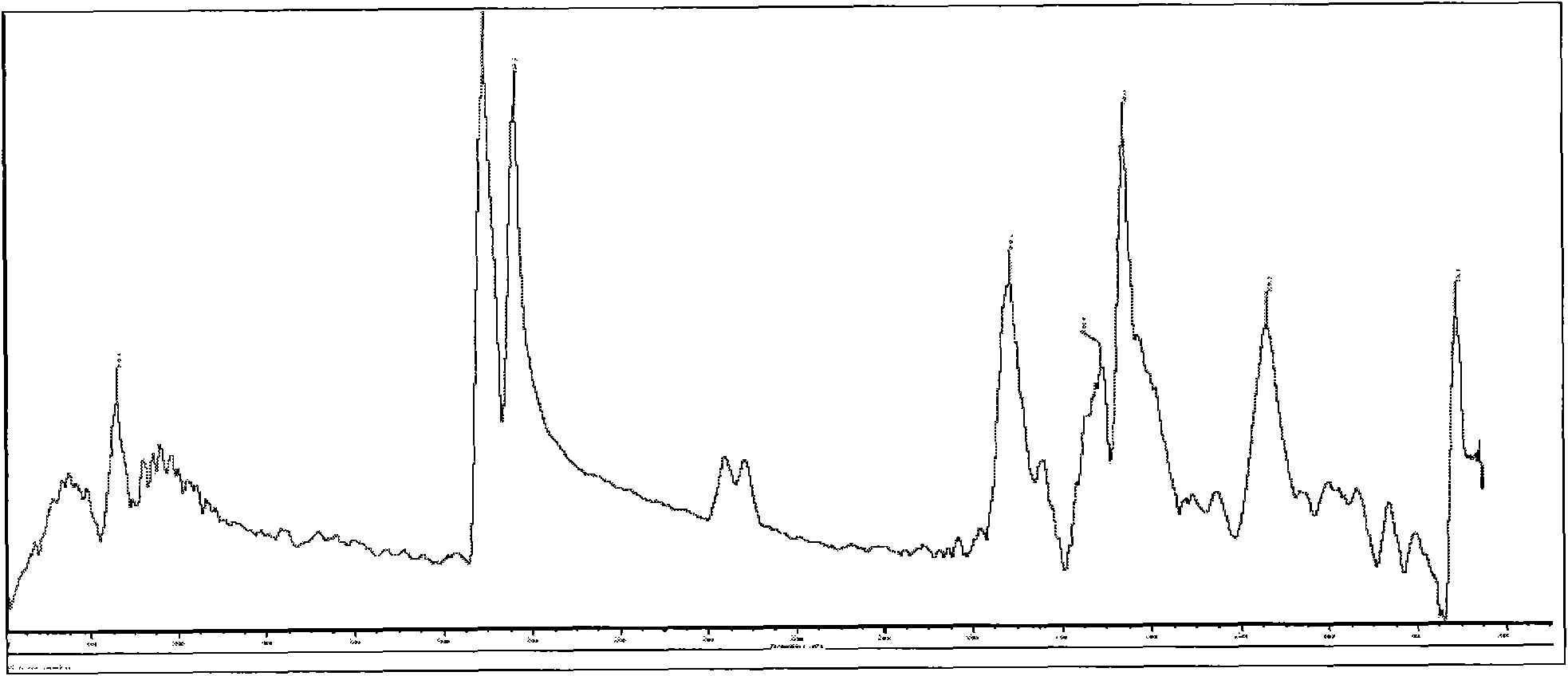

[0048] The coated fibers were irradiated with ultraviolet light for 10 minutes, and the fibers were ultrasonically washed with acetone after irradiation. According to the total reflection infrared spectrum (ATR-FTIR), compared with the original silk, the infrared spectrum of the irradiated fiber is at 800-900cm -1 / 1000~1100cm -1 / 1650cm -1 / 1175cm -1 / A strong absorption peak appeared, and the C=O group capt...

Embodiment 2

[0050] Soak ultra-high molecular weight polyethylene fibers in n-heptane for 12 hours, then extract them with acetone for 2 hours to obtain pretreated ultra-high molecular weight polyethylene fibers, mix 2wt% benzophenone (BP) with 0.8wt% Vinyl acetate (PVAc) was dissolved in acetone solution to prepare a coating solution, and then the swollen pretreated ultra-high molecular weight polyethylene fiber was soaked in the coating solution for 3 hours and protected by nitrogen gas, and then taken out and placed in a vacuum desiccator , evacuate, and take it out after 30 minutes.

[0051] The coated fiber is soaked in methacrylic acid (MA) solution, the concentration of acrylic acid is 30%, the solvent is deionized water, the soaking time is 10h, the fiber is taken out and placed under ultraviolet light for 15min, and then washed to remove homopolymer, and then soak the fiber in 30% TMPTMA solution, the solvent is tetrahydrofuran, and then react under ultraviolet radiation. After t...

Embodiment 3

[0054] Dissolve 1.0% benzophenone (BP) and 1.0% polyvinyl alcohol in tetrahydrofuran solution to prepare a coating solution, then soak the swollen fibers in it, soak in nitrogen for 1 hour, take it out and put it in a vacuum dryer , evacuate, and take it out after 30 minutes.

[0055] The coated fiber is soaked in methacrylic acid (MA) solution, the concentration of methacrylic acid is 20%, the solvent is deionized water, and the soaking time is 2h. After 2 hours, take out the fiber and irradiate it under ultraviolet light for 15 minutes, then wash to remove the homopolymer, then soak the fiber in 25% TMPTMA solution, solvent acetone, and react under ultraviolet irradiation. After the reaction, the fiber is post-treated to obtain a graft-modified fiber. The irradiation temperature of the above two steps is both 60° C. (the temperature inside the quartz tube).

[0056] The external spectrum (ATR-FTIR) of the grafted fiber after total reflection showed a strong 1715.0cm -1 (C=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com