Amorphous crystallizer

A crystallizer and amorphous technology, applied in the field of crystallizers for the production of amorphous alloys, can solve problems such as immature structure and parameters, failure of various water cooling structures, lack of cooling structures, etc., to achieve uniform cooling in the axial direction and improve precision , high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

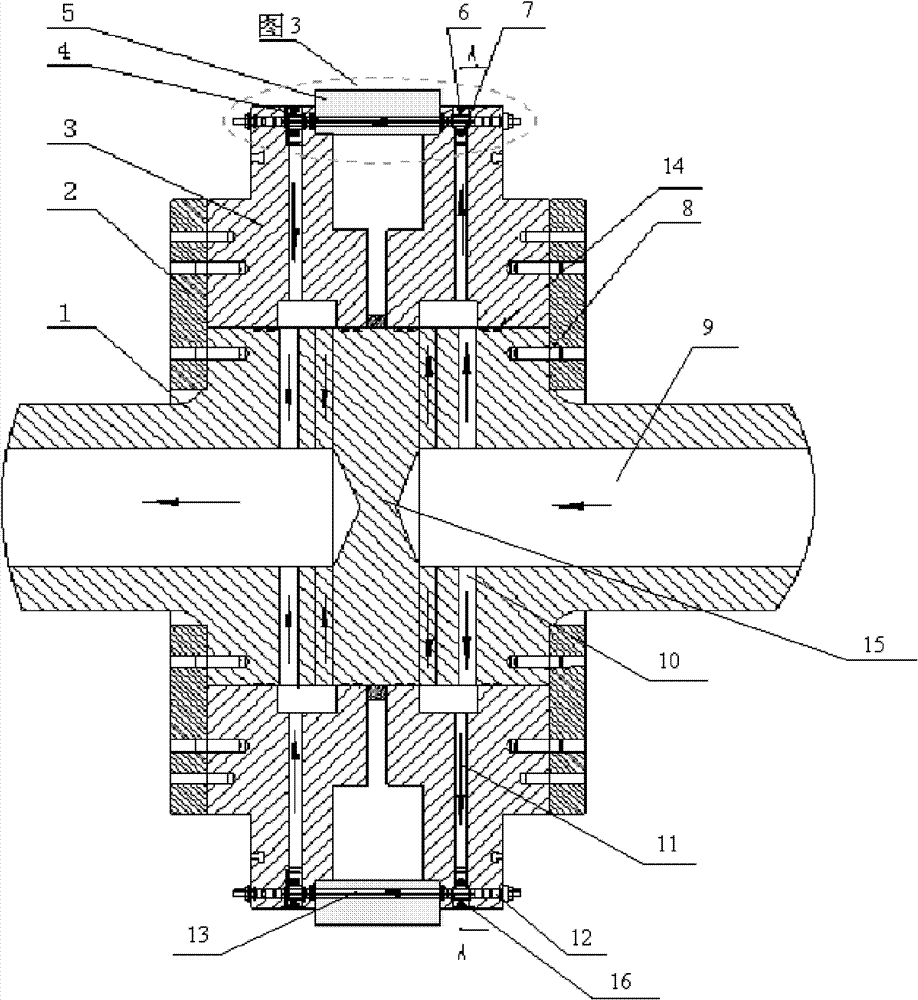

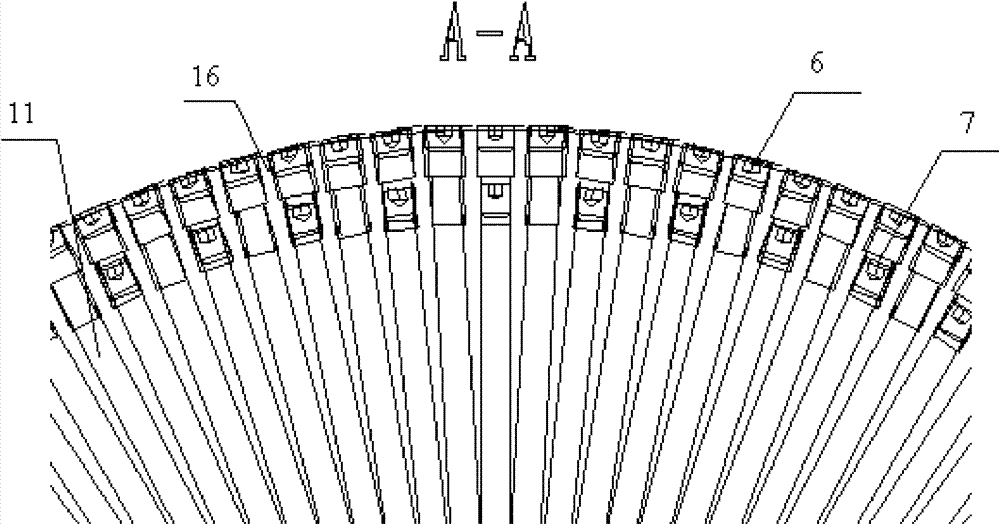

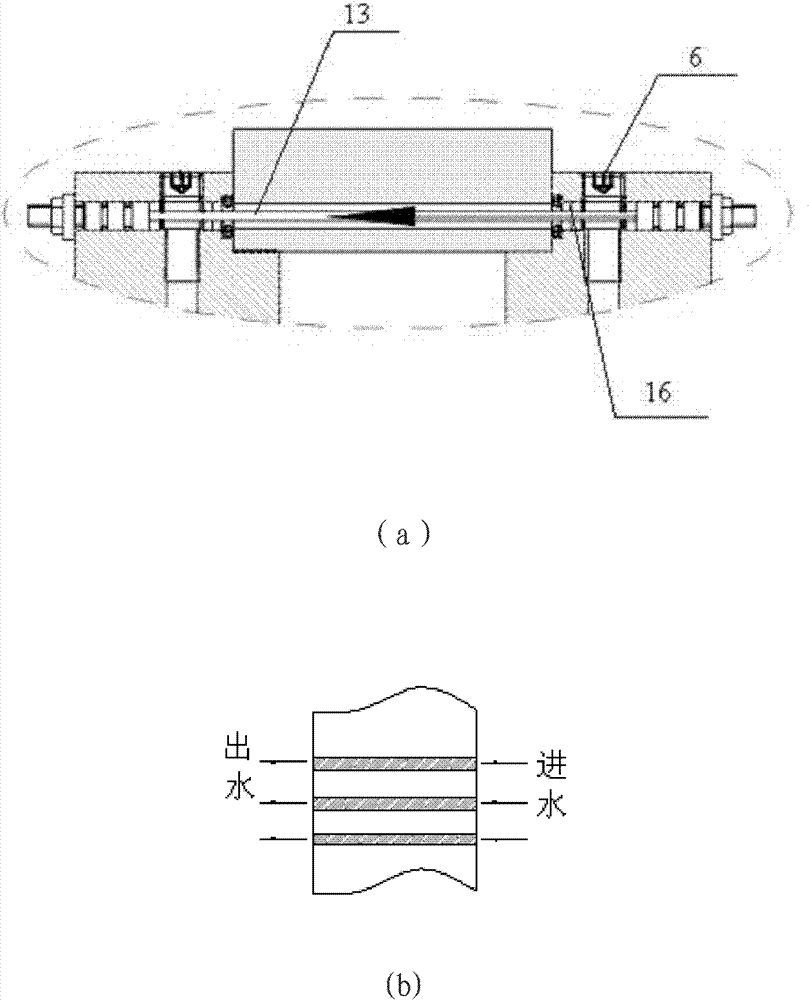

[0014] figure 1 It is a front sectional view of an embodiment of the present invention. 1 is the rotating main shaft, 2 is the end cover, 3 is the copper sleeve support, 4 is the flow rate adjustment rod, 5 is the chrome-zirconium copper sleeve, 6 is the screw plug, 7 is the screw plug, 8 is the twisting conical pin, 9 is the rotating main shaft Deep hole, 10 is the second radial through hole of the rotating spindle, 11 is the first radial through hole for supporting the copper sleeve, 12 is the second axial through hole for supporting the copper sleeve, 13 is the first axial through hole for the copper sleeve, 14 For sealing ring, 15 is the center of the rotating main shaft, and 16 is the end face groove supported by the copper sleeve. Both the copper sheath 5 and the copper sheath support 3 are annular, and there is a copper sheath support 3 on each of the left and right sides of the copper sheath 5 . The end cover 2 is connected to the rotating main shaft 1 and the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com