Manufacturing method of capillary structure of flat-sheet heat pipe

A flat-plate heat pipe and capillary structure technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of burning, affecting the working performance of heat pipes, increasing the thermal resistance of heat pipes, etc., and achieve the effect of ensuring heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

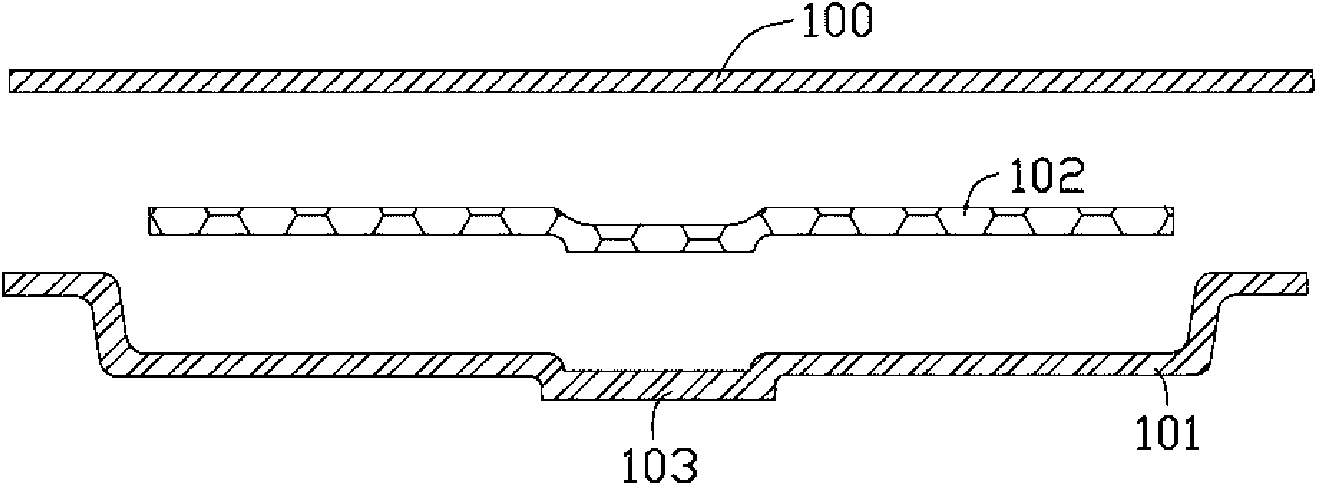

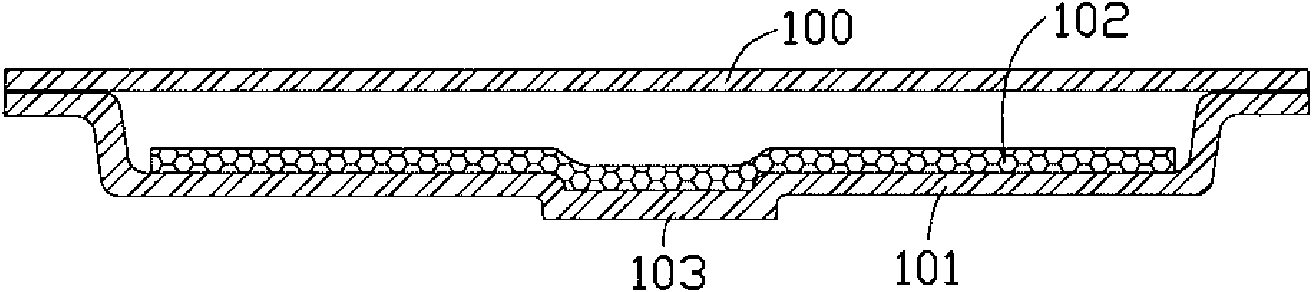

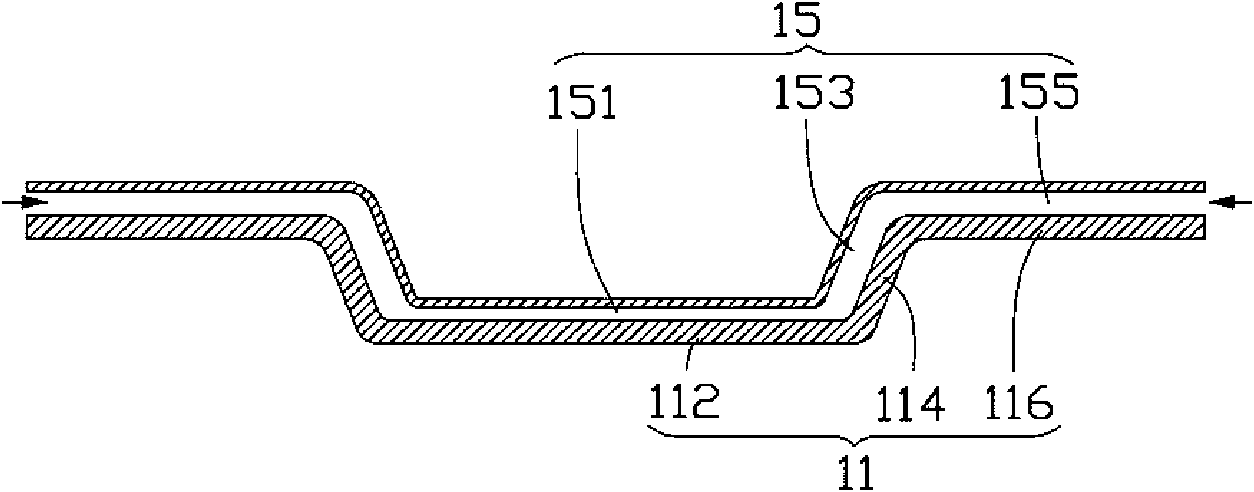

[0026] Such as image 3 and Figure 4 As shown, it is the lower cover plate 11 of the flat heat pipe 10 of the first embodiment of the present invention and the capillary structure 13 attached to the upper surface of the lower cover plate 11. The specific manufacturing process is as follows: (1) provide a metal lower Cover plate 11, the lower cover plate 11 is stamped and arranged in a bowl shape, has a horizontal heat absorbing portion 112, two extension portions 114 extending upward and outward from opposite ends of the heat absorbing portion 112 and self-extending (2) provide a number of metal powders; (3) provide a mold 15, the profile of the mold 15 is roughly similar to the lower cover plate 11, and it is an inner opening with an opening downward. empty chamber. The mold 15 includes a first receiving section 151 corresponding to the heat absorbing portion 112 of the lower cover 11 , a second receiving section 153 corresponding to the extending portion 114 , and a third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com