Tube fin type cooler based on thermal medium flow rate

A heat medium, tube-fin technology, applied in indirect heat exchangers, heat exchanger types, tubular elements, etc., can solve the problems of high heat dissipation requirements, low fin density and form requirements, and waste of heat exchange capacity. Simple processing technology, low cost of use, and the effect of ensuring heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

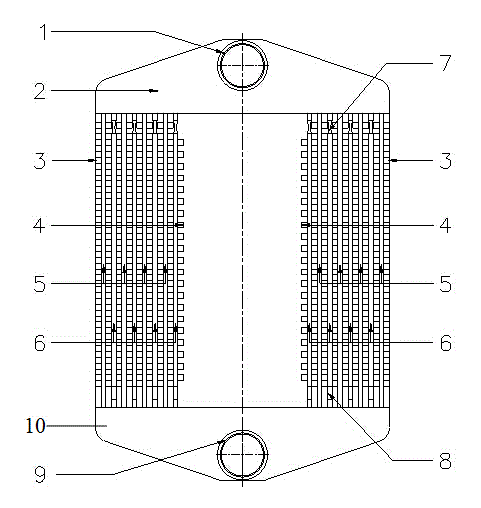

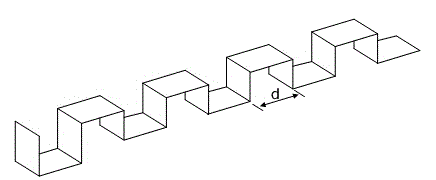

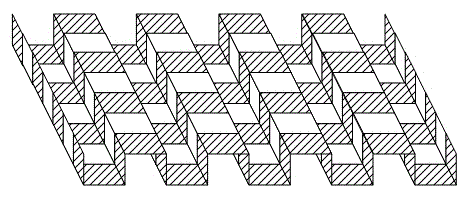

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0025] According to the simulation calculation, it is found that due to the influence of the structure of the radiator head, the flow rate and corresponding pressure in each channel of the radiator are quite different. Figure 9 It is the pressure difference curve between the channels of the common structure intercooler under different working conditions, where Case9 corresponds to the working condition with a larger heat medium flow rate. Depend on Figure 9 It can be seen that under the condition that the overall flow rate of the heat medium is large, the difference in pressure difference between the channels reaches several thousand Pa. Even under the condition of small flow rate, the difference of pressure difference is close to 400Pa. In the channel with higher flow, the pressure may reach more than 2000 Pa. For liquid-gas heat exchange radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com