Through-wall type filter element and dust removal device

A filter element and through-wall technology, which is applied in the field of through-wall filter elements, can solve the problems of high equipment investment cost, large floor space, and low density, and achieve the effect of compact structure, small floor space, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

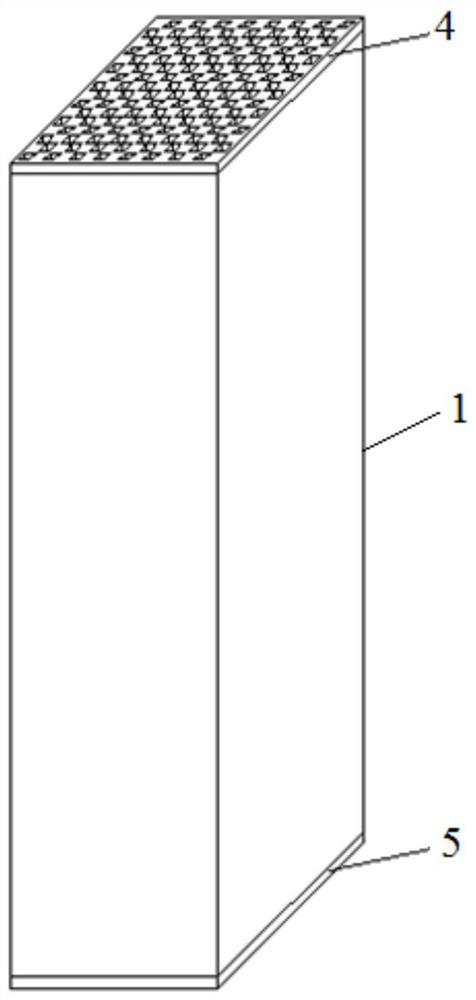

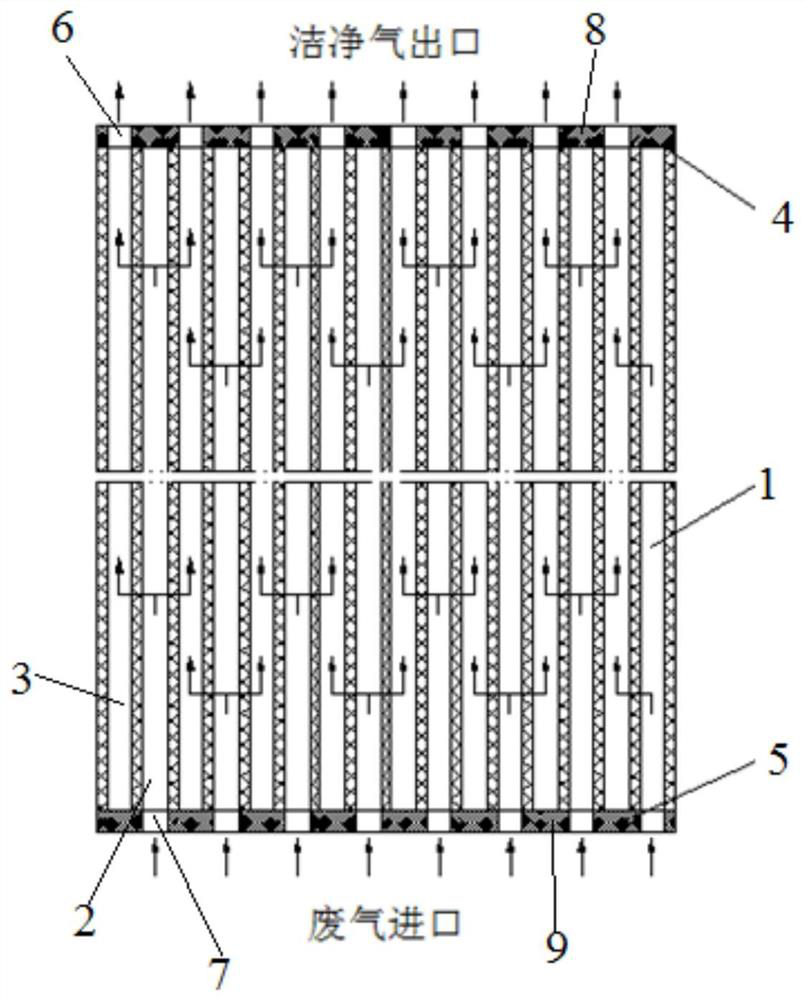

[0034] refer to Figure 1-Figure 3 As shown, this embodiment provides a through-wall filter element, including a filter element body 1, the filter element body 1 is a ceramic filter element or a ceramic fiber filter element, an air passage group is opened on the filter element body 1, and the air passage group includes an air inlet passage 2, The air outlet 3 arranged adjacent to the air inlet 2, the air inlet 2 and the air outlet 3 are all hollow structures with one end open and the other end blocked by a blocking member. The blocked end is located on the same side, and the blocked end of the inlet passage 2 and the open end of the air outlet passage 3 are located on the same side. Wherein, the central axis of the inlet passage 2 and the central axis of the outlet passage 3 in this embodiment are parallel to each other.

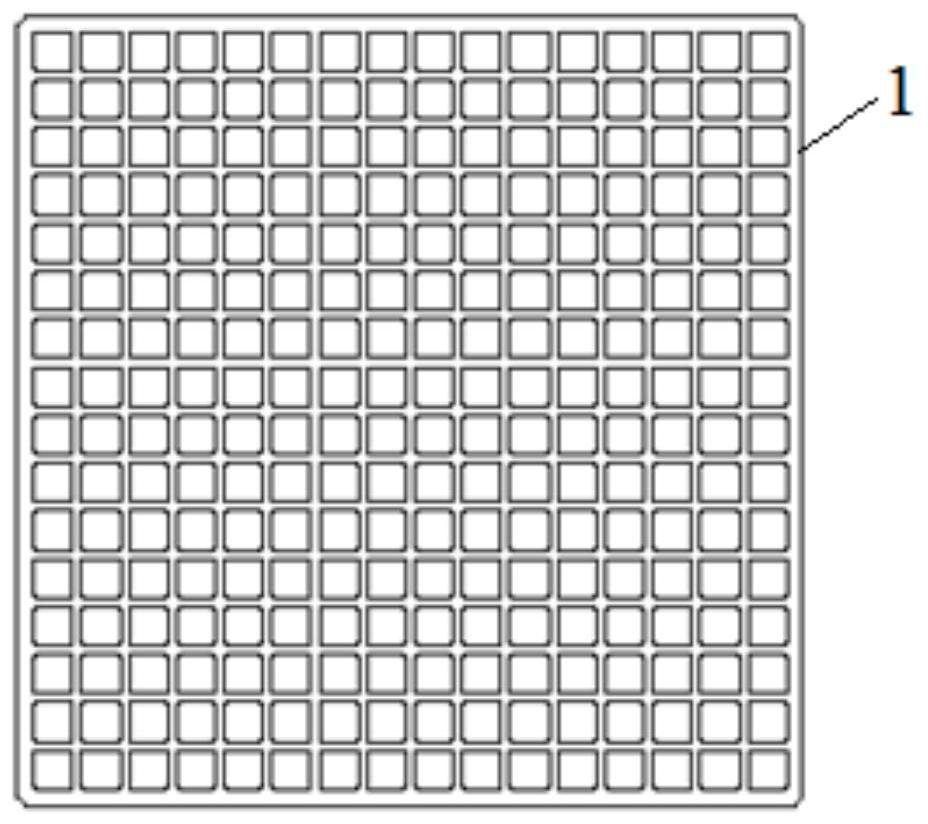

[0035] The filter element body 1 in this embodiment has a rectangular structure with a square cross section and a rectangular vertical section. By restric...

Embodiment 2

[0051] The structural difference between the through-wall filter element in this embodiment and the through-wall filter element in the embodiment is that each air channel group in this embodiment has N inlet channels 2, where N is greater than or equal to 2 is an even number; N air inlets 2 are distributed in a rectangular array of M rows×2 columns, where M=N / 2, and an air outlet 3 is arranged between two adjacent air inlets 2 in each row.

[0052] Specifically, N in this embodiment is 6, that is, each airway group includes 6 inlet channels 2 and 3 outlet channels 3 . In each airway group, six air inlets 2 are distributed in a rectangular array of 3 rows×2 columns.

[0053] When N / 2×L=2×P, and 2×P is an even number, if the first blocking plate 4 and the second blocking plate 5 are used to block the end of the inlet passage 2 and the outlet passage 3 respectively When the end is blocked, the first block plate 4 and the second block plate 5 have the same structure, that is, the...

Embodiment 3

[0057] refer to Figure 8 As shown, this embodiment provides a dust removal device, including the through-wall filter element 10 provided in the embodiment of the present invention, and also includes a housing 11, and the housing 11 is respectively provided with an air inlet 12 and an air outlet 13. The wall filter element 10 is disposed in the casing 11 , and the through-wall filter element 10 is located between the air inlet 12 and the air outlet 13 .

[0058] Specifically, the housing 11 in this embodiment is provided with a support grid 14 and a sealing partition 15 sequentially from bottom to top. The support grid 14 and the sealing partition 15 divide the housing 11 into rows from bottom to top. Ash chamber 16, raw air chamber 17, and clean air chamber 18.

[0059] Specifically, the air inlet 12 in this embodiment is located at the lower part of the side wall of the housing 11 and communicates with the ash discharge chamber 16 , and the air outlet 13 is located at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com