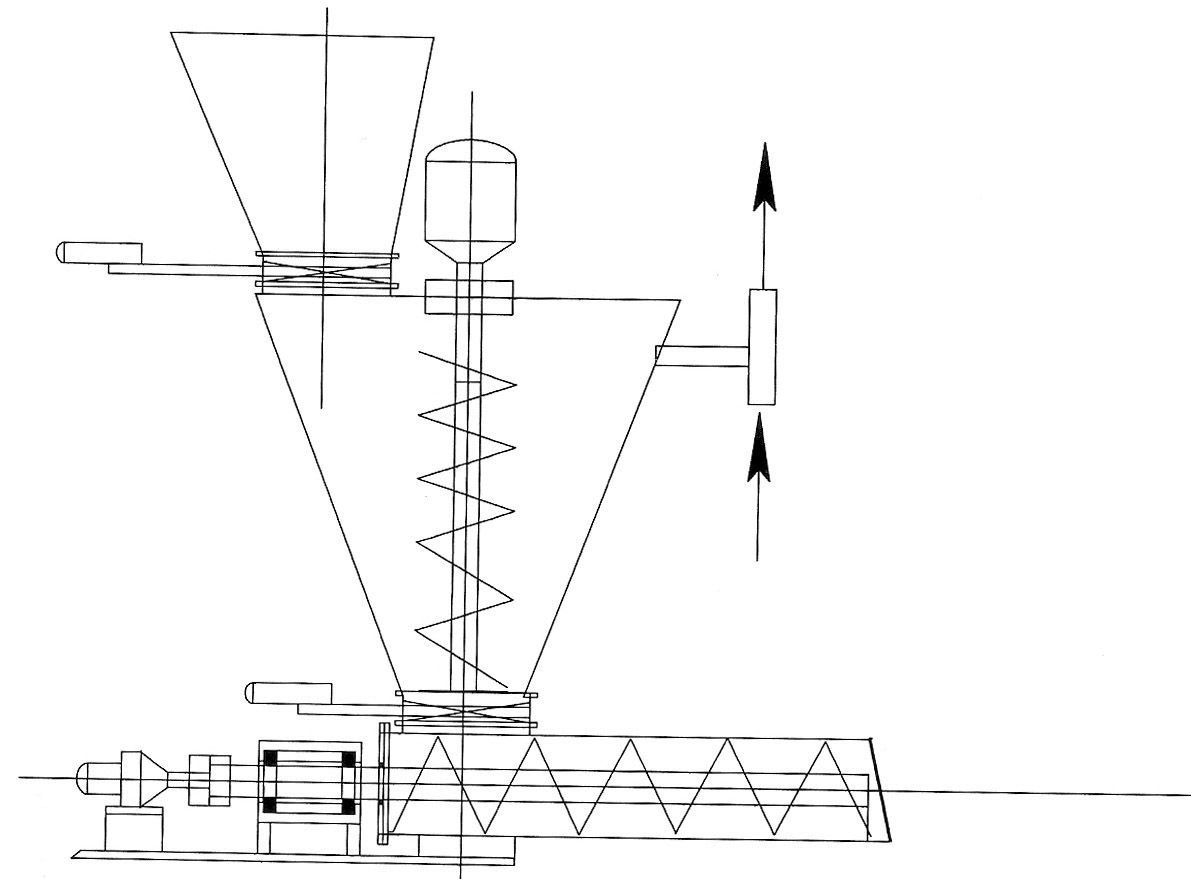

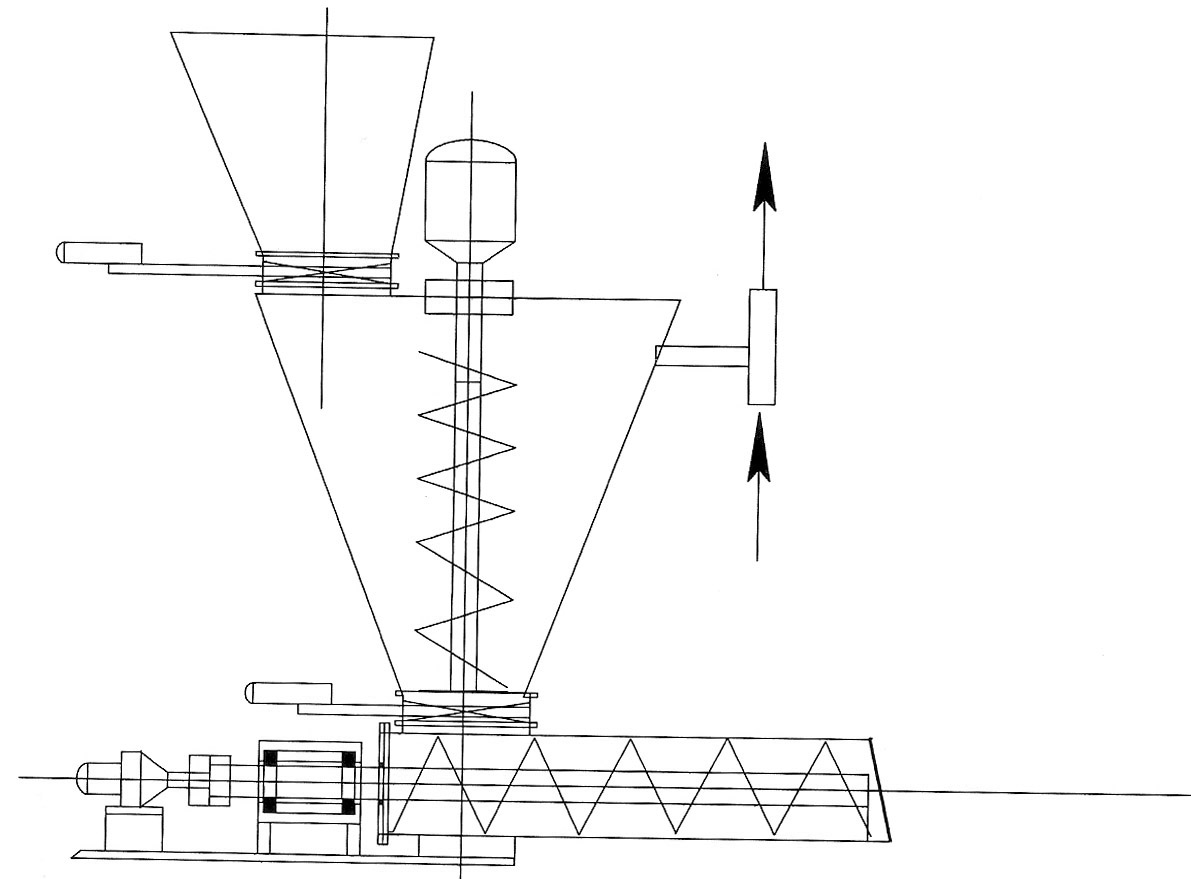

Waste pyrolysis screw feed pump for household garbage and waste tires

A technology of domestic waste and screw feeding, applied in the direction of educts, charging devices, special forms of dry distillation, etc., can solve the problem of arching feeding interruption, oil and gas leakage, hindering domestic waste, waste tire waste anaerobic or oxygen-depleted external thermal decomposition. Process and other issues to achieve the effect of realizing the whole process automation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A pyrolysis screw feeding pump for domestic garbage and waste tire waste, including a vertically installed primary screw feeder, the bottom of which is connected to a horizontally installed secondary screw feeder, and the primary screw feeder has a hopper 1 , the first screw 3 driven by the first motor 2 is set in the hopper, and the first screw blade 4 is set on the first screw. The material inlet and the inner space of the hopper are the ventilation chamber 6, the ventilation chamber communicates with the negative pressure generator through the external connection pipe 7, the inlet knife valve 8 for opening and closing the inlet is set at the inlet, and the inlet valve 8 is set at the outlet. Open and close the outlet knife valve 9 of the discharge port; the second screw 11 driven by the second motor 10 is installed in the barrel of the secondary screw feeder, and the second screw blade 12 is arranged on the second screw.

[0021] A self-falling cover plate 13 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com