Hydraulic multichannel conversion valve

A multi-way reversing valve and hydraulic technology, which is applied in the direction of fluid pressure actuators, earth movers/shovels, servo motor components, etc., can solve the fatigue damage of hydraulic components, unstable working speed, and laborious manipulation, etc. problem, to achieve the effect of soft transition of pressure oil increment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

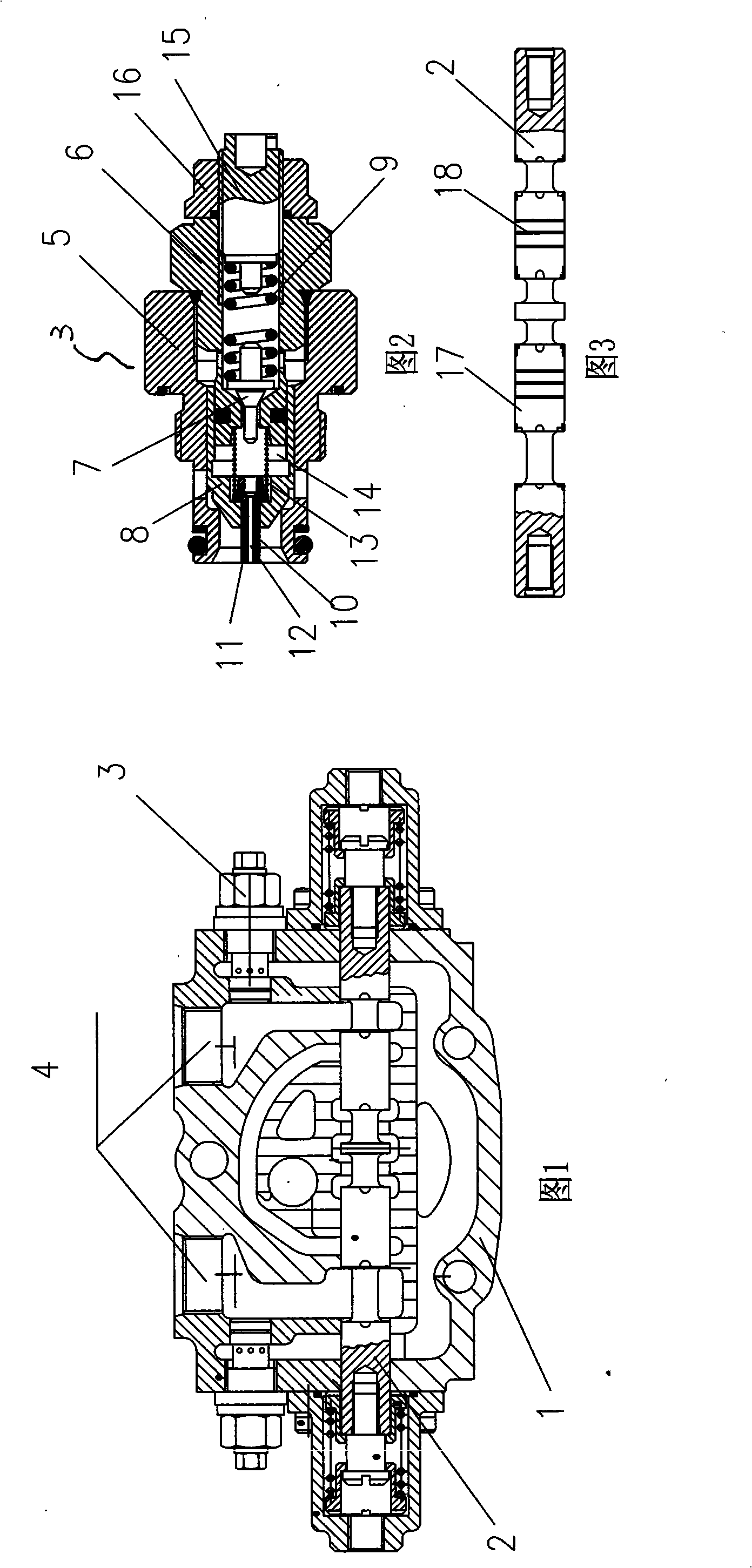

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] As shown in the figure, a hydraulic multi-way reversing valve is composed of left and right driving valves. The driving valve includes a driving valve body 1 and a valve core 2. The driving valve body is provided with an overload protection valve 3 and an overload protection valve. It is connected with the oil inlet and outlet port 4 of the valve body. The overload protection valve includes a main valve body 5, an auxiliary valve body 6, a valve needle 7 and a one-way valve core 8. The one-way valve core plays the role of replenishing oil, effectively solving the problem of Insufficient oil supply for a single action causes negative pressure at the oil supply port to prevent cavitation. The rear end of the main valve body is screwed with an auxiliary valve body, and a valve needle is placed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com