Process for partitioning and three-dimensional material distribution of ceramic tiles

A vitrified brick and three-dimensional technology, which is applied in the field of vitrified brick partitioned three-dimensional fabric technology, can solve the problems of not well reflecting the natural and smooth effect of natural stone, mechanical and rigid pattern characteristics, and achieves a wide range of designs and realistic effects. , Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

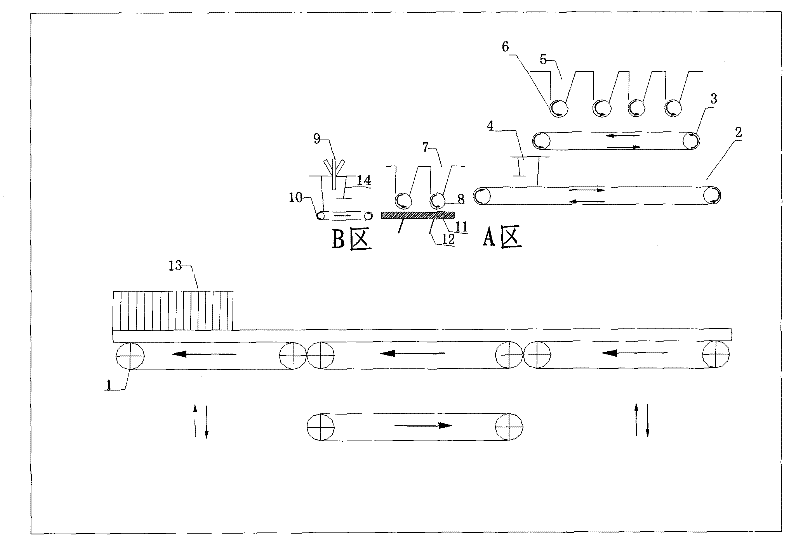

[0023] Such as figure 1 Shown; a vitrified brick divisional three-dimensional cloth process, the process includes A-area fabric delivery, B-area fabric delivery, thread material delivery and combined accumulation, the A-area fabric delivery is to place the micro-powder fabric in four fabric hoppers In 5, the four fabric rollers 6 below the fabric hopper 5 are rotated and dropped onto the conveyor belt 3, and the conveyor belt 3 moves to send the fabric into the fabric storage hopper 4, and the outlet below the storage hopper 4 is provided with a conveyor belt 2, and the conveyor belt 2 Rotate to evenly spread the micropowder fabric on the conveyor belt 2, and the front and bottom of the conveyor belt 2 are suspended in the air. The wire material conveying is to rotate the wire material 7 from the wire unloading drum 8 and drop it onto the vibrating screen 11. The vibrating screen 11 is suspended in parallel at 0 degrees, and the inclined baffle plate 12 is connected underneath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com