A process and equipment for making three-time cloth imitation jade texture vitrified bricks

A technique of imitating jade and vitrified bricks, applied in the manufacture of tools, supply devices, etc., to achieve a wide range of designs, obvious effects, and natural and smooth texture lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

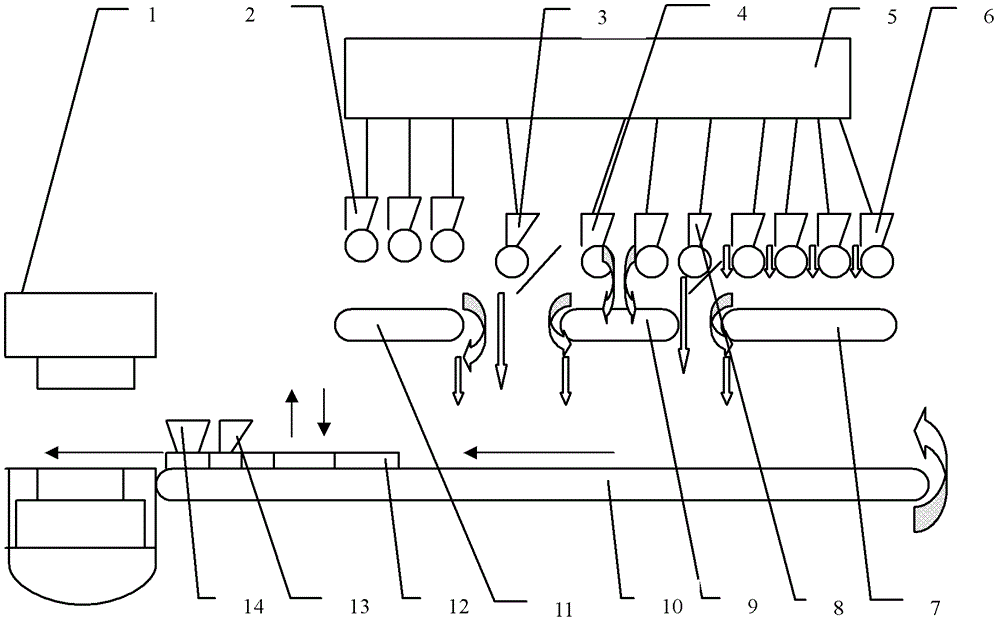

[0021] A kind of technology of making three times cloth imitation jade texture vitrified brick, its used technology equipment such as figure 1 As shown, the process device includes a stacking overall conveying device, a powder beating device for making micronized powder, a combined micron powder unloading device, and a blanking conveying device. The blanking conveying device is above the integral conveying belt 10, the micropowder combined discharging device is above the blanking conveying device, and the powder beating and micronizing device 5 is at the top of the entire equipment system. The micropowder combination blanking device includes a combined micropowder structure 2, a combined crystalline micropowder structure 6, and a pair of micropowder structure components 4. The blanking conveying device includes a crystalline micropowder blanking conveyor belt 7, the first line blanking roller device 3, the second Two line blanking drum device 8 and vibrating sieve, to from mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com