A distributing device and process for multi-texture composite ceramic bricks

A cloth device and multi-texture technology, applied in supply devices, manufacturing tools, etc., can solve the problems of limited use occasions, low surface hardness, non-wear-resistant products, etc., and achieve large texture contrast, strong controllability, and natural texture lines. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

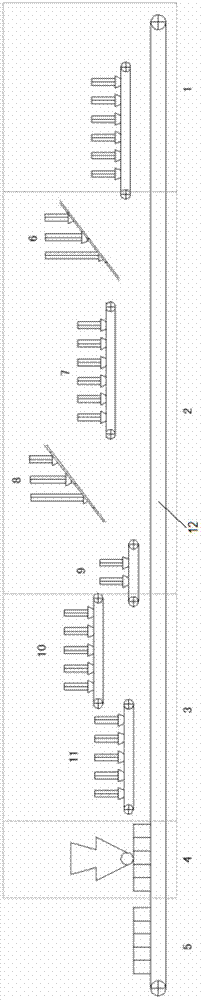

[0037] Such as figure 1 As shown, a distributing device for multi-textured combined ceramic bricks includes a system consisting of 30 grinding machine feeding systems and an integral conveyor belt, in which the controller controls the 30 grinding machine feeding systems to complete the micropowder fineness control Feeding control, the integral conveying belt conveys the fine powder with texture effect into the press for pressing, including:

[0038] Combination of feeding roller a1, pre-collecting fine powder, forming ribbon pattern, ribbon and rotating texture, including six sets of feeding roller combinations, each of which includes a fabric storage hopper, and a bottom set under the fabric storage hopper Material roller, vibration and switch air valve;

[0039] Combining the blanking roller b2 to form triangular or penetrating mottled silk stripes and group patterns, including the engraved roller combination 6, the toothed roller combination 7, the strip texture roller com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com