Multi-rod driving mechanism

A driving mechanism and multi-link technology, which is applied in mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of narrow curve adjustment range, complex structure, narrow design range of connecting rods, etc., and achieve wide curve adjustment range , increase the degree of freedom, design a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

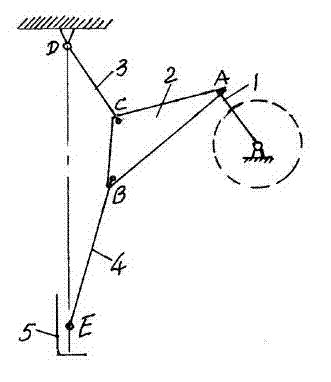

[0012] like figure 1 As shown, the present invention is composed of a triangular block 2, a connecting rod 3, and a connecting rod 4. One end of the connecting rod 3 is connected to the fixed fulcrum of the body at point D, and the other end is connected to the triangular block at point C, and the triangular block is connected to the driving rod 1. At point A, the connection point B of the triangular block is connected with the connecting rod 4, and the other end of the connecting rod 4 is connected with the slider 5 at point E.

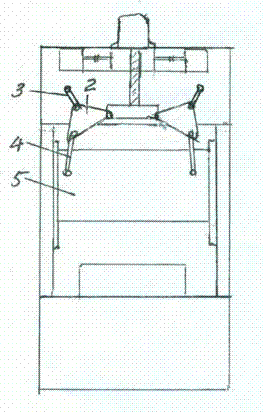

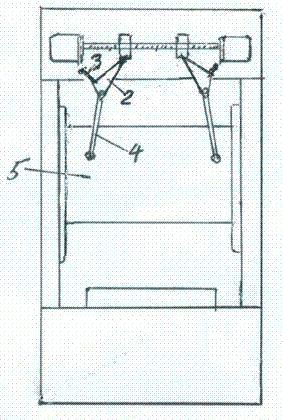

[0013] like figure 2 As shown, the connecting rod driving mechanism of the present invention is installed on the servo press, and is a vertical driving type. There are two connecting rod driving mechanisms. Nut, in addition, one corner of the triangle block is connected to one end of the connecting rod 3, and the other end of the connecting rod 3 is connected to the fixed fulcrum on the body, the third angle of the triangle is connected to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com