A preparation device and process for ceramic tiles imitating Australian sandstone texture

A technology for preparing devices and textures, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of insufficient variety of decoration overall paving effects, insufficient texture layers, and single color tone, and achieve a wide range of designs and texture layering effects like stone Realistic, Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

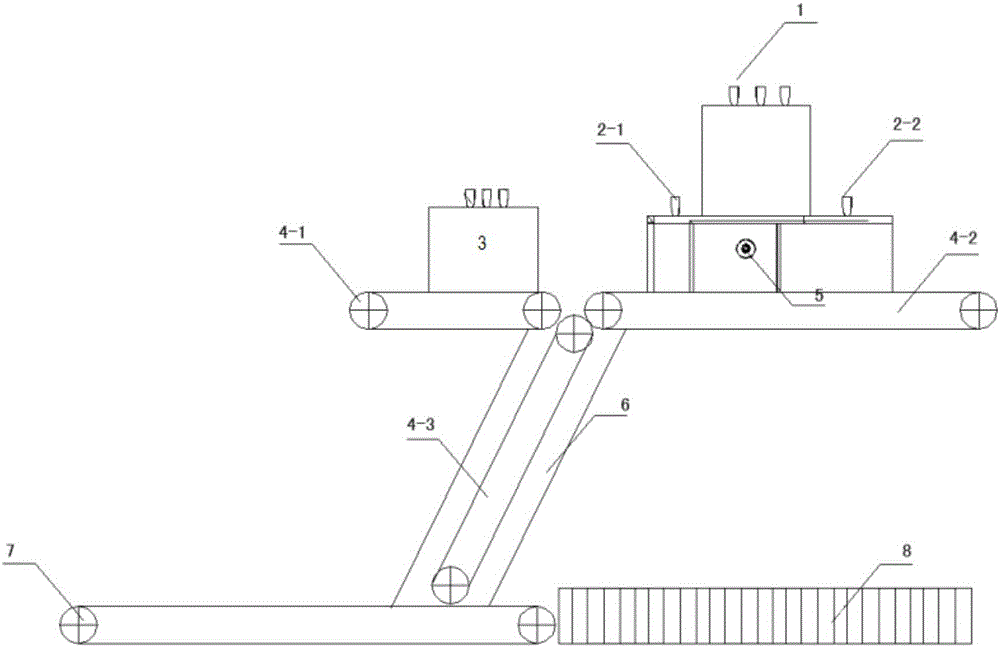

[0044] A preparation device for imitating Australian sandstone texture tiles, comprising:

[0045] Color control roller combination blanking device 1: including multiple fixed storage hoppers assembled with materials of different colors, and rotating blanking rollers and fixed inclined plates arranged in sequence under each fixed storage hopper; the color control roller described in this embodiment is The combined blanking device 1 is arranged above the rear of the powder truck, and includes three sets of fixed storage hoppers, rotating blanking drums and fixed inclined plates.

[0046] Main material unloading drum 2-1: including the main material storage hopper, the main material drum, and the outlet gate. The main material storage hopper is connected above the main material drum, and the outlet gate is installed to control the amount of material; the main material unloading The roller 2-1 is arranged in front of the color control roller combination blanking device 1;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com