Patents

Literature

36 results about "Texture control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

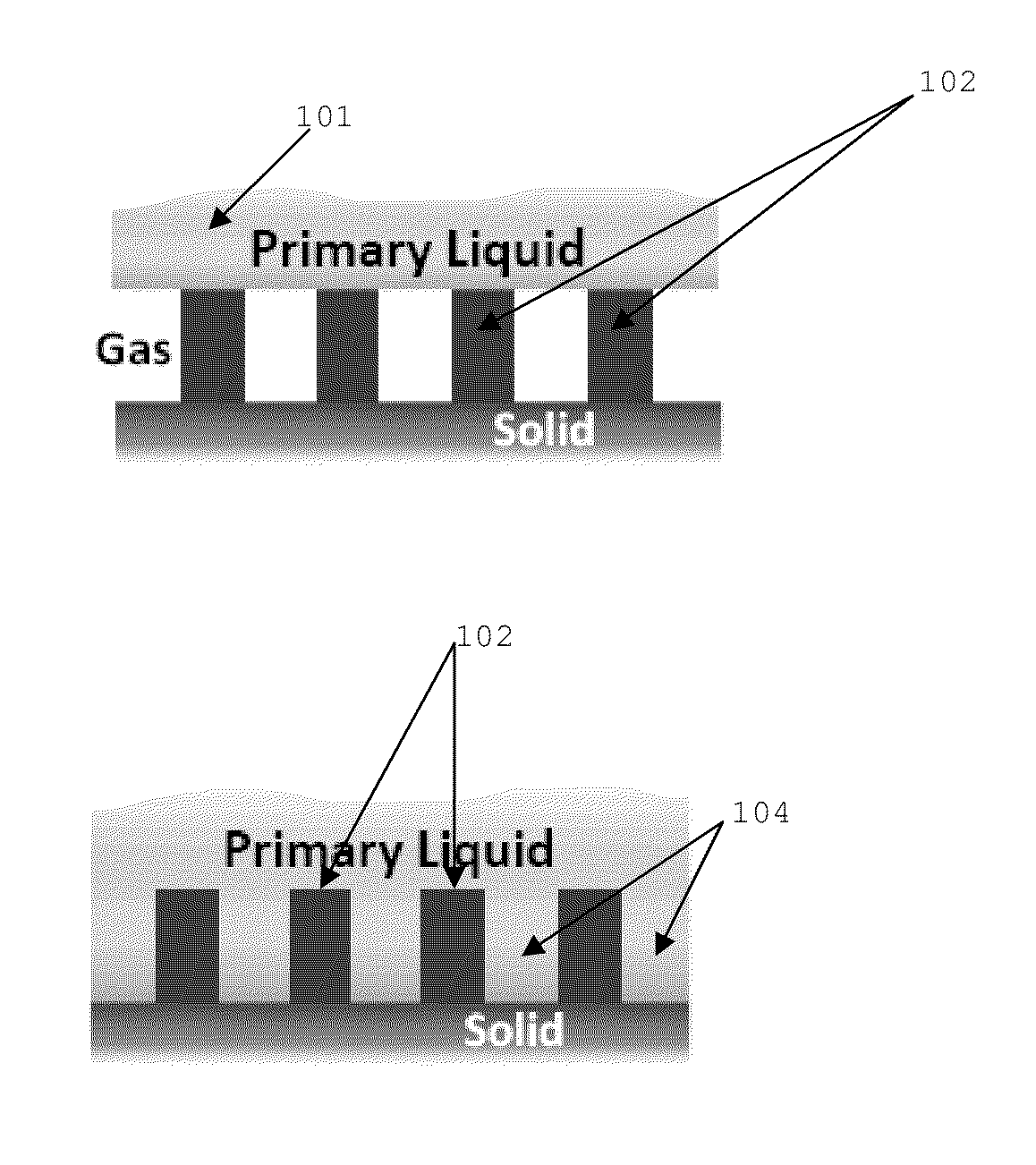

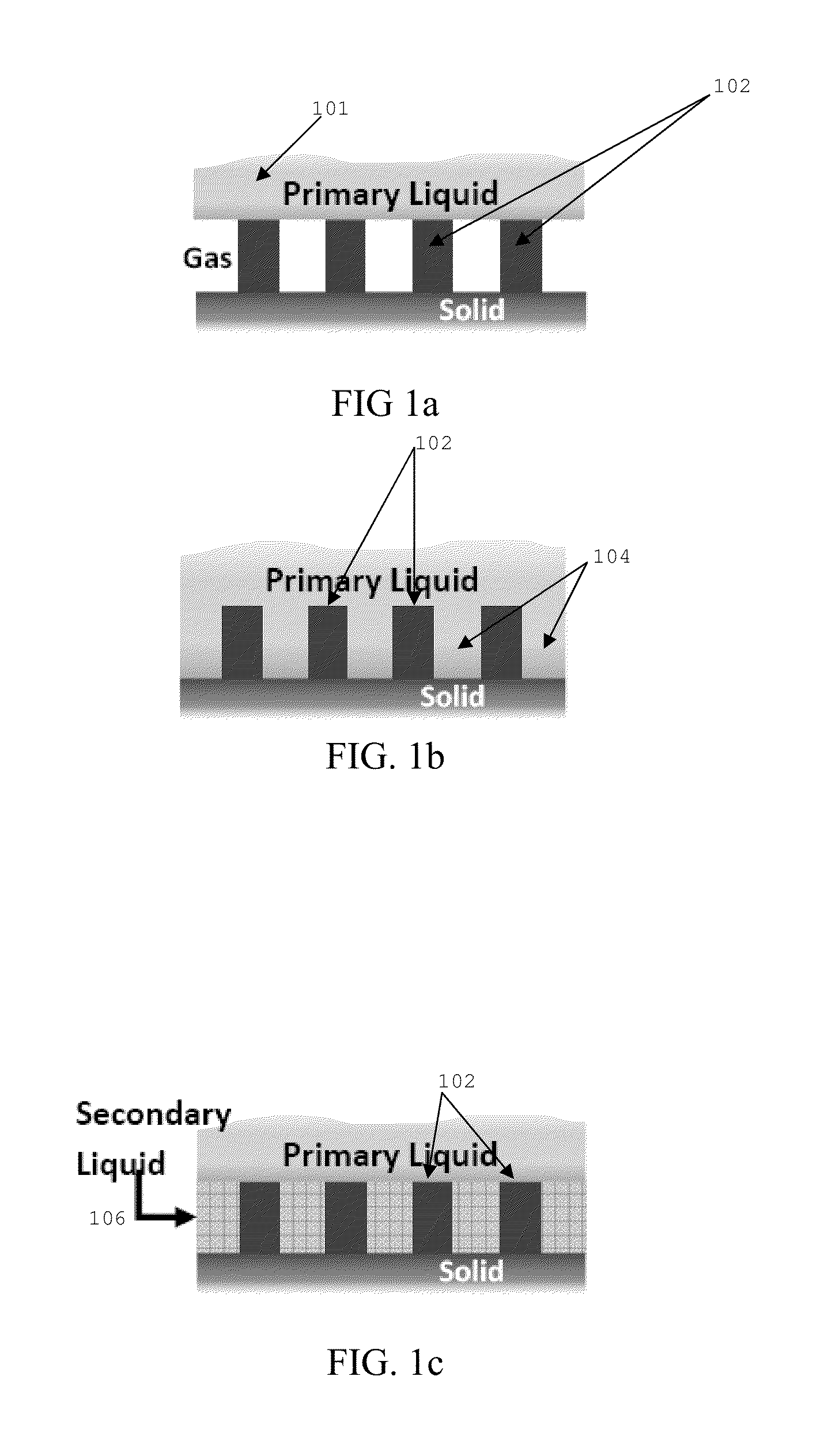

Articles and methods for modifying condensation on surfaces

InactiveUS20130220813A1Enhance heat transfer coefficientEnhance condensationElectrolysis componentsVolume/mass flow measurementChemistryMicrometer

Owner:MASSACHUSETTS INST OF TECH

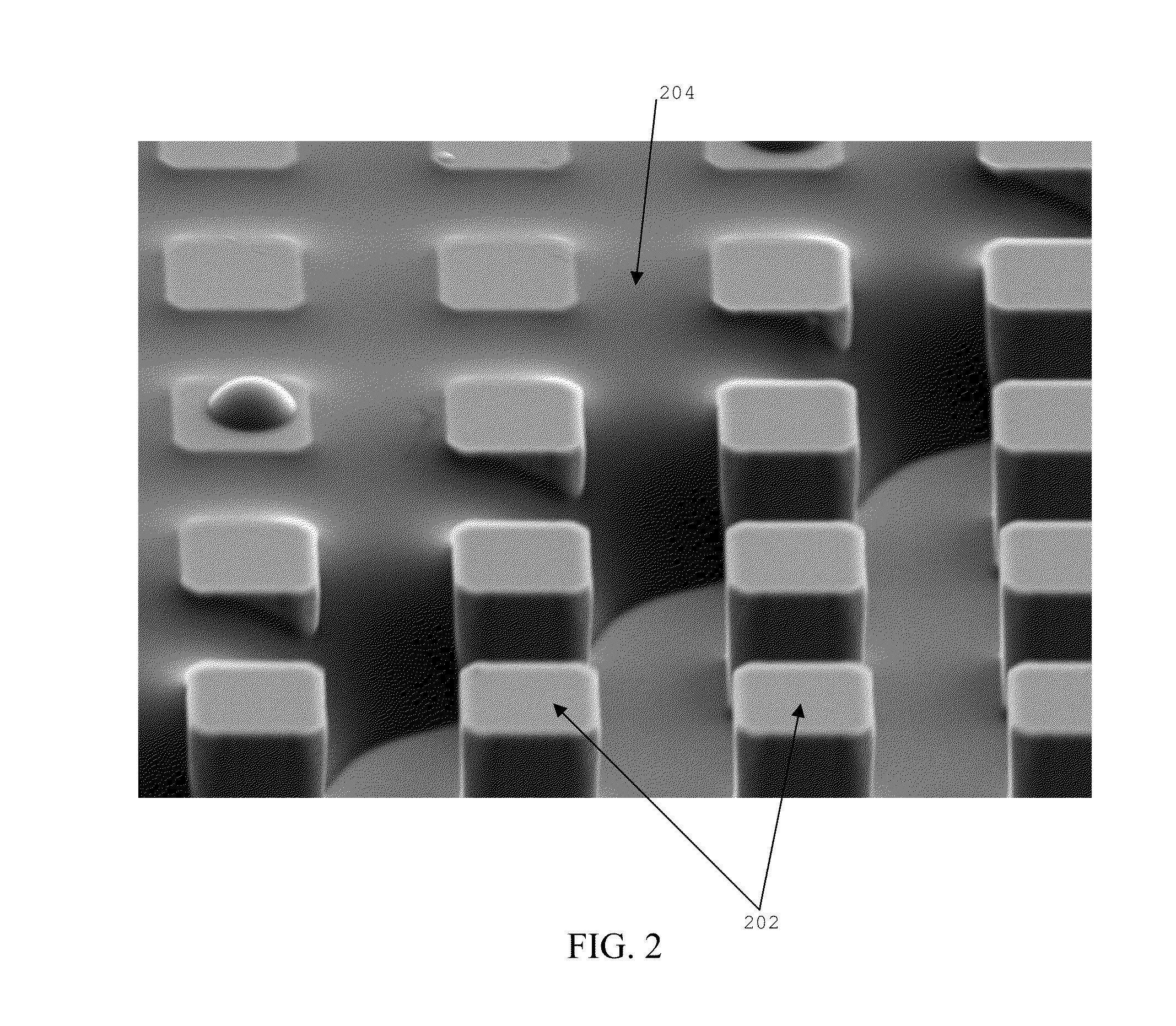

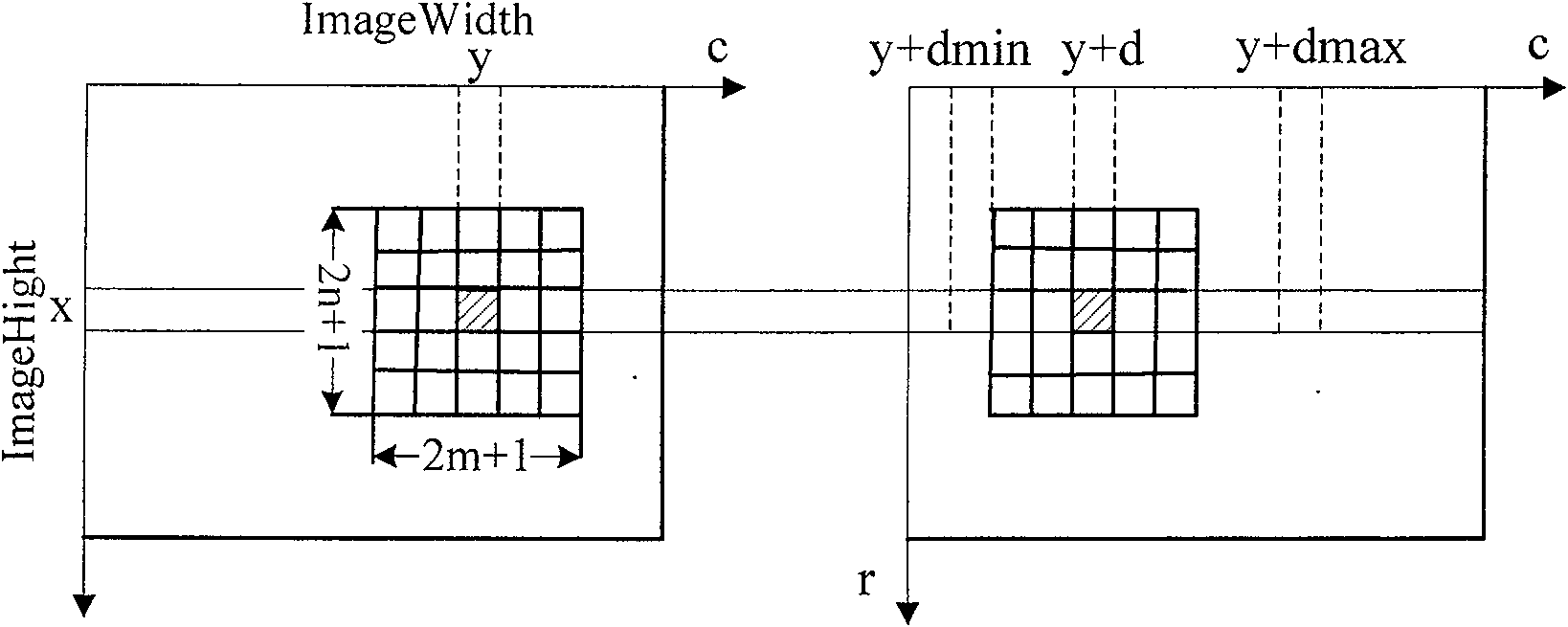

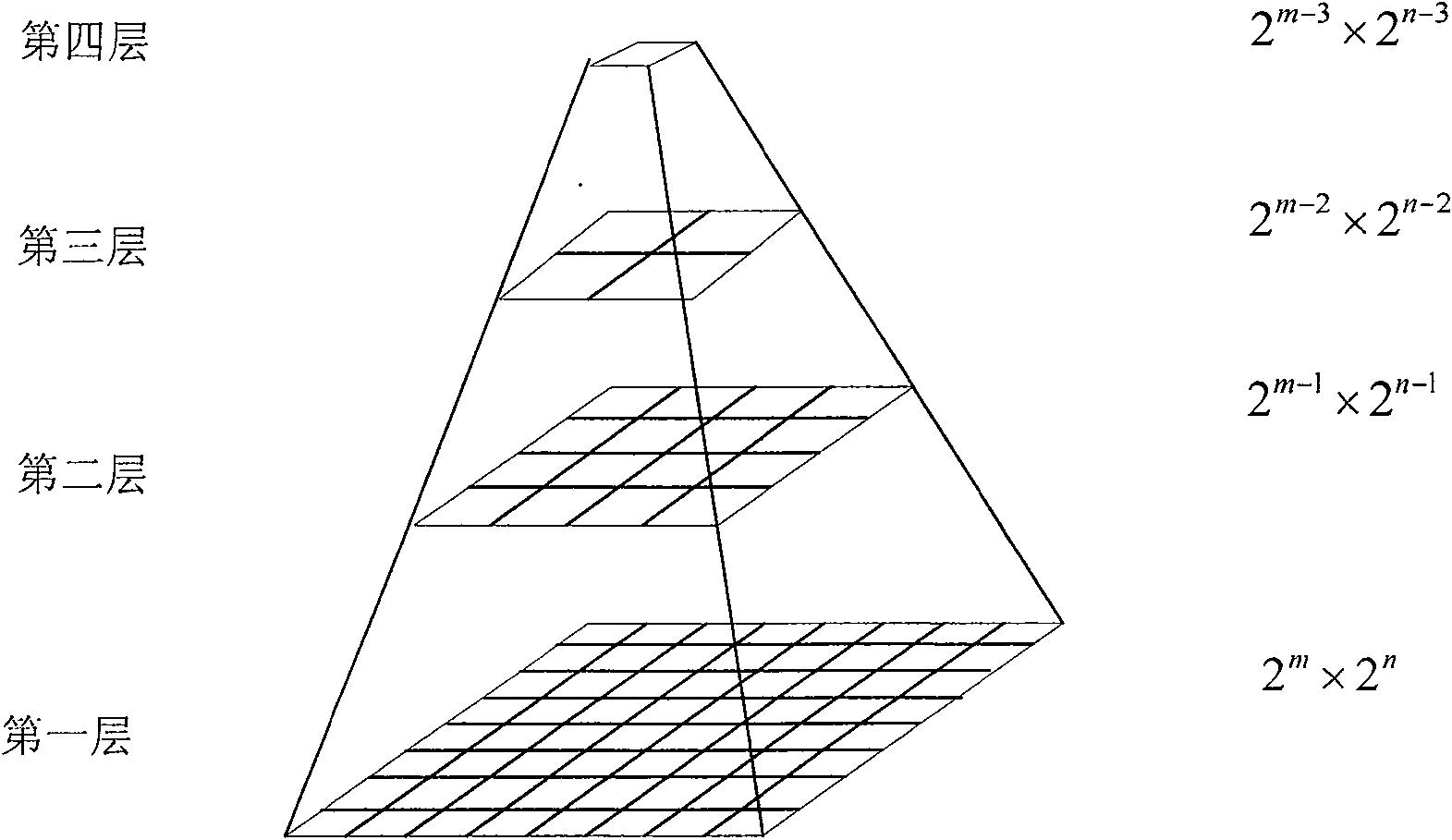

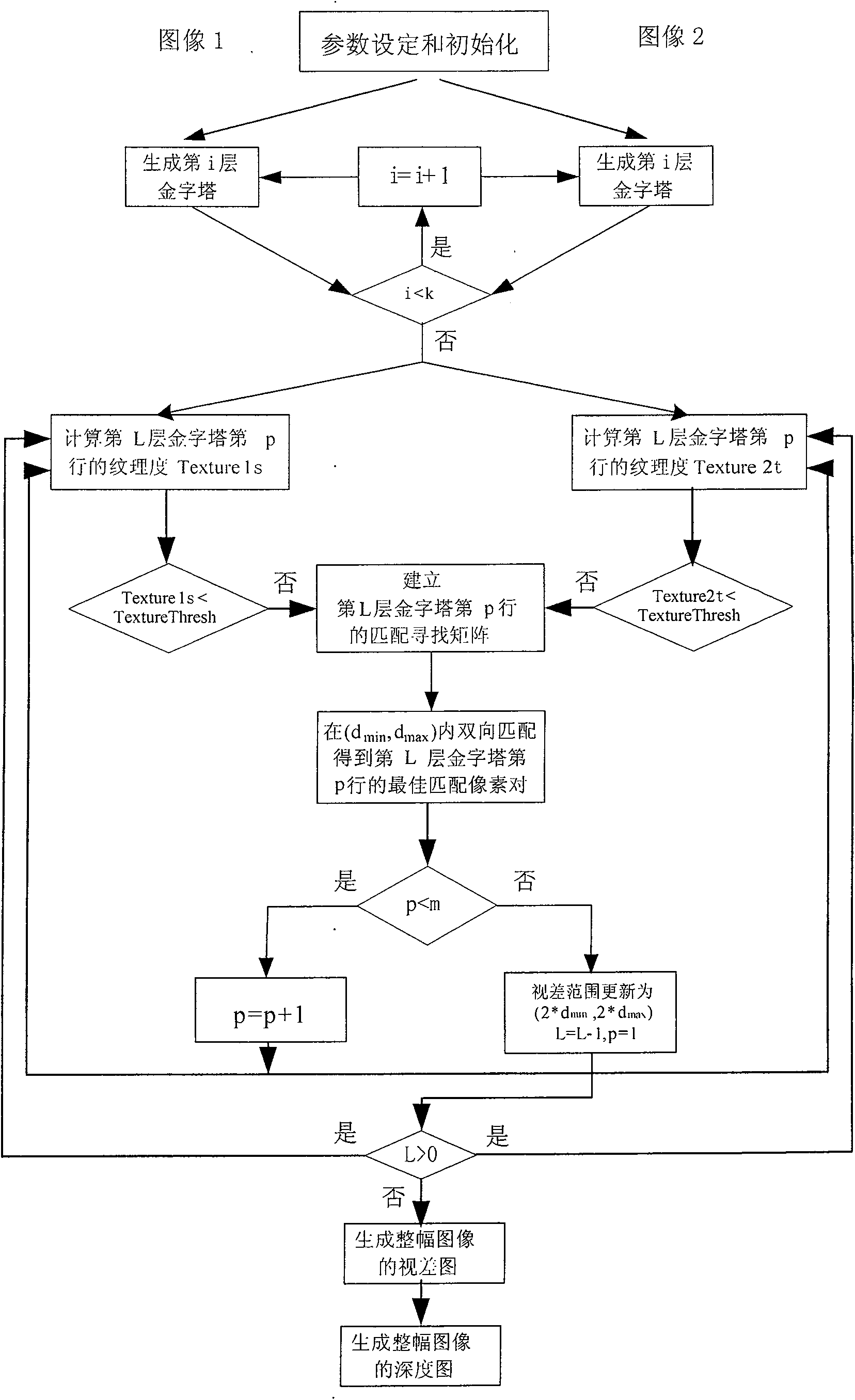

Real time binocular vision guidance method facing to underwater carrying vehicle

InactiveCN101251379AOptical rangefindersPhotogrammetry/videogrammetryVision algorithmsTexture control

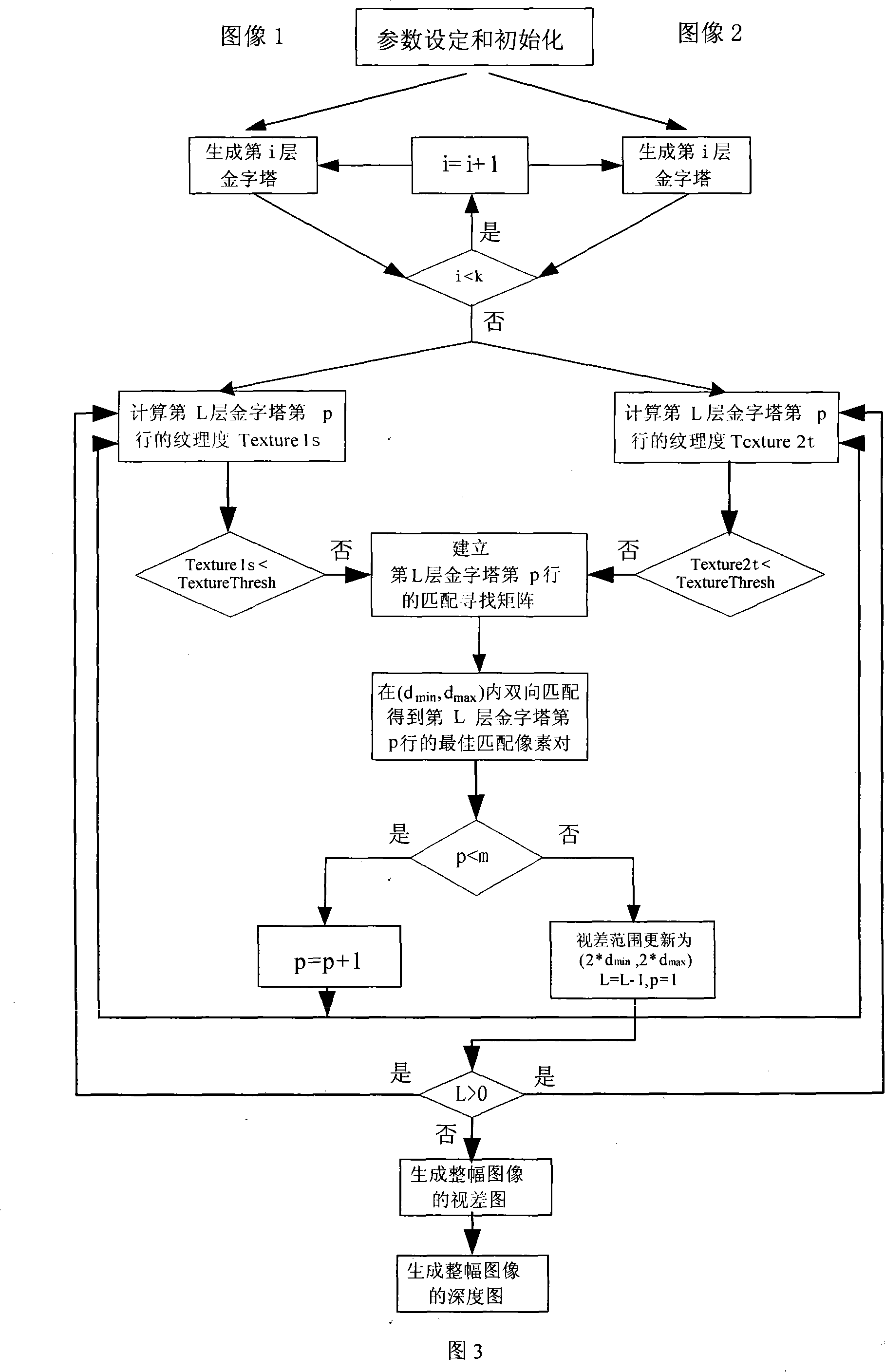

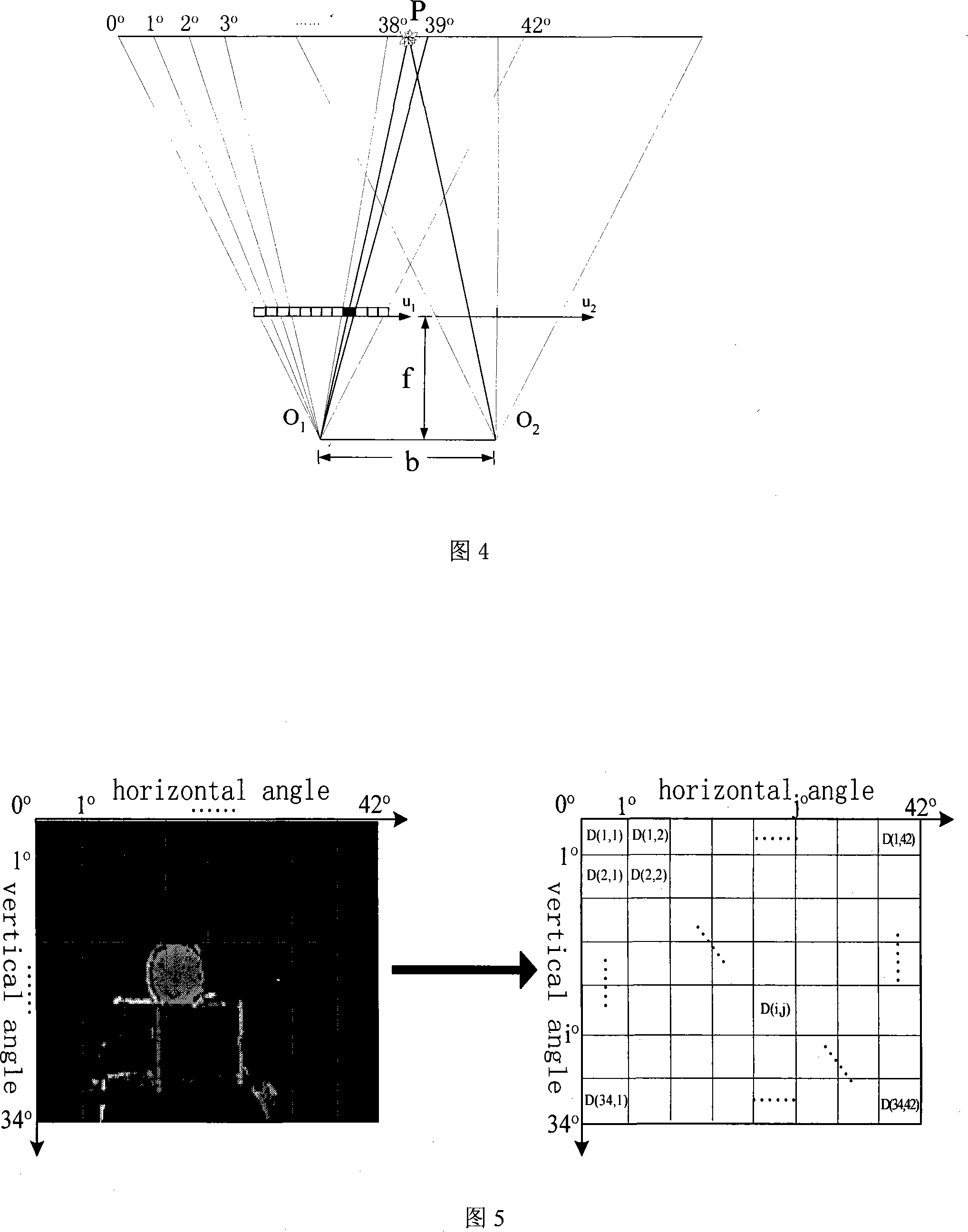

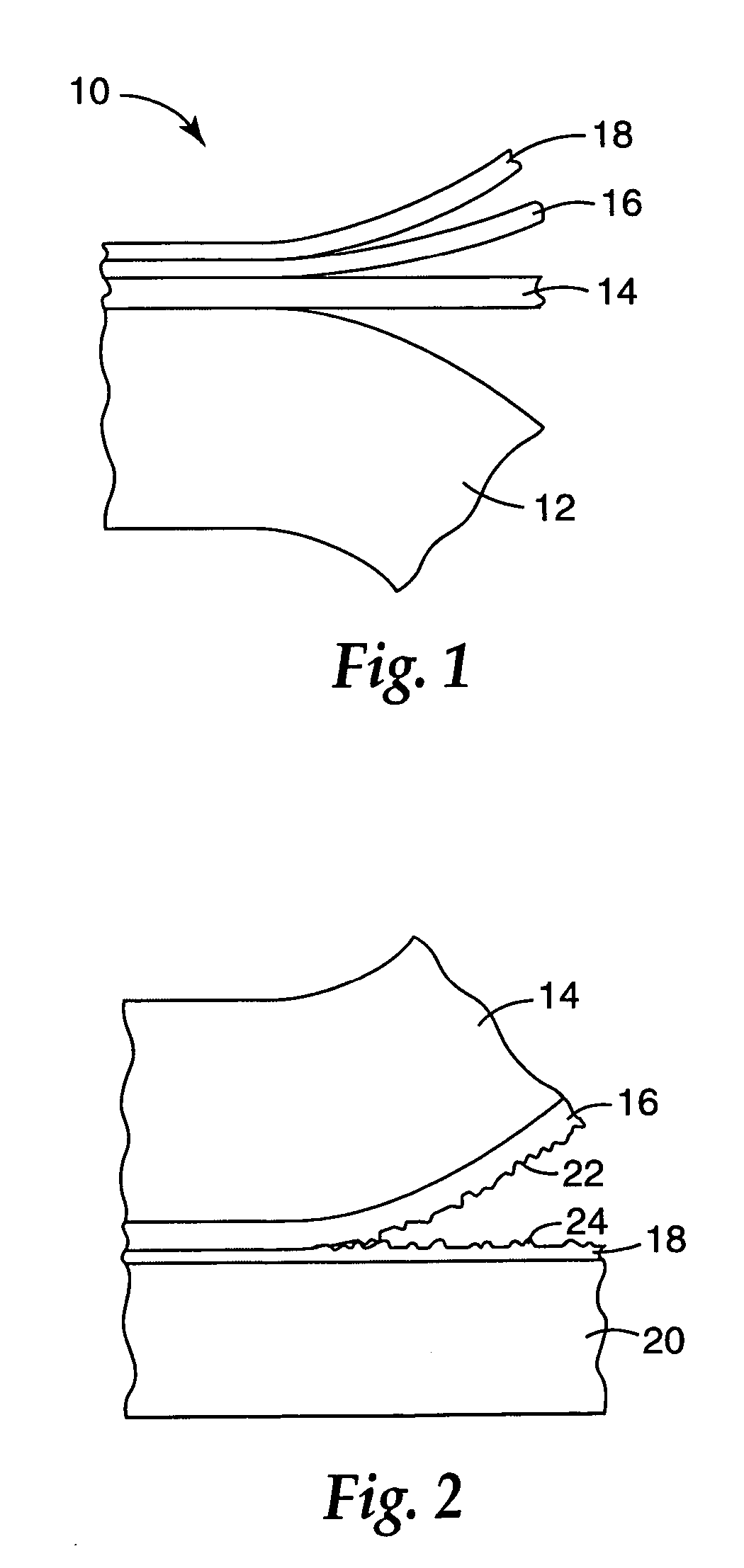

The invention provides a real-time binocular vision guidance method for an underwater vehicle. Aimed at the characteristics of the marine environment where the underwater vehicle operates, the invention puts forward a pyramid normalized covariance binocular vision algorithm based on the texture control to realize the real-time property of the application level with the precision stabled at the centimeter level. Regarding the final demonstration of an environmental message, the real-time binocular vision guidance method puts forward a virtual sonar model, thereby expressing the 2.5-dimensinal message as a barrier (or target) matrix based on the virtual sonar model. And the matrix contains the depth and bearing information of the barrier (or target).

Owner:HARBIN ENG UNIV

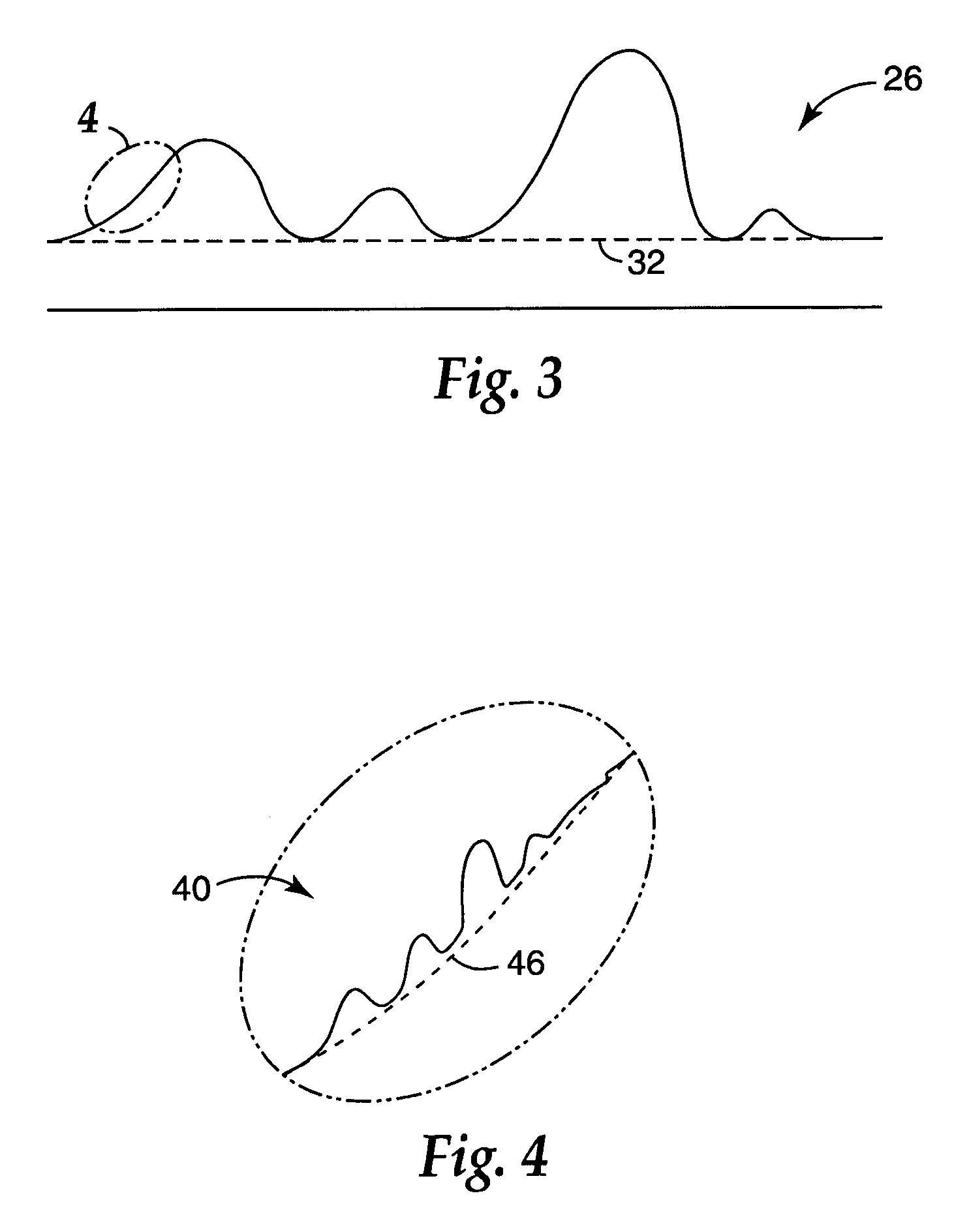

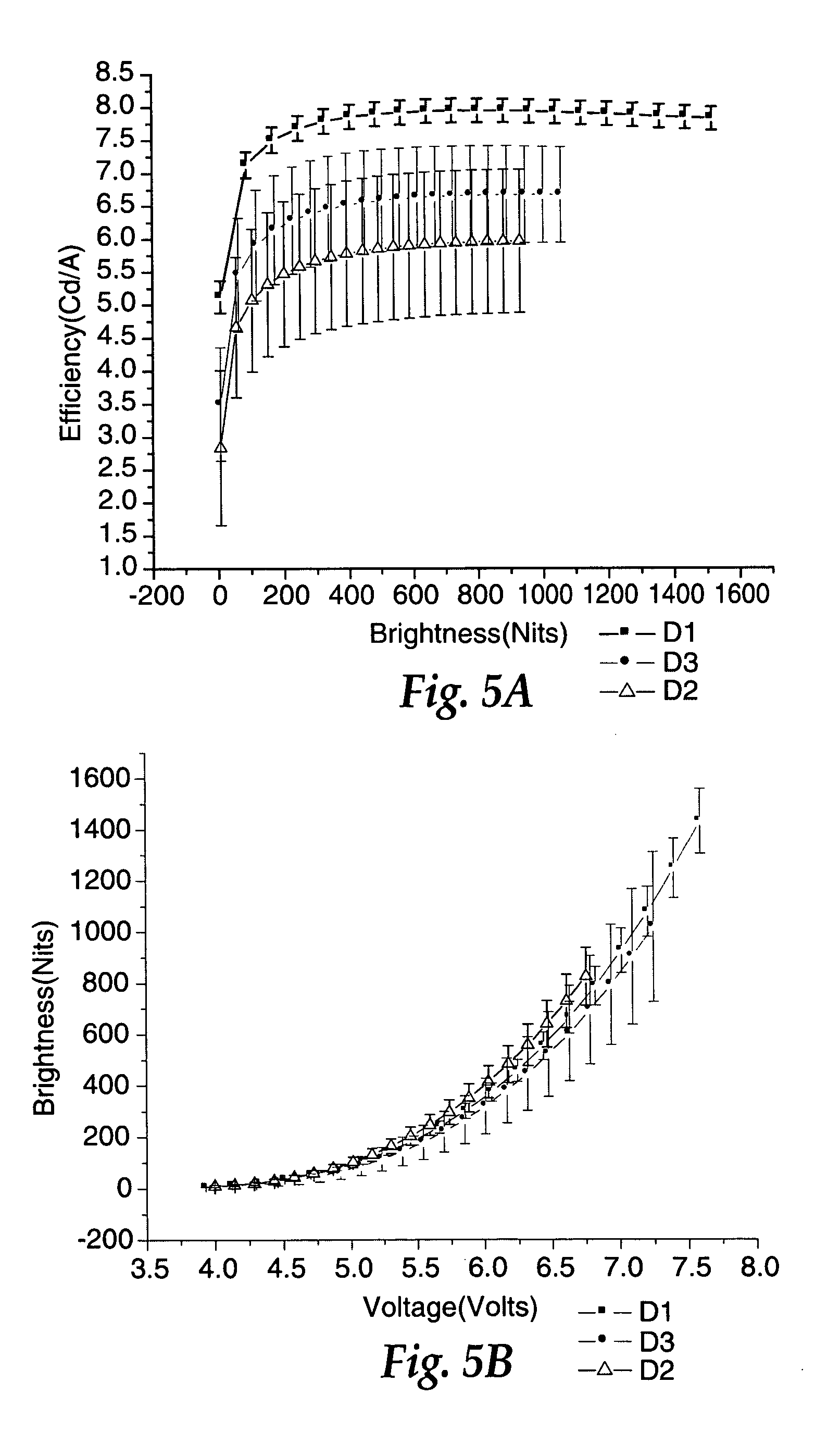

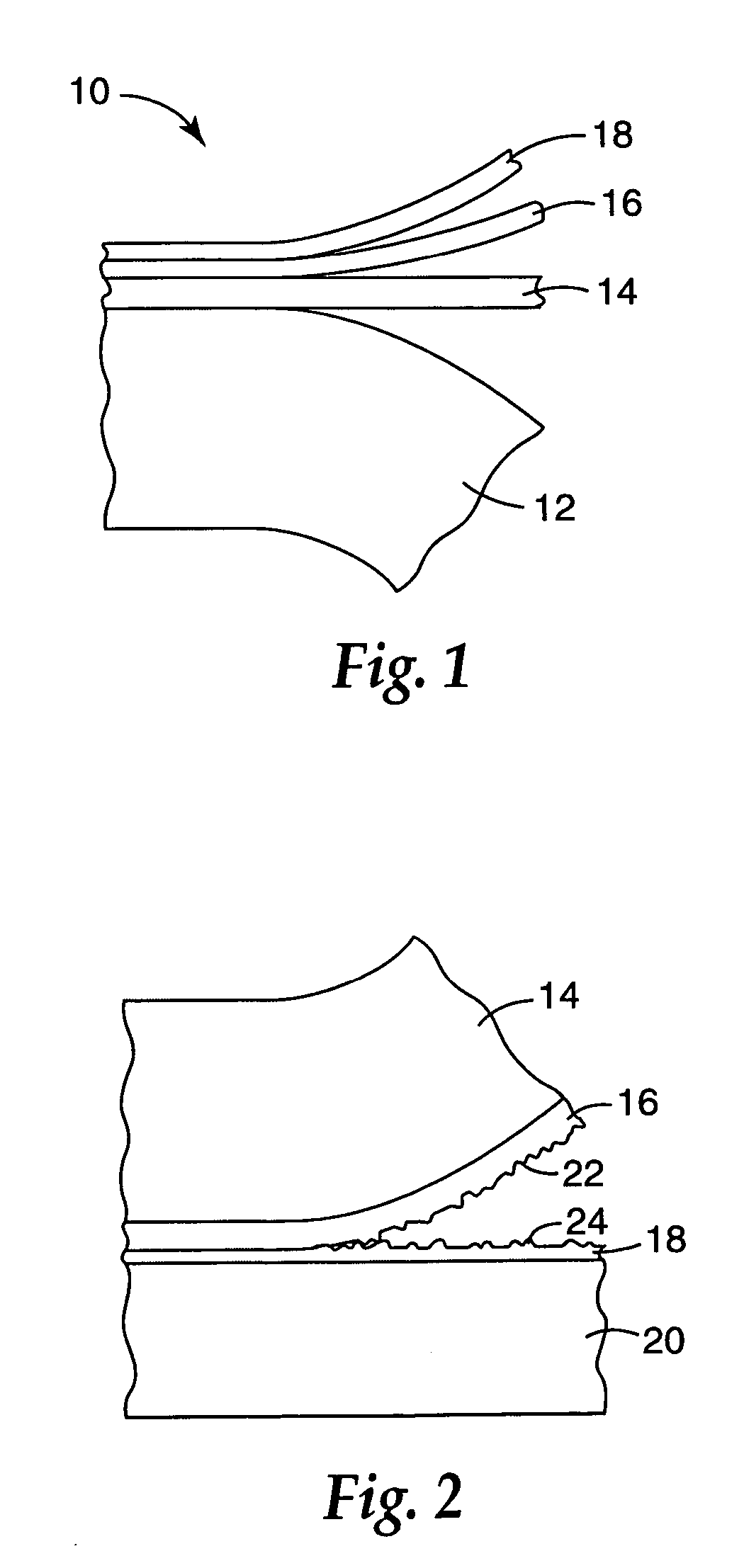

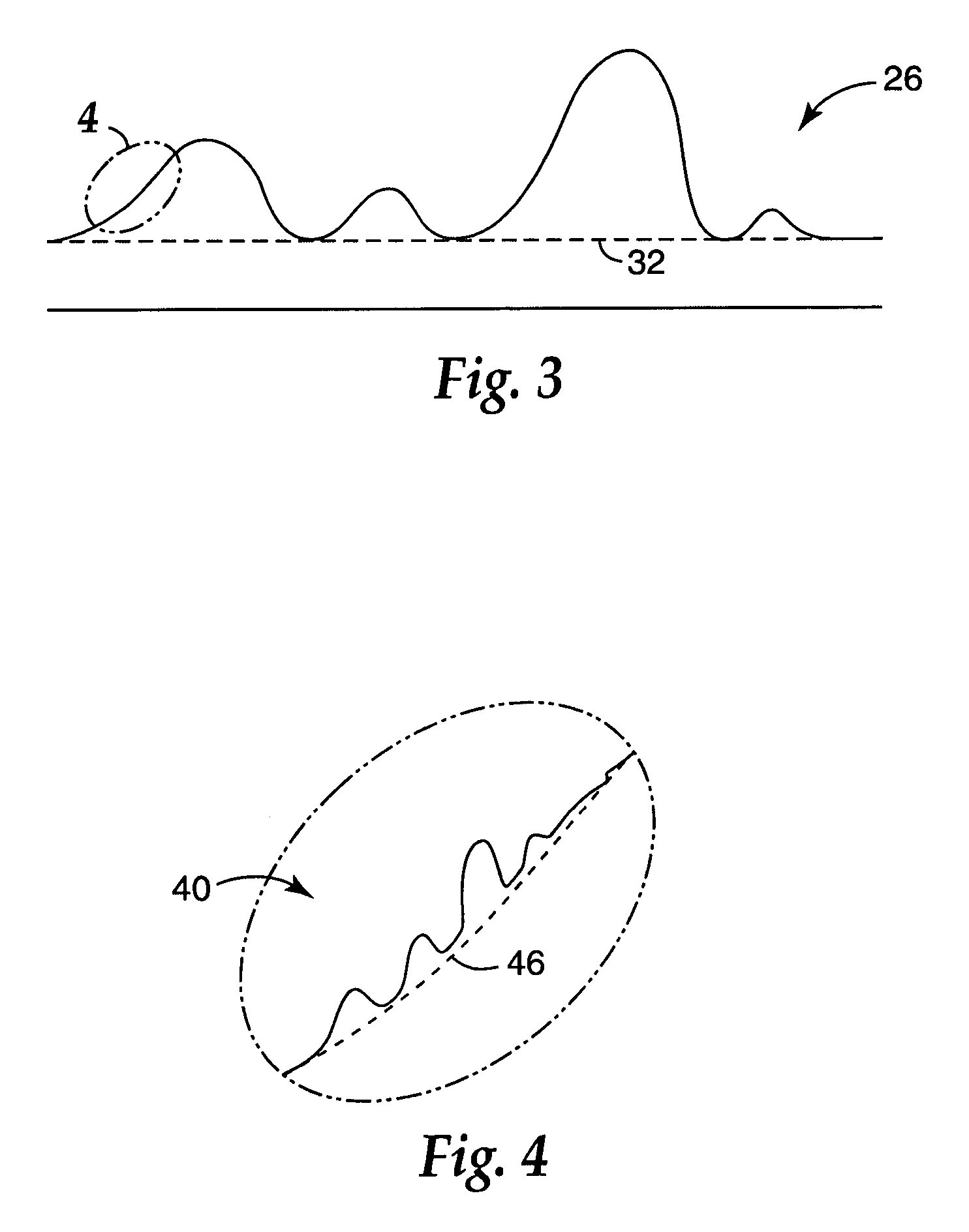

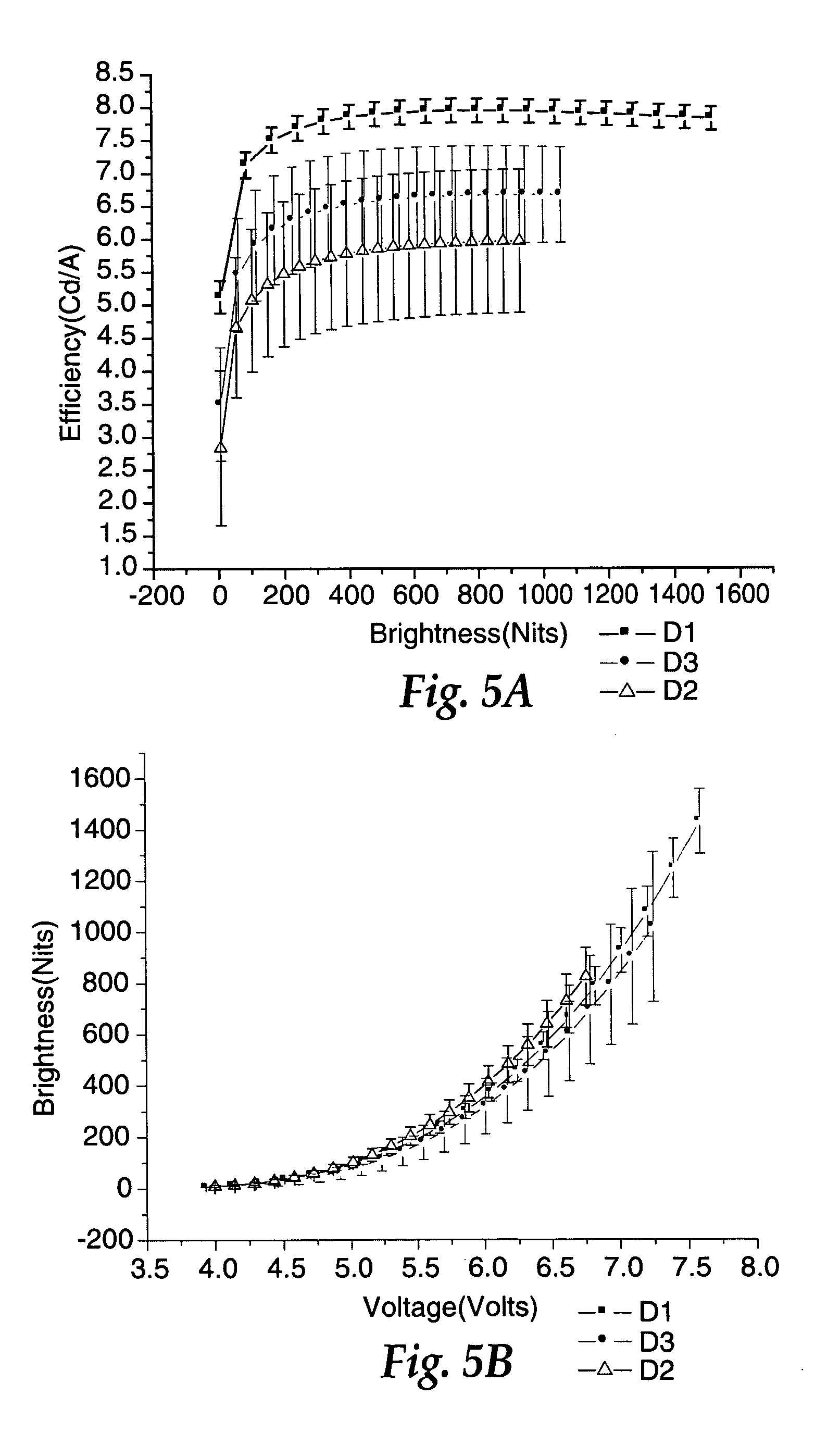

Texture control of thin film layers prepared via laser induced thermal imaging

A thermal transfer donor element is provided which includes a support, light-to-heat conversion layer, interlayer, and thermal transfer layer. When the donor element is brought into contact with a receptor and imagewise irradiated, a portion of the transfer layer is transferred to the receptor. The relative surface texture of the layers can be at least partially controlled, prior to imaging of the donor element, for desired effects in the resulting receptor device. The construction and process of the donor element is useful in making colored images including applications such as color proofs, color filter elements, and organic light emitting displays.

Owner:SAMSUNG DISPLAY CO LTD

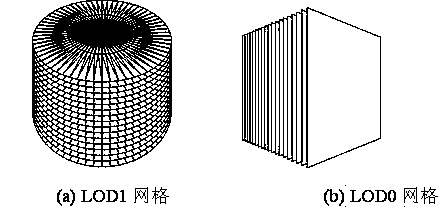

Method for achieving real-time rendering of large-scale realistic volumetric cloud

The invention discloses a method for achieving real-time rendering of large-scale realistic volumetric cloud on a stream processor. The method comprises the steps of establishing a novel grid model based on the Level of Detail (LOD) technology, forming 2D textures controlling the shape of the cloud, establishing a multiple forward scatter model of the cloud and carrying out illumination computation of the cloud. The method is characterized in that the reflection effect on the sky and the sun is achieved through the cubic textures, the illumination result obtained through precomputation is stored through 3D textures, and the illumination computation of the cloud is simplified; the factors such as the coverage rate of the cloud in the sky, the density of the cloud and wind are comprehensively considered. The method is particularly suitable for real-time rendering carried out when the cloud covers most or all of the sky, and has the advantages that the speed is high, the simulation degree is high and the platform compatibility is good.

Owner:HARBIN DIANSHI SIMULATION SCI & TECH

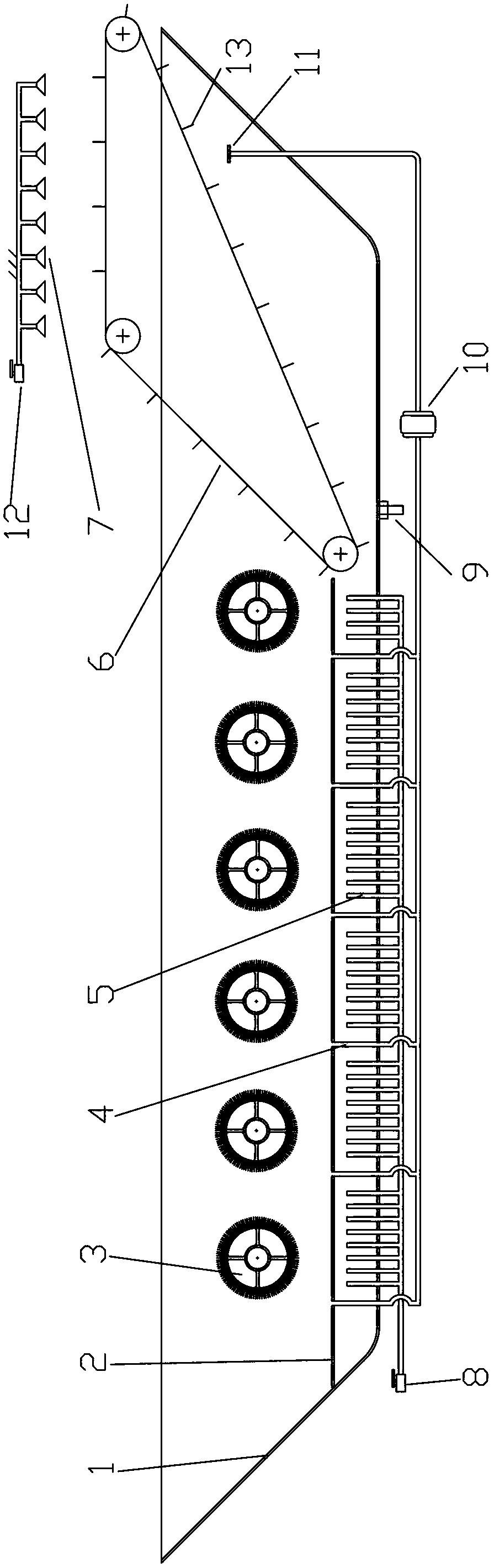

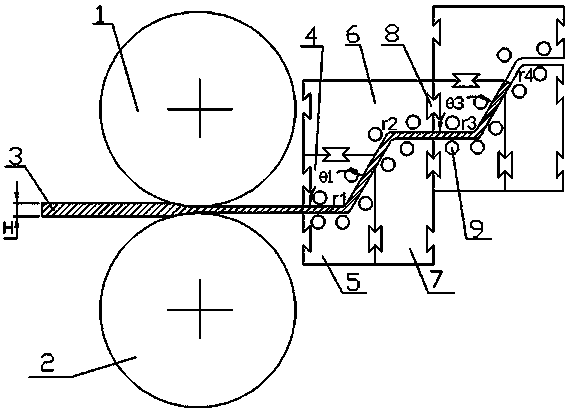

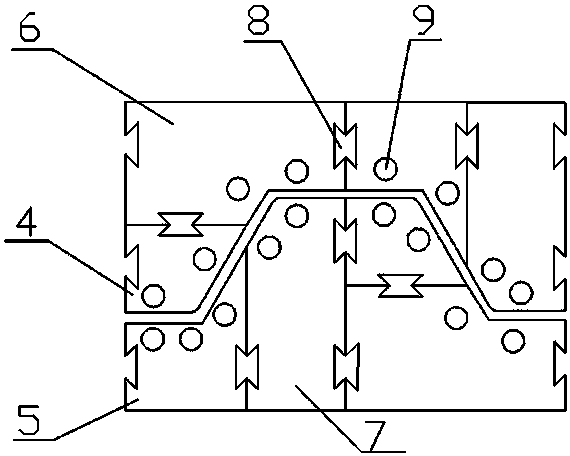

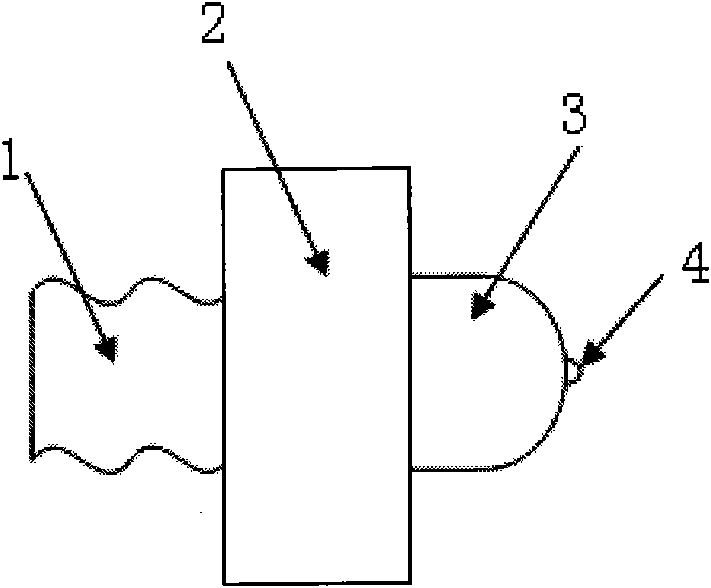

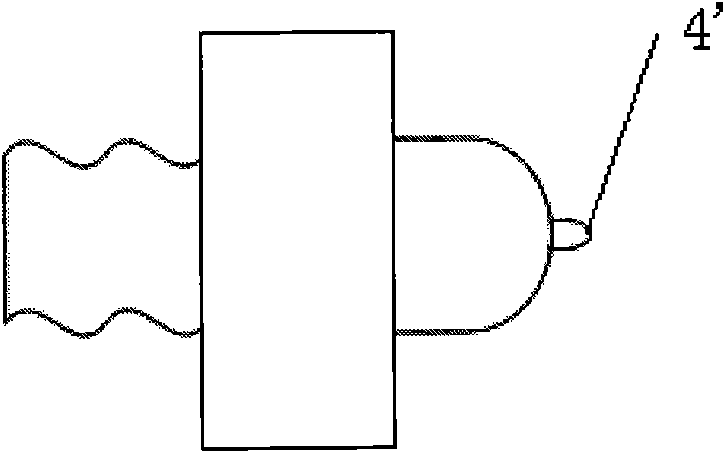

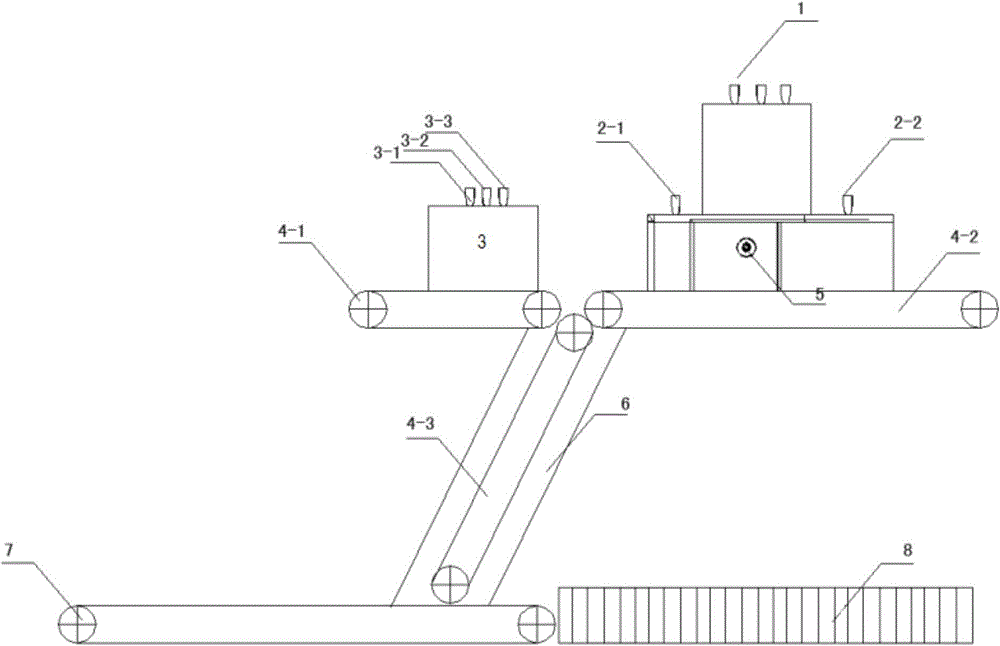

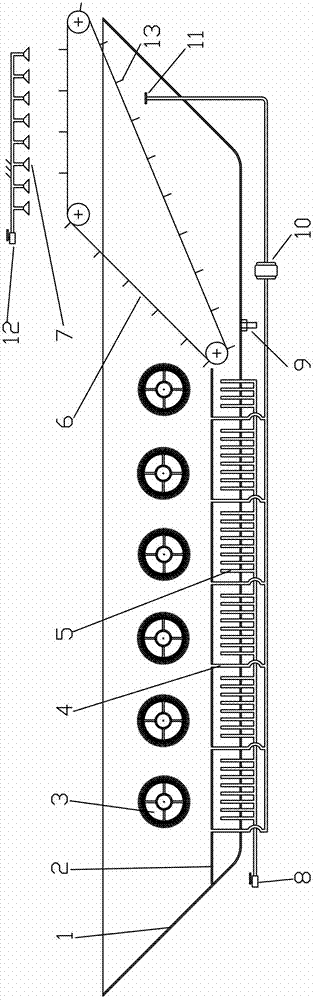

Multi-action type sea cucumber cleaning machine

ActiveCN103212555AGuaranteed cleaning qualityCleaning processes and apparatusWater dischargeTexture control

The invention discloses a multi-action type sea cucumber cleaning machine, comprising a soaking pond (1) with a water discharging port (9) at the bottom part, wherein a net partitioning plate (2) is paved at the middle-lower part of the soaking pond; rolling brushes (3) are arranged above the net partitioning plate at intervals; foaming pipes (5) are arranged under the net partitioning plates at intervals and are connected with an air pumping unit; surging pipes are also arranged under the net partitioning plate at intervals and are connected with a water body pumping unit; one side of the net partitioning plate is provided with a belt transmission unit; and a spraying unit is arranged above one section of a conveying belt. The multi-action type sea cucumber cleaning machine disclosed by the invention has the advantages that a multi-action mode is adopted to clean sea cucumber, so that the cleaning quality of the sea cucumber can be effectively ensured, and the multi-action type sea cucumber cleaning machine is applicable to the cleaning procedure before the texture control in the processing process of a sea cucumber product.

Owner:DALIAN POLYTECHNIC UNIVERSITY

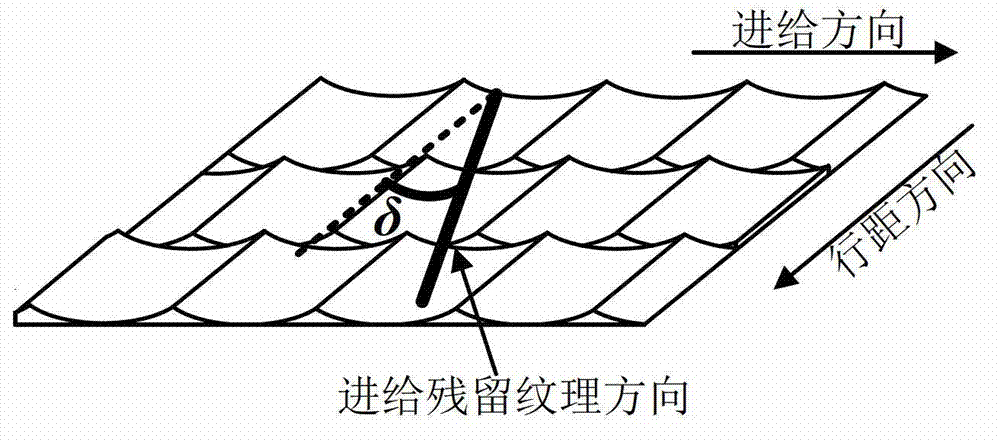

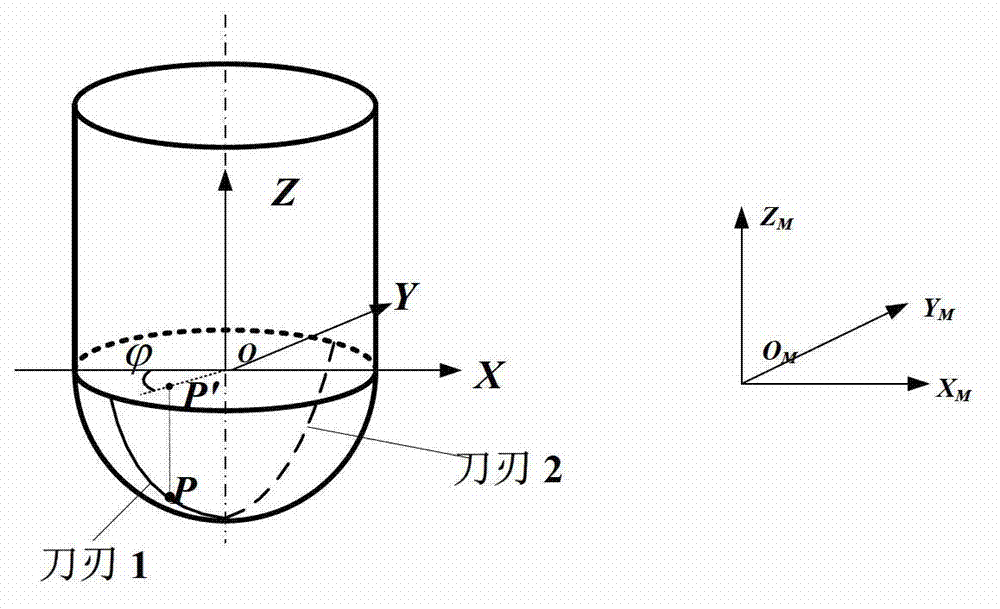

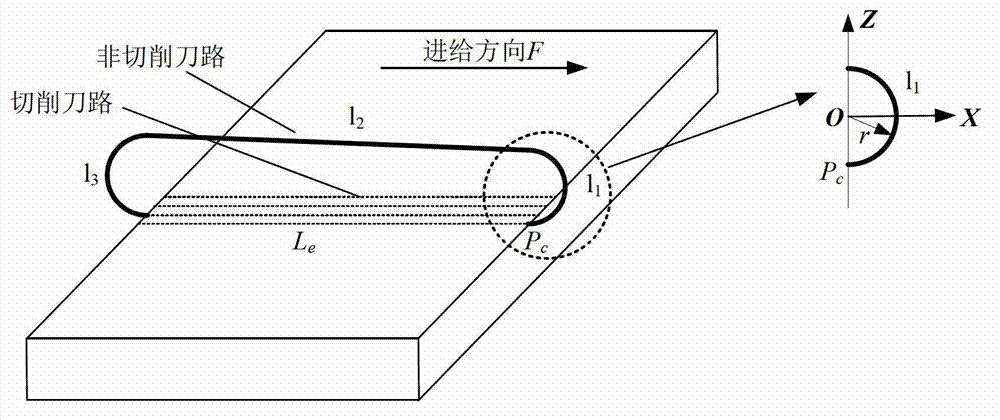

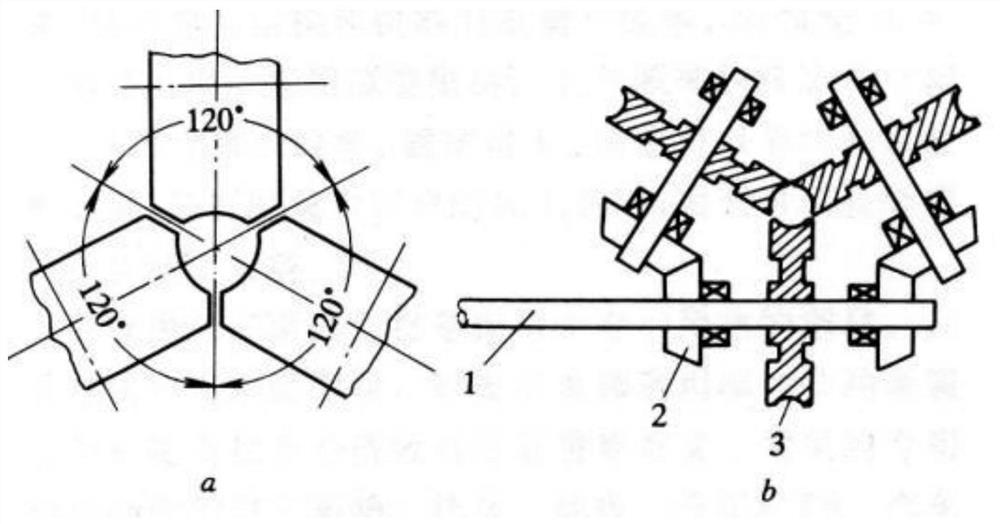

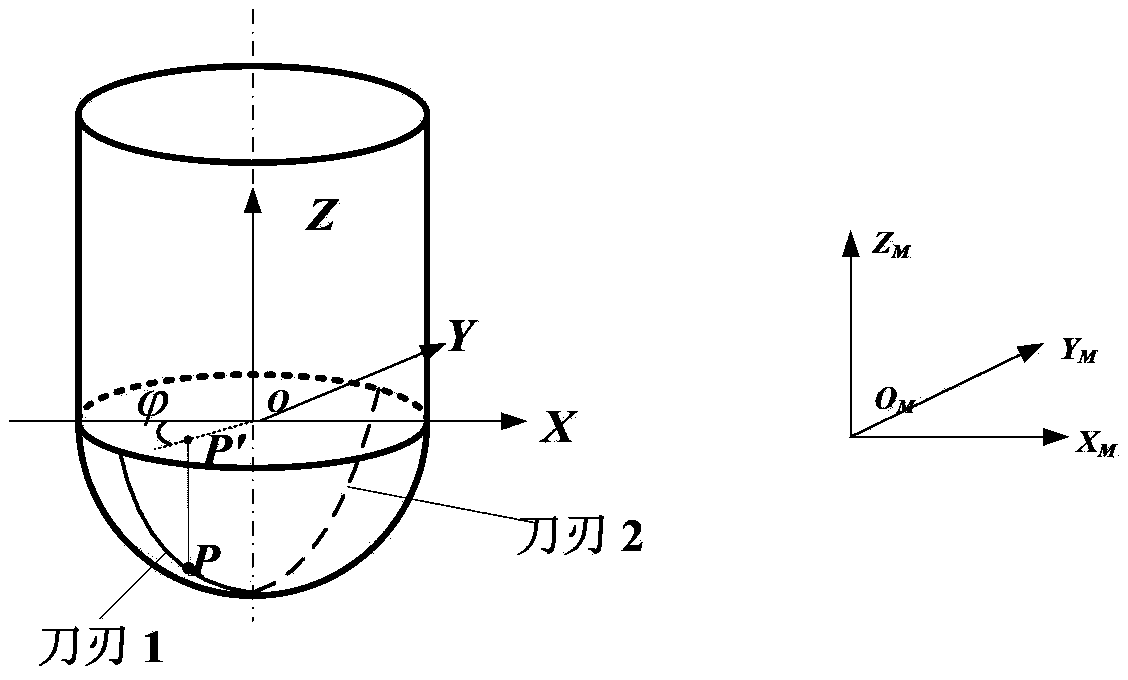

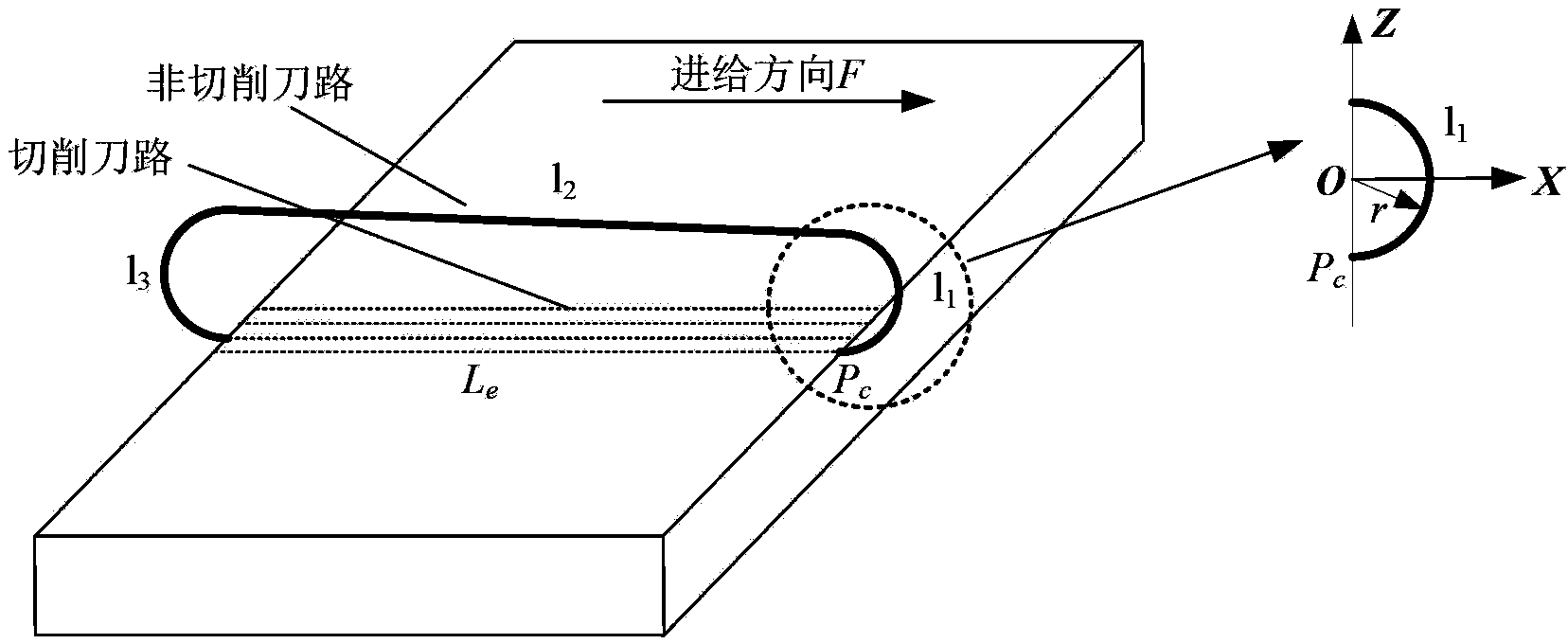

Ultraprecise milling surface topography texture control method

ActiveCN103042434AEffective controlEasy to controlAutomatic control devicesFeeding apparatusPhase differenceTexture control

The invention discloses an ultraprecise milling surface topography texture control method. The method includes that a machining surface topography texture direction angle delta is set; a tool starting phase angle difference Delta<phi> of adjacent tool paths is determined according to the texture direction angle delta, tool path planning of a cutting area and a non-cutting area is conducted according to the tool starting phase angle difference Delta<phi>, and a tool path file is generated; and ultraprecise milling can be achieved by using the tool path file. By controlling the tool starting phase angle difference of the adjacent tool paths instead of controlling a starting phase angle of each row of tool paths, a starting process of moving of a spindle and various shafts is avoided, and controlling feasibility is greatly improved. In addition, by planning non-cutting paths, the tool starting phase angle difference of the adjacent tool paths is effectively controlled, and control for the ultraprecise milling surface topography is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

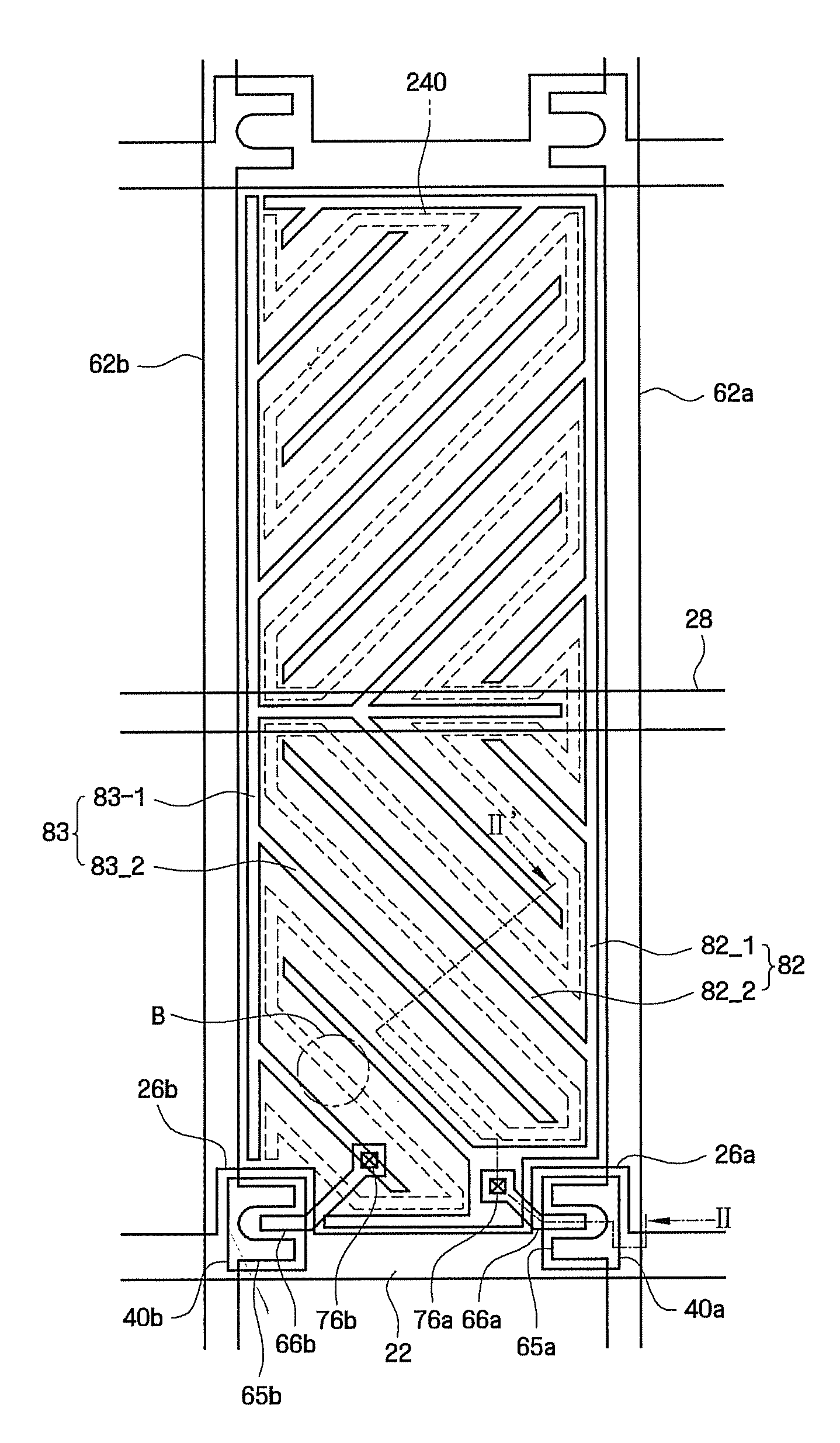

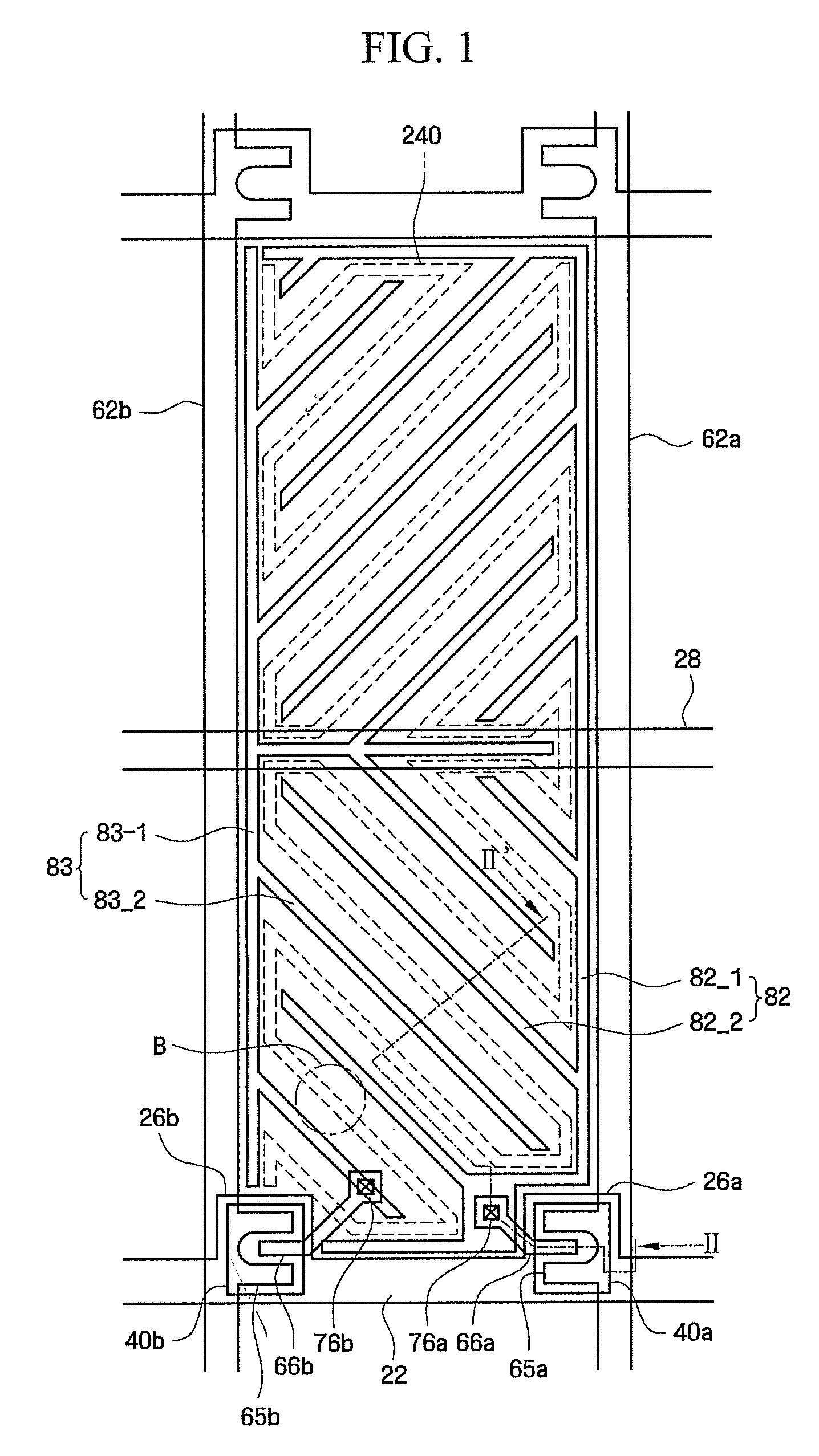

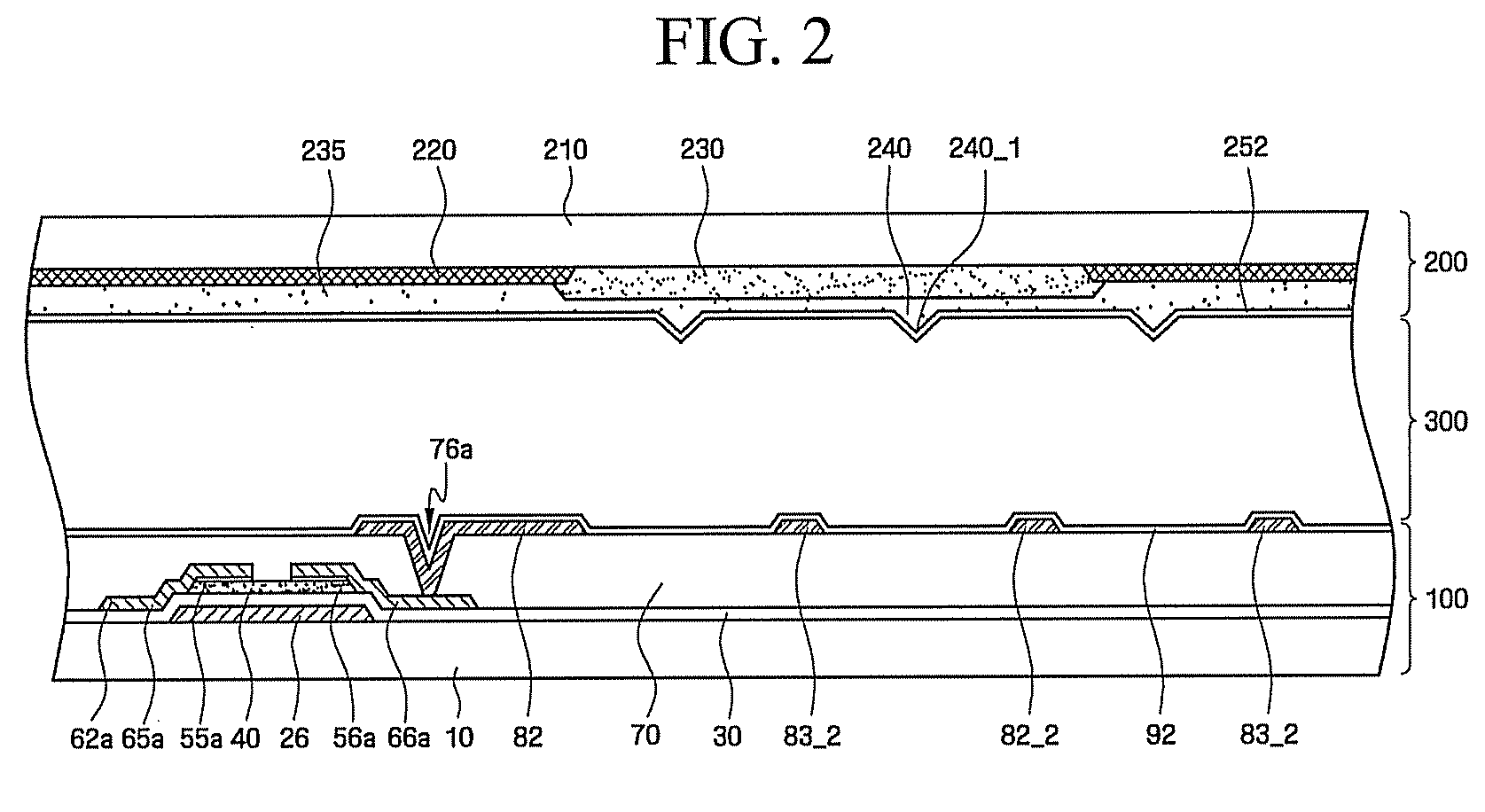

Liquid crystal display and method thereof

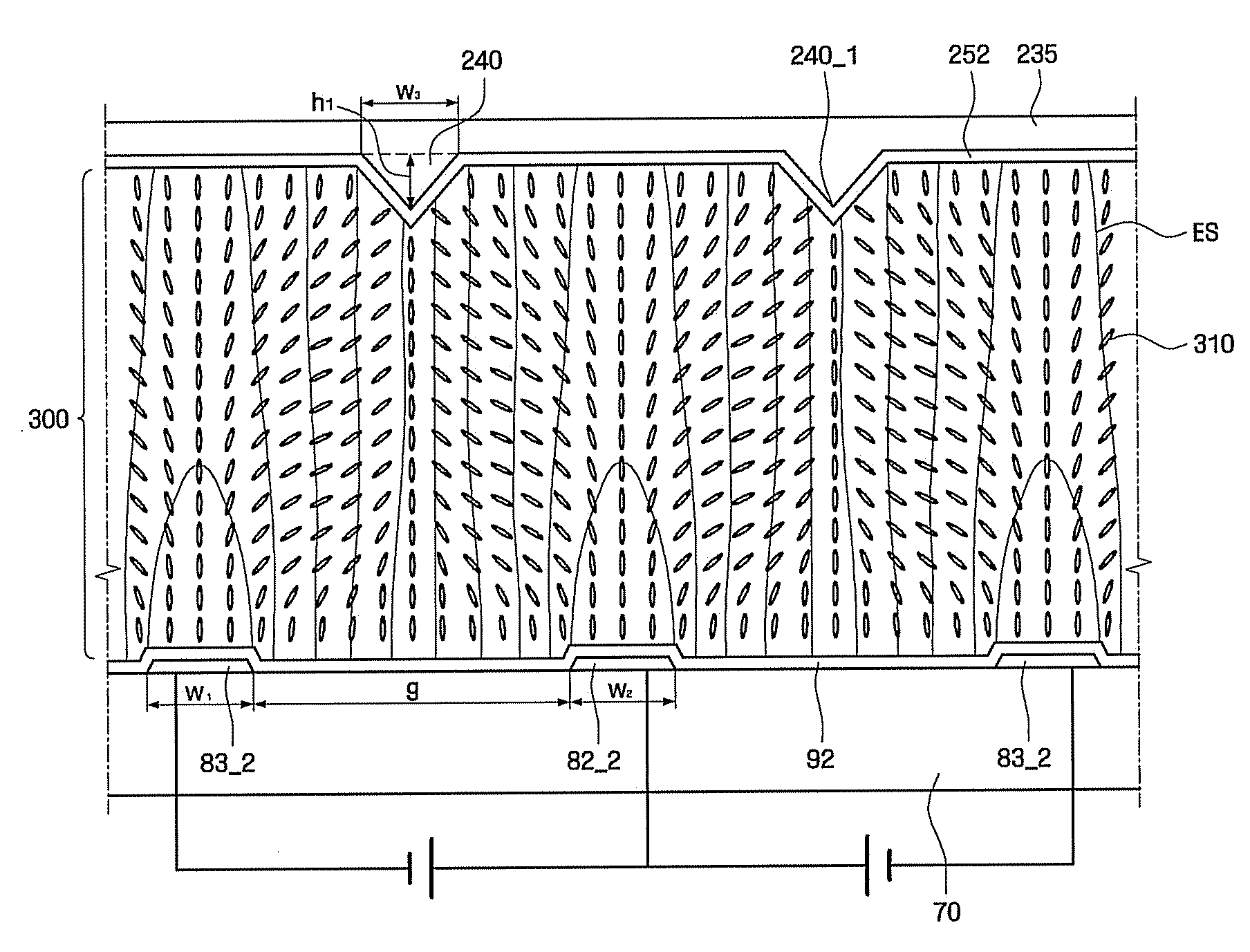

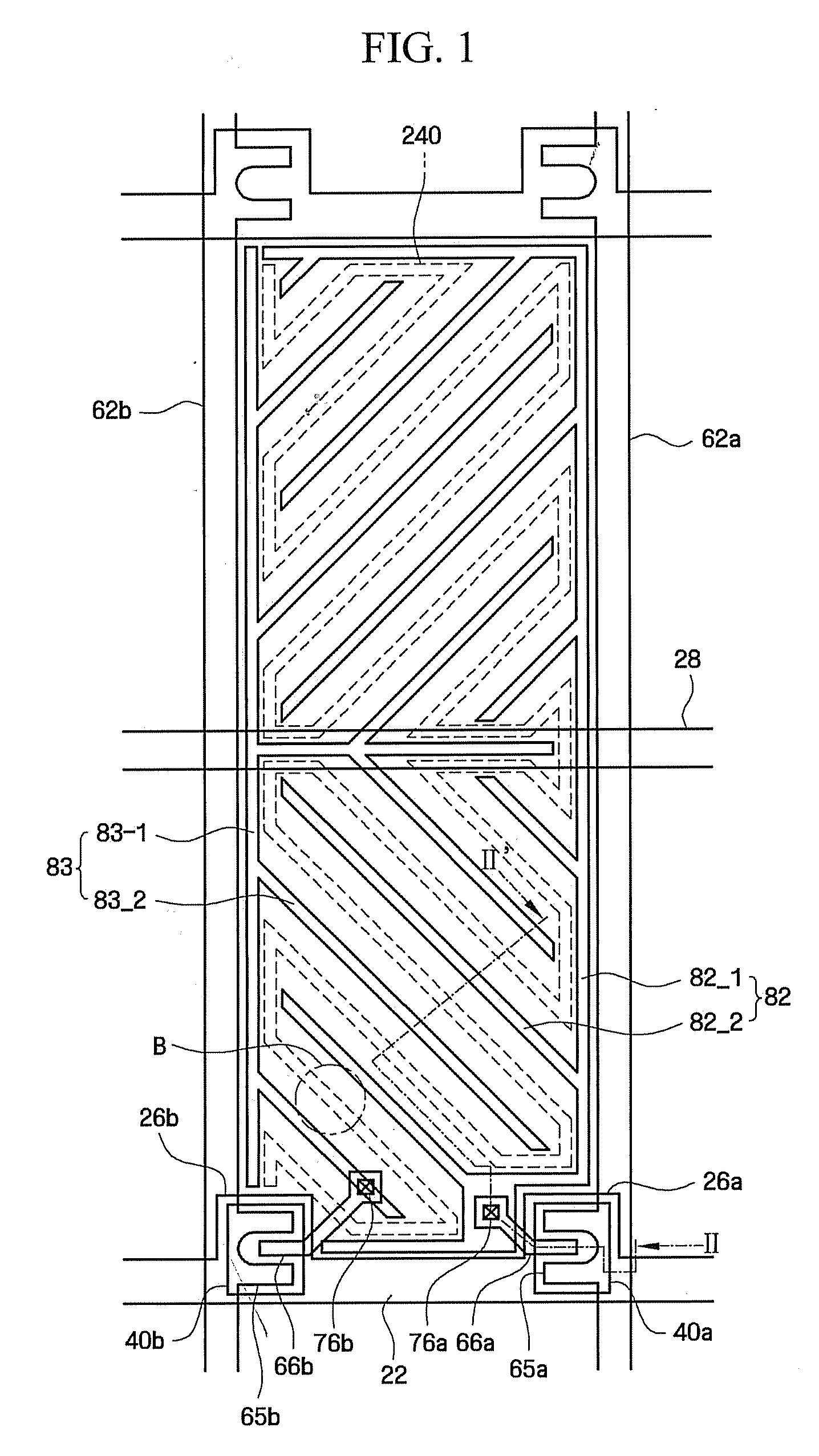

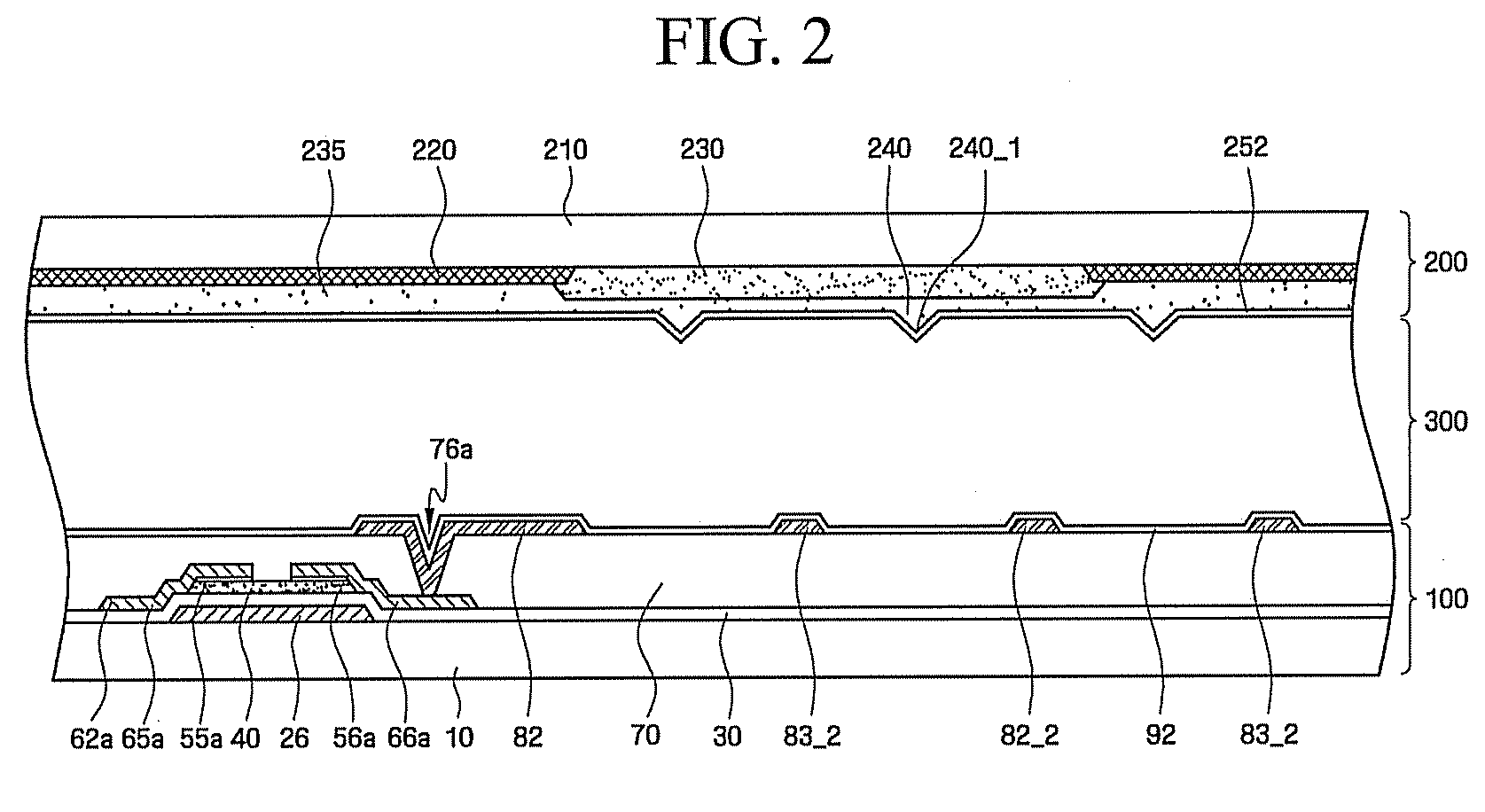

A liquid crystal display (“LCD”) having controlled texture and reduced response time includes first and second insulation substrates which are separated from each other and face each other, a liquid crystal layer which is interposed between the first and second insulation substrates and has liquid crystal molecules, a pixel electrode which is disposed on the first insulation substrate and includes a plurality of first linear electrode patterns, a common electrode which is disposed on the first insulation substrate and includes a plurality of second linear electrode patterns separated from the first linear electrode patterns by a predetermined gap, and a texture control portion which is disposed in an area corresponding to the gap and formed on the first or second insulation substrate, wherein the first and second linear electrode patterns are arranged in an alternating fashion.

Owner:SAMSUNG DISPLAY CO LTD

42CrMo4 wind driven generator main shaft control method

ActiveCN107858590AMeet the use requirementsImprove performanceFurnace typesHeat treatment furnacesWind drivenChemical composition

The invention relates to the field of material composition design and heat treatment, in particular to a high-performance 42CrMo4 wind driven generator main shaft control method. According to weight percentage, a 42CrMo4 wind driven generator main shaft comprises the following chemical components including 0.39%-0.42% of C, 0.20%-0.30% of Si, 0.70%-0.80% of Mn, 1.10%-1.20% of Cr, 0.25%-0.30% of Mo, not larger than 0.10% of Cu, not larger than 0.05% of Al, not larger than 0.012% of P, not larger than 0.008% of S and the balance Fe. According to the high-performance 42CrMo4 wind driven generatormain shaft control method, through microalloy adding, molten steel purification treatment and forging and heat treatment texture control, the finally manufactured 42CrMo4 wind driven generator main shaft has the good toughening matching degree; and at the under-skin 185 mm position, the yield strength (Re) is larger than or equal to 525 MPa, the strength of extension (Rm) is larger than or equalto 680 MPa, the elongation (A) is larger than or equal to 16%, and the -30 DEG C ballistic work (AKv) is larger than or equal to 27 J.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

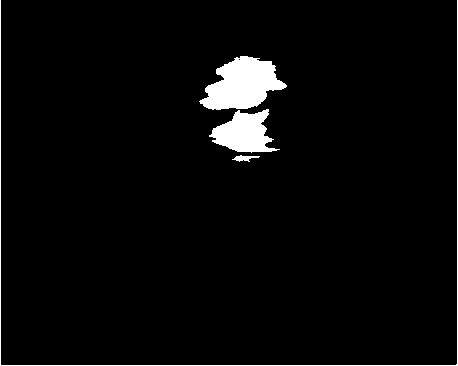

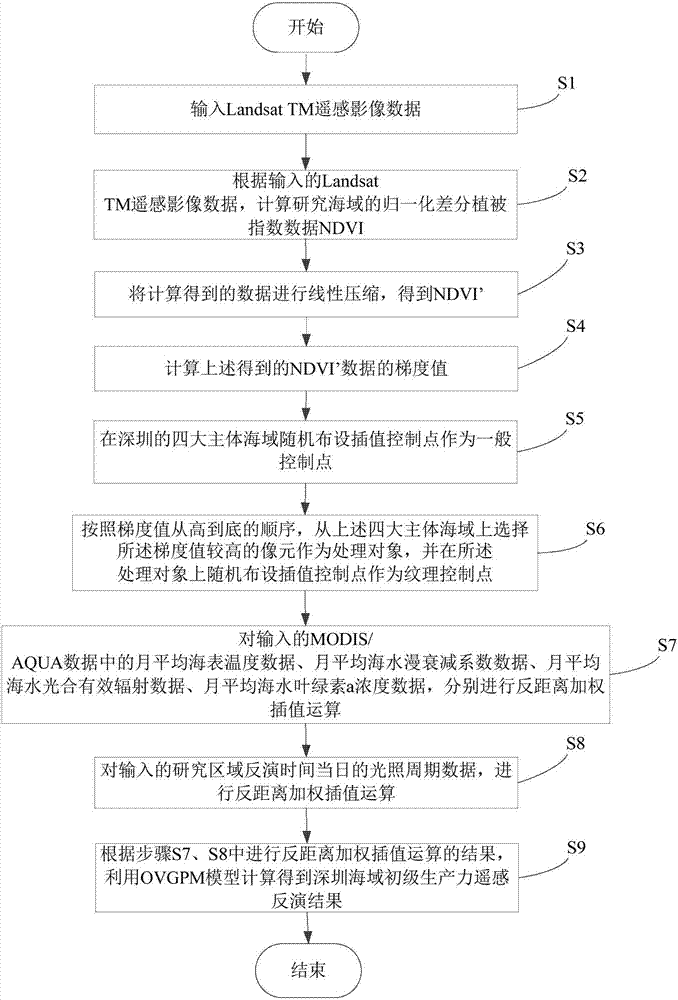

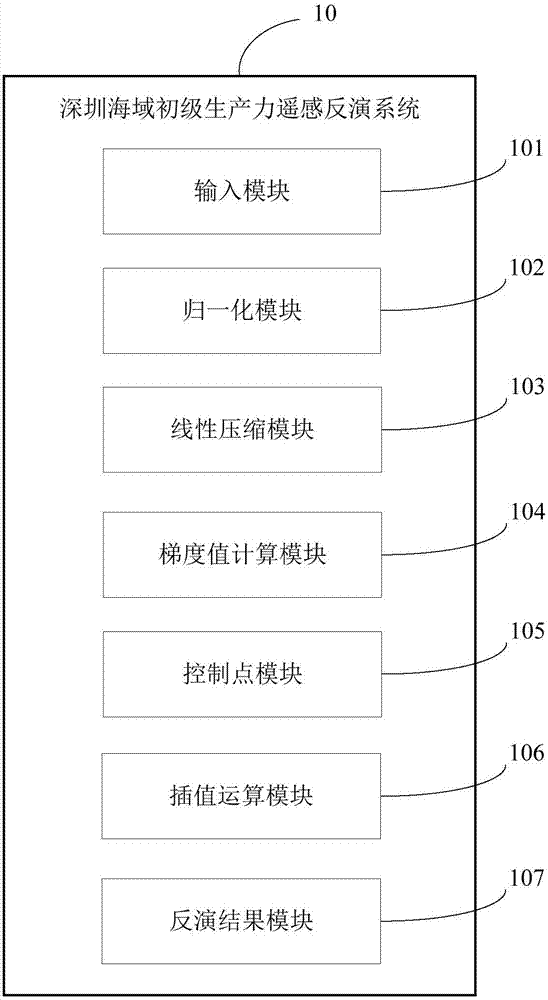

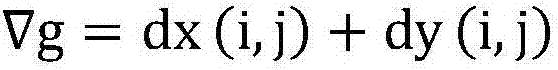

Remote-sensing inversion method and system for primary productivity of Shenzhen marine sites

The invention relates to a remote-sensing inversion method for primary productivity of Shenzhen marine sites. The method comprises that Landsat TM remote-sensing image data is input; normalized difference vegetation index (NDVI) data of the Shenzhen marine sites is calculated; the NDVI data is compressed linearly to obtain NDVI'; a gradient value nablag of the obtained NDVI' data is calculated; interpolation control points are laid in the four main Shenzhen marine sites randomly and serve as common control points; a pixel of a higher nablag value is selected from the four main Shenzhen marine sites and serves as a processing object deltap, and interpolation control points are laid in the deltap randomly and serve as texture control points; inverse-distance weighted interpolation operation is carried out on data in MODIS / AQUA; photoperiod data of the Shenzhen sites in the present day is inversed, and inverse-distance weighted interpolation operation is carried out; and an OVGPM model is used to obtain a remote-sensing inversion result of the primary productivity of the Shenzhen oscean sites by calculation. The invention also relates to a remote-sensing inversion system for the primary productivity of the Shenzhen marine sites. Thus, the primary productivity of the Shenzhen marine sites can be inversed in a more accurate, simpler and rapider way.

Owner:SHENZHEN INST OF ADVANCED TECH

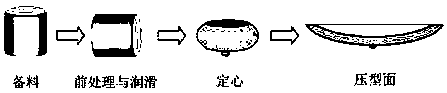

Forging method for improving flaw detection bottom losses of GH4169 alloy die forgings

InactiveCN108246947AMeet the final requirementsImprove yieldMetal-working apparatusTemperature controlTexture control

The invention belongs to the field of forging heat machining, and relates to a molding method which meets flaw detection bottom loss physicochemical testing and is used for GH4169 alloy die forgings.According to the method, a prefabricated biscuit is subject to single hitting texture control, then biscuit machining is carried out, biscuit flaw detection bottom loss checking is carried out, and finally die forging molding is carried out; and the deformation amount is singly controlled in the above forging links, the prefabricated biscuit deformation amount is maximum, and the die forging deformation amount is minimum. According to the molding method of the GH4169 alloy die forgings, through temperature control, forging production heating number control and control over all-link technological parameters including temperature, forging time, deformation amount, the hammering number and hammering time in particular, the deformation amount is coincident with that required by bottom loss checking, the product finally meets the needed requirement, and the finished product rate of the product is effectively improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Texture control of thin film layers prepared via laser induced thermal imaging

A thermal transfer donor element is provided which includes a support, light-to-heat conversion layer, interlayer, and thermal transfer layer. When the donor element is brought into contact with a receptor and imagewise irradiated, a portion of the transfer layer is transferred to the receptor. The relative surface texture of the layers can be at least partially controlled, prior to imaging of the donor element, for desired effects in the resulting receptor device. The construction and process of the donor element is useful in making colored images including applications such as color proofs, color filter elements, and organic light emitting displays.

Owner:SAMSUNG DISPLAY CO LTD

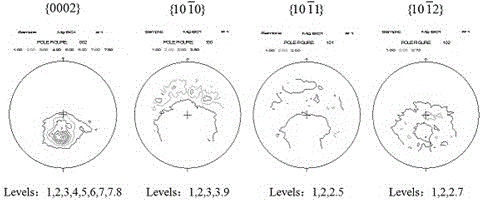

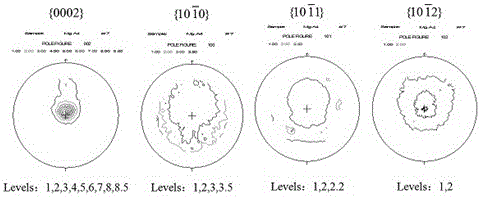

Semi-solid billet fast preparation method based on texture control idea

The invention discloses a method for fast preparing a semi-solid thixoforming billet and belongs to the technical field of semi-solid billet preparation. The preparation method includes the following steps that an AZ91 magnesium alloy bar material prepared through a semi-continuous drawing cast method is heated to 215 DEG C, heat preservation is conducted for 15 minutes so as to keep the temperature uniform, a heated bar material is put in a 215-DEG C ECAP steel mold, the channel inner-angle transition radius of the mold is controlled to be within 1 / 15 of the diameter of the AZ91 bar material, after squeezing is conducted for one pass, a billet is taken out of the mold and put in an 560-DEG C resistance furnace, heat preservation is conducted for a certain time, water cooling is conducted till the temperature reaches the room temperature, and a semi-solid billet is obtained; or ECAP squeezing is conducted for multiple passes through a Bc path, squeezing is conducted for at most two passes through a C path, and squeezing is conducted for at most four passes through a Ba path; and then semi-solid remelting is conducted, and the semi-solid thixoforming billet is prepared. By means of the semi-solid billet fast preparation method based on the texture control idea, on the basis of existing technologies, control is conducted on aspects of the mold structure and the ECAP deformation, and therefore, it is possible that the semi-solid thixotropy billet which is small in grain size and high in sphericity degree is fast prepared.

Owner:HARBIN UNIV OF SCI & TECH

Texture controlling method of high temperature molten crystal growth axially

A segmental texture control method for growing crystal in easy axis direction in high-temp molten substance features that when the temp is near the smelting point, the temp is slowly raised and is held for a certain time in static magnetic field for obtain uniform temp in the high-temp molten substance, when the intensity of static magnetic field is higher, the molten substance is solidified at higher speed, and when the intensity of static magnetic field is lower, the molten substance is solidified at low speed.

Owner:SHANGHAI JIAO TONG UNIV

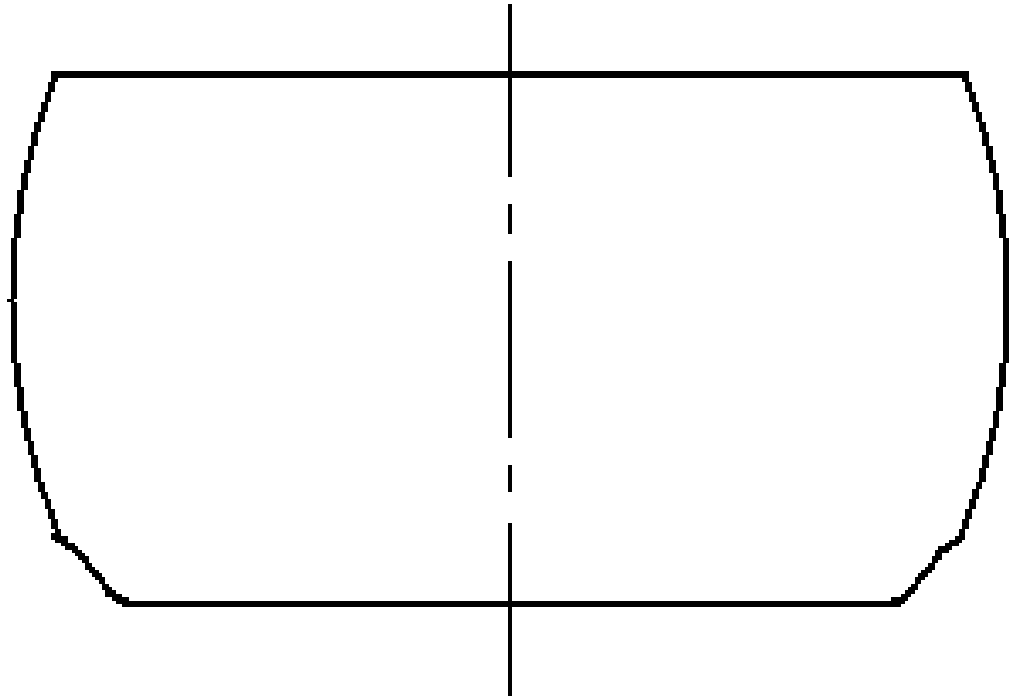

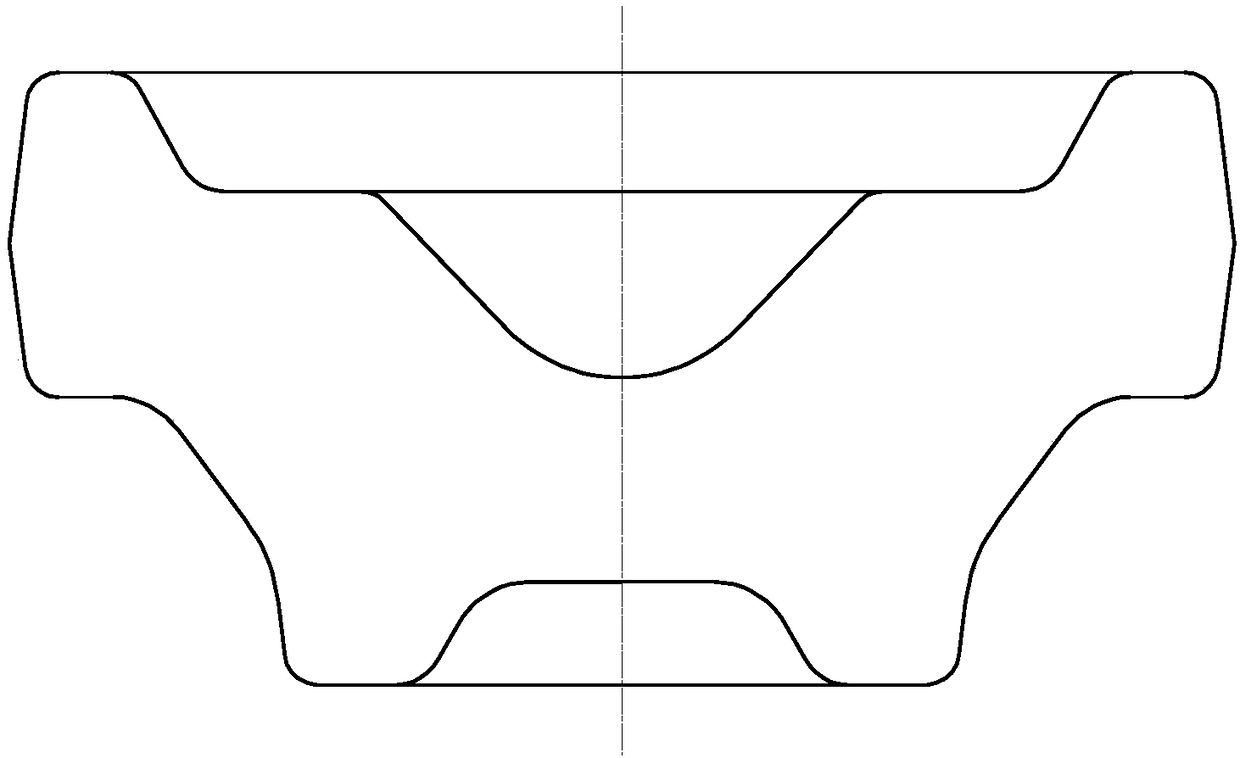

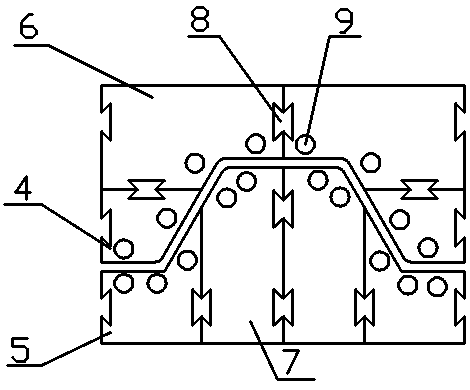

Combined die for shearing, bending, compounding and deforming magnesium alloy board

PendingCN107584022AIncrease productivityRolling path changeShaping toolsTexture controlShearing deformation

The invention discloses a combined die for shearing, bending, compounding and deforming a magnesium alloy board, and belongs to the technical field of magnesium alloy board plastic deformation. The combined die can be used for preparing high-performance deforming magnesium alloy. The die mainly comprises a shearing die body, a bending die body and swallow-tail-shaped keys, wherein the shearing diebody is divided into an upper shearing die body and a lower shearing die body, the bending die is divided into an upper bending die body and a lower bending die body, and all the die bodies are fixedly connected through the swallow-tail-shaped keys. The advantages of large shearing deformation and bending deformation are integrated, the flexibility is large, the die utilization rate is high, accumulative stress of composite deformation of shearing and bending under different technological parameters in the single rolling process of boards of different thicknesses can be achieved, therefore superfine and texture control of crystal is achieved, and excellent forming performance, mechanical performance and surface quality are represented.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-stress weak texture control method for pure copper disc type cartridge shape cover

The invention provides a low-stress weak texture control method for a pure copper disc type cartridge shape cover. The method comprises gradient temperature changing accumulation large plasticity extrusion forming, cold precision shape correcting, vibration aging and low-temperature stress removal. In gradient temperature changing accumulation large plasticity extrusion forming, the preheating temperature ranges from 300 DEG C to 510 DEG C, and the heating time ranges from 30 s to 90 s; and then the deformation temperature ranges from 280 DEG C to 490 DEG C, and the heat preservation time ranges from 1 h to 3 h. The method solves the technical problems that according to a conventional plastic forming method, texture is serious, symmetry is poor, and a structure is uneven; and dual controlover the accurate cartridge shape cover boundary dimension and the inner uniform structure is achieved, and the penetration capability and stability of the cartridge shape cover are improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

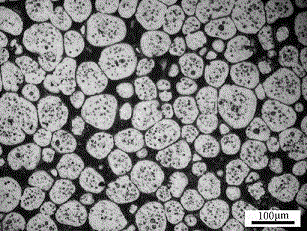

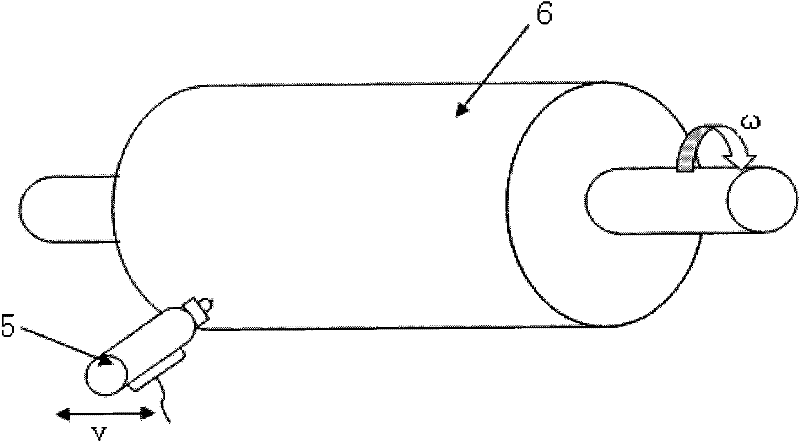

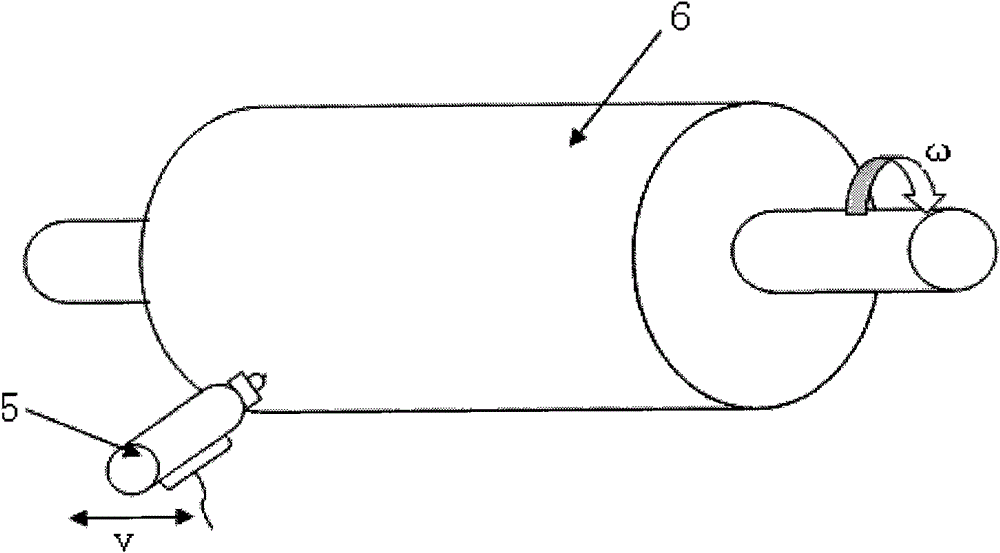

Surface Texturization of Thin Strip Continuous Casting Crystal Roller

The invention discloses a method for texturing the surface of a strip-casting crystallization roller. During rotation of the crystallization roller, a hemispheric or ellipsoidal conical texture point is attached to the surface of the crystallization roller and linearly moves along the axial direction of the crystallization roller at a certain speed v, wherein the texture point is hemispheric or ellipsoidal conical; a high-frequency impactor drives the texture point which is fixedly connected with the high-frequency impactor to impact the surface of the crystallization roller with a certain impact strength along the radial direction of the crystallization roller; and spherical crown-shaped or circular pits which are uniformly distributed linearly are formed in the surface of the crystallization roller. The method has quite high controllability. By controlling the oscillation frequency and amplitude of the high-frequency impactor, the linear speed of the texture point and the rotating speed of the crystallization roller, the texturing control process can be quantified, so that the appearance of the surface of the crystallization roller is more uniform and more regular.

Owner:BAOSHAN IRON & STEEL CO LTD

Device and process for preparing ceramic tile simulating Austrian sandstone textures

Owner:JIANGXI CIMIC CERAMICS +1

Multi-function sea cucumber cleaning machine

ActiveCN103212555BGuaranteed cleaning qualityCleaning processes and apparatusMode of actionTexture control

The invention discloses a multi-function sea cucumber cleaning machine, which comprises a immersion pool (1) with a drain outlet (9) at the bottom, a mesh partition (2) laid on the middle and lower part of the soaking pond, and rollers arranged at intervals above the mesh partition. brushes (3); foam tubes (5) are arranged at intervals below the mesh partition, and the foam pipes are connected to the air pumping unit; surge pipes are also arranged at intervals below the mesh partition, and the surge pipes are connected to the water body pump Conveyor unit; one side of the mesh partition is provided with a belt conveying unit, and a spray unit is provided above a section of the conveyor belt. The invention adopts multiple action modes to clean the sea cucumbers, can effectively guarantee the cleaning quality of the sea cucumbers, and is suitable for the cleaning process before texture control in the sea cucumber product processing process.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Liquid crystal display with texture control portion between pixel and common electrodes and method thereof

A liquid crystal display (“LCD”) having controlled texture and reduced response time includes first and second insulation substrates which are separated from each other and face each other, a liquid crystal layer which is interposed between the first and second insulation substrates and has liquid crystal molecules, a pixel electrode which is disposed on the first insulation substrate and includes a plurality of first linear electrode patterns, a common electrode which is disposed on the first insulation substrate and includes a plurality of second linear electrode patterns separated from the first linear electrode patterns by a predetermined gap, and a texture control portion which is disposed in an area corresponding to the gap and formed on the first or second insulation substrate, wherein the first and second linear electrode patterns are arranged in an alternating fashion.

Owner:SAMSUNG DISPLAY CO LTD

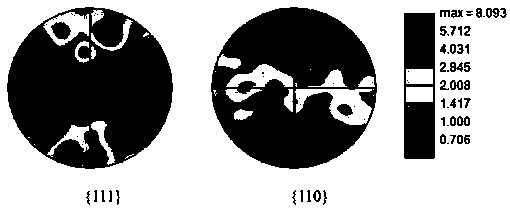

07MnNiMoDR steel for low-temperature pressure vessel and texture control method of 07MnNiMoDR steel

PendingCN114507811ALow costImprove densification performanceFurnace typesHeat treatment furnacesTemperingTexture control

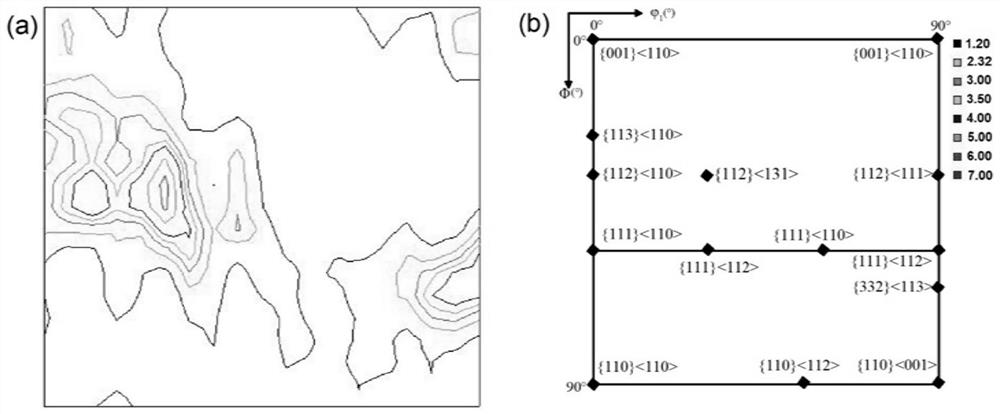

The invention discloses 07MnNiMoDR steel for a low-temperature pressure vessel and a texture control method of the 07MnNiMoDR steel, which adopts low-carbon, molybdenum and nickel alloying and niobium, vanadium, titanium and other composite microalloying design, and adopts a reasonable'subcritical quenching + tempering 'process to prepare the 07MnNiMoDR steel for the low-temperature pressure vessel. The results that the 07MnNiMoDR steel for the low-temperature pressure vessel is high in texture randomization degree, the grain orientation is relatively diffused, and the percentage content of each typical texture is relatively balanced are achieved, so that the toughness of the 07MnNiMoDR steel for the low-temperature pressure vessel is greatly improved, and the 07MnNiMoDR steel plate which is stable in performance, meets the standard requirement and can be used for authentication is produced.

Owner:NANJING IRON & STEEL CO LTD

Cold-rolled high-strength titanium alloy pipe texture control method

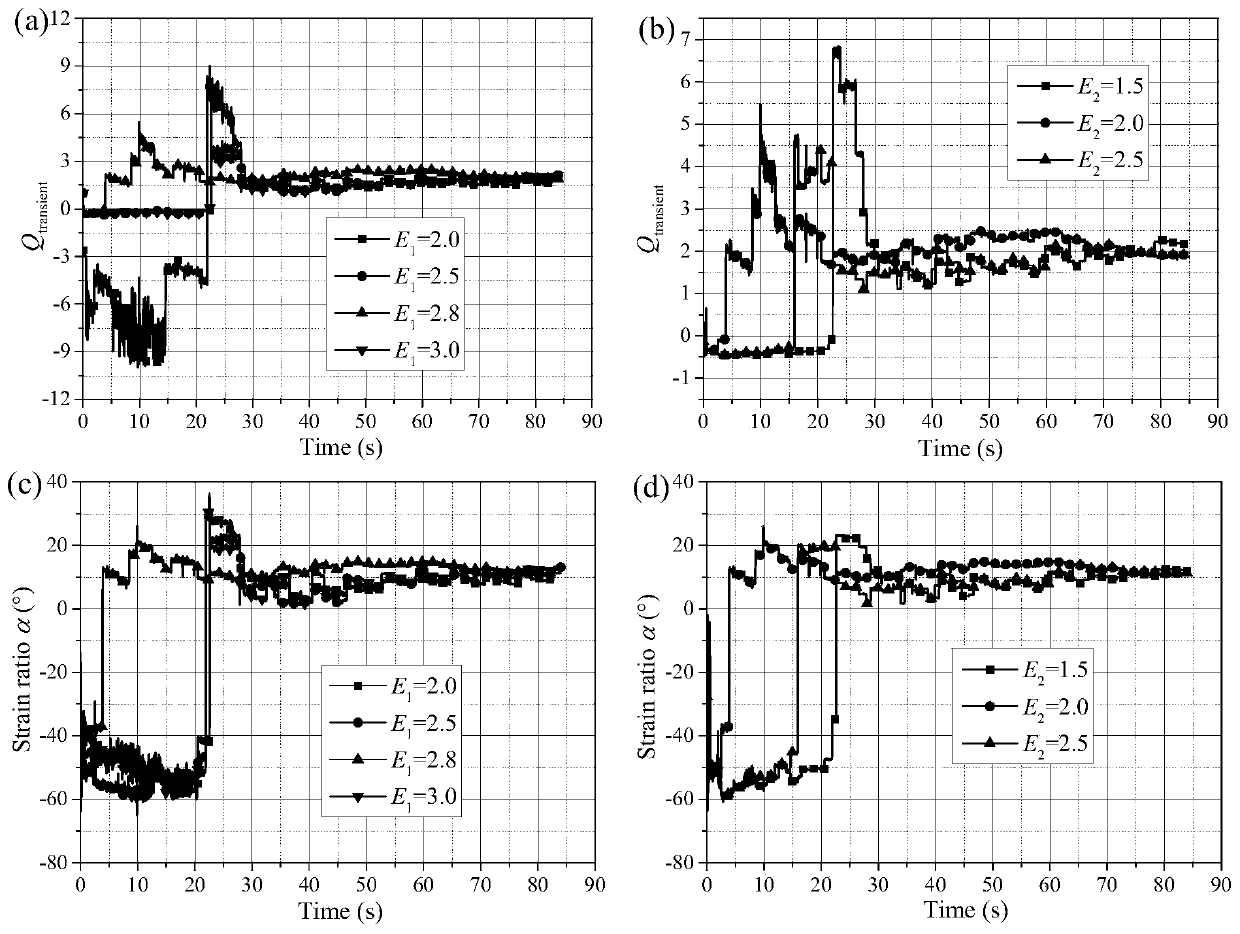

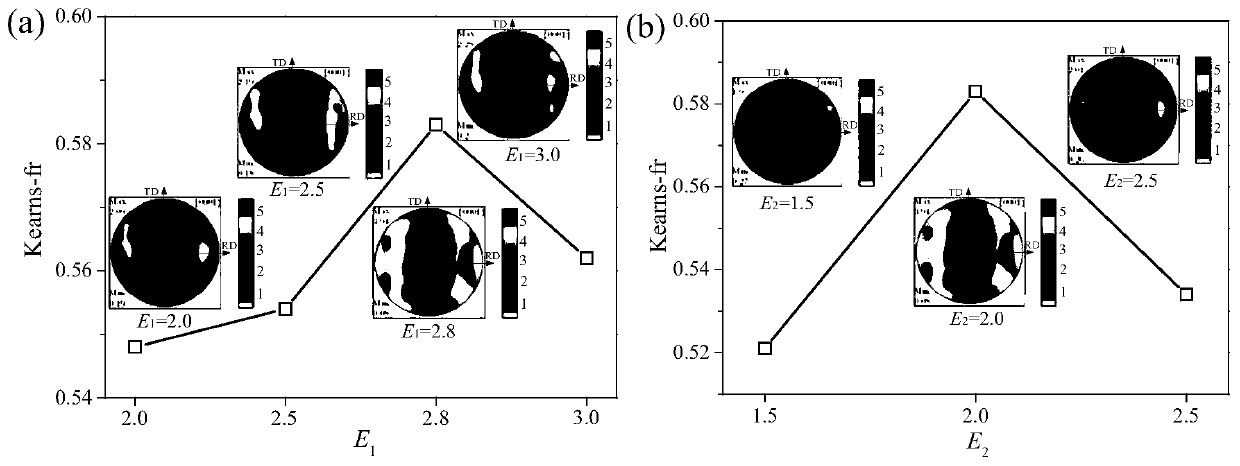

ActiveCN110158005AEfficient and precise regulationEasy to implementTexture controlGreek letter epsilon

The invention discloses a cold-rolled high-strength titanium alloy pipe texture control method. Overall adjustment and control are performed by adjusting the overall Q value and equivalent strain epsilon e in the cold rolling process, and then pipe texture fine adjustment and control are achieved by adjusting the pipe strain path in the rolling process. By means of the method provided by the invention, precise control over the cold-rolled high-strength titanium alloy pipe texture and performance can be more effectively achieved, in addition, no extra procedure needs to be added, implementing is easy, and the application prospects are wide.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for improving impact toughness of TMCP steel for ships through texture control

ActiveCN112126759AIncrease productivityStrong production efficiencyTemperature control deviceTexture controlWater cooling

Owner:NORTHEASTERN UNIV +1

A quasi-continuous laser metal 3D printing method to realize the crystallographic texture control of nickel-based alloys

ActiveCN107790717BImprove consistencyImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceNickel based

Owner:HUNAN UNIV

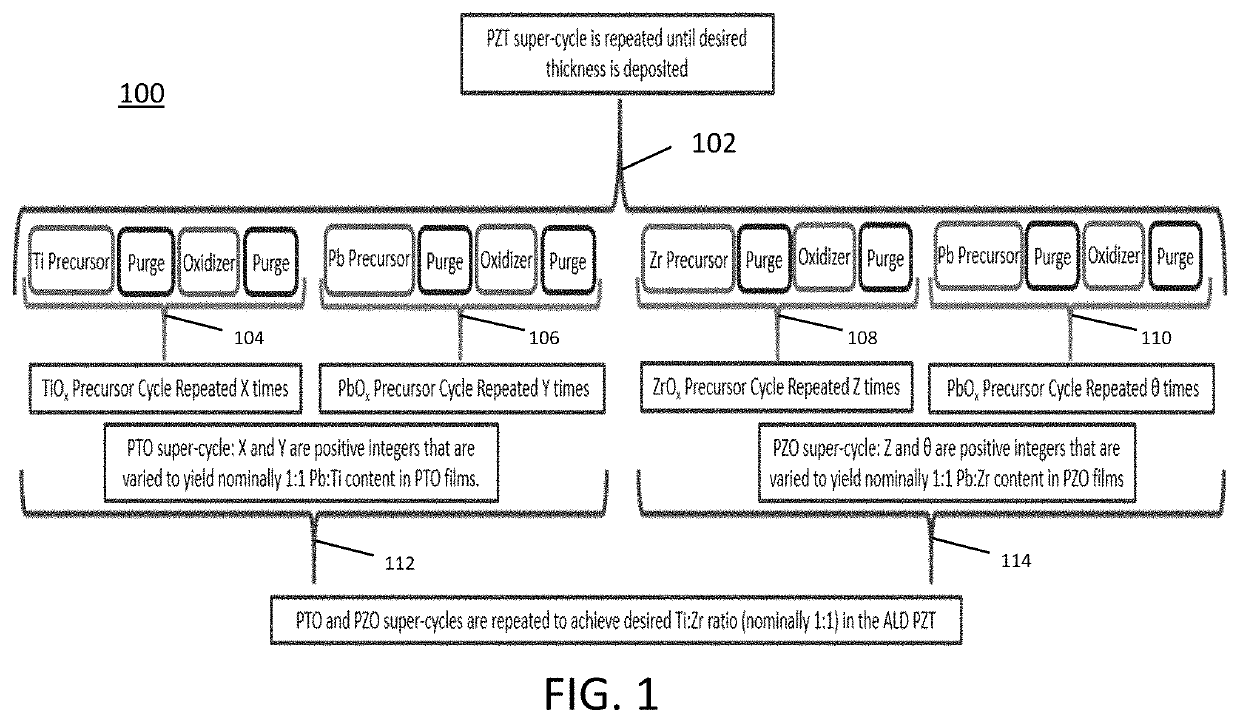

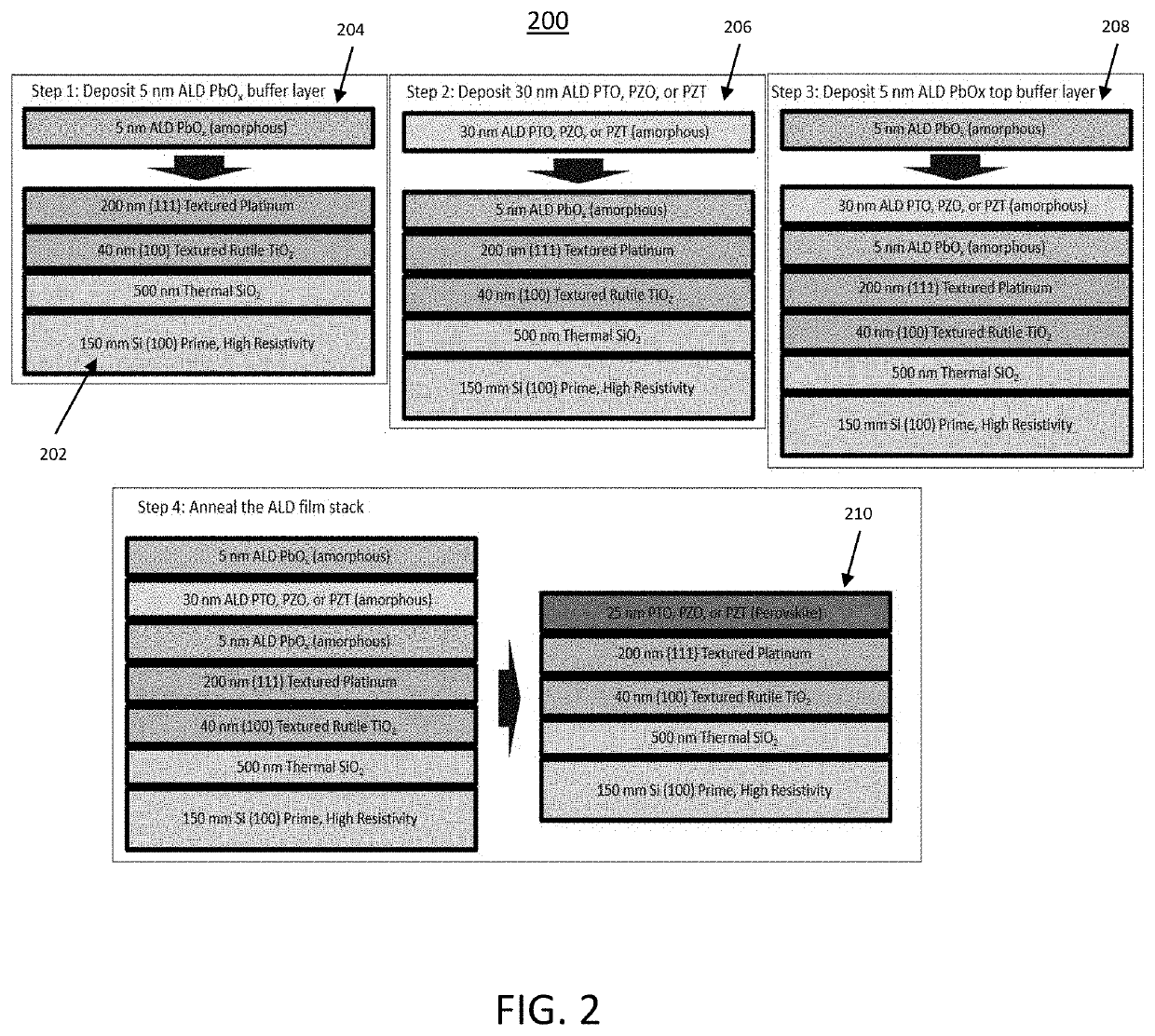

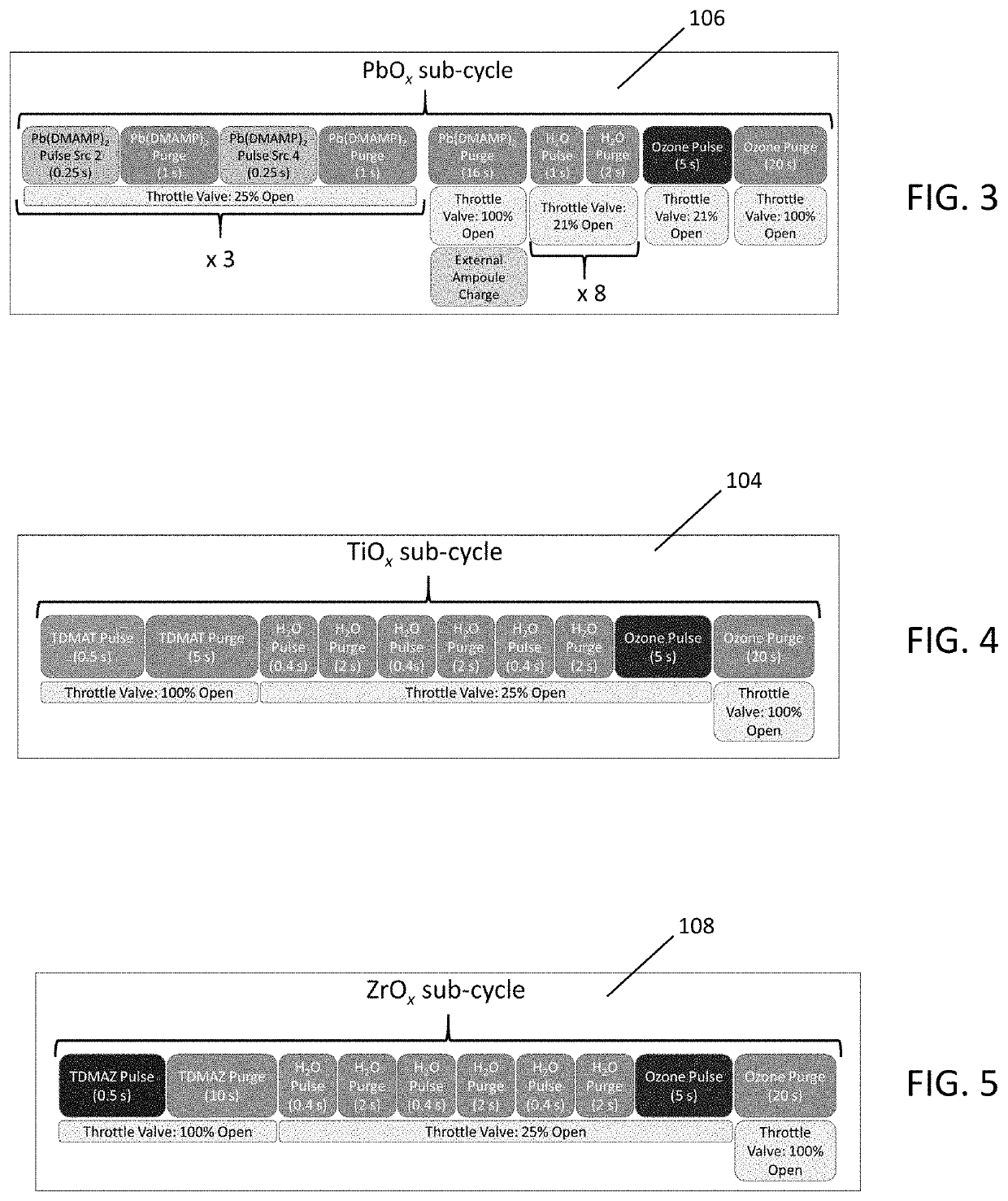

Deposition and texture control of pbtio3, pbzro3, and pbzrxti1-xo3

InactiveUS20200224312A1Piezoelectric/electrostrictive/magnetostrictive devicesChemical vapor deposition coatingLead zirconate titanateChemisorption

A method of depositing a thin film of lead titanate (PTO), lead zirconate (PZO) or lead zirconate titanate (PZT) comprising depositing a PTO, PZO or PZT layer upon a substrate whereby growth occurs primarily due to self-limited surface chemisorption of pulsed chemical vapor, and annealing the PTO, PZO, or PZT layer and substrate.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for texturing surface of strip-casting crystallization roller

The invention discloses a method for texturing the surface of a strip-casting crystallization roller. During rotation of the crystallization roller, a hemispheric or ellipsoidal conical texture point is attached to the surface of the crystallization roller and linearly moves along the axial direction of the crystallization roller at a certain speed v, wherein the texture point is hemispheric or ellipsoidal conical; a high-frequency impactor drives the texture point which is fixedly connected with the high-frequency impactor to impact the surface of the crystallization roller with a certain impact strength along the radial direction of the crystallization roller; and spherical crown-shaped or circular pits which are uniformly distributed linearly are formed in the surface of the crystallization roller. The method has quite high controllability. By controlling the oscillation frequency and amplitude of the high-frequency impactor, the linear speed of the texture point and the rotating speed of the crystallization roller, the texturing control process can be quantified, so that the appearance of the surface of the crystallization roller is more uniform and more regular.

Owner:BAOSHAN IRON & STEEL CO LTD

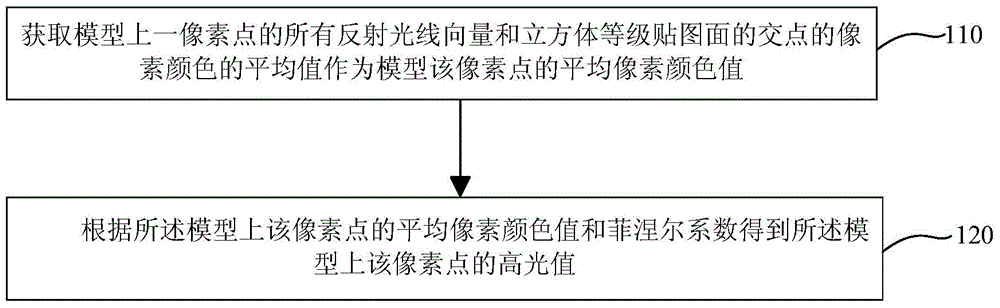

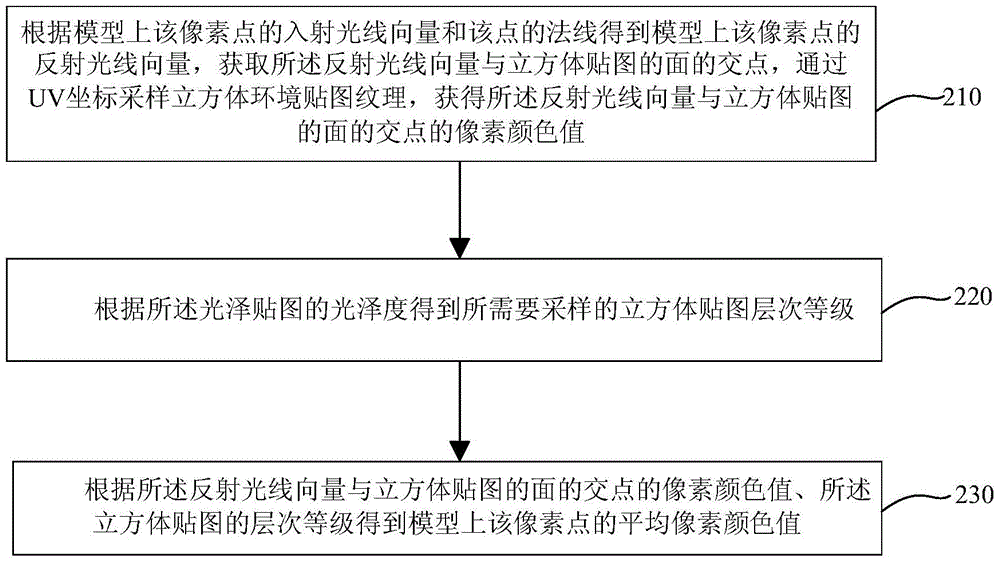

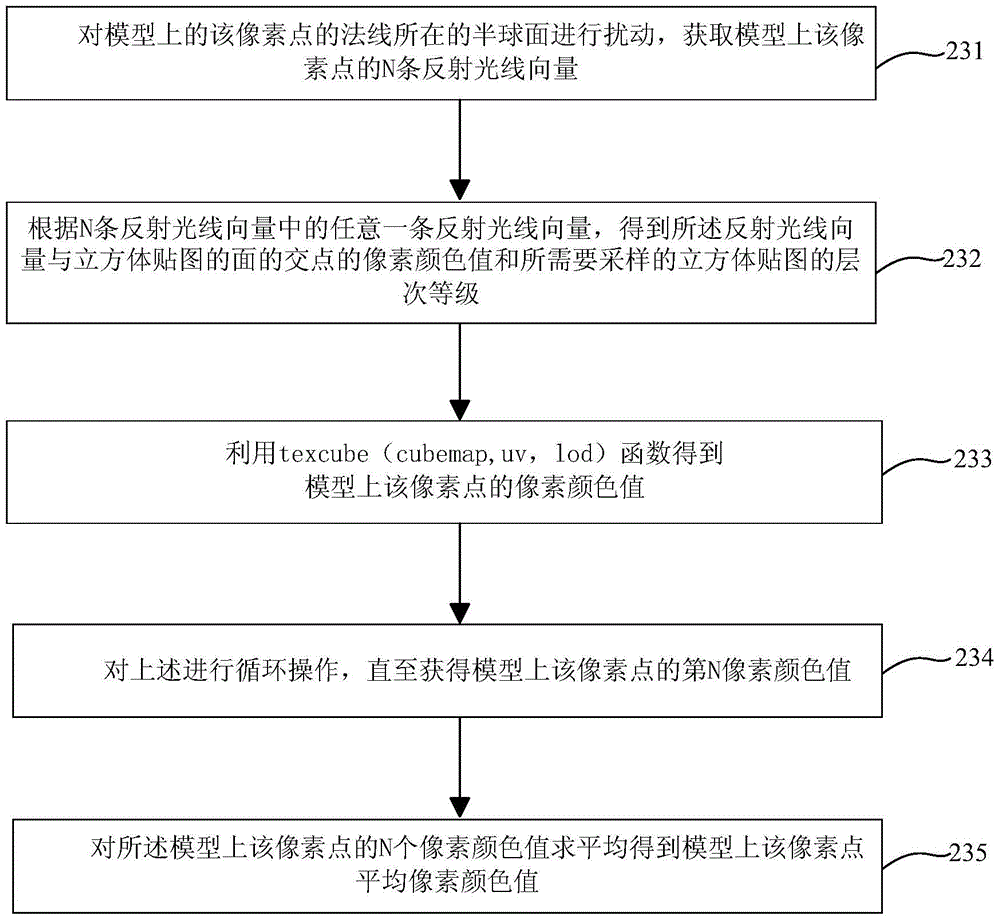

A method and device for controlling the definition of high light reflection by using texture

ActiveCN104392481BRealistic visual effectsEasy to control3D-image renderingComputer graphics (images)Texture control

The invention provides method and device for controlling specular reflection definition by mapping. The method comprises the steps of acquiring an average value of pixel colors of points in which all reflection ray vectors of a pixel point in a model are intersected with a cube-level mapping plane, and treating the average value as the average pixel color value of the pixel point; obtaining an specular value of the pixel point in the model according to the average pixel color value of the pixel point in the model and fresnel coefficients. According to the method and device, the surrounding environment is rendered to the model by mapping, the glossiness of gloss mapping can be adjusted to control the model to reflect the definition of the surrounding environment, and therefore, the model has the effect of real vision.

Owner:WUXI FANTIAN INFORMATION TECH

Real time binocular vision guidance method facing to underwater carrying vehicle

The invention provides a real-time binocular vision guidance method for underwater vehicles. Aiming at the characteristics of the marine environment where the underwater vehicle moves, a pyramid normalized covariance binocular vision algorithm based on texture control is proposed, which achieves real-time performance at the application level, and the accuracy can be stabilized at the centimeter level. For the final representation of environmental information, a virtual sonar model is proposed to represent the 2.5-dimensional environmental information as an obstacle (or target) matrix based on the virtual sonar model, which includes the depth and depth of the obstacle (or target) orientation information.

Owner:HARBIN ENG UNIV

A 42crmo4 wind turbine main shaft control method

ActiveCN107858590BMeet the use requirementsImprove performanceFurnace typesHeat treatment furnacesWind drivenChemical composition

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

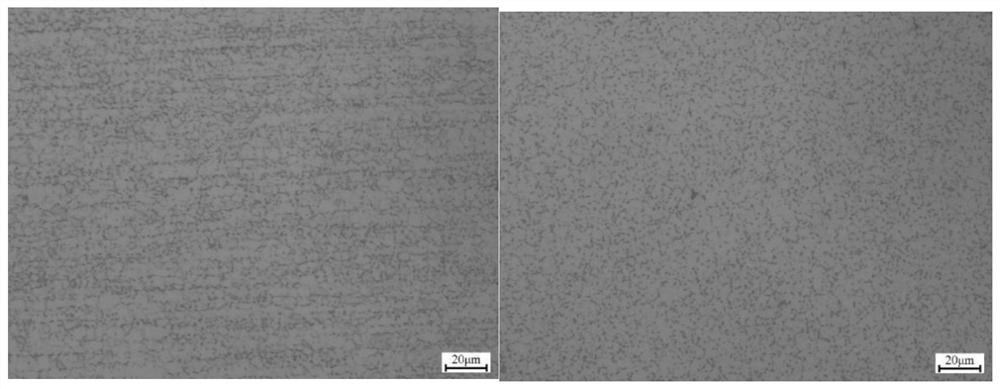

A preparation method of titanium alloy wire with high torsional performance based on texture control

ActiveCN111014286BIncrease the breaking torsion angleEliminate overdraw forgingMetal rolling arrangementsTexture controlTitanium alloy

The embodiment of the present invention provides a method for preparing titanium alloy wire with high torsional performance based on texture control. At 10-20°C above the phase transition point of phase titanium alloy, the material undergoes "α+β→β" phase transformation, eliminating the axial texture formed by elongation forging and billet rolling, so as to obtain the consistency of transverse and longitudinal microstructure and properties On the other hand, the introduction of the "Y-type three-roller warm rolling" method changes the stress mode of the material plastic deformation process, with the radial rolling stress as the main force and the axial tensile stress as the supplementary force. There is rolling friction between them, which greatly weakens the axial and radial anisotropy during the warm rolling process of the wire, and the grain shape and size of the transverse and longitudinal structures are basically the same, thereby improving the radial (circumferential) torsion performance of the wire, and Greatly improve the fracture torsion angle of titanium alloy wire.

Owner:西安圣泰金属材料有限公司

Ultraprecise milling surface topography texture control method

ActiveCN103042434BEffective controlEasy to controlAutomatic control devicesFeeding apparatusPhase differenceTexture control

The invention discloses an ultraprecise milling surface topography texture control method. The method includes that a machining surface topography texture direction angle delta is set; tool starting phase angle difference of adjacent tool paths is determined according to the texture direction angle delta, tool path planning of a cutting area and a non-cutting area is conducted according to the tool starting phase angle difference, and a tool path file is generated; and ultraprecise milling can be achieved by using the tool path file. By controlling the tool starting phase angle difference of the adjacent tool paths instead of controlling a starting phase angle of each row of tool paths, a starting process of moving of a spindle and various shafts is avoided, and controlling feasibility is greatly improved. In addition, by planning non-cutting paths, the tool starting phase angle difference of the adjacent tool paths is effectively controlled, and control for the ultraprecise milling surface topography is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com