Combined die for shearing, bending, compounding and deforming magnesium alloy board

A combined mold and plate shearing technology, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low mold utilization, difficult forming, weak plastic deformation ability, etc., and achieves improved production efficiency and high utilization , the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

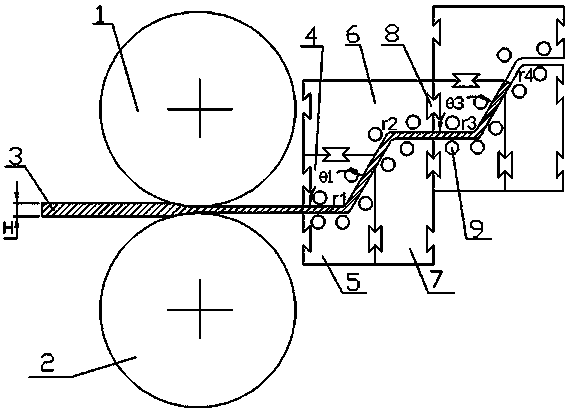

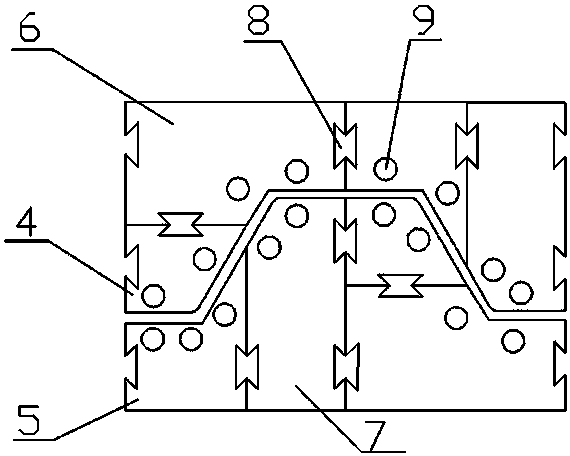

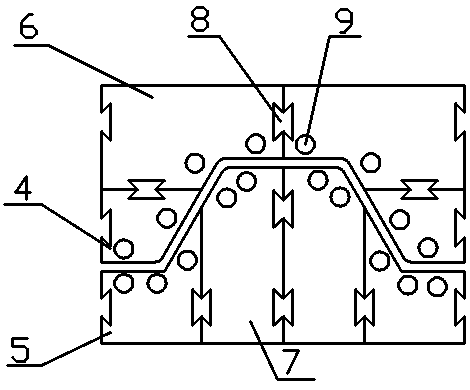

[0015] The present invention proposes a composite mold for shearing and bending composite deformation of magnesium alloy plates. The composite mold includes a shearing mold, a bending mold and a dovetail key. The mold (5) and the bending mold are divided into the upper bending mold (6) and the lower bending mold (7). The molds are connected and fixed by dovetail keys (8). The upper shearing mold (4) and the lower shearing mold ( 5) The shearing channel is formed, the inner arc radius of the shearing channel is r1, the upper bending mold (6) and the lower bending die (7) form a bending channel, and the radius of the inner and outer arcs at the corners of the bending channel is r2 , The built-in heating pipe (9) in the mold can control the mold temperature, and the height of the mold channel is kept equal everywhere to realize the cumulative supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com