A preparation method of titanium alloy wire with high torsional performance based on texture control

A technology of torsional performance, titanium alloy wire, applied in the direction of metal rolling, etc., can solve the problems of poor plastic deformation, low longitudinal elastic modulus of titanium alloy, difference in axial and longitudinal properties, etc., to achieve consistent grain shape and size, The effect of weakening anisotropy and increasing fracture torsion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

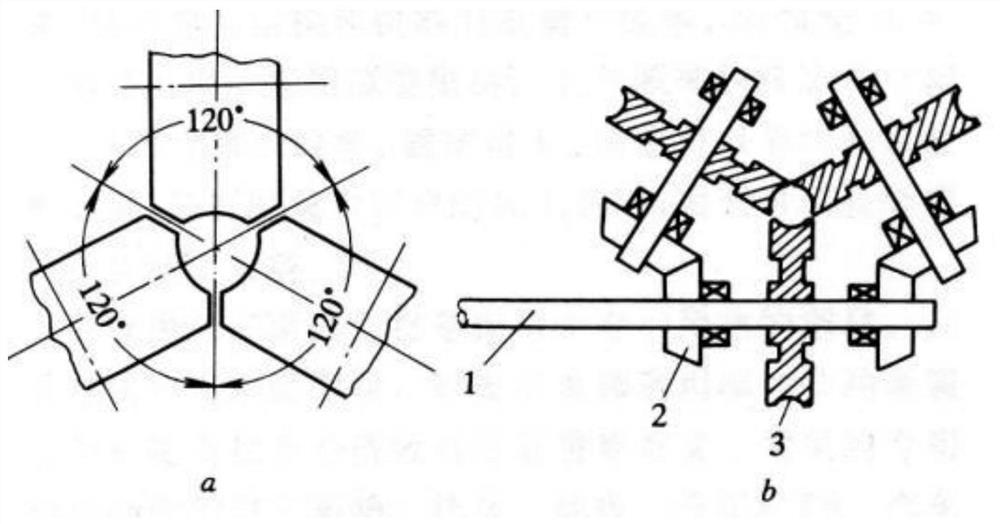

[0027] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0028] See Figure 1-Figure 4 . The embodiment of the present invention provides a method for preparing titanium alloy wire with high torsional performance based on texture control, including:

[0029] S110. Obtain a blank, wherein the blank is a Φ60 rolled titanium alloy blank;

[0030] S120. Rolling the billet a second time to obtain a pretreated billet; wherein the pretreated billet is a Φ10 rolled titanium alloy billet made by rolling the billet from a Φ60 rolled titanium alloy billet;

[0031] S130. According to the preset method, perform rounding and peeling treatment on the pre-treated billet to obtain a secondary processed billet; wherein, the preset meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com