Surface Texturization of Thin Strip Continuous Casting Crystal Roller

A technology of continuous casting crystallization and crystallization roll, applied in the field of strip steel casting, can solve problems such as low efficiency, and achieve the effects of strong controllability, uniform appearance and regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

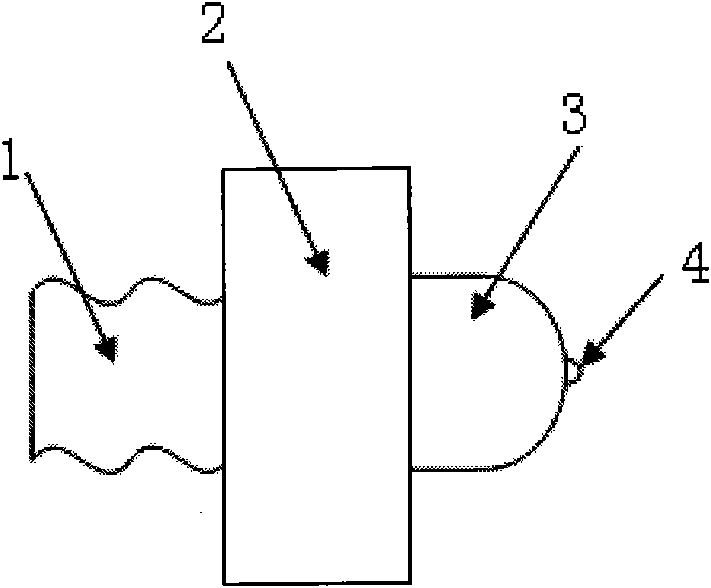

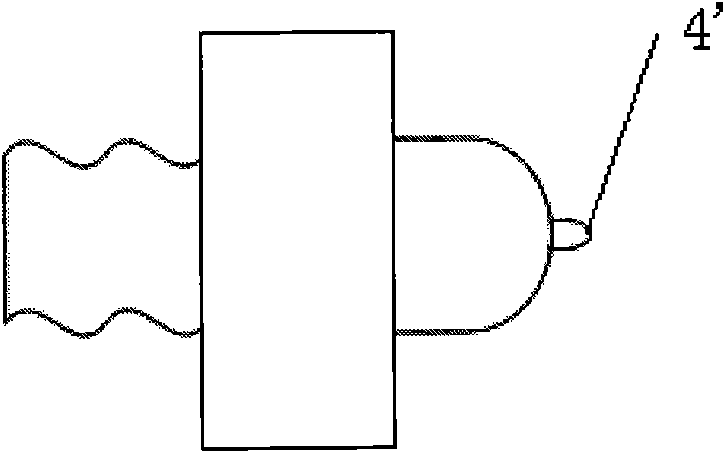

[0032] The hemispherical or ellipsoidal cone-shaped texture tip in the embodiments 1-6 of the present invention is compared with figure 1 with figure 2 The connector shown is connected to a high-frequency impactor. figure 1 Among them, the hemispherical textured tip 4 is fixedly connected to the fixed rod 3, the fixed rod 3 is connected to one end of the connecting rod 1 through the locking cap 2, and the other end of the connecting rod 1 is used for connecting with a high-frequency impactor. In addition, the hairy tip can also be like figure 2 The ellipsoid cone-shaped texturing tip 4'is shown.

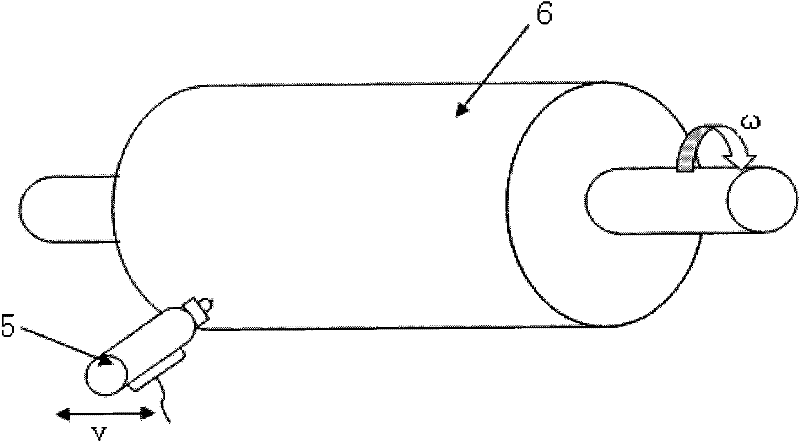

[0033] Such as image 3 As shown, during the texturing process, one side of the texturing tip is close to the surface of the crystallizing roller 6, and together with the high-frequency impactor 5 connected to it, the surface of the crystallizing roller 6 moves linearly with a speed of v along its axial direction. The other side is driven by the high-frequency impactor 5 to impact on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com