Semi-solid billet fast preparation method based on texture control idea

A semi-solid and billet technology, which is applied in the field of magnesium alloy semi-solid billet preparation, can solve the problems of semi-solid billets such as low sphericity, large crystal grains, and large plastic deformation, so as to improve the effect of grain refinement and sphericity Higher, less likely effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

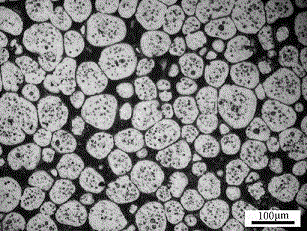

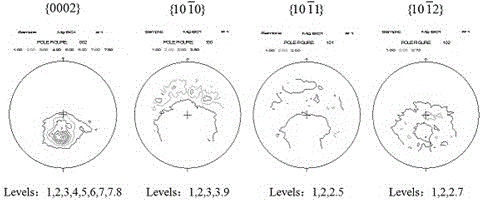

[0033] Embodiment 1: Preparation of large-size semi-solid blank

[0034] Raw material: semi-continuous drawing and casting AZ91 magnesium alloy bar stock

[0035] Size: Φ60x150mm

[0036] Mold inner corner radius: r=3mm

[0037] The preparation method comprises the following steps:

[0038] (1) ECAP extrusion: Heat the AZ91 magnesium alloy bar to 210°C and keep it warm for 15 minutes. Also heat the ECAP mold (the angle between the two channels is 90°) to 210°C, and then put the bar into the entrance of the mold. Spray MoS2 lubricant on the contact surface between the bar and the entrance of the die, start the press, and slowly extrude the bar at an extrusion speed of 1.5mm / s until the bar can be taken out from the exit of the die;

[0039] (2) Semi-solid remelting: Put the rod taken out from ECAP into the resistance furnace, vacuumize, put argon gas as a protective atmosphere to prevent oxidation, keep the resistance furnace at 570°C for 15 minutes, then take out the billet...

Embodiment 2

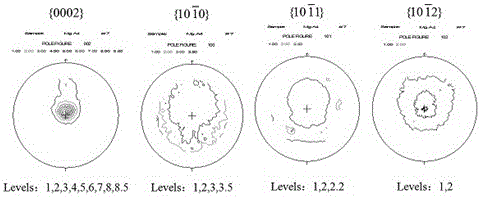

[0040] Example 2: Preparation of smaller size semi-solid billets

[0041] Raw material: extruded AZ91 magnesium alloy bar

[0042] Size: Φ20x45mm

[0043] Mold inner corner radius: r=1mm

[0044] The preparation method comprises the following steps:

[0045] (3) ECAP extrusion: Heat the AZ91 magnesium alloy bar to 210°C and keep it warm for 10 minutes. Also heat the ECAP mold (the angle between the two channels is 90°) to 180°C, and then put the bar into the entrance of the mold. On the contact surface between the bar and the entrance of the die, spray graphite lubricant, start the press, and slowly extrude the bar at an extrusion speed of 0.5 mm / s until the bar can be taken out from the exit of the die. Then put the bar into the ECAP inlet again, extrude continuously for 4 passes according to the Bc path, and take it out from the outlet;

[0046] (4) Semi-solid remelting: put the AZ91 magnesium alloy bar that has been extruded by ECAP into a resistance furnace, vacuumize,...

Embodiment 3

[0047] Example 3: Preparation of smaller size semi-solid billets

[0048] Raw material: semi-continuous drawing and casting AZ91 magnesium alloy bar stock

[0049] Size: Φ10x45mm

[0050] Mold inner corner radius: r=0.5mm

[0051] The preparation method comprises the following steps:

[0052](5) ECAP extrusion: Heat the AZ91 magnesium alloy bar to 200°C and keep it warm for 8 minutes. Also heat the ECAP mold (the angle between the two channels is 90°) to 190°C, and then put the bar into the entrance of the mold. On the contact surface between the bar and the entrance of the die, spray graphite lubricant, start the press, and slowly extrude the bar at an extrusion speed of 0.5 mm / s until the bar can be taken out from the exit of the die. Then put the bar into the ECAP inlet again, extrude the second pass according to the C path, and take it out from the mold outlet;

[0053] (6) Semi-solid remelting: Put the AZ91 magnesium alloy bar that has been extruded by ECAP into a res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com