A quasi-continuous laser metal 3D printing method to realize the crystallographic texture control of nickel-based alloys

A 3D printing, nickel-based alloy technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of dendrite structure growth and lack of solidification texture, so as to improve the microstructure and improve the consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] A quasi-continuous laser metal 3D printing method for realizing the crystallographic texture regulation of nickel-based alloys, comprising the following steps:

[0024] Step 1: Set the laser output to the quasi-continuous laser mode, that is, modulate the laser into an intermittent output on the order of milliseconds, and perform preliminary optimization on the quasi-continuous laser metal 3D printing process window. The preliminary optimization of the process window includes: laser waveform, laser The power, spot diameter, powder feeding amount and duty cycle are used to obtain a preliminary optimized process window; the powder feeding laser metal 3D printing method is selected.

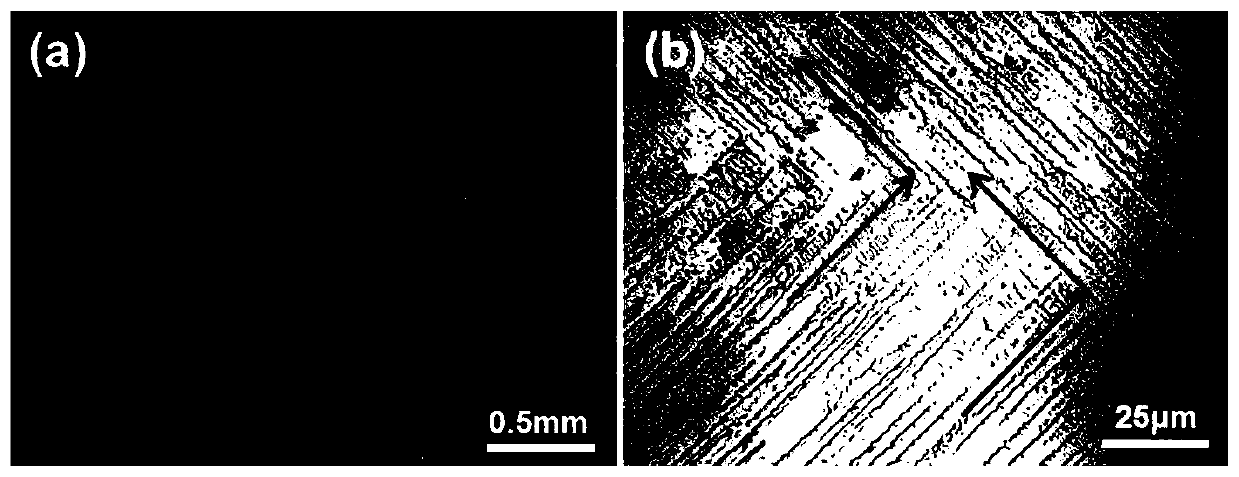

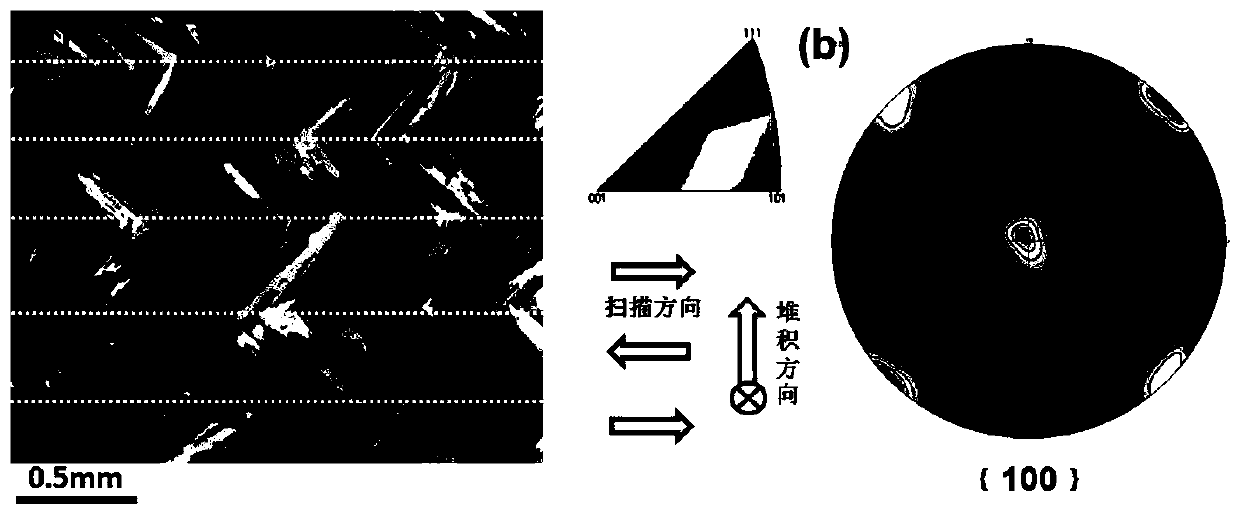

[0025] Step 2: Use the finite element heat transfer model to calculate the temperature field of the molten pool during the quasi-continuous laser metal 3D pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com