07MnNiMoDR steel for low-temperature pressure vessel and texture control method of 07MnNiMoDR steel

A pressure vessel and low-temperature technology, applied in the field of metallurgy, to achieve the effects of improving low-temperature impact toughness, improving compactness, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

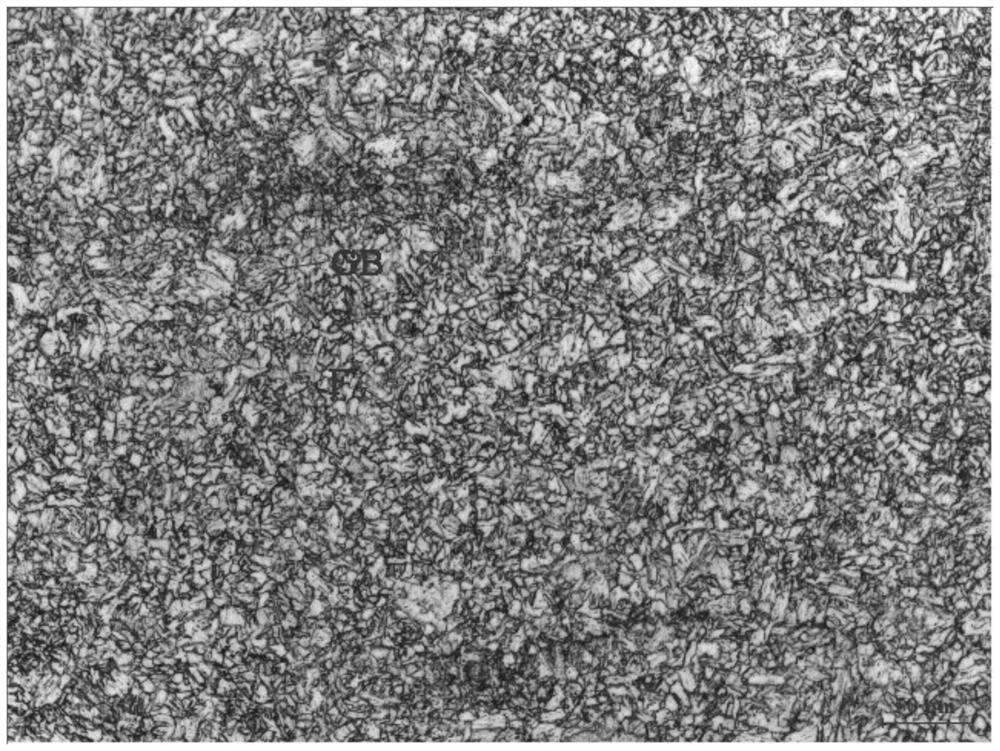

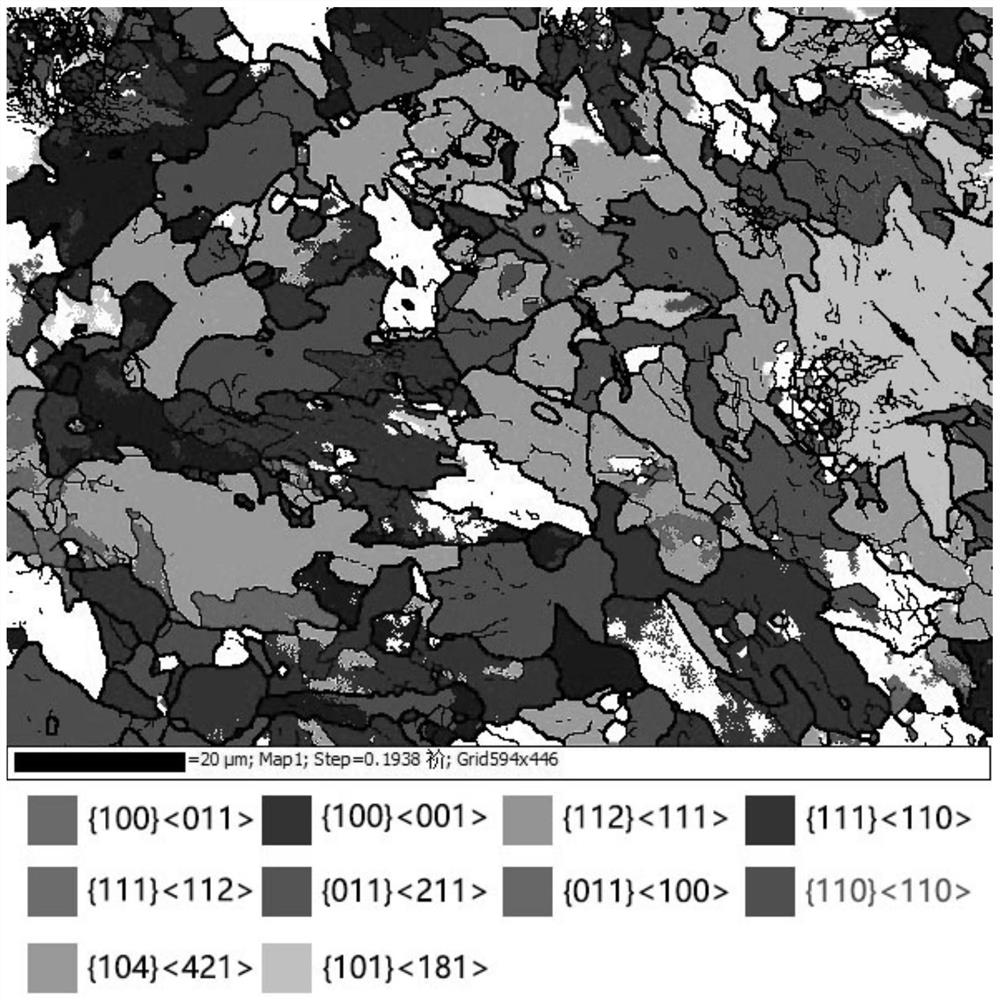

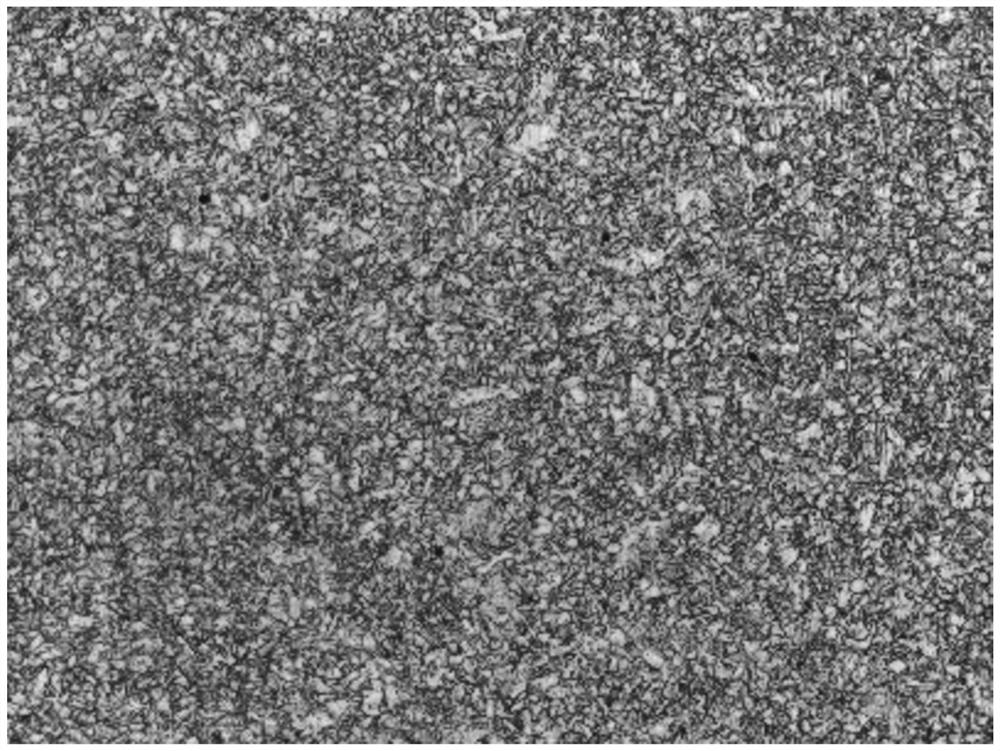

Image

Examples

Embodiment 1

[0028] The thickness of this 07MnNiMoDR steel plate is 48mm, and the following composition ratio and production method are adopted. Ingredient content (wt) is:

[0029] C: 0.067%, Si: 0.211%, Mn: 1.508%, P: 0.007%, S: 0.0009%, Ni: 0.392%, Al: 0.036%, Mo: 0.270%, Nb: 0.029%, V: 0.046%, Ti: 0.0029%, Ca: 0.0019%, and the rest are Fe and residual elements.

[0030] The production method of this steel plate is as follows:

[0031] (1) Steelmaking process: S≤0.005% after molten iron pretreatment, P≤0.010% after deep converter desulfurization, S≤0.002% after LF deep desulfurization, ultra-low As, Sb, Sn, Pb, Bi, B residual element control , The smelting uses molten iron with qualified composition as the raw material, and alloys are added during the molten steel smelting process to avoid the increase of residual elements. After the end of RH, the temperature of the molten steel is 1515°C. When reaching the continuous casting tundish, the superheat of the molten steel is controlle...

Embodiment 2

[0038] The thickness of this 07MnNiMoDR steel plate is 48mm, and the following composition ratio and production method are adopted. Ingredient content (wt) is:

[0039] C: 0.068%, Si: 0.212%, Mn: 1.509%, P: 0.0076%, S: 0.001%, Ni: 0.393%, Al: 0.037%, Mo: 0.271%, Nb: 0.030%, V: 0.047%, Ti: 0.0029%, Ca: 0.002%, and the rest are Fe and residual elements.

[0040] The production method of this steel plate is as follows:

[0041](1) Steelmaking process: S≤0.005% after molten iron pretreatment, P≤0.010% after deep converter desulfurization, S≤0.002% after LF deep desulfurization, ultra-low As, Sb, Sn, Pb, Bi, B residual element control , The smelting uses molten iron with qualified composition as the raw material, and alloys are added during the molten steel smelting process to avoid the increase of residual elements. After the end of RH, the temperature of the molten steel is 1518°C. When reaching the continuous casting tundish, the superheat of the molten steel is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com