Method for improving impact toughness of TMCP steel for ships through texture control

A technology for impact toughness and marine use, which is applied in the field of improving the impact toughness of TMCP steel for marine using texture control technology, can solve problems such as affecting the low temperature toughness of steel plates, small anisotropy of mechanical properties, and deteriorating low temperature toughness of steel plates, and achieves the production process. The effect of stability, low implementation difficulty and stable performance

Active Publication Date: 2020-12-25

NORTHEASTERN UNIV +1

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Texture strengthening is an additional geometric strengthening of controlled-rolled high-strength steel. However, in the production and research of ship plate steel, the influence of texture factors on the low-temperature toughness of steel plates was often ignored.

In fact, the crystallographic orientation can significantly affect the low-temperature to

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

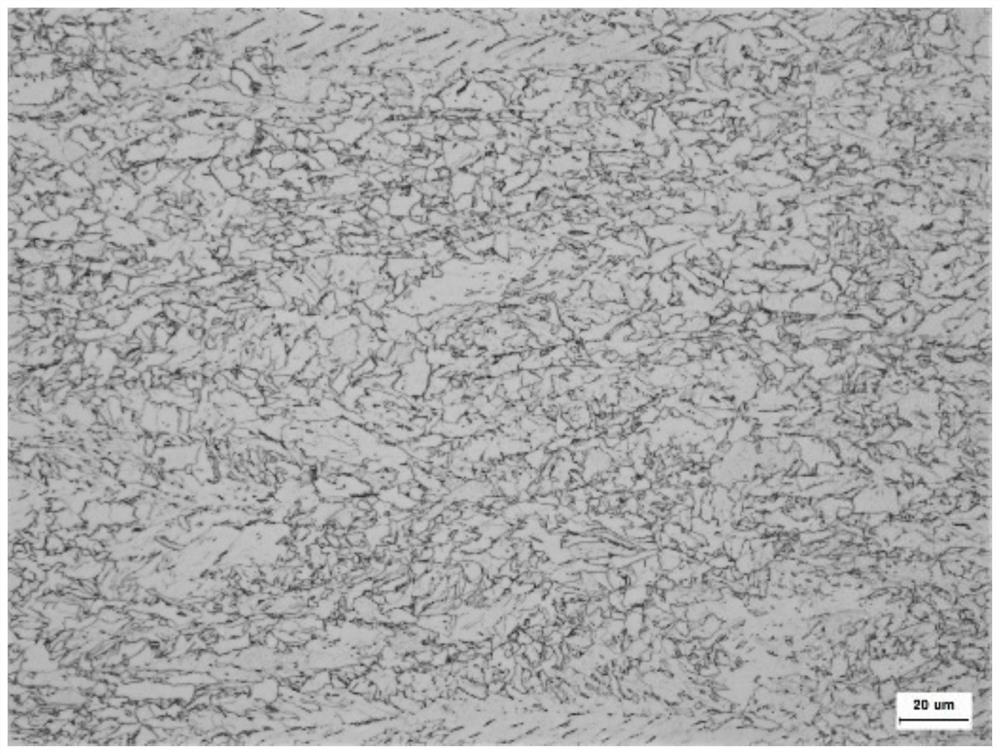

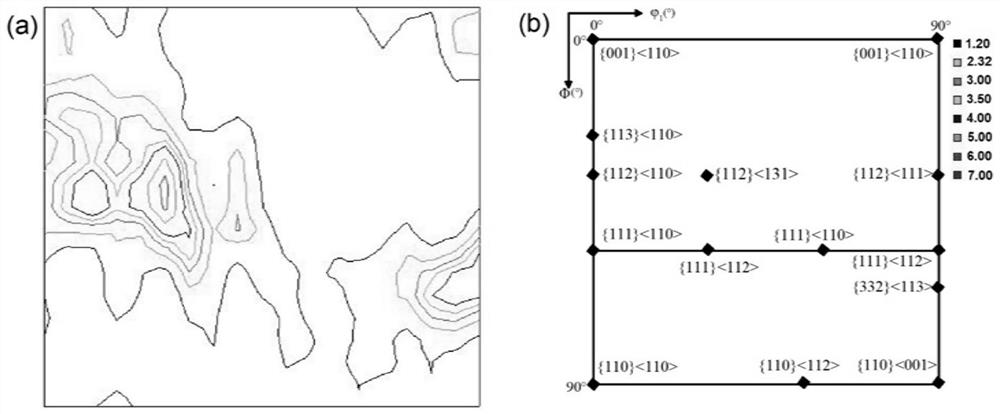

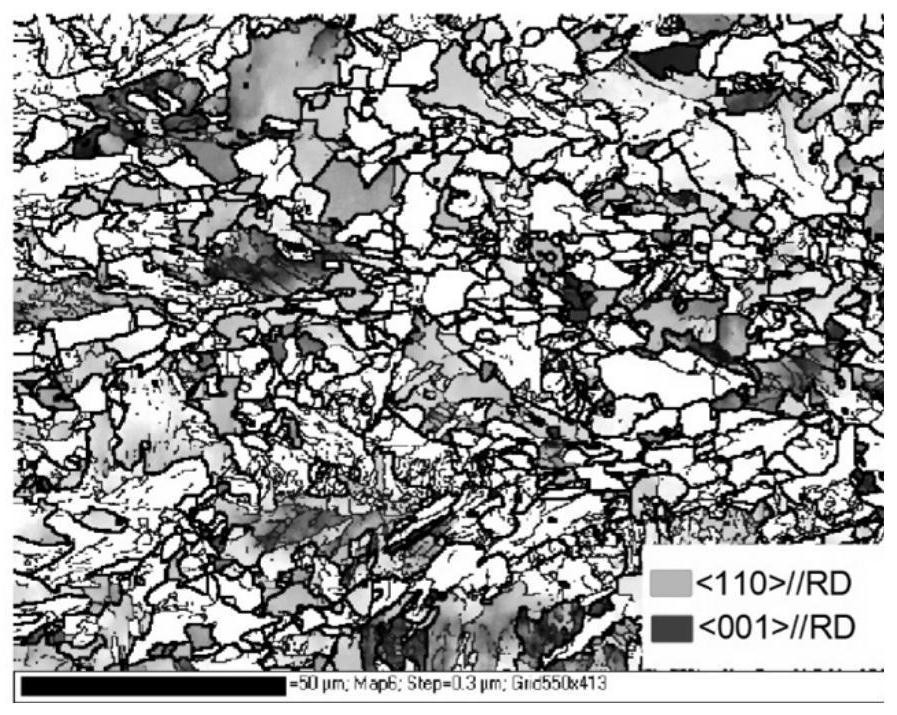

The invention discloses a method for improving the impact toughness of TMCP steel for ships through texture control. According to the method, conventional industrial EH47 continuous casting billets are used as raw materials, a TMCP two-stage controlled rolling process is adopted, intermediate billet deformation distribution is controlled under the conditions of a low compression ratio and a high finishing rolling temperature, and the four-stage cooling method of air cooling, water cooling, air cooling and water cooling is adopted after rolling so that high-strength texture distribution is obtained at the center of a steel plate; and the impact energy of the steel plate under the condition of -80 DEG C is improved by adopting a high-strength favorable texture of the core part of the steel plate and a uniformly distributed high-content {110} slip surface. According to the production method, the impact toughness of the steel plate at the temperature of -80 DEG C can be obviously improved,the production process is simple, the operability is high, the implementation difficulty is low, and the texture control effect is obvious.

Description

technical field [0001] The invention belongs to the field of steel plate manufacturing for ships, and in particular relates to a method for improving the impact toughness of TMCP steel for ships by utilizing texture control technology. Background technique [0002] In recent years, with the large-scale development of ships, the safety of ships has been seriously challenged, which has led to the rapid development of large-thickness ship steel with excellent low-temperature toughness. When the TMCP process is used to produce steel for ships, low-carbon microalloying treatment and a certain amount of Ni element are added in terms of composition, and the total compression ratio in the rolling process is increased and the deformation in the rough rolling stage and the deformation in the finishing rolling stage are optimized. amount, and finally change the flattened state of the austenite after final rolling, coupled with a suitable post-rolling cooling procedure, to achieve the r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D8/02B21B37/74

CPCB21B37/74C21D8/0205C21D8/0226C21D2211/002C21D2211/005

Inventor 田勇王红涛叶其斌王昭东王国栋赵晋斌邱保文

Owner NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com