Cold-rolled high-strength titanium alloy pipe texture control method

A technology of titanium alloy tube and control method, applied in the field of metal material processing, can solve the problems of single process design index, CSR value and performance fluctuation of finished tube, and achieve the effect of efficient and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example is a comparison of pipe texture and CSR value under different rolling specification design schemes based on numerical simulation. The specific implementation process includes the following steps:

[0027] In the first step, based on the ABAQUS finite element software and the viscoplastic self-consistent model (VPSC model), combined with the actual rolling conditions, a two-roll Pilger cold-rolled TA18 titanium alloy tube macro and micro numerical prediction platform was established for the macro deformation during the rolling process Accurate simulation and prediction of behavior and micro-texture evolution;

[0028] The second step is to design different pass rolling schemes, pass specification design schemes and corresponding Q total and ε e As shown in Table 1, rolling scheme 1 uses 6 passes, and its total equivalent strain ε e is 3.58, and the rolling Q of each pass total are basically greater than 1.3, the second rolling scheme adopts 4 passes, and ...

Embodiment 2

[0034] This embodiment is a numerical simulation comparison of pipe texture and CSR value under different mold design parameters based on numerical simulation. The specific implementation process includes the following steps:

[0035] In the first step, the numerical simulation adopts the macro-microscopic numerical prediction platform of the two-roll Pilger cold-rolled TA18 titanium alloy tube established in Example 1, and the simulated rolling specification is selected from Φ32×3mm→Φ17.48×1.07mm;

[0036] In the second step, different pass index and pass clearance index are selected for mold design, and the selection scheme of pass index and pass clearance index is shown in Table 2;

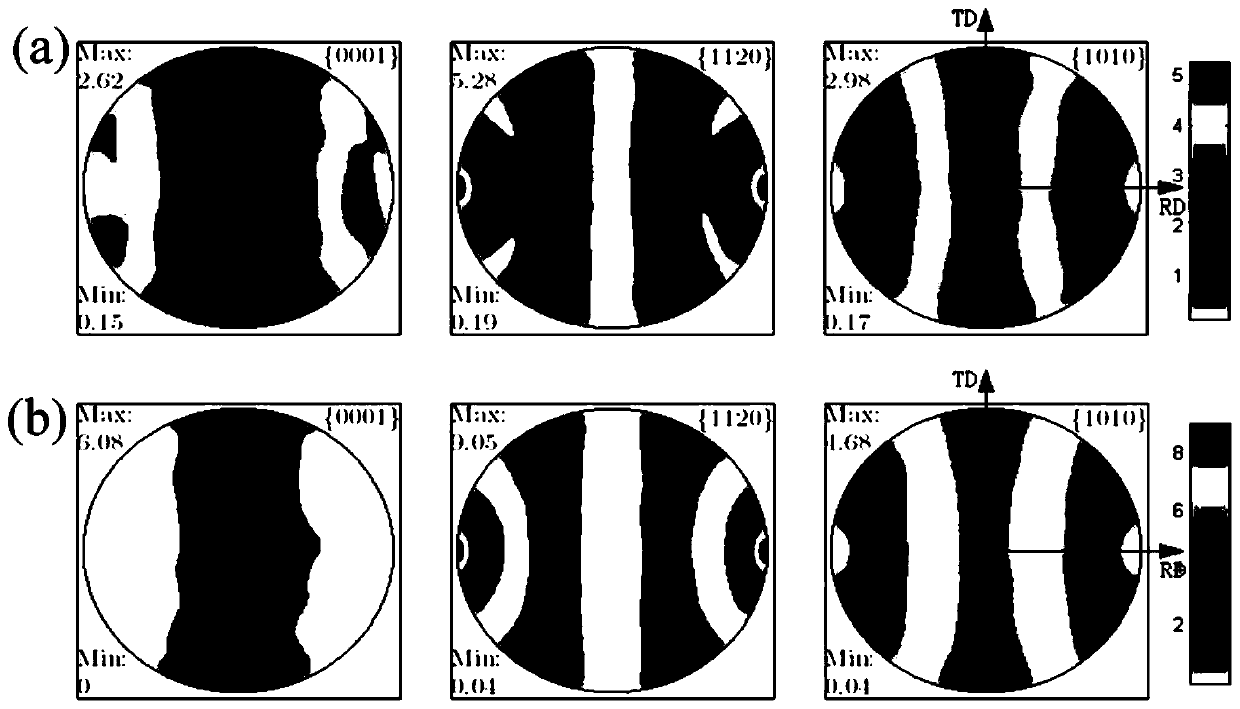

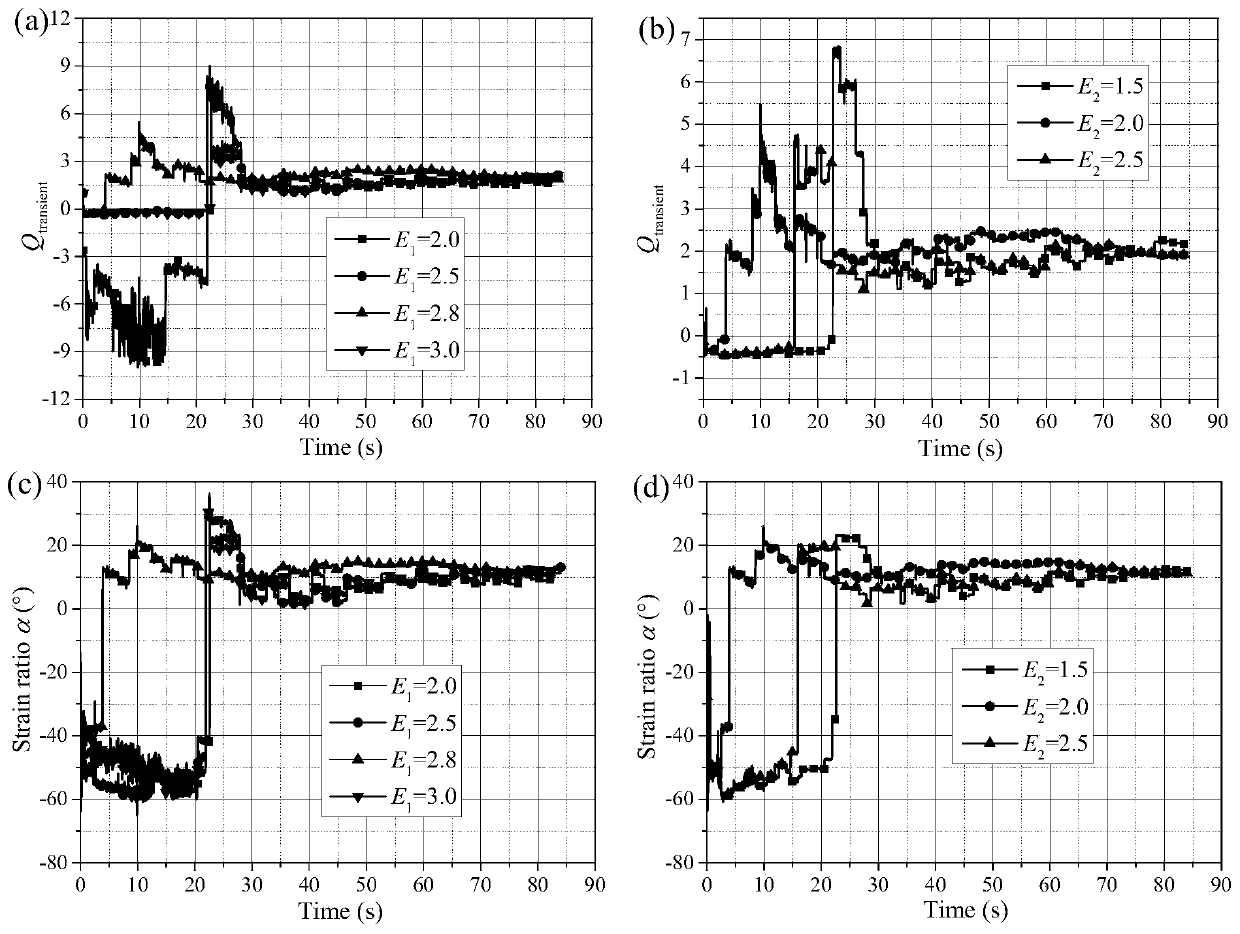

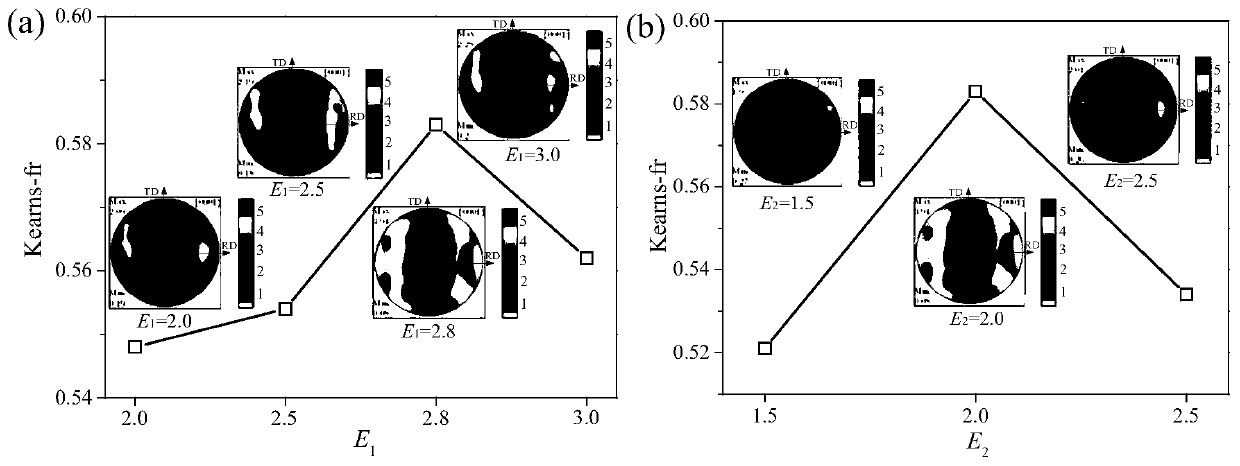

[0037] The third step is to obtain the mold design pair Q through numerical simulation transient and α influence law such as figure 2As shown, the pipe texture under different mold design parameters is as follows image 3 shown.

[0038] Table 2 Selection scheme of mold design parameters

...

Embodiment 3

[0042] In this embodiment, the high-strength TA18 titanium alloy pipe with a specification of Φ12×0.9mm is used as the target object, and the cold rolling test is carried out to measure the CSR value of the finished product. The specific implementation process includes the following steps:

[0043] In the first step, the rolling scheme 1 in Table 1 is used to carry out 6 passes of two-roller pilger cold rolling, and the die design for each pass is E 1 and pass clearance index E 2 Select 2.8 and 2.0 respectively, the pipe is subjected to vacuum recrystallization annealing at 750°C in the middle of each rolling pass, and the pipe is subjected to vacuum stress relief annealing at 550°C after the final rolling pass;

[0044] In the second step, the CSR value of the finished pipe is obtained by uniaxial tensile test combined with three-dimensional digital correlation (DIC) screen strain measurement system. The measurement results are as follows: Figure 4 As shown, the CSR value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com