Method and device for friction spot welding of titanium alloy/ultra-high molecular weight polyethylene overlap

An ultra-high molecular weight, titanium alloy technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of ineffective control of temperature and down pressure, inability to achieve effective connection of titanium alloys, poor melt flow ability, etc. , to facilitate the connection parameters, improve the quality and strength of the joint, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

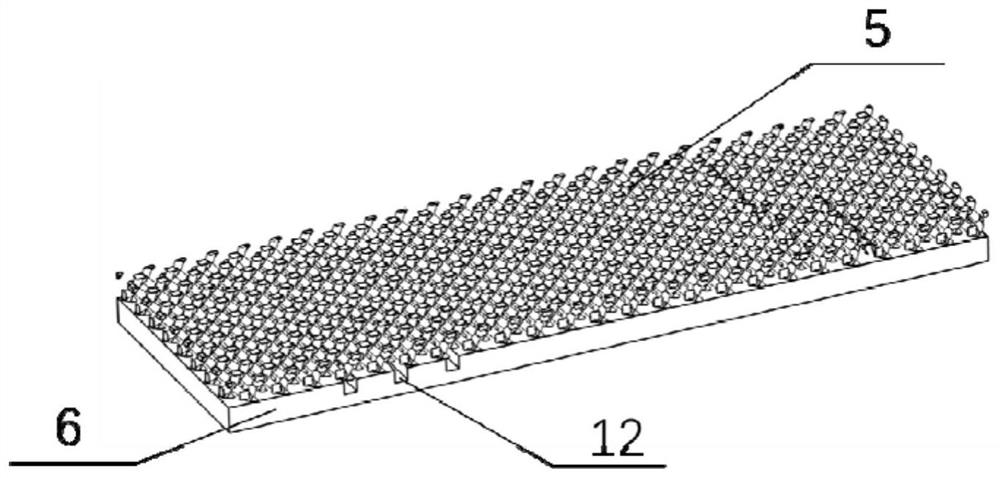

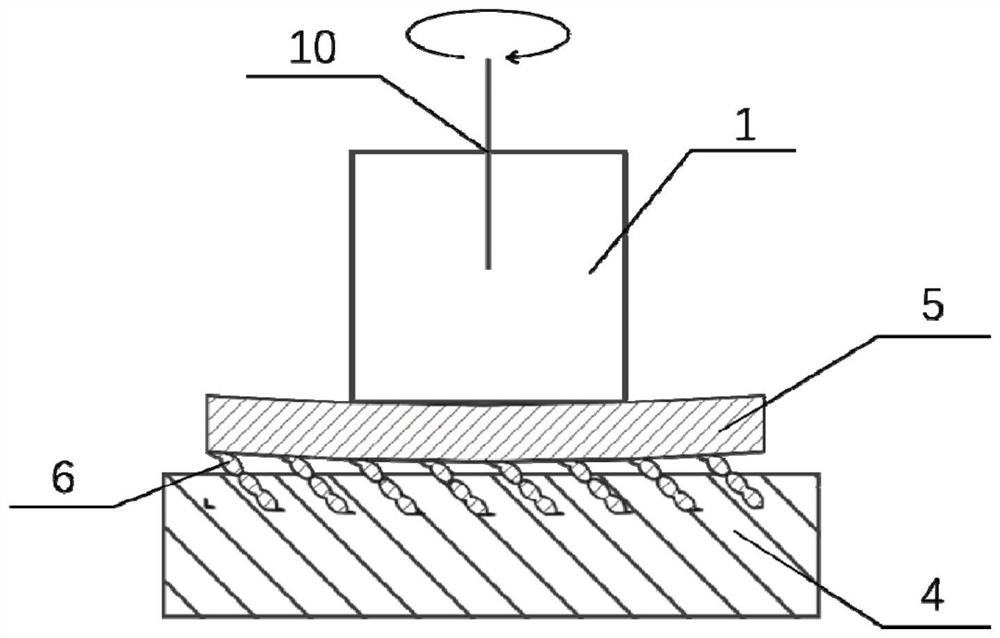

[0050] Such as figure 2 , using the method of the present invention, design and manufacture a double-layer titanium alloy structure with three-dimensional printing technology, the lower layer rough layer 6 is a solid block part, and its surface average roughness (Ra) is 100-500 μm, and the upper layer titanium alloy 5 is a diamond type Complex porous structure with a porous diameter of 0.6mm–1.2mm. Both layers have a thickness of 2 mm. The dimensions of metal and UHMWPE sheets are 4mm×20mm×60mm and 6mm×25mm×60mm (height×width×length), respectively. The melting point of the polymer plate is 136° C., and an opening 12 for inserting a thermocouple is provided on the side of the metal.

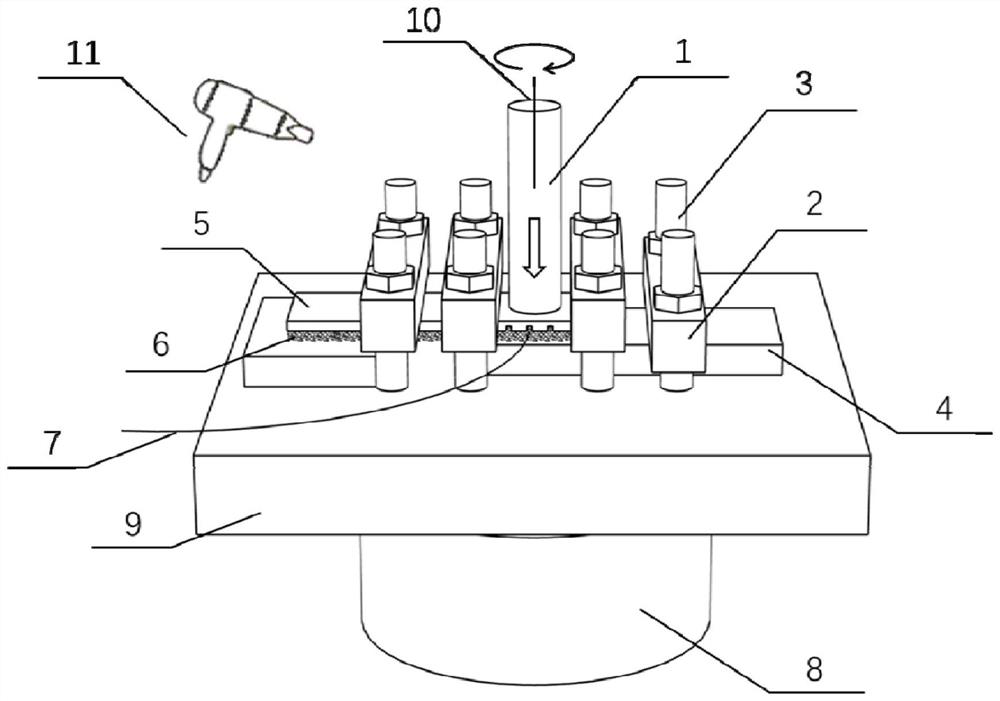

[0051] Such as figure 1 , put pressure sensor 8 through The thick thread of the thick thread is fixed on the lower end of the workbench 9, the three-dimensionally printed titanium alloy porous structure rough layer 6 is placed downwards, and placed in an overlapping connection with the ultra...

Embodiment 2

[0058] According to the method in Embodiment 1, the titanium alloy and ultra-high molecular weight polyethylene sheet with the same parameters were clamped on the workbench, and preheated with a heat gun. Start the rotary tool 1 and rotate it at a speed of 555rpm to press down on the surface of the titanium alloy 5, firstly press down at a pressing speed of 0.04mm / s for 20s, and when it reaches the pressing amount of 0.8mm, adjust the pressing speed to 0.013mm / s Continue to press down for 30 seconds, and stop rotating and pressing down to 1.2mm. Wait for 3 minutes until the interface temperature drops to 50°C and lift the rotary tool 1, and the connection process ends.

[0059] In this example, the temperature at the center of the interface reached 340°C. At the same time, the peak pressure reached 1700N, and the pressure increase at the peak pressure at the connection end was significantly reduced, which proved that the softening degree of the polymer was obvious. The streng...

Embodiment 3

[0062] According to the method in Embodiment 1, the titanium alloy and ultra-high molecular weight polyethylene sheet with the same parameters were clamped on the workbench, and preheated with a heat gun. Start the rotary tool 1 and rotate it at a speed of 555rpm to press down on the surface of the titanium alloy 5, firstly press down at a pressing speed of 0.04mm / s for 20s, and when it reaches the pressing amount of 0.8mm, adjust the pressing speed to 0.02mm / s Continue to press down for 30 seconds until the 1.4mm press down, stop turning and press down. Wait for 3 minutes until the interface temperature drops to 50°C and lift the rotary tool 1, and the connection process ends.

[0063] The temperature at the center of the interface measured in this embodiment reaches 400° C., which has reached the temperature of severe thermal degradation of polymers. At the same time, the peak downforce reached 1600N, and the pressure growth rate decreased to a negative value at the end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com