Manipulator to control clamping deformation

A manipulator and gripper arm technology, applied in the field of manipulators that control gripping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

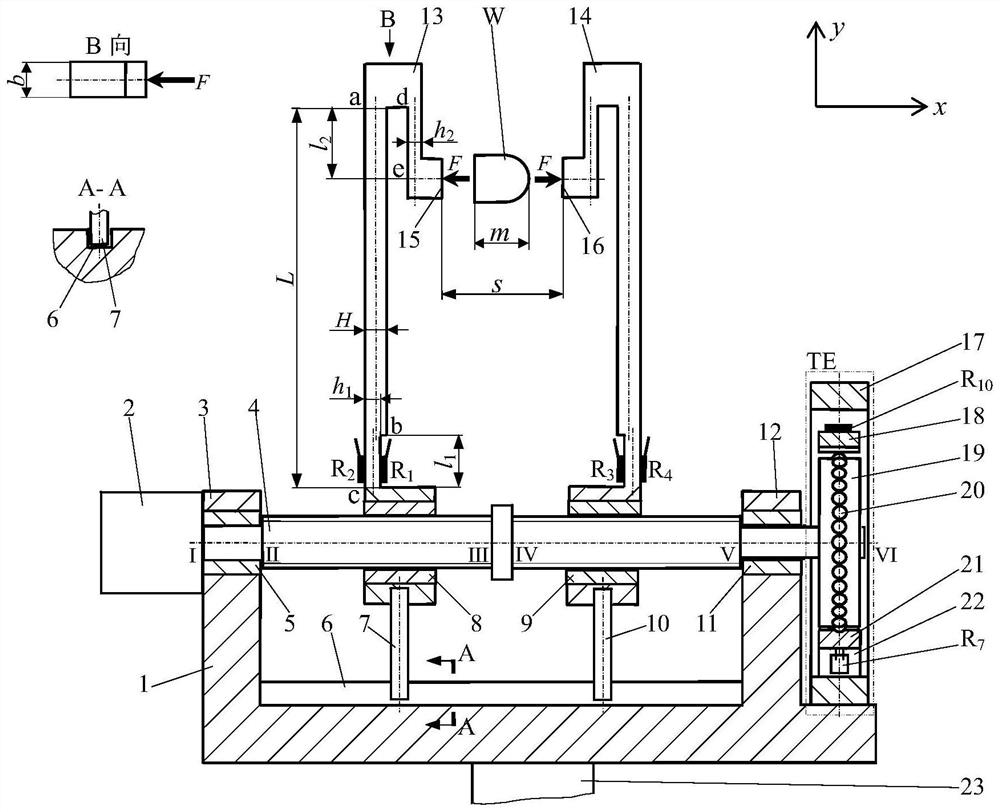

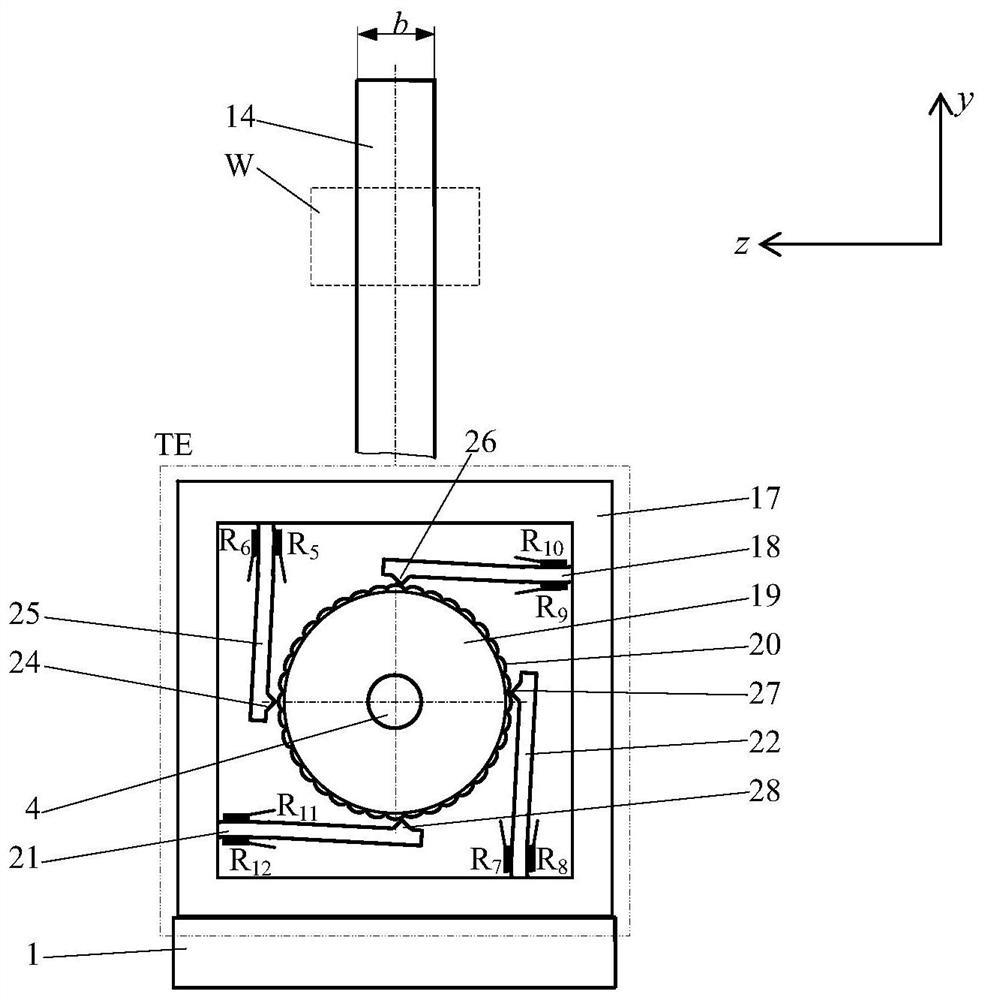

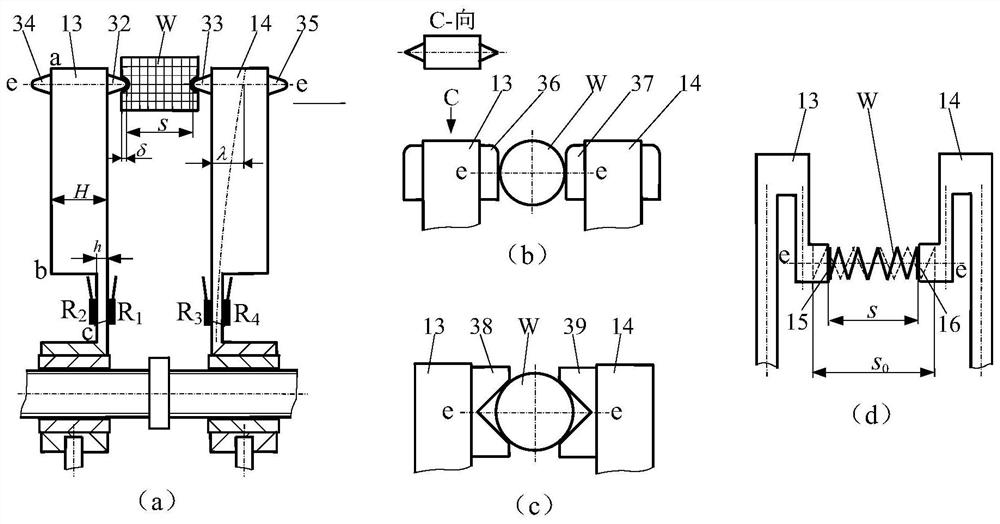

[0082] Below in conjunction with accompanying drawing this design is described further.

[0083] refer to Figure 1-Figure 6 , this design is a manipulator to control clamping deformation. The manipulator is composed of a frame 1, an encoding screw, a driver 2, a gripper and a numerical control.

[0084] The structure of the frame 1 includes a rectangular base plate, a shaft coupling 23 located below the base plate for connecting the robot arm, a left bearing support plate 3 located on the left side above the base plate, a right bearing support plate 12 located on the right side above the base plate, and a The U-shaped guide limit groove 6 on the upper surface. The left bearing support plate 3 is embedded with the left bearing 5, and the right bearing support plate 12 is embedded with the right bearing 11. The two bearings are in a coaxial position, and the axis is parallel to the axis of the U-shaped guide limit groove 6.

[0085] The coding screw consists of a micrometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com