Tablet line flower fabric technology for vitrified tiles

A vitrified brick and tableting technology, applied in the direction of forming conveyors, etc., can solve the problems of not well reflecting the natural smooth effect of natural stone, mechanical and rigid, and achieve a wide range of designs, realistic effects, and uniform line layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

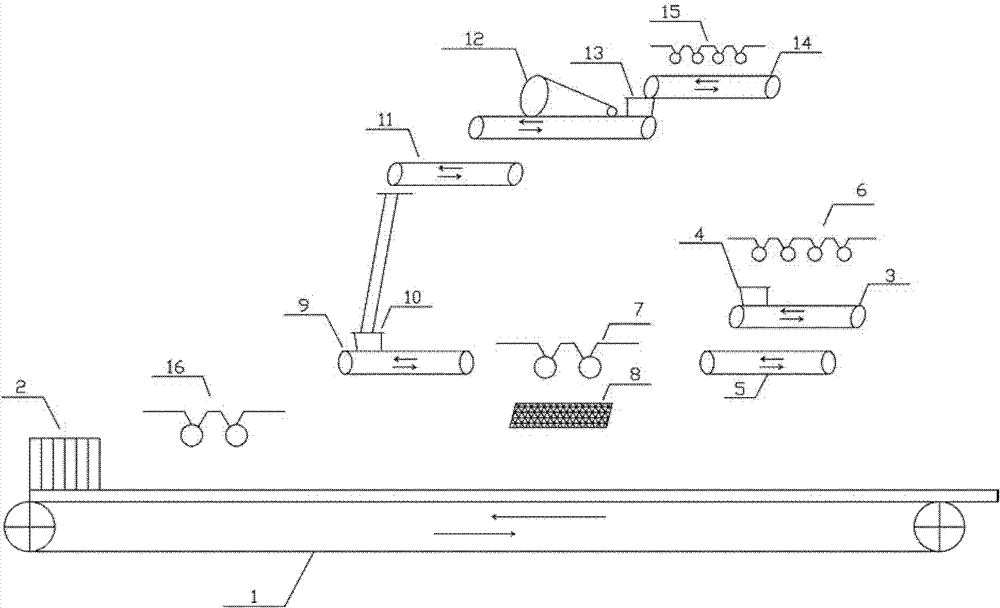

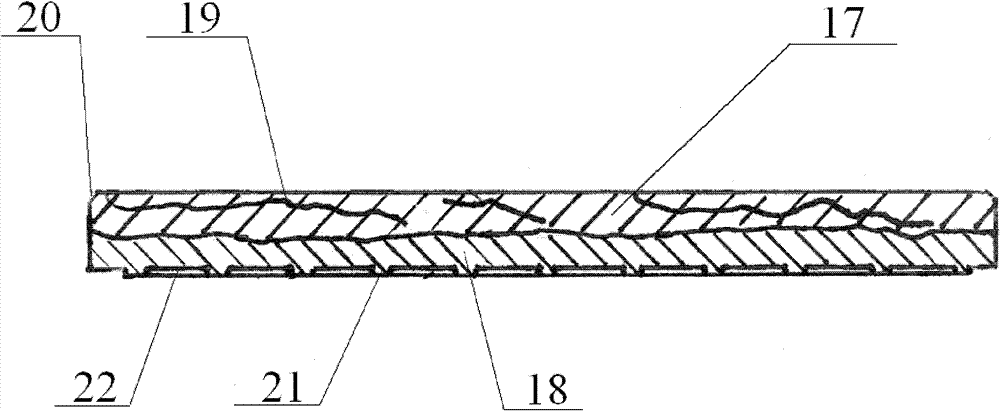

[0021] The invention discloses a vitrified tile sheet-pressing line pattern cloth process, which includes four steps of fabric conveying, thread material conveying, tablet granulation, and sub-regional combination accumulation of cloth.

[0022] Fabric conveying is to place the micro-powder fabric in the fabric hopper, and the fabric roller below the fabric hopper rotates and drops the material into the fabric storage hopper. The outlet below the storage hopper is the conveyor belt. The front and bottom of the conveyor belt are suspended, and the suspended side is close to the front line bucket. At the rear end, the micropowder fabric falls from the suspended side of the conveyor belt and accumulates on the flat plate;

[0023] Line material conveying is to turn the line material from the line unloading drum to the baffle plate and the vibrating screen, and the vibrating screen will spread the line thinly and evenly to the bottom and cover the fabric;

[0024] Tablet granulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com