Method of manufacturing metal embossed plate

a technology of metal embossed plate and manufacturing method, which is applied in the direction of vehicle components, transportation and packaging, etc., can solve the problems of increasing the number of devices installed, and increasing the weight of road vehicles, so as to reduce the strain on the raw metal plate, improve the rigidity and increase the total thickness of the metal embossed plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Embodiments of the present invention will now be described with reference to the drawings.

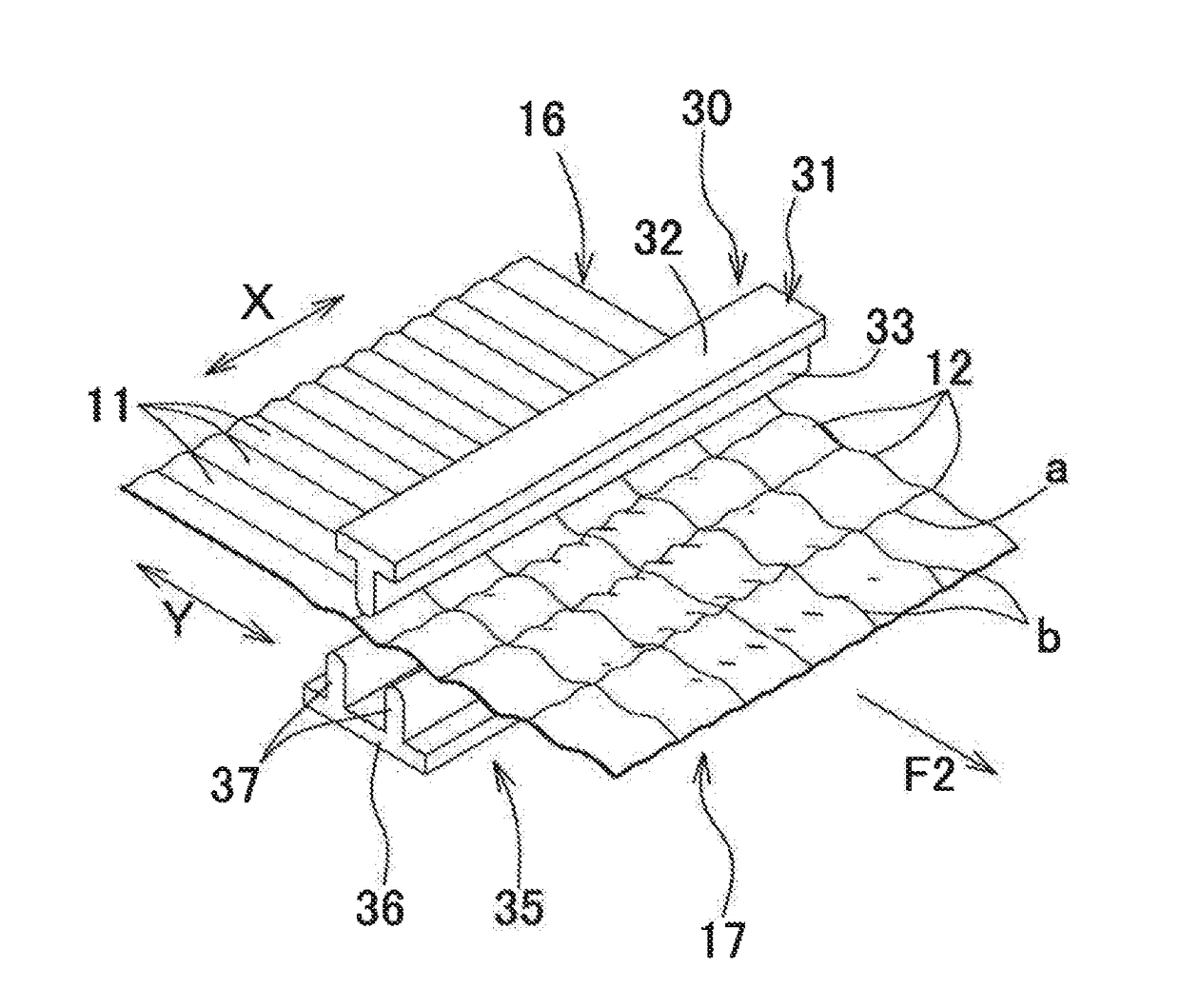

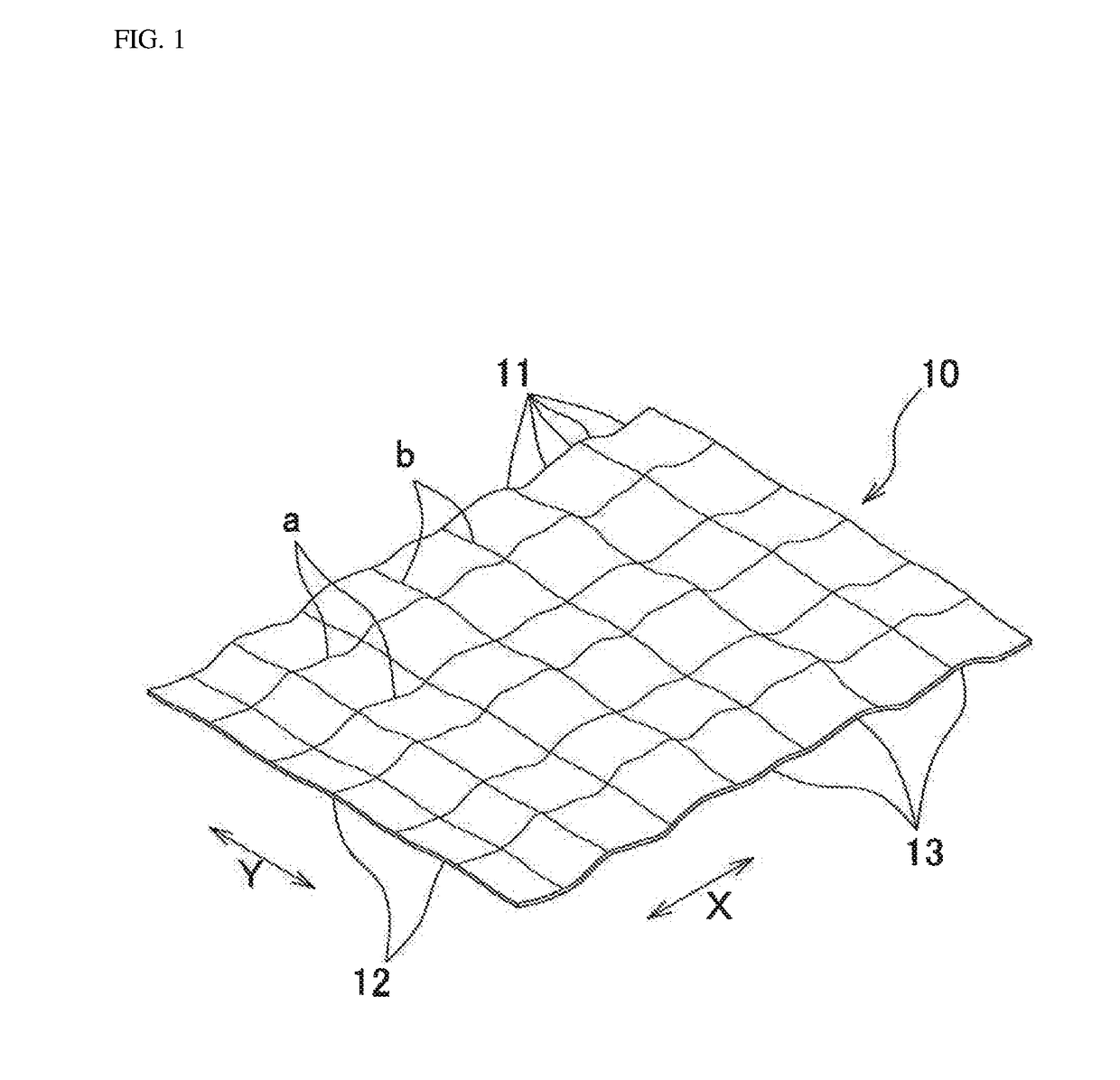

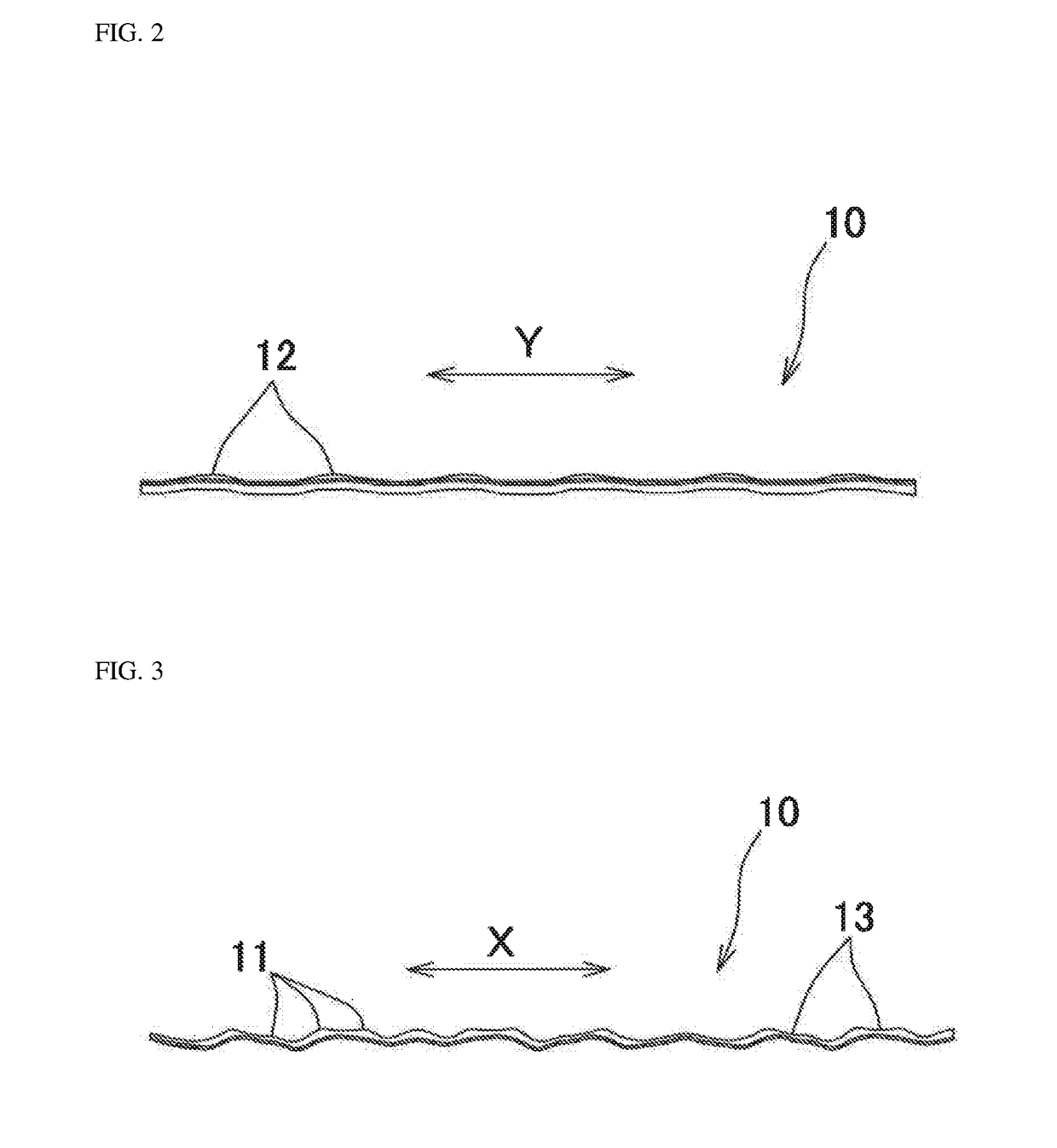

[0036]As illustrated in FIGS. 1 to 3, a metal embossed plate 10 manufactured by a manufacturing method of the present invention has, on the entire plate, corrugations including combination of a plurality of first corrugated portions 11 formed in a first direction X, a plurality of second corrugated portions 12 formed in a second direction Y approximately orthogonal to the first direction X with a half-height and a pitch longer than those of the first corrugated portions 11, and a plurality of third corrugated portions 13 approximately in the first direction X. Curved lines a and b in the drawings are explanatory auxiliary lines drawn to show high portions and low portions of the corrugated portion.

[0037]The method of manufacturing the metal embossed plate 10 includes a first corrugating step illustrated in FIGS. 4 and 5 in which a flat raw metal plate 15 is die-pressed to sequentially for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| half-height A1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com