Distribution method for vitrified tiles high in simulated Xiuyan jade effect

A technology of vitrified bricks and fabrics, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of products that are not suitable for high-simulation Xiuyu effects, and achieve obvious imitation jade effects, wide product design range, and natural and smooth texture lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

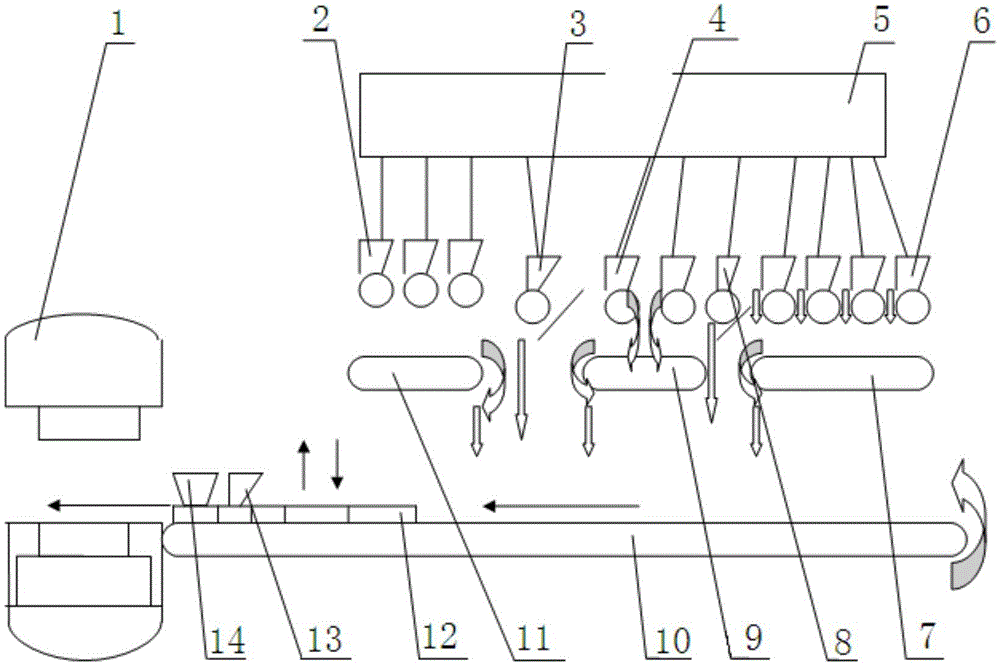

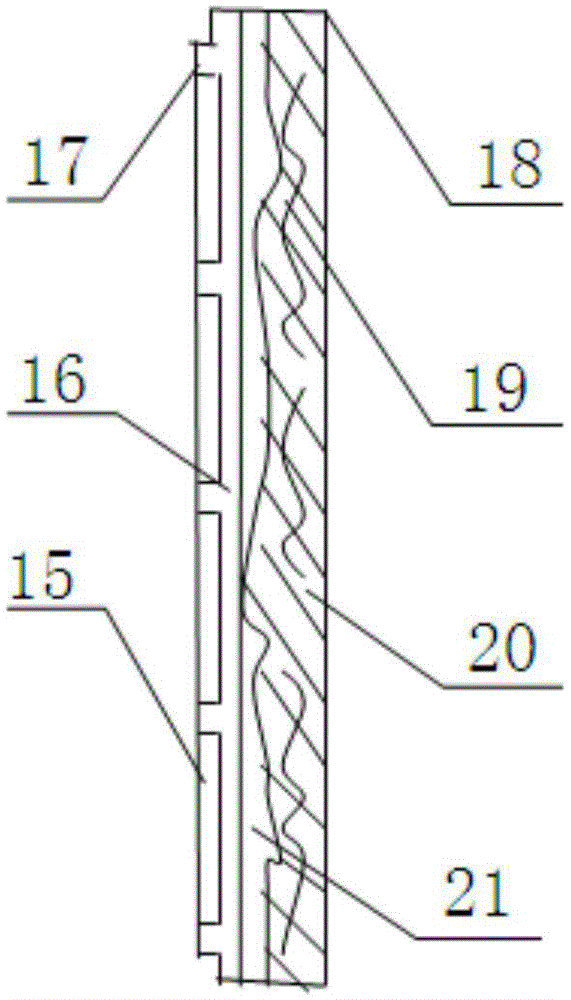

[0031] A method for distributing vitrified bricks with a high simulation effect of Xiuyu, including the process of making micro-powder from powder, the process of combining micro-powder cutting, the process of blanking and conveying, the process of integrally conveying the stacked materials, and the process of feeding the powder into the press;

[0032] Powder making micropowder process: use the powder machine to prepare the required surface powder, these surface powders include group crystal micropowder, line micropowder, profiling micropowder and ribbon combination micropowder, and supply the micropowder combination blanking process; micropowder combination blanking Process: accept various surface powders separately, and transfer various surface powders to the blanking conveying process; blanking conveying process: convey various surface powders from the micro-powder combination blanking process to the stacking overall conveying process Integral stacking conveying process: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com