Motorized airgun

a motorized air gun and air gun body technology, applied in the field of motorized air guns, can solve the problems of difficult shooting accuracy, difficult assembly, bulky airguns, etc., and achieve the effect of wide design range and simplified construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

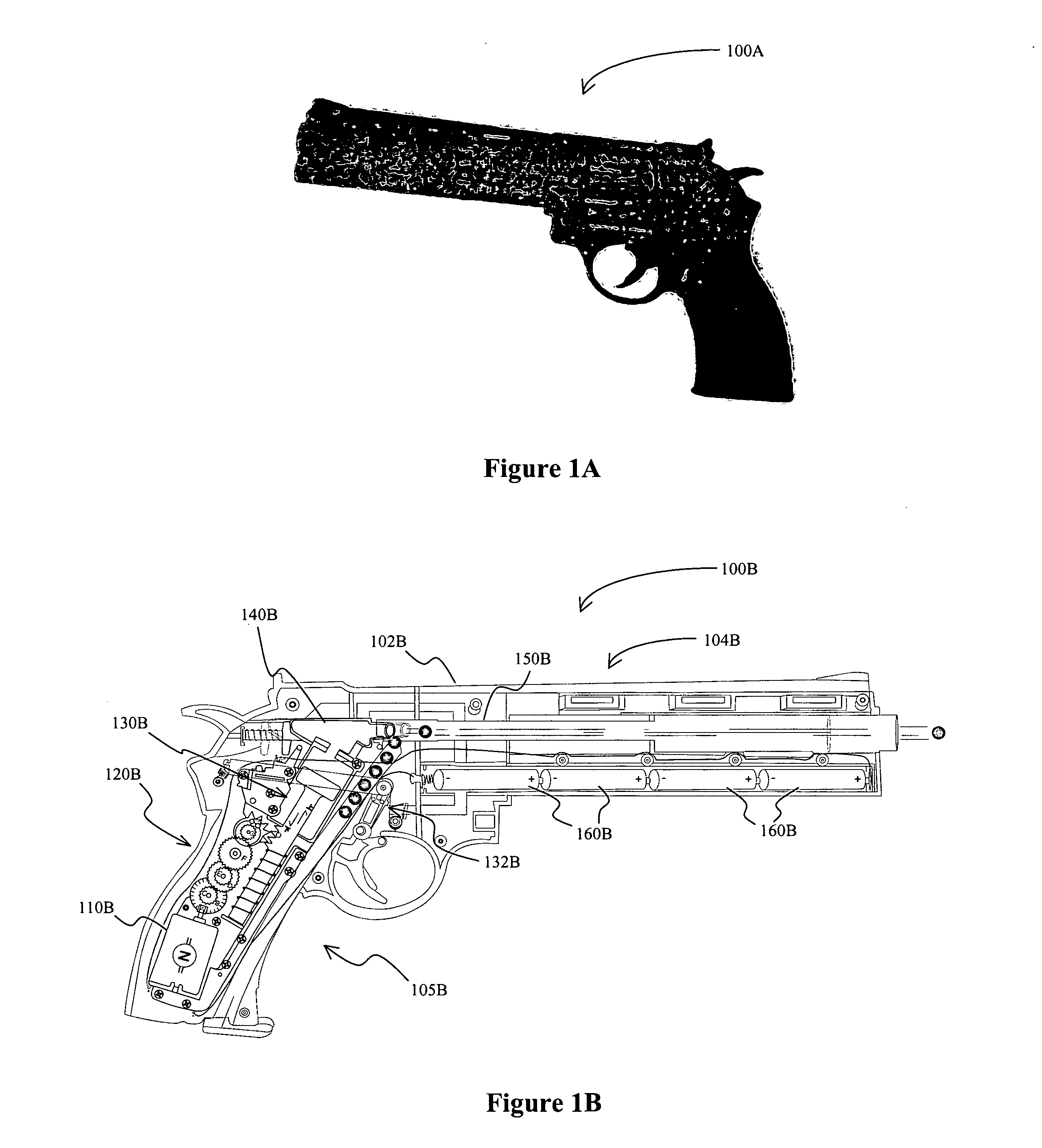

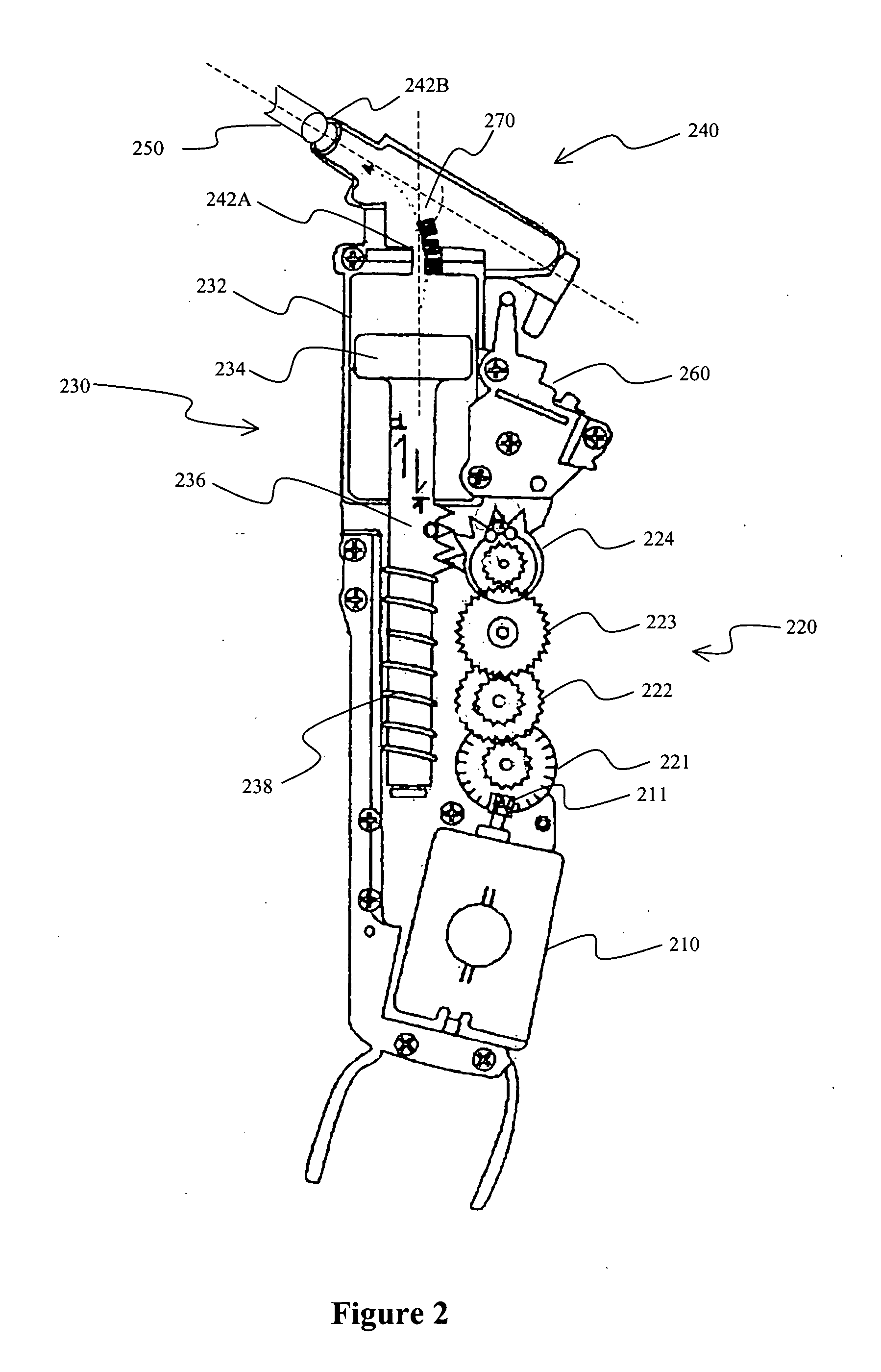

[0014]The inventor has discovered that a motorized airgun can be manufactured in a simple and effective manner that substantially improve performance and assembly while reducing cost. Most advantageously, the airguns contemplated herein comprise a barrel and a pneumatic cylinder that are in a non-coaxial and angled position relative to each other, wherein fluid coupling is achieved by an intermediate conduit. Such configuration not only allow spatial separation of the barrel from the pneumatic cylinder, but also eliminate recoil effects otherwise observed with airguns in which the springs and plunger are coaxially oriented relative to the barrel and trajectory of the projectile.

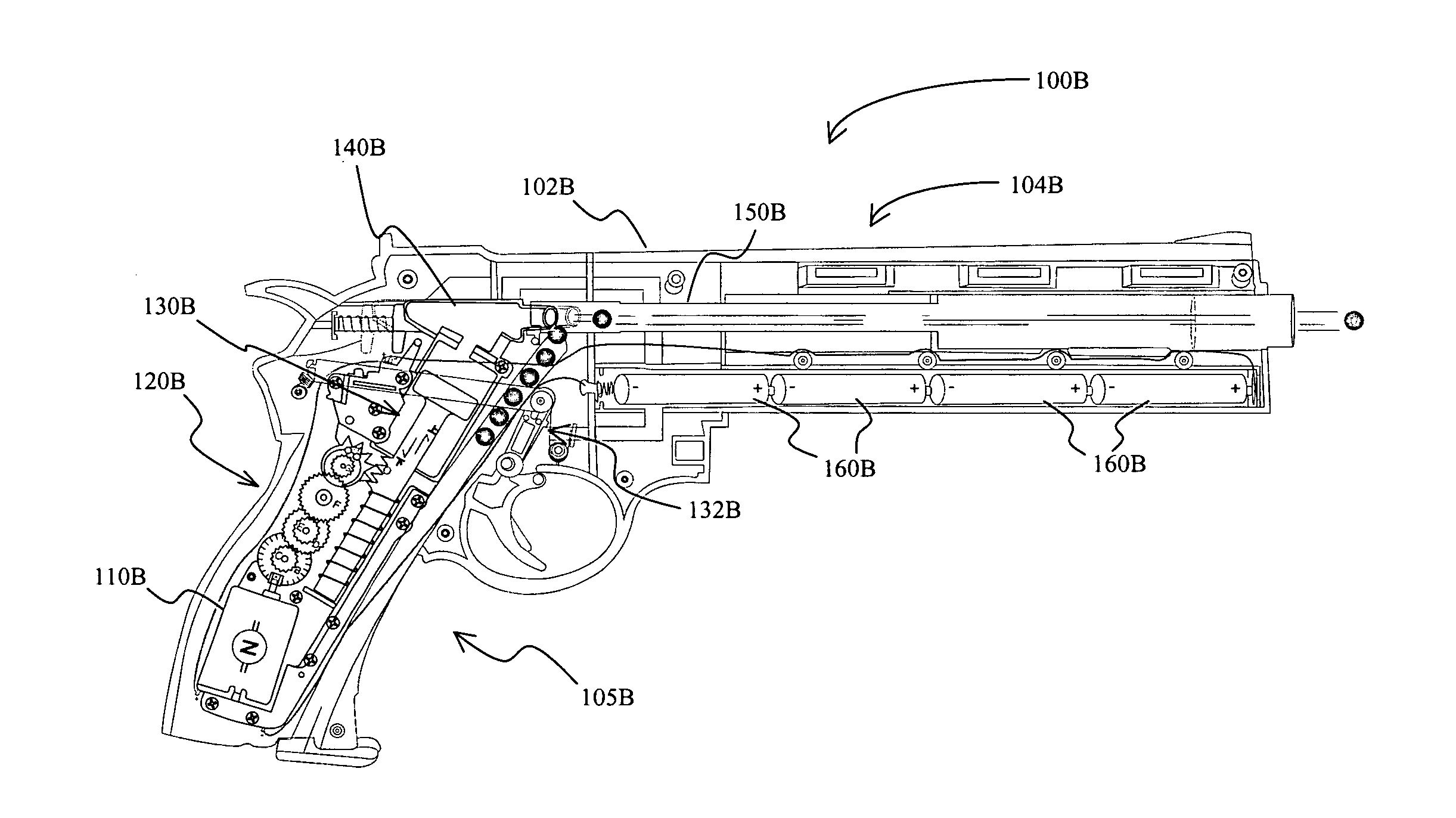

[0015]One exemplary motorized airgun is depicted in FIG. 1A in which the airgun 100A is configured as a revolver. FIG. 1B schematically illustrates the airgun of FIG. 1A in a opened configuration. Here, airgun 100B has a plastic housing 102B with a barrel portion 104B and a handle portion 105B. Within the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com