Quantum well infrared focal plane photosensitive element chip with grating in bottom coupling mode and preparation method thereof

A technology of well infrared focus and coupling grating, which is applied in the field of bottom coupled grating quantum well infrared focus plane photosensitive element chip and its preparation, achieving the effect of novel and unique structure, avoiding manufacturing process and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

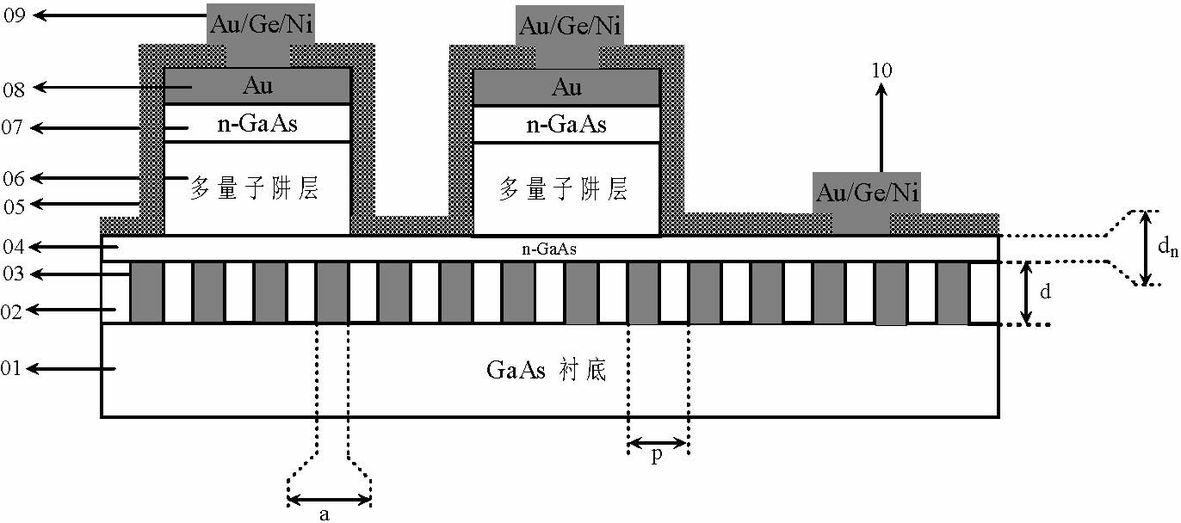

[0014] Depend on figure 1 Given, the photosensitive element chip of the present invention is composed of several parts from bottom to top:

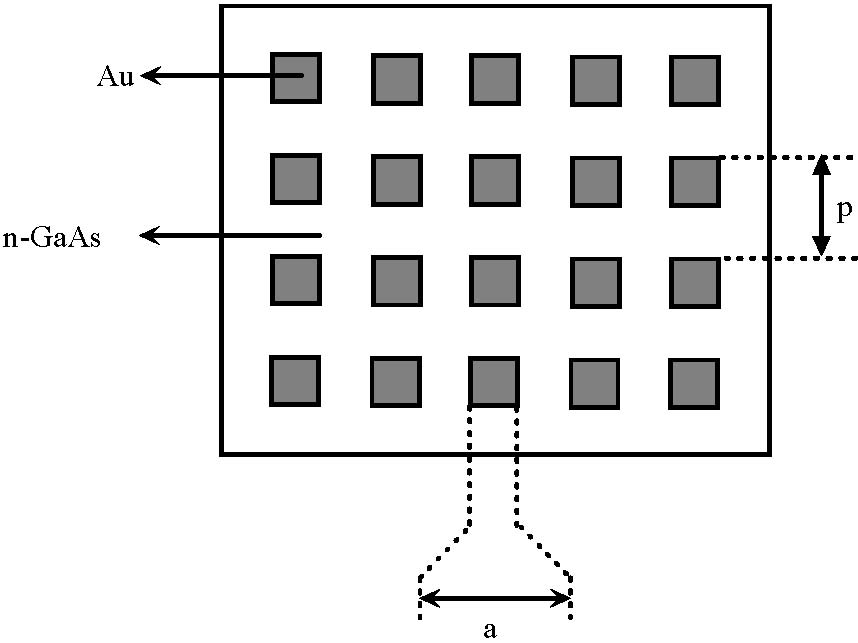

[0015] On the gallium arsenide substrate 01, there is a transmission grating composed of n-type gallium arsenide 02 and gold 03 alternately and periodically arranged. There is a GaAs / AlGaAs multi-quantum well layer 06, an n-type gallium arsenide upper contact layer 07 on the GaAs / AlGaAs multi-quantum well layer, a gold (Au) reflective layer 08 on the n-type gallium arsenide upper contact layer, gold ( On the Au) reflective layer, there is a gold / germanium / nickel (Au / Ge / Ni) alloy upper electrode 09, and one end of the n-type gallium arsenide lower contact layer 04 has a gold / germanium / nickel alloy common lower electrode 10, n-type arsenic Gallium oxide lower contact layer, GaAs / AlGaAs mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com