SC-type optical fiber connector

A technology for optical fiber connectors and connecting parts, which is applied in the coupling of optical waveguides and other directions, can solve the problems of affecting the optical coupling efficiency, uneven radial force, affecting the service life, etc., to improve the optical coupling efficiency and radial force. Uniform, extended service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

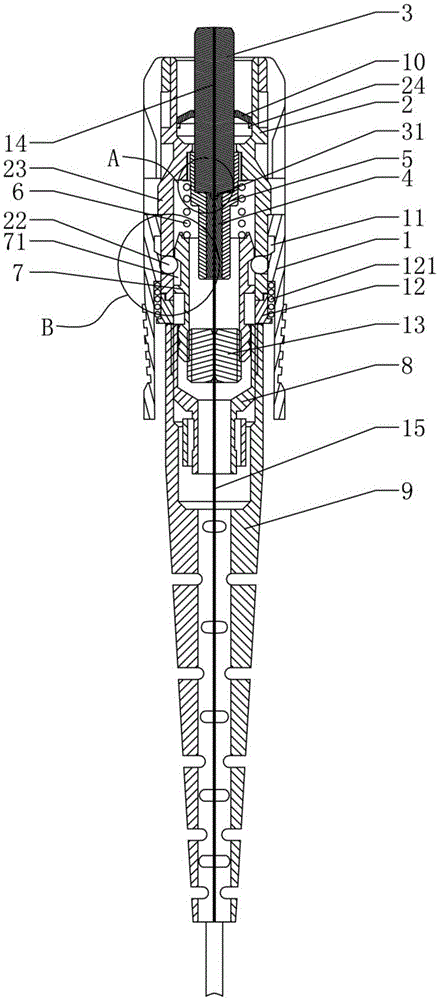

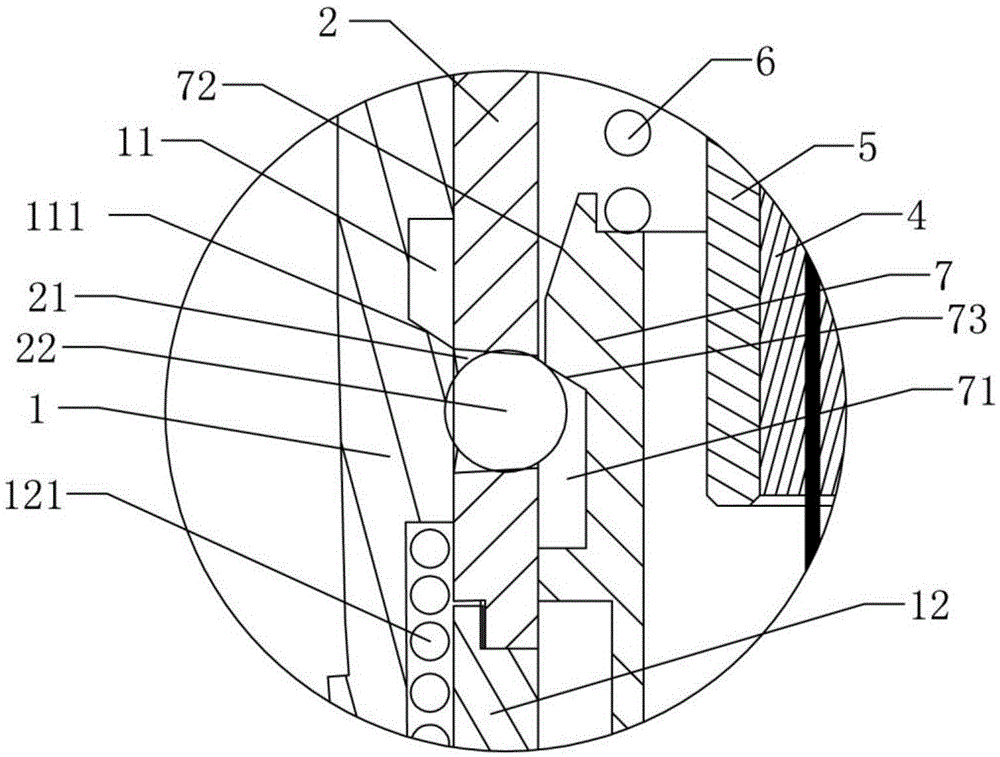

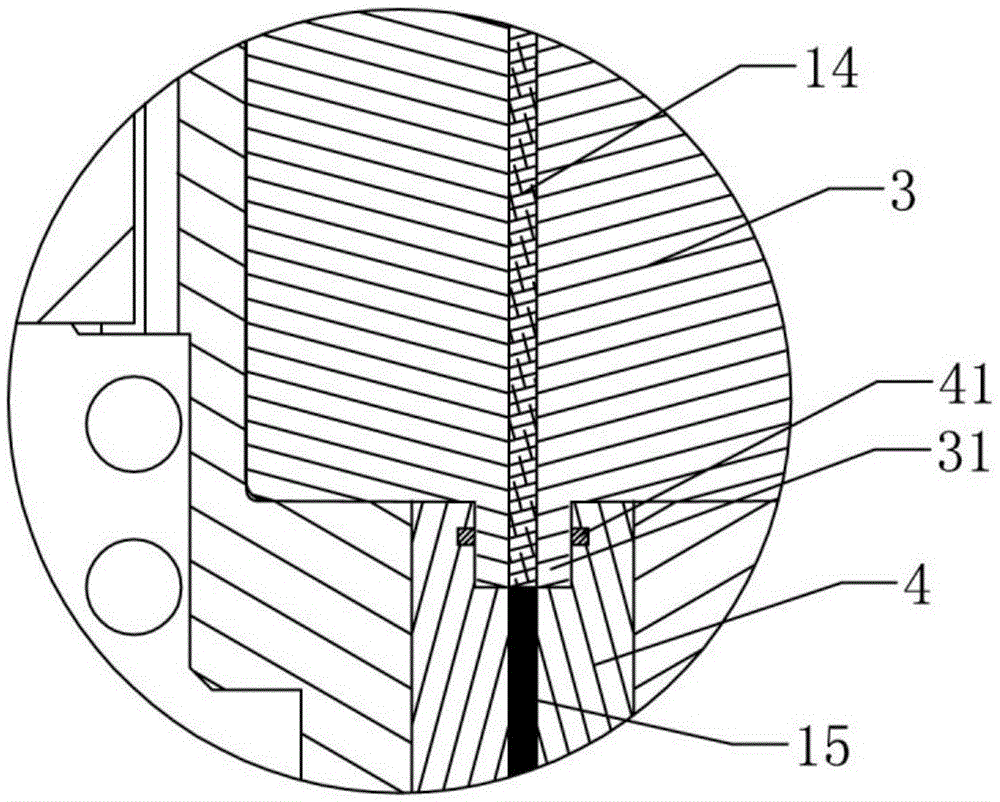

[0023] Such as Figure 1 to Figure 3 An SC-type optical fiber connector shown includes a package housing 1, a socket seat 2, a first ferrule 3, a second ferrule 4, a tail handle 5, a balance spring 6, a support seat 7, a ring nut 8 and The rubber sleeve 9, the socket seat 2 is sleeved in the packaging shell 1, the first ferrule 3 and the second ferrule 4 are inserted into the tail handle 5, the first ferrule 3, the second ferrule 4 and the tail The handle 5 is fixed by an adhesive to form a ferrule assembly. The tail handle 5 is sleeved in the sleeve seat 2, and the front end of the tail handle 5 is offset against the sleeve seat 2, and the front end of the support seat 7 extends into the sleeve seat 2. A balance spring 6 is connected between the tail handle 5 and the support seat 7, the ring nut 8 is sleeved on the rear end of the support seat 7, and the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com