Optical distance measuring device and manufacturing method therefor

A distance measuring device and a manufacturing method technology, which are applied in the field of optical distance measuring devices, can solve problems such as the failure of the second optical path, enlargement of the distance measuring device, improper structure, etc., and achieve suppression of light leakage, high distance measurement accuracy, Improve the effect of optocoupler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

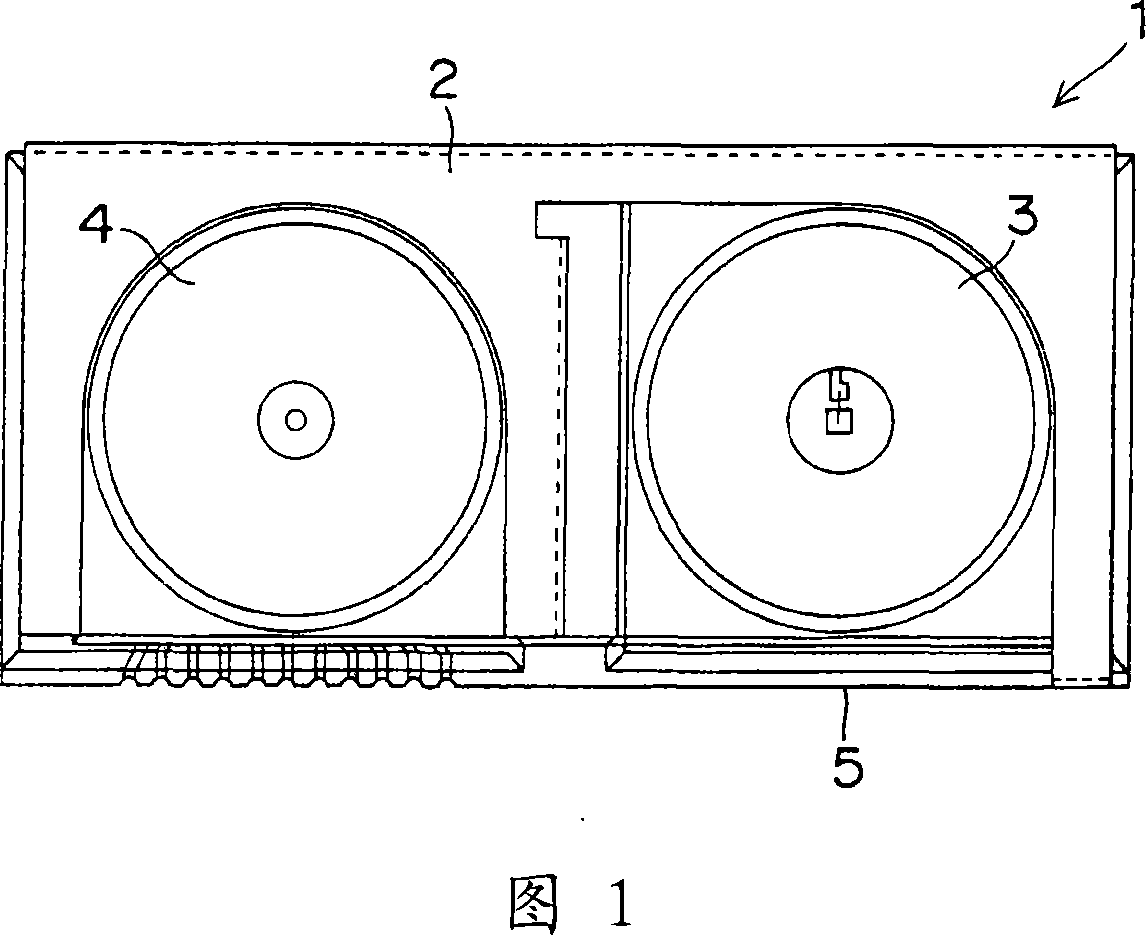

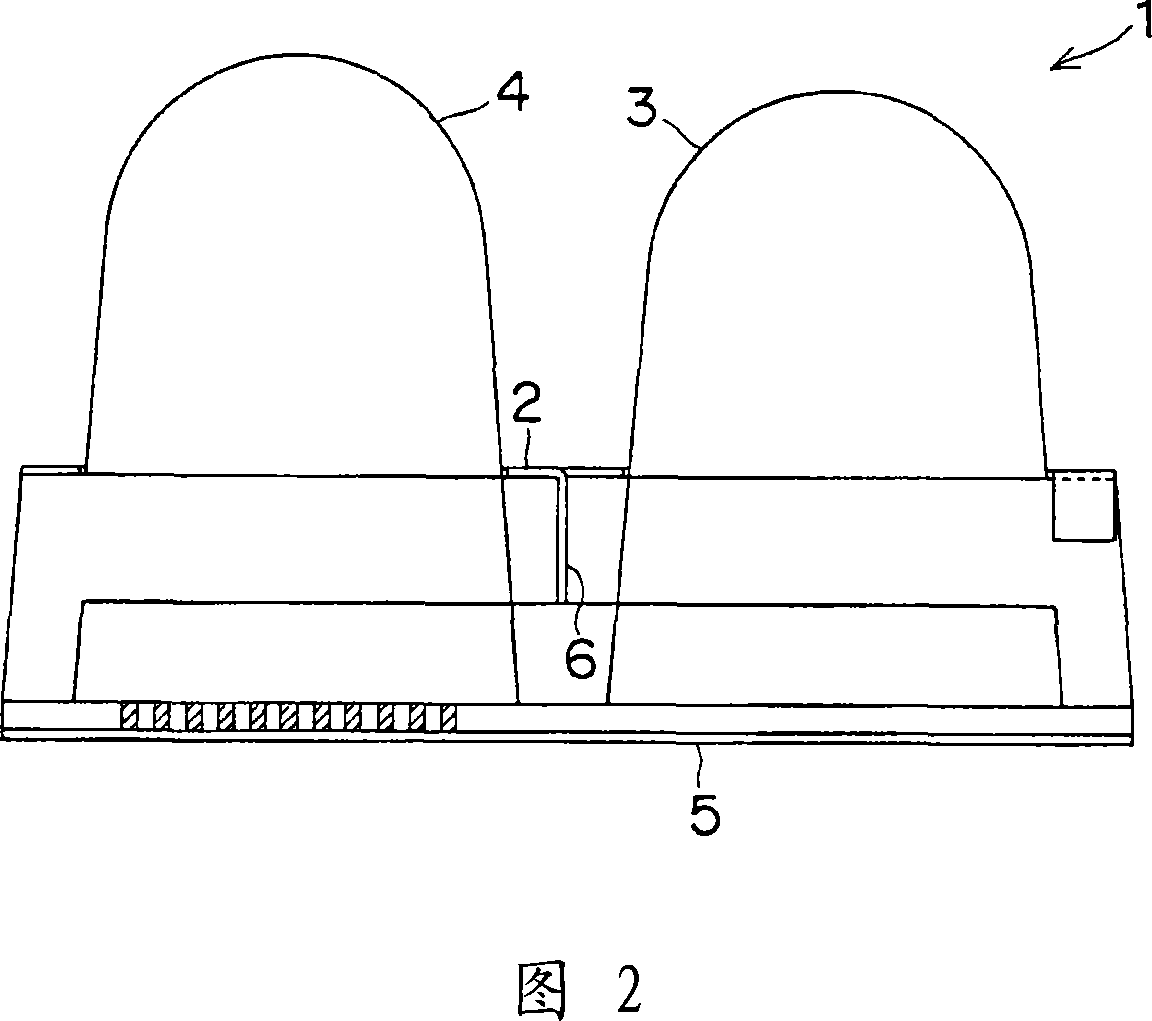

[0073] FIG. 1 is a plan view of an optical distance measuring device 1 according to the present embodiment. In addition, FIG. 2 is a side view of the optical distance measuring device 1 shown in FIG. 1 . In addition, this optical distance measuring device 1 uses a first optical path in which the light emitted from the light emitting element is reflected by the distance measuring object and detected by the light receiving element, and the light emitted from the light emitting element is not reflected by the distance measuring object. The second optical path detected by the above-mentioned light-receiving element is especially suitable for small-sized optical ranging of electronic equipment such as special-purpose automatic machinery or mechanical contacts with small mechanical contacts that need to detect obstacles, or non-contact control equipment. device.

[0074]The present optical distance measuring device 1 has a structure shielded by a shielding case 2 so that electrical...

no. 2 approach

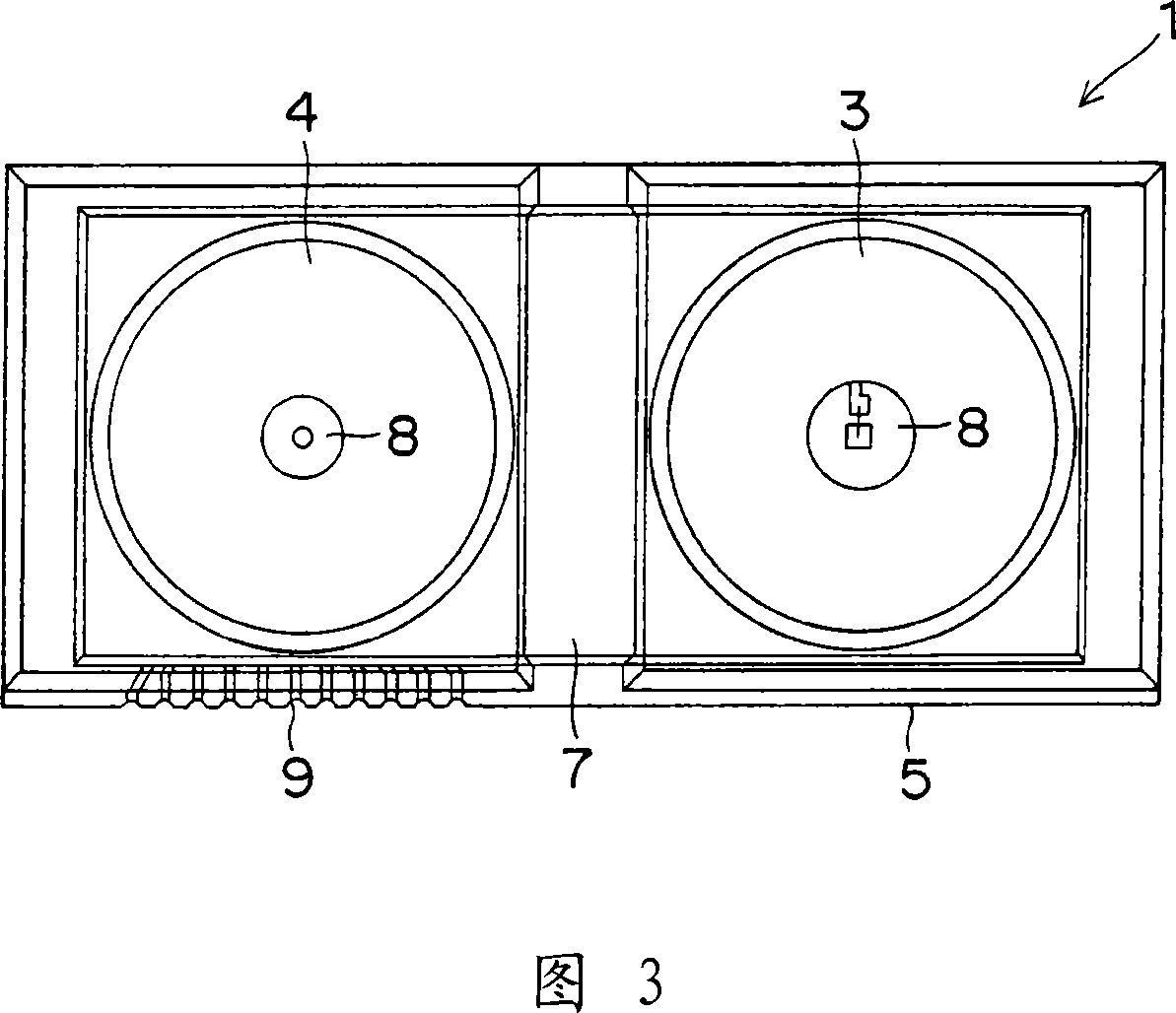

[0100] In the optical distance measuring device 1 of the above-mentioned first embodiment, as shown in FIG. The light from the light receiving element 11 generates light interference, and the value of the SN ratio is deteriorated by the light interference, thereby increasing the measurement error. In addition, since most of the light passing through the second optical path 18 enters the above-mentioned end surface of the light receiving element 11, the light coupling efficiency of the second optical path 18 decreases. Therefore, the present embodiment relates to an optical distance measuring device in which, in particular, the optical coupling efficiency of the second optical path is further improved, and distance measurement can be performed with high accuracy even when the temperature changes greatly.

[0101] Hereinafter, the optical distance measuring device according to this embodiment will be described in detail focusing on the differences from the first embodiment descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com