Patents

Literature

200results about How to "Suppress light leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

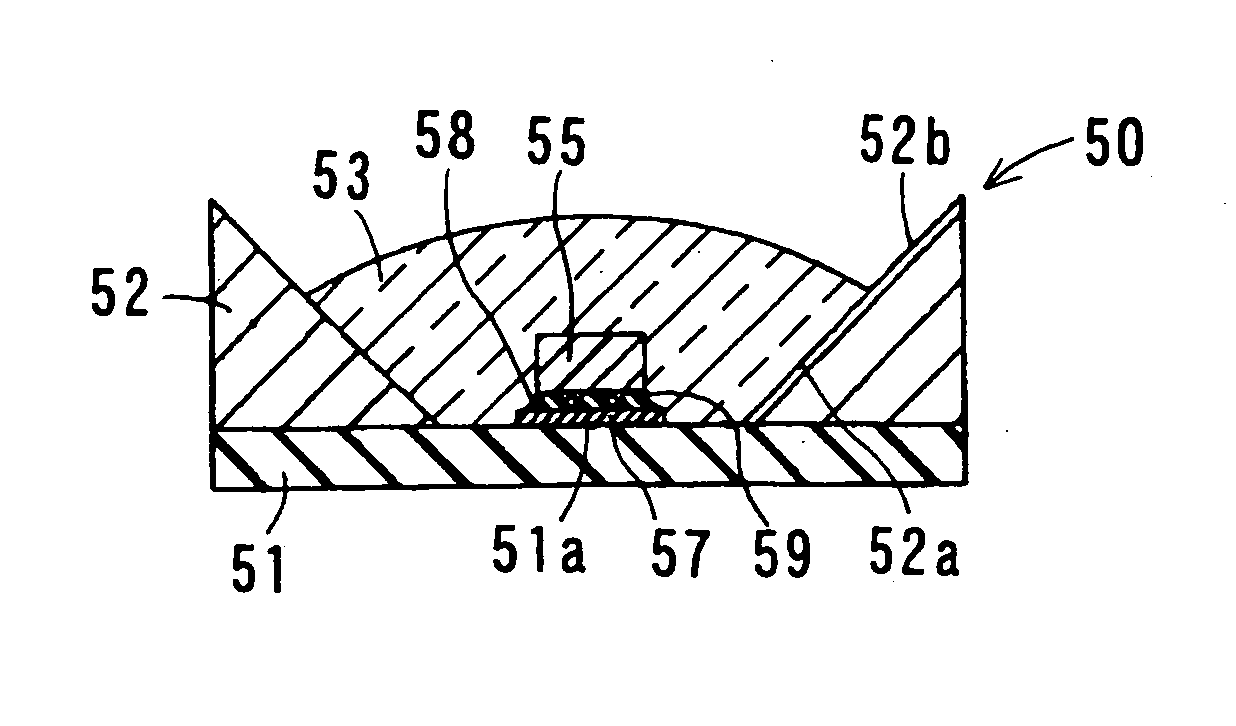

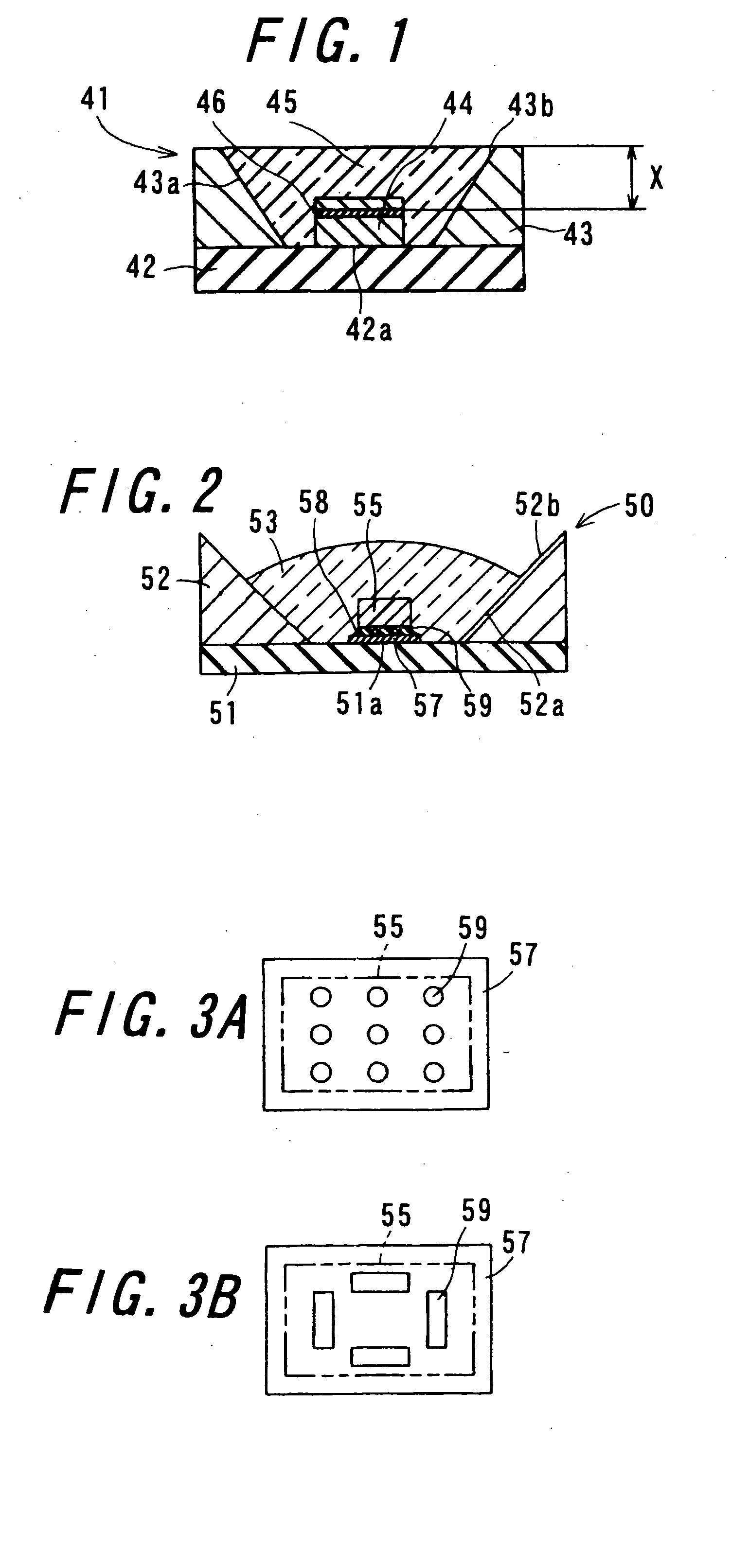

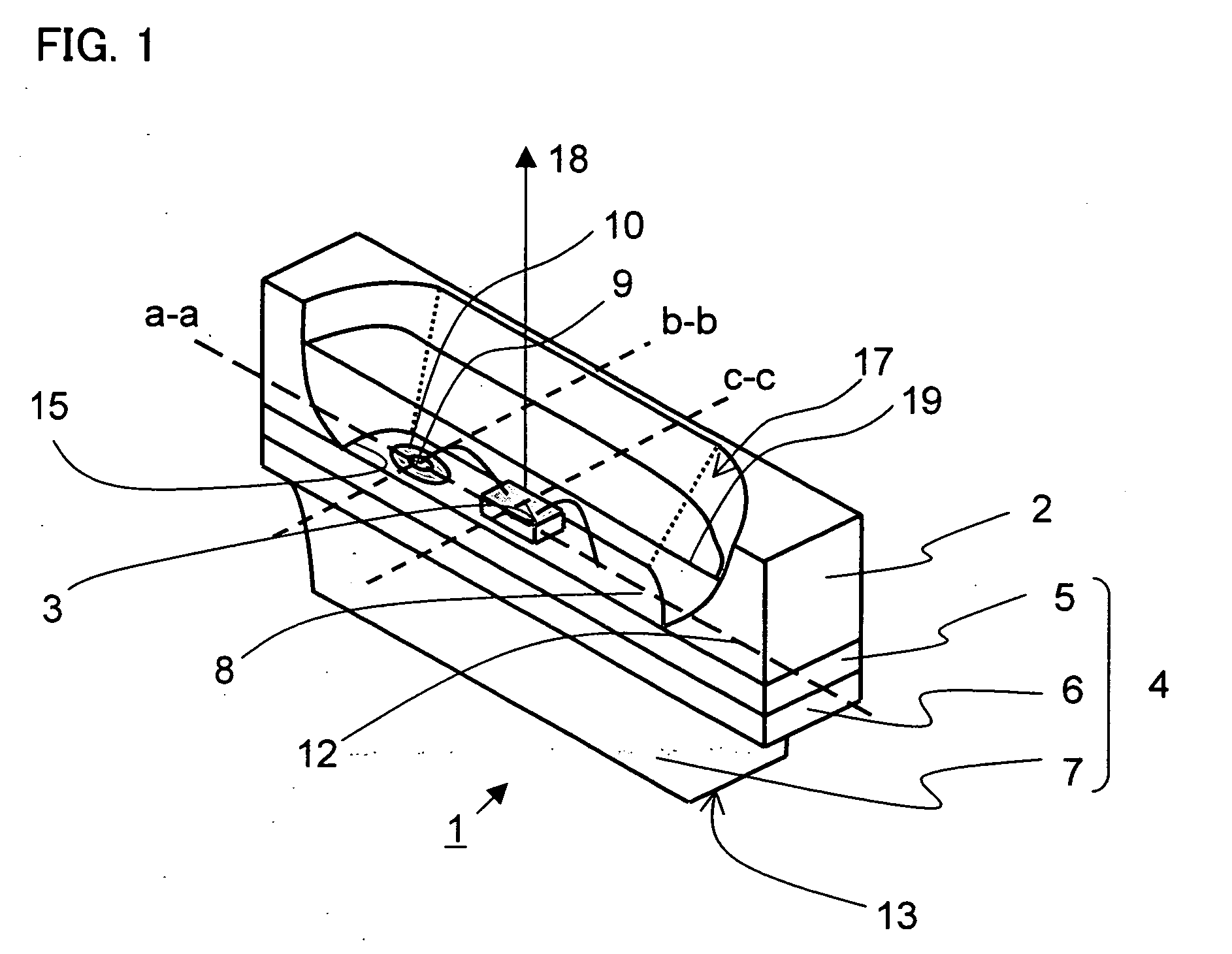

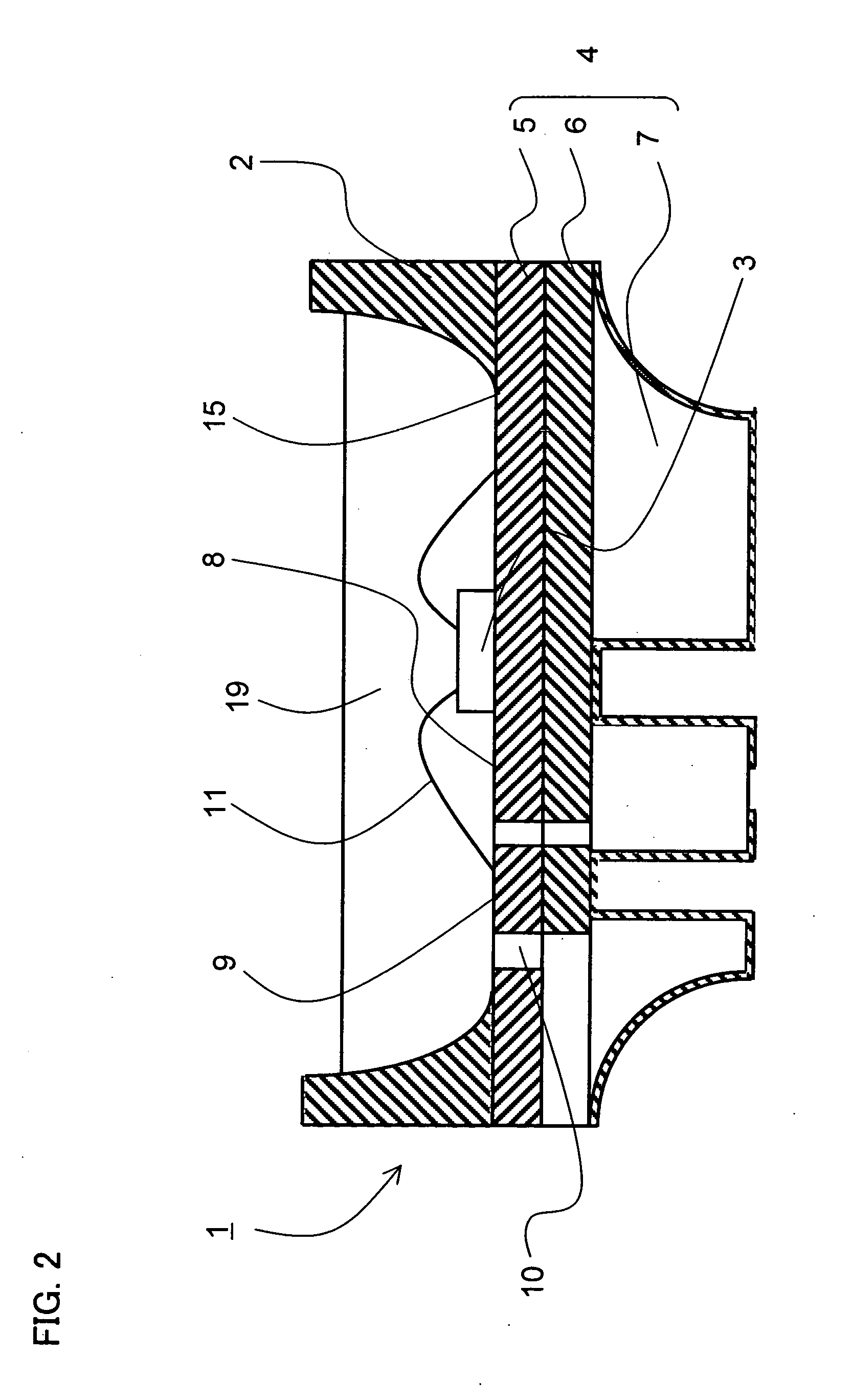

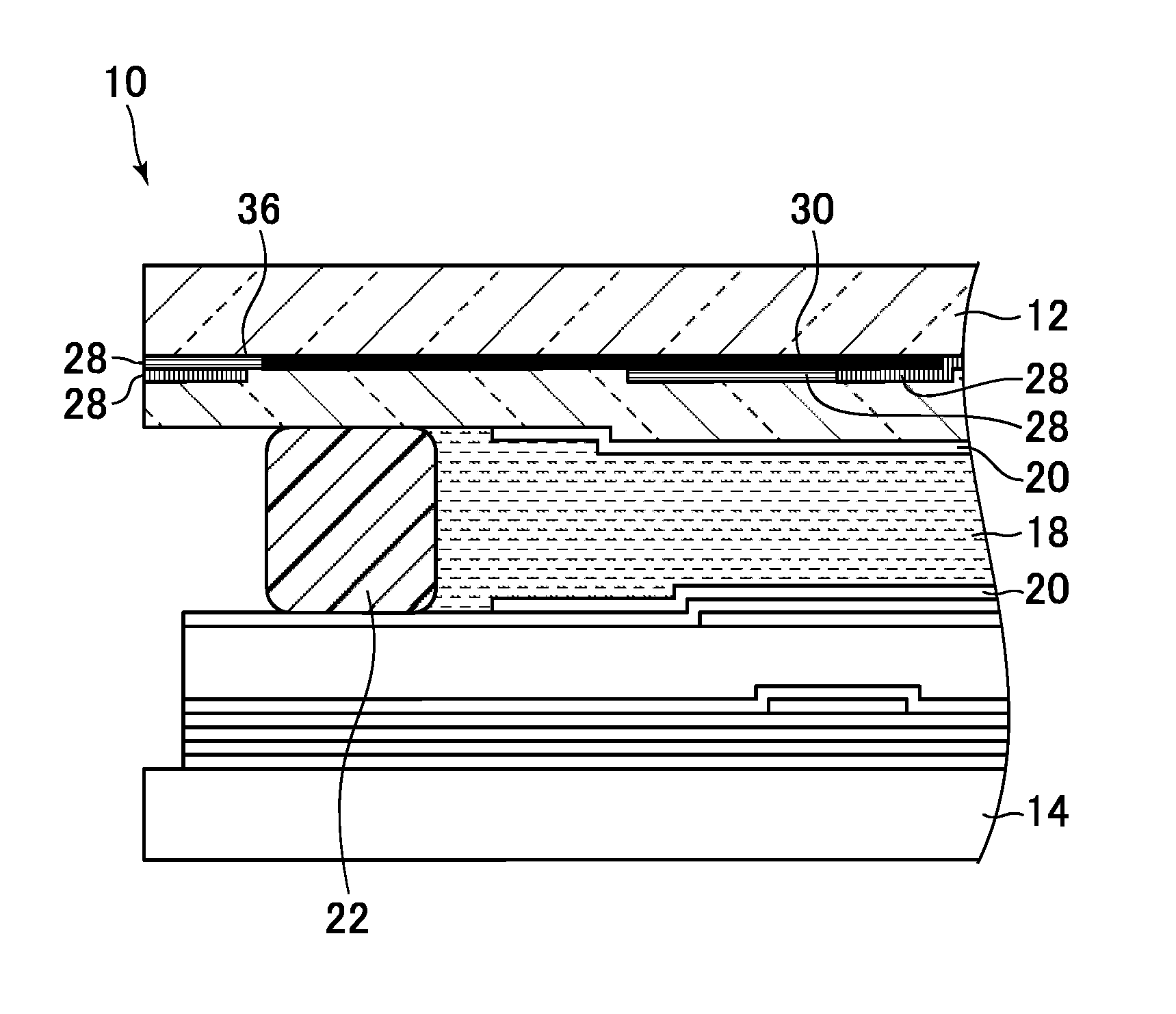

Package for housing light-emitting element, light-emitting apparatus and illumination apparatus

InactiveUS20050133808A1Increasing radiation light intensityImprove cooling effectSolid-state devicesPrintingElectrical conductorEngineering

A light-emitting apparatus provides a ceramic-made base body, a frame body, a light-emitting element, a conductor layer and a light-transmitting member. The base body has on its upper surface a mounting portion for the light-emitting element. The frame body is joined to the upper surface of the base body so as to surround the mounting portion, with its inner peripheral surface shaped into a reflection surface. The wiring conductor has its one end formed on the upper surface of the base body and electrically connected to the light-emitting element, and has another end led to a side or lower surface of the base body. The light-transmitting member is disposed inside the frame body so as to cover the light-emitting element, which contains fluorescent materials for performing wavelength conversion. The base body is so designed that ceramic crystal grains range in average particle diameter from 1 to 5 μm.

Owner:KYOCERA CORP

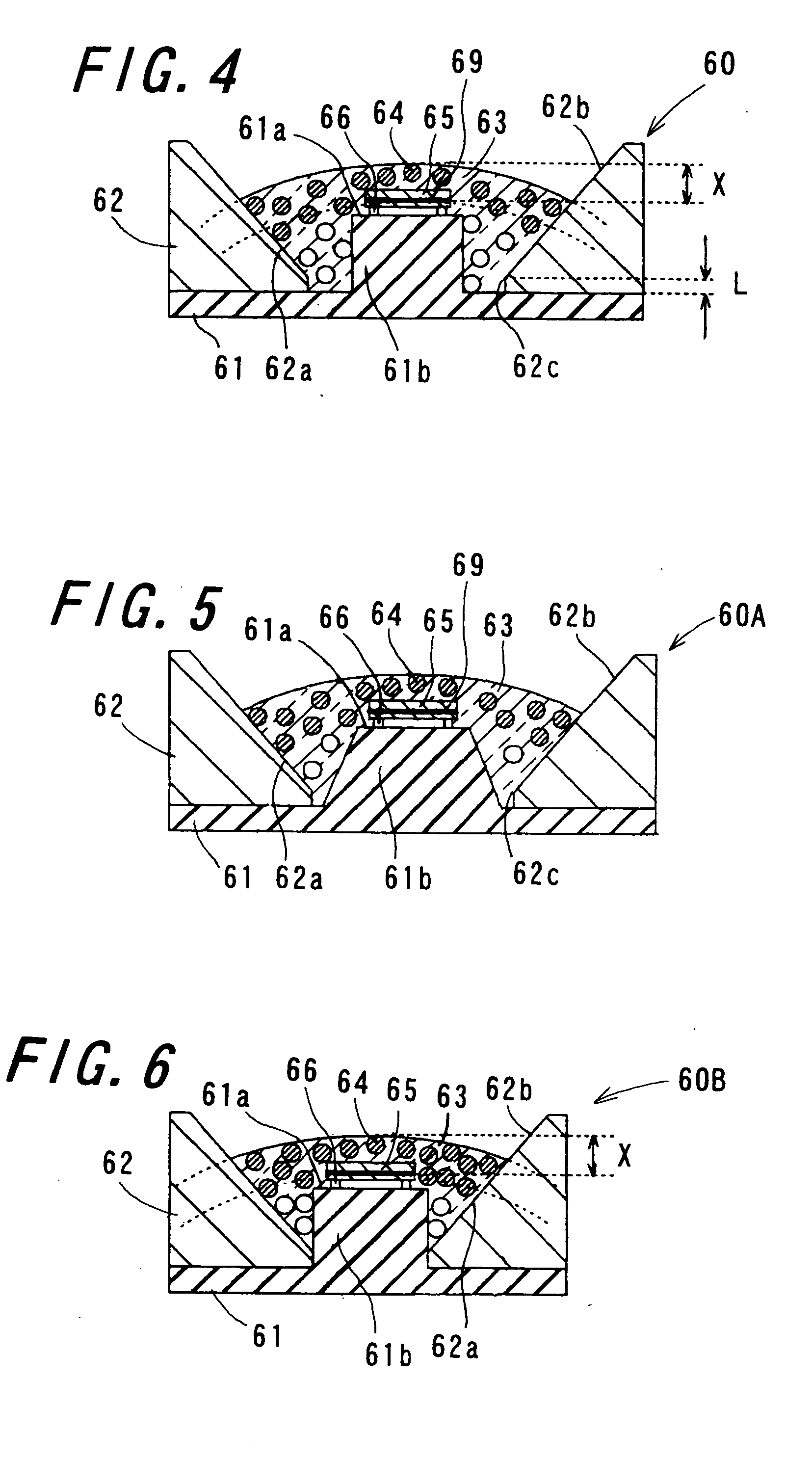

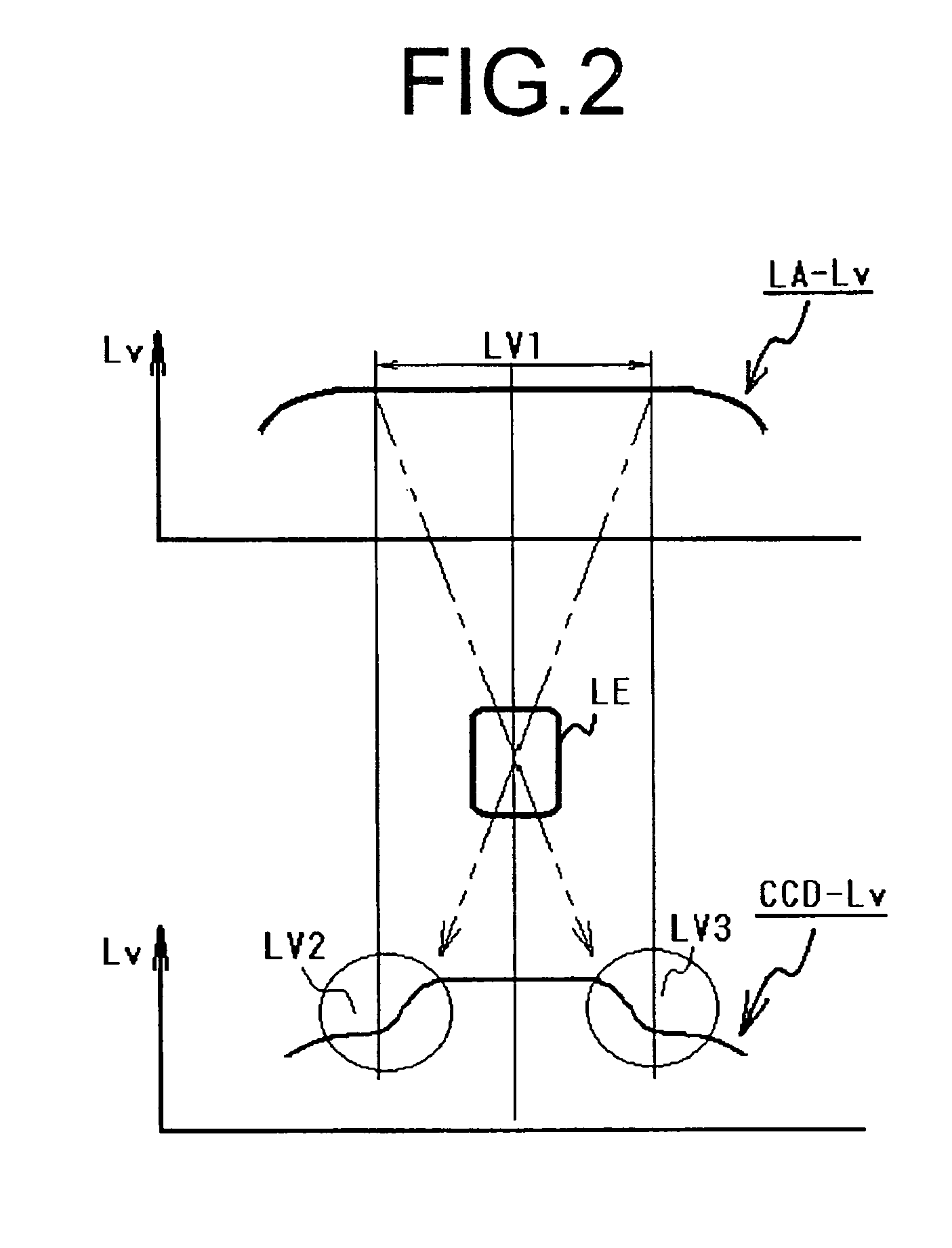

Light emitting element, production method thereof, backlight unit having the light emitting element, and production method thereof

InactiveUS20070114555A1Effective coolingIncrease light intensitySolid-state devicesOptical light guidesDriving currentOptoelectronics

A light emitting element includes: A light emitting element, includes: at least one LED chip provided on an installation surface of a substrate; a metallic reflecting plate, provided upright in a light projecting direction of the LED chip on the installation surface so as to surround an entire periphery of the LED chip, the metallic reflecting plate reflecting light projected from the LED chip to guide the light to a light projecting surface provided in the light projecting direction; and a first metallic portion and a second metallic portion, respectively connected to the LED chip as electrode terminals for supplying a driving current to the LED chip, each being formed in an area surrounded by the metallic reflecting plate on the installation surface, wherein an insulating section is formed surrounding the second metallic portion, to electrically insulate the second metallic portion from other portion in the area, and the first metallic portion is formed outside the insulating section in the area as an installation surface metallic reflecting film so as to be in contact with the metallic reflecting plate.

Owner:BIOGENTIS +1

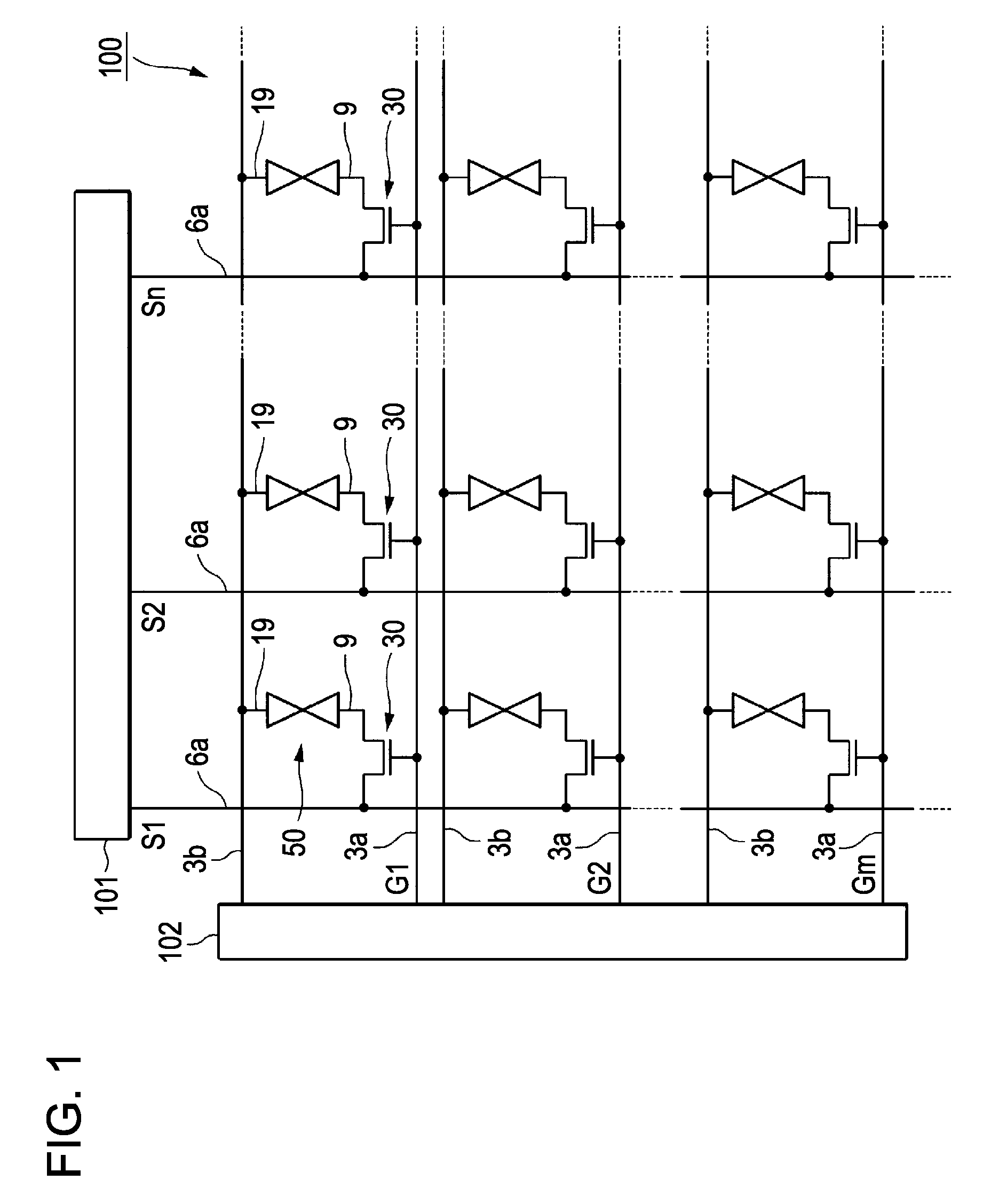

Liquid crystal display apparatus

InactiveUS7113163B2Increase the number ofIncrease probabilityStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

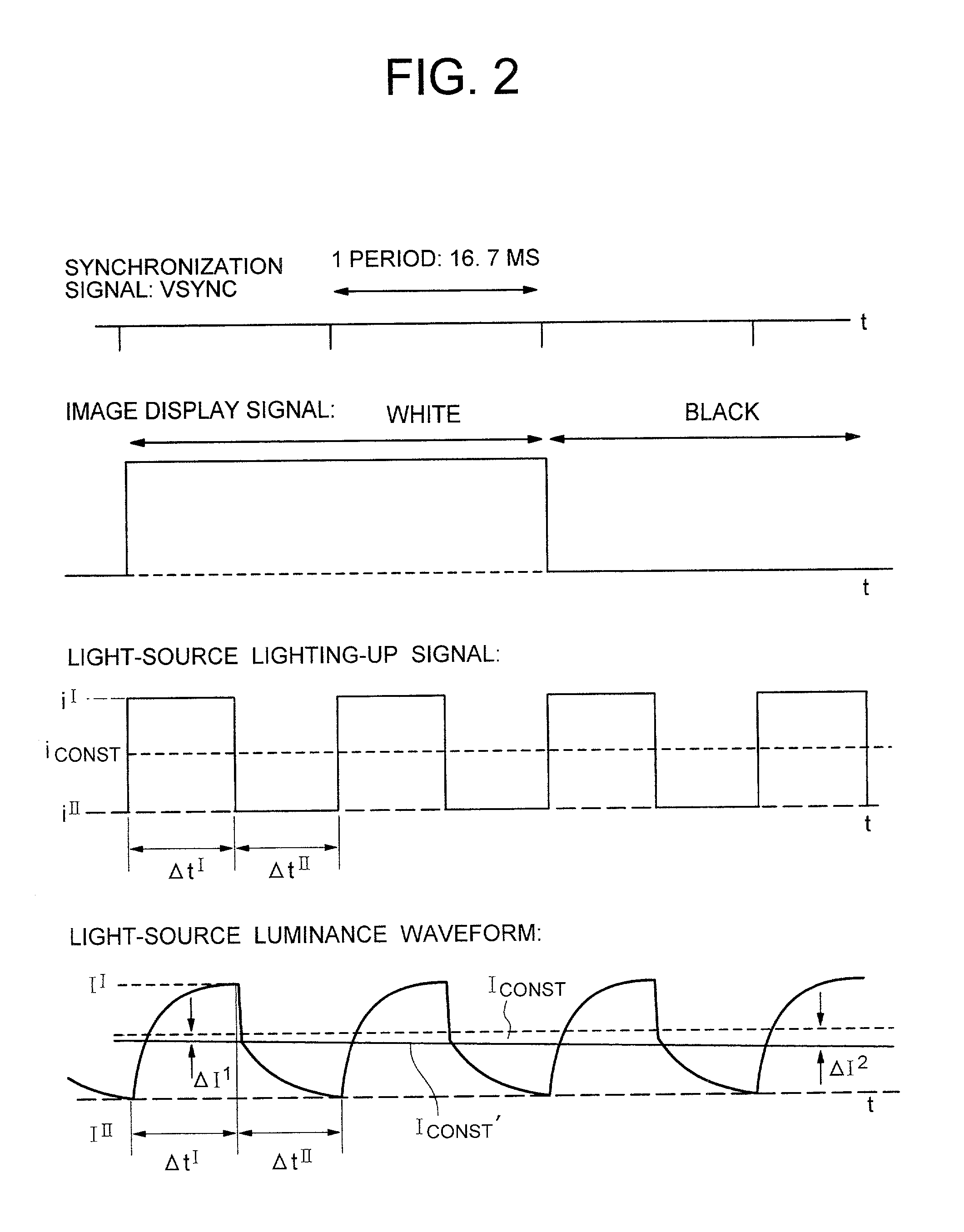

The present invention includes a panel on which a plurality of pixels are located, a light-source for visualizing an image displayed on the plurality of pixels, a controlling circuit for controlling the light-source, and an image-signal tone characteristic controlling circuit. Moreover, the light-source controlling circuit has a function of repeating a period. Here, the period includes a 1st time-period during which an electric current having a 1st intensity is fed to the light-source, and a 2nd time-period during which an electric current having a 2nd intensity differing from the 1st intensity is fed to the light-source. The light-source controlling circuit controls the 1st time-period and the 2nd time-period in accordance with display information. Also, in accordance with the display information as well, the tone characteristic controlling circuit is controlled so that the excellent contrast will be always available.

Owner:HITACHI DISPLAYS +1

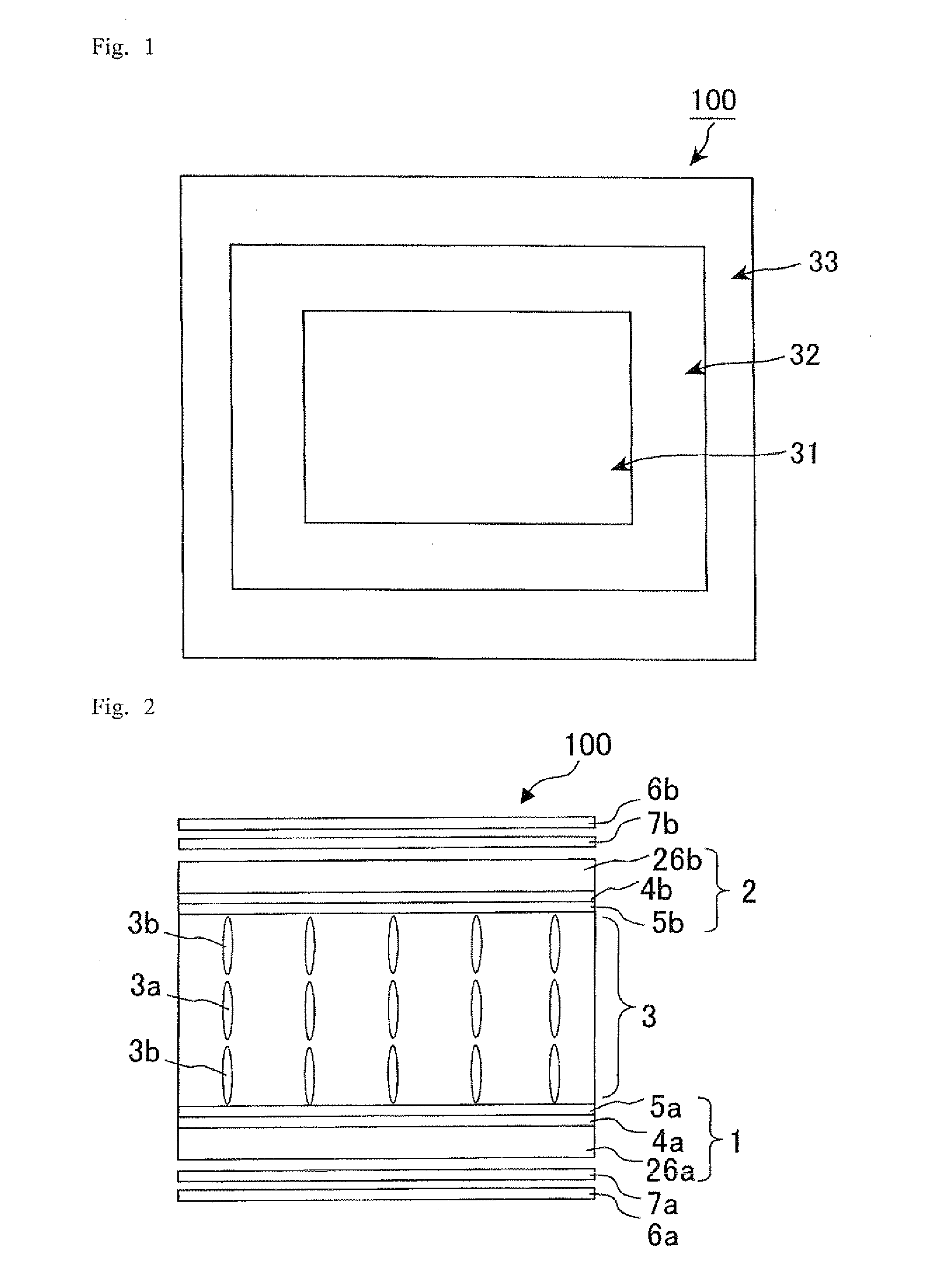

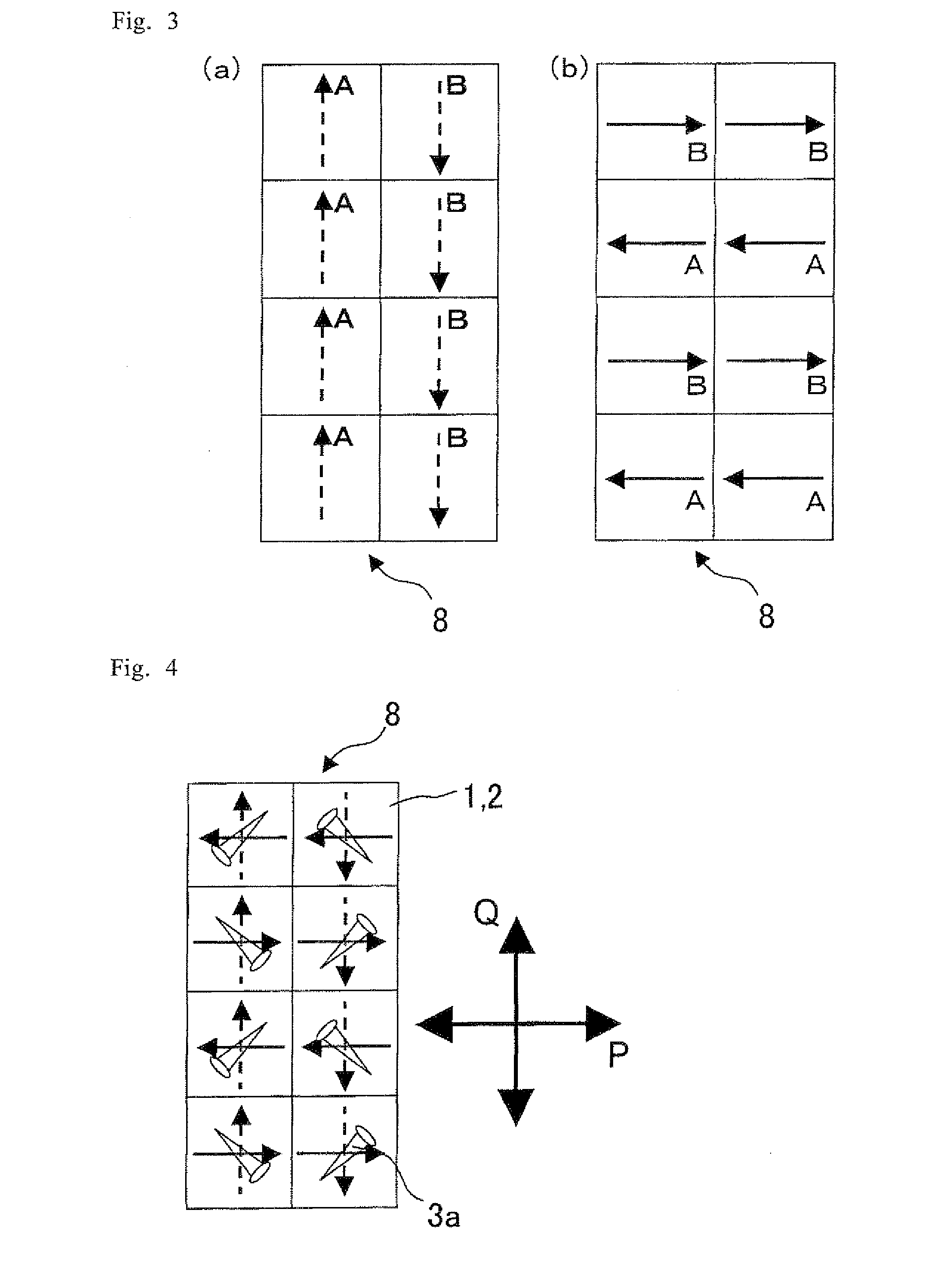

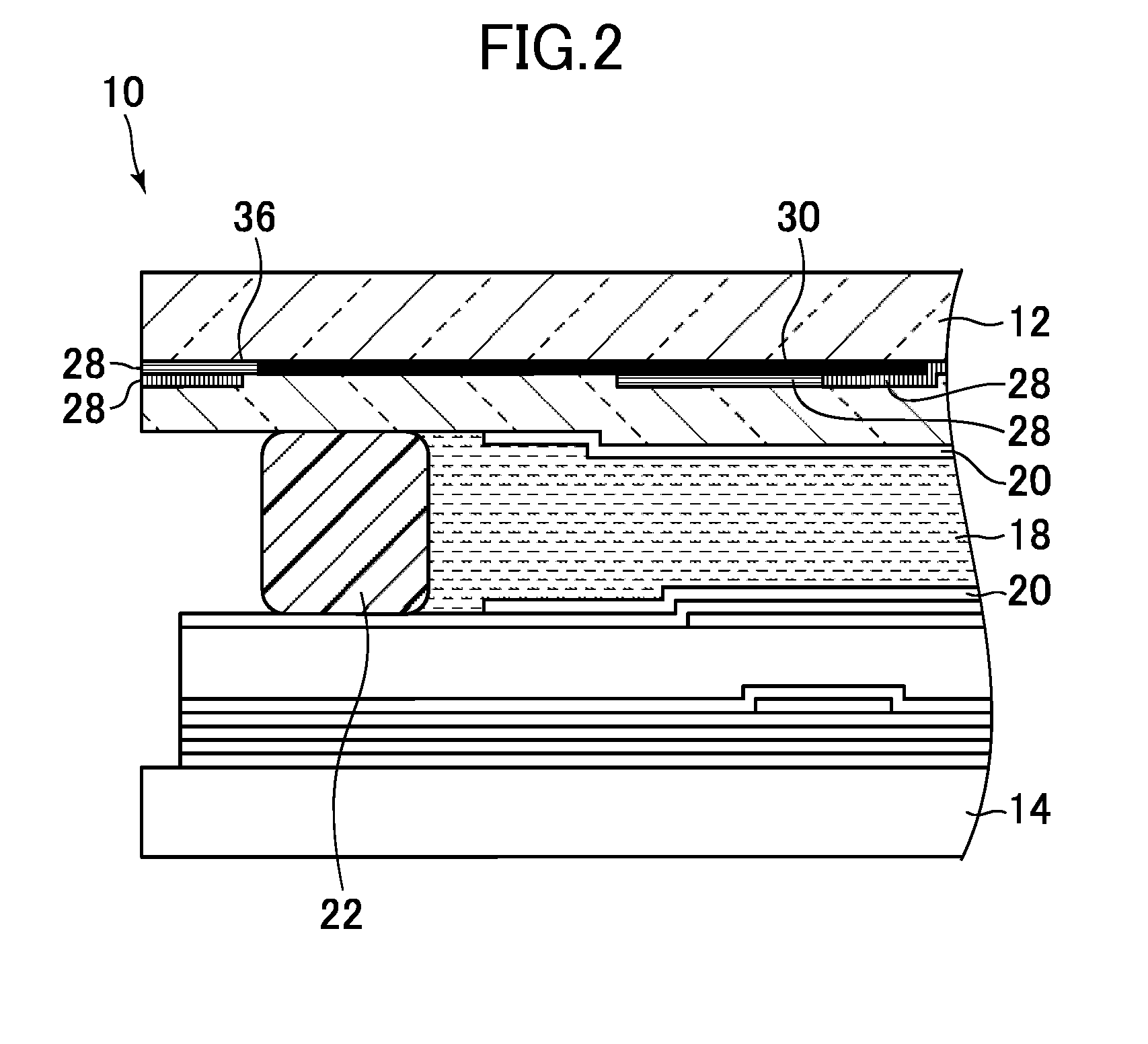

Display panel and display device

ActiveUS20090115933A1Suppress light leakageEasily realizedNon-linear opticsDisplay deviceEngineering

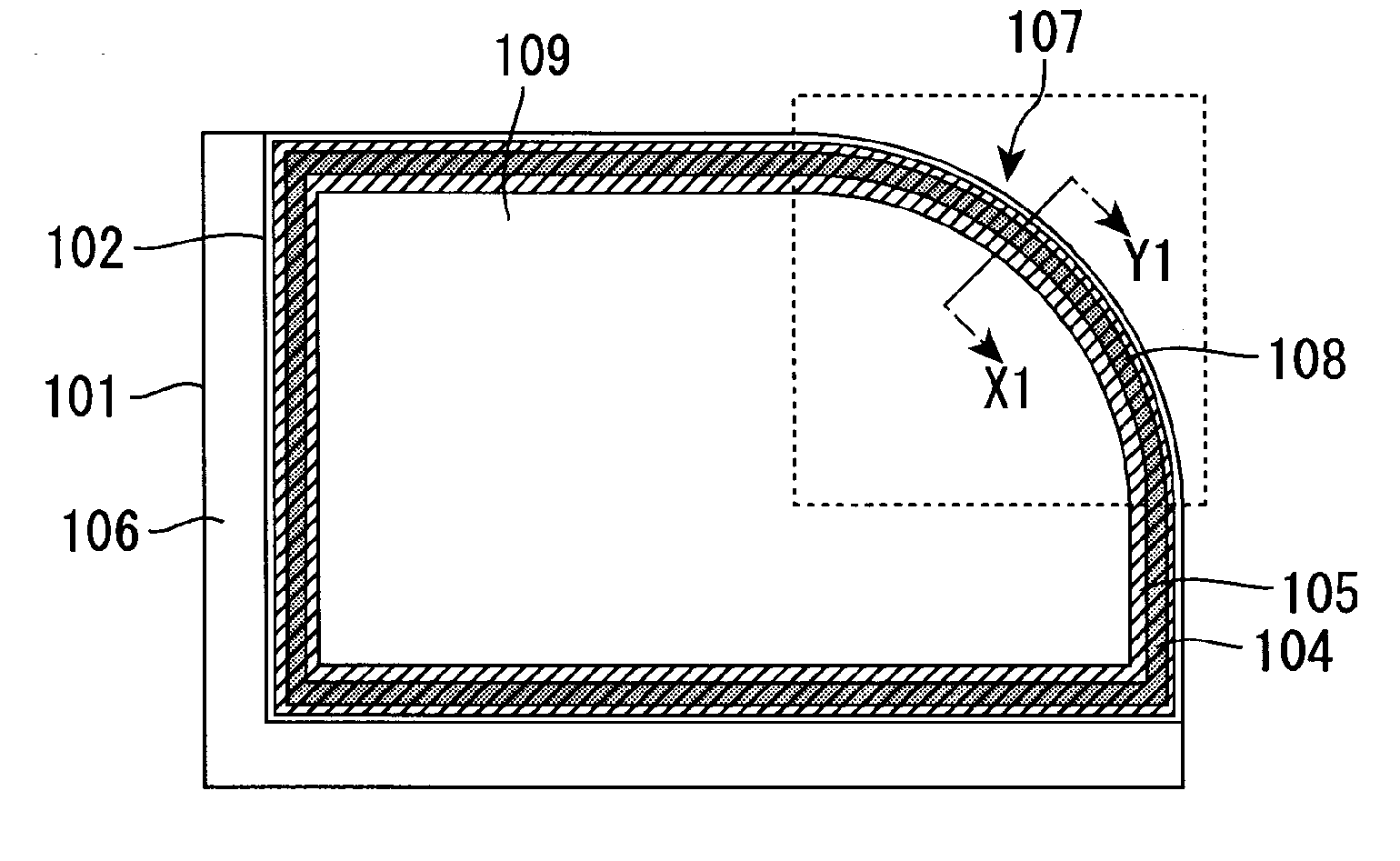

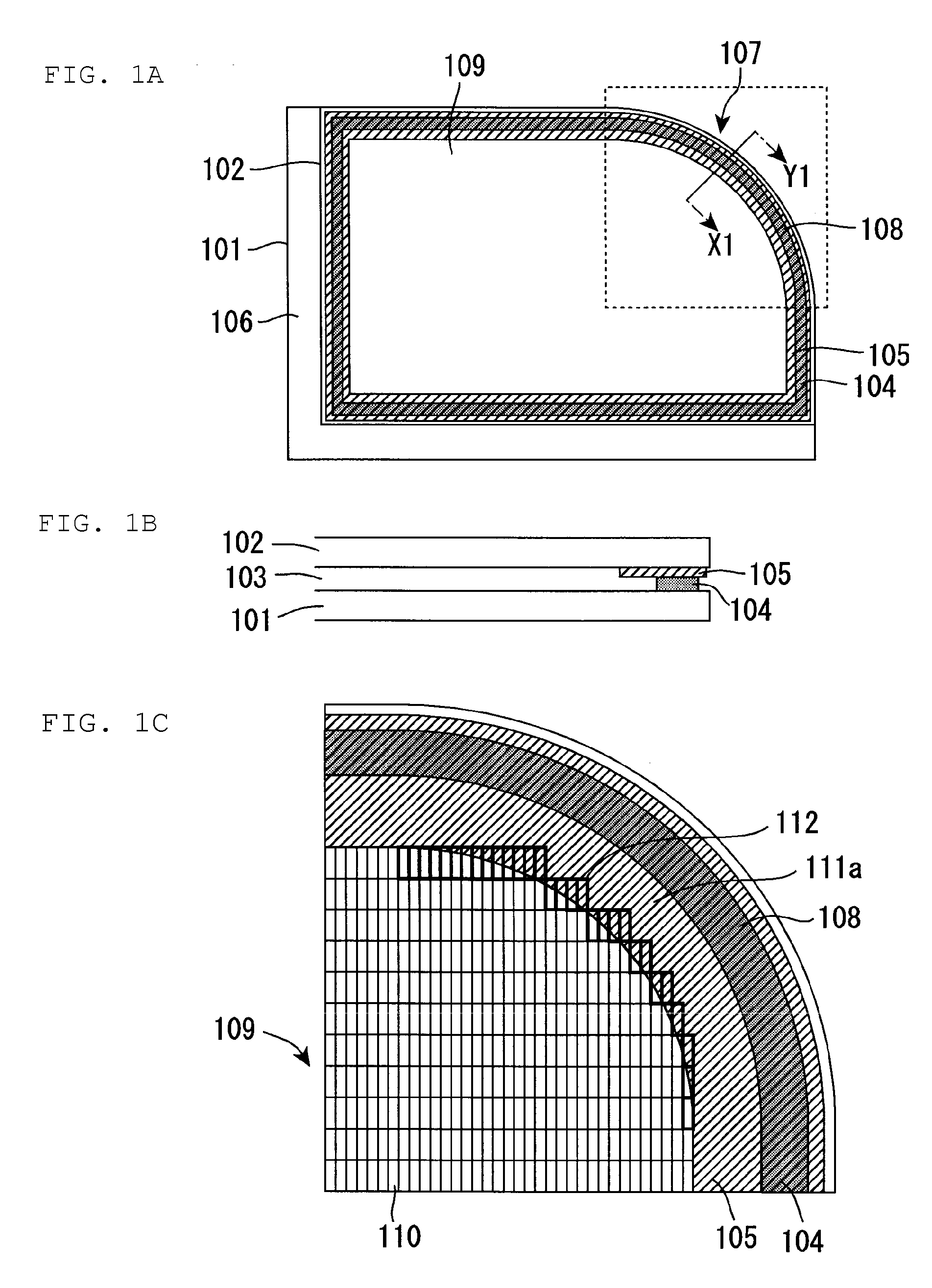

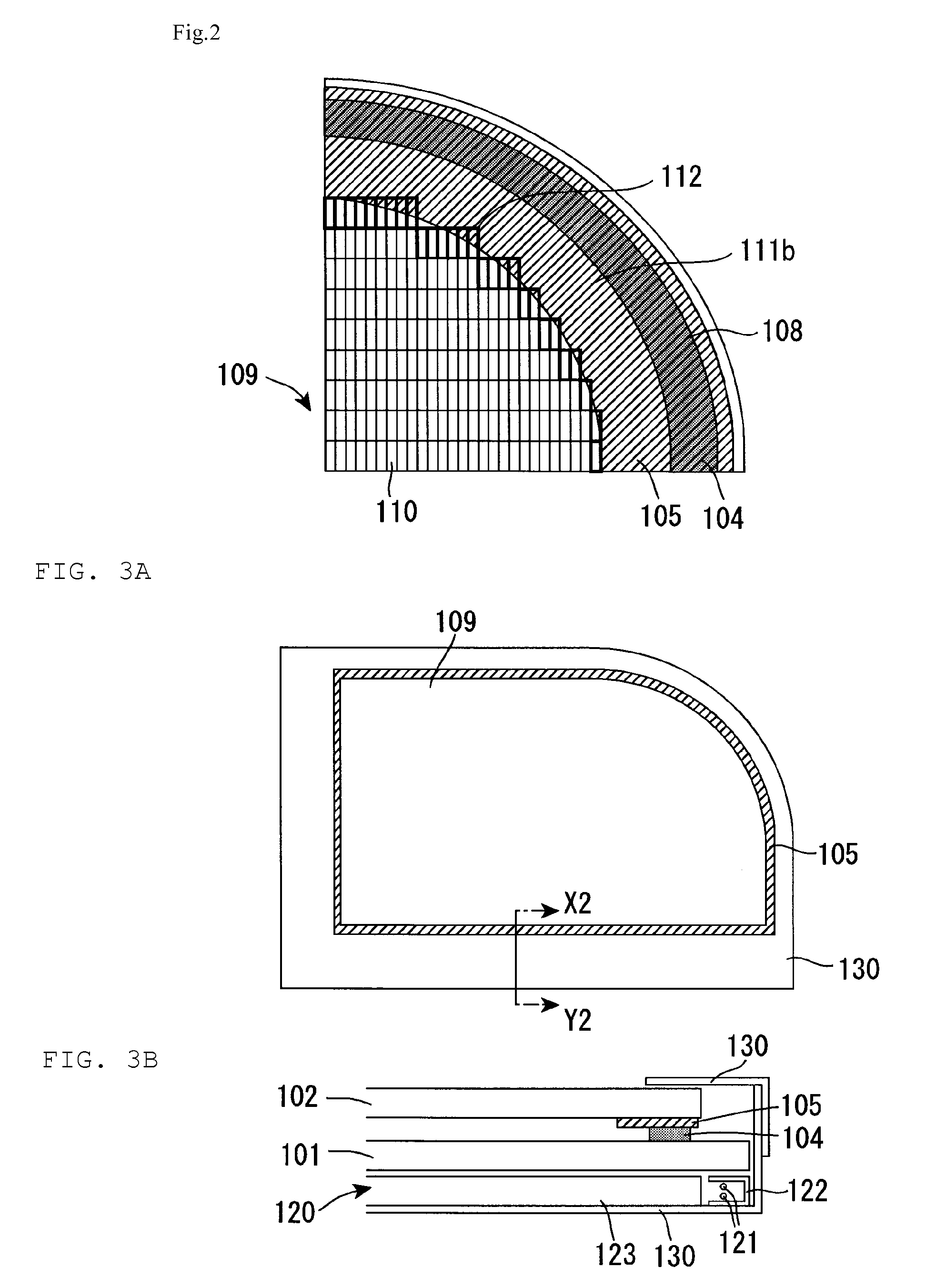

Each of a display panel and a display device includes a display region in which an image with uniform display quality is displayed and a curved line can be displayed in the contour. The display panel includes a shielding member and a plurality of pixels arrayed in a display region, wherein the shielding member includes a shielding curved portion having a curved planar shape, and the shielding curved portion shields the plurality of pixels to form a curved contour of the display region.

Owner:UNIFIED INNOVATIVE TECH

Display Device

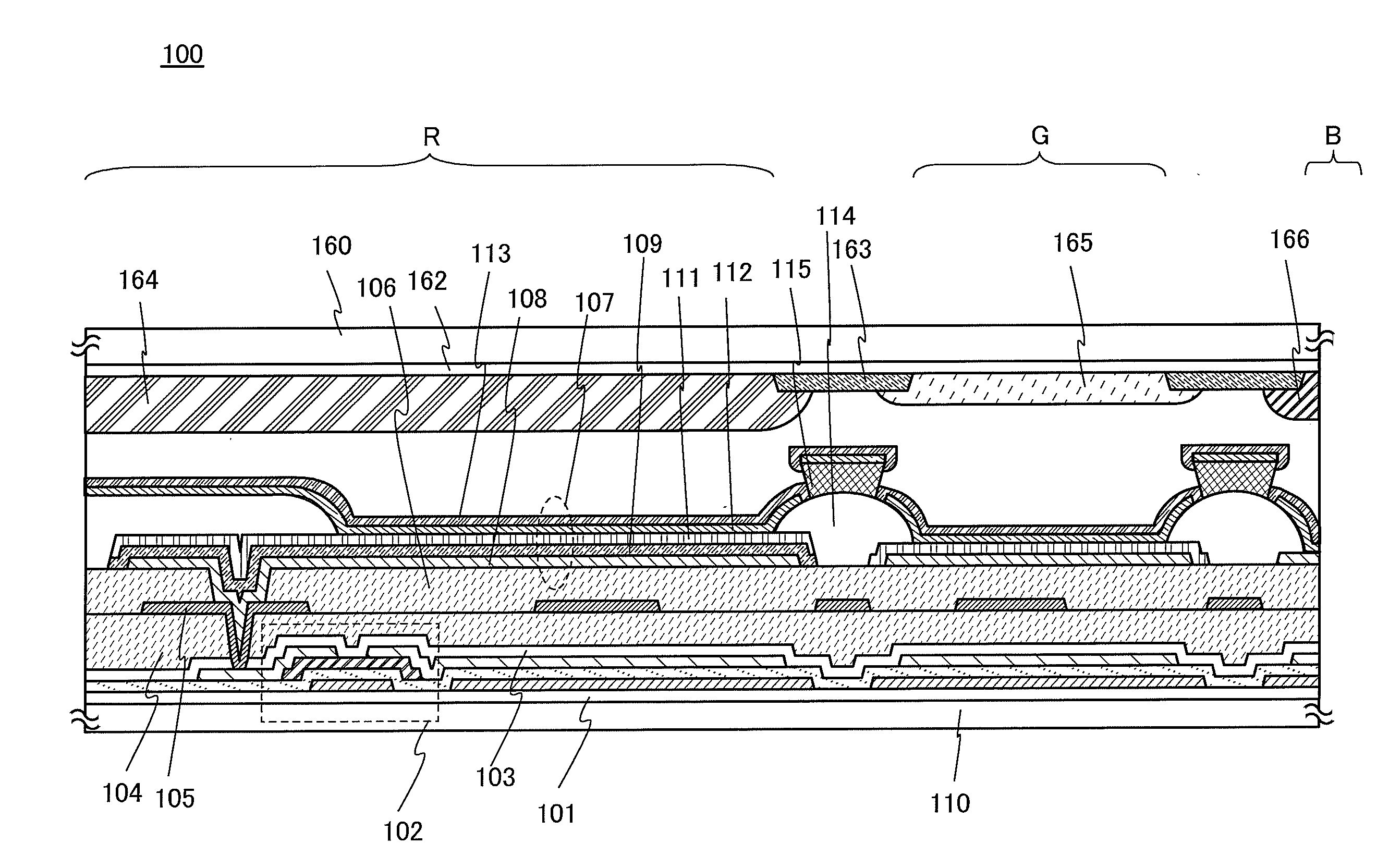

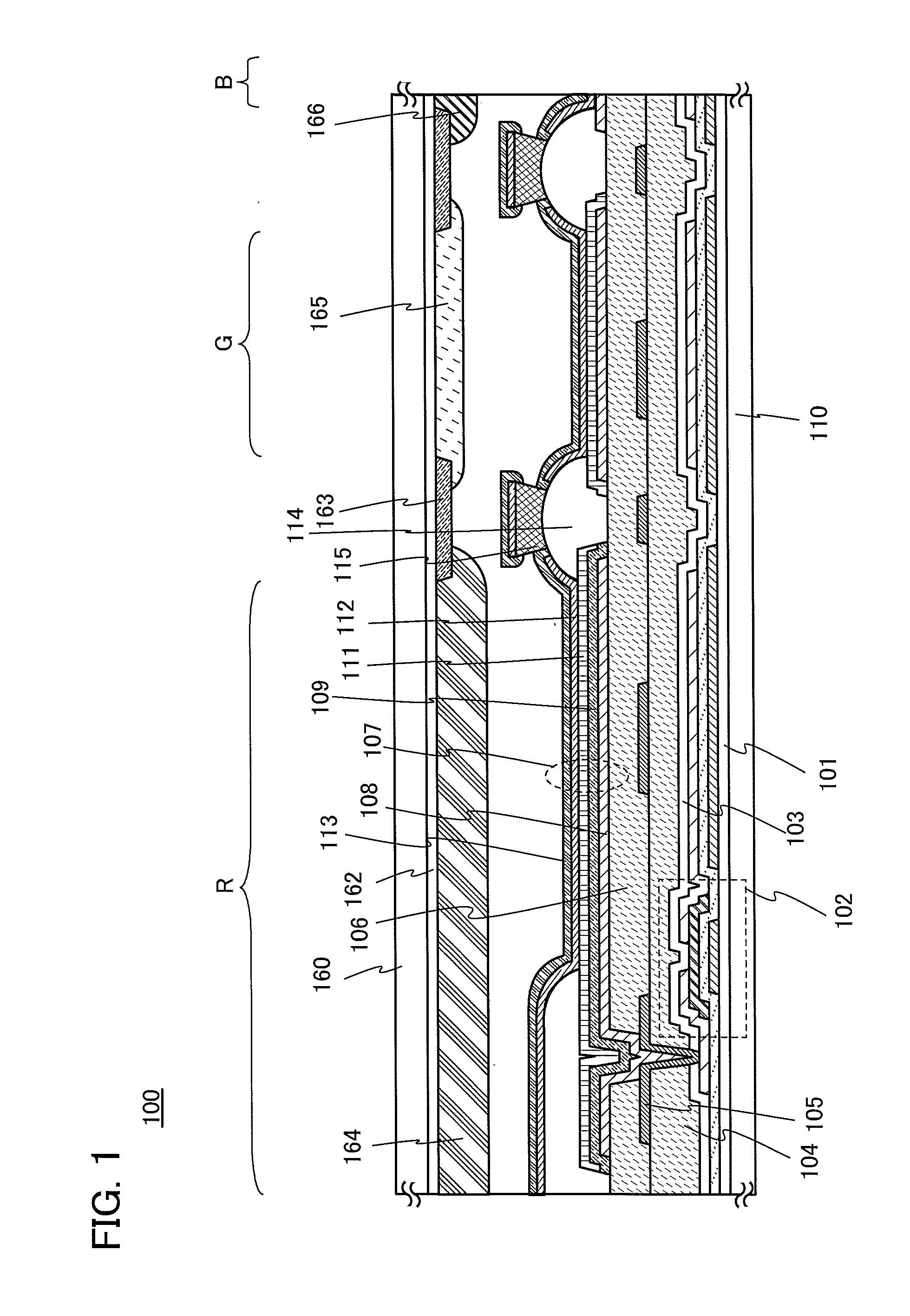

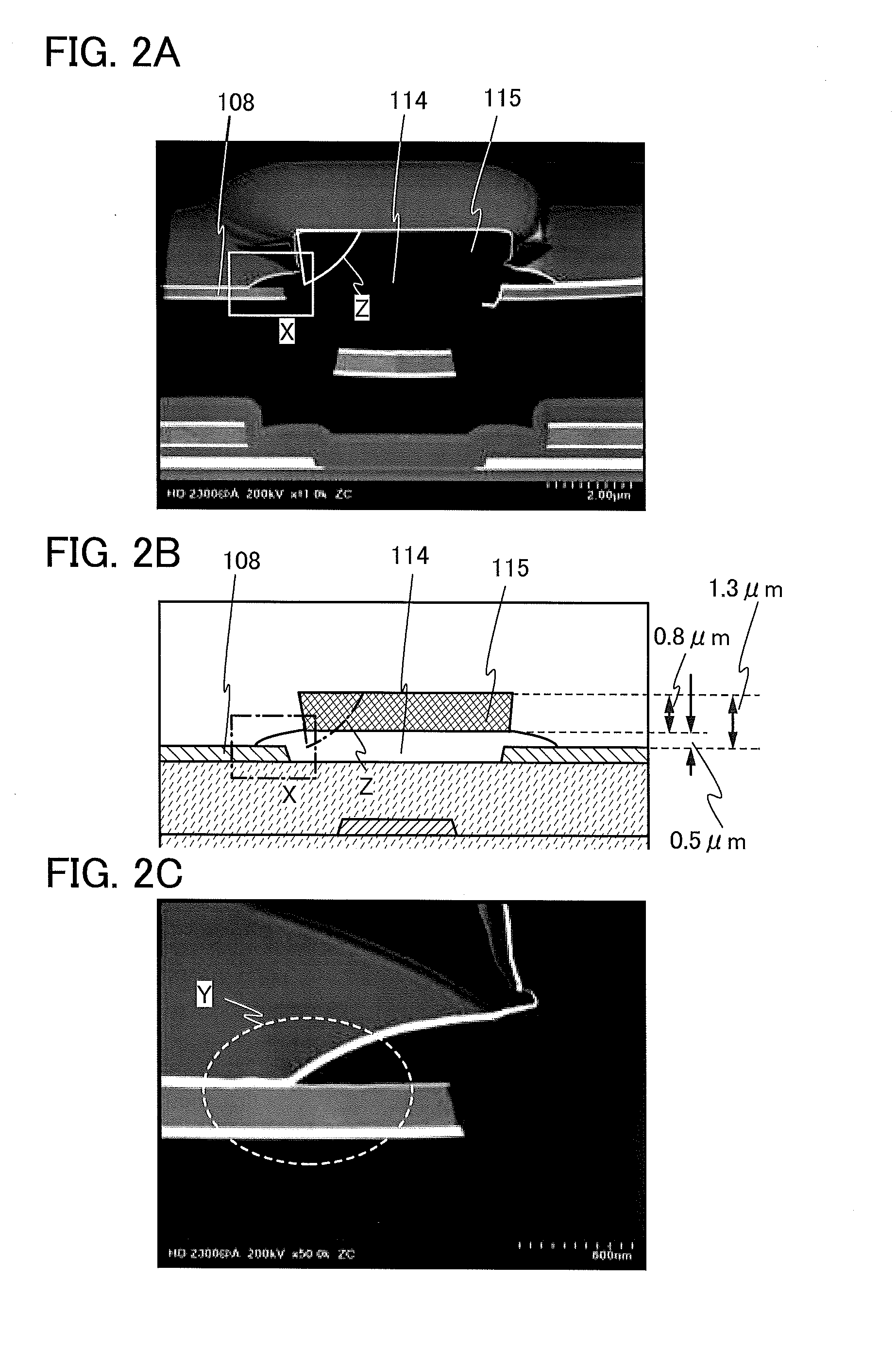

ActiveUS20140035456A1Reduce luminanceImprove contrastDischarge tube luminescnet screensElectroluminescent light sourcesCurve shapePhysics

To improve image quality of a full-color organic EL display panel. A partition has a stacked structure formed using different materials. A lower partition has a curved shape, and an upper partition has a flat top surface. An angle formed between a plane surface connecting a lower end of a side surface with an upper end of the side surface of the upper partition and the top surface of the upper partition is less than or equal to 90°. The height of the partition is controlled to be greater than or equal to 0.5 μm and less than or equal to 1.3 μm. With such a structure, a large color organic EL display panel achieves high-definition display.

Owner:SEMICON ENERGY LAB CO LTD

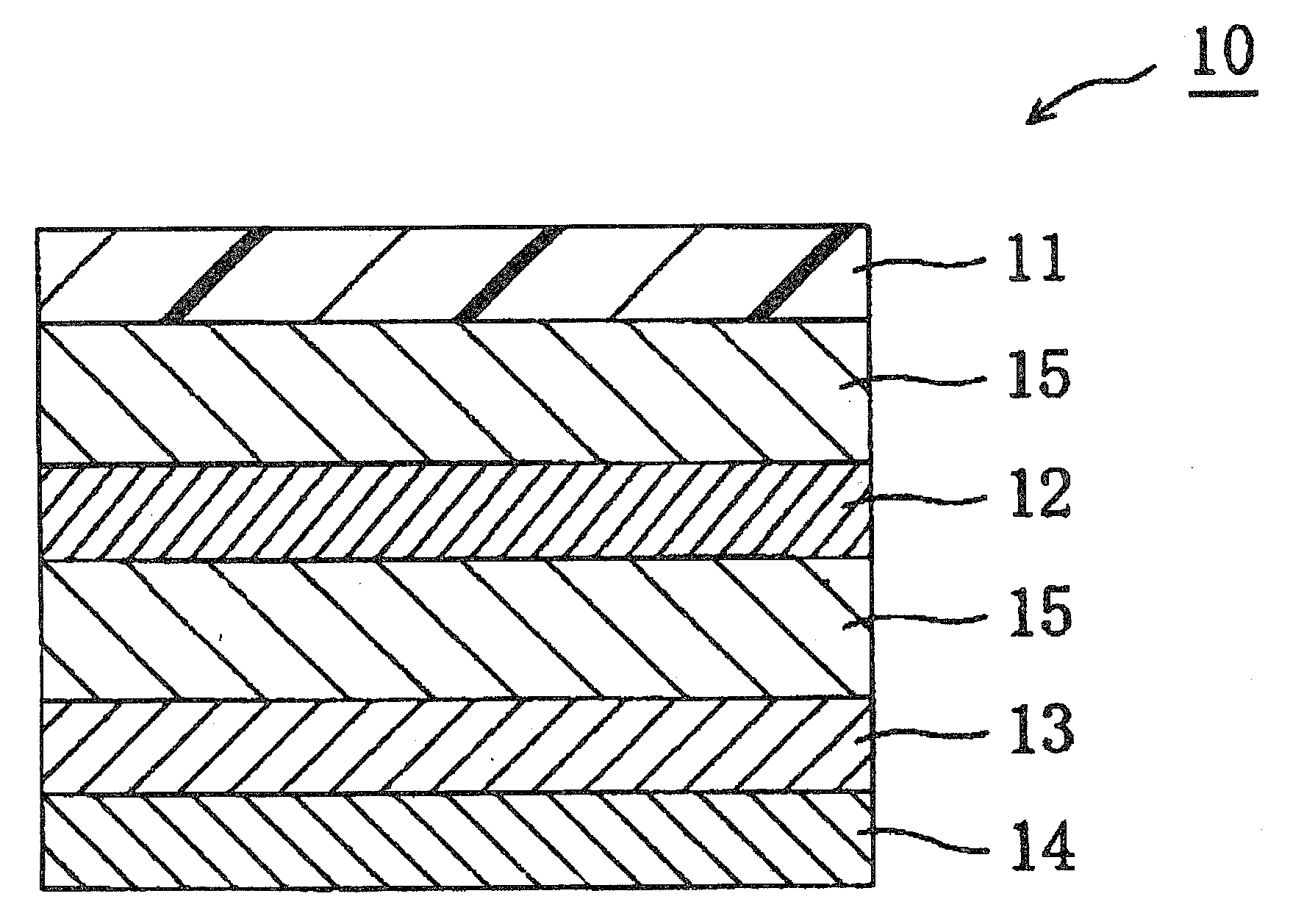

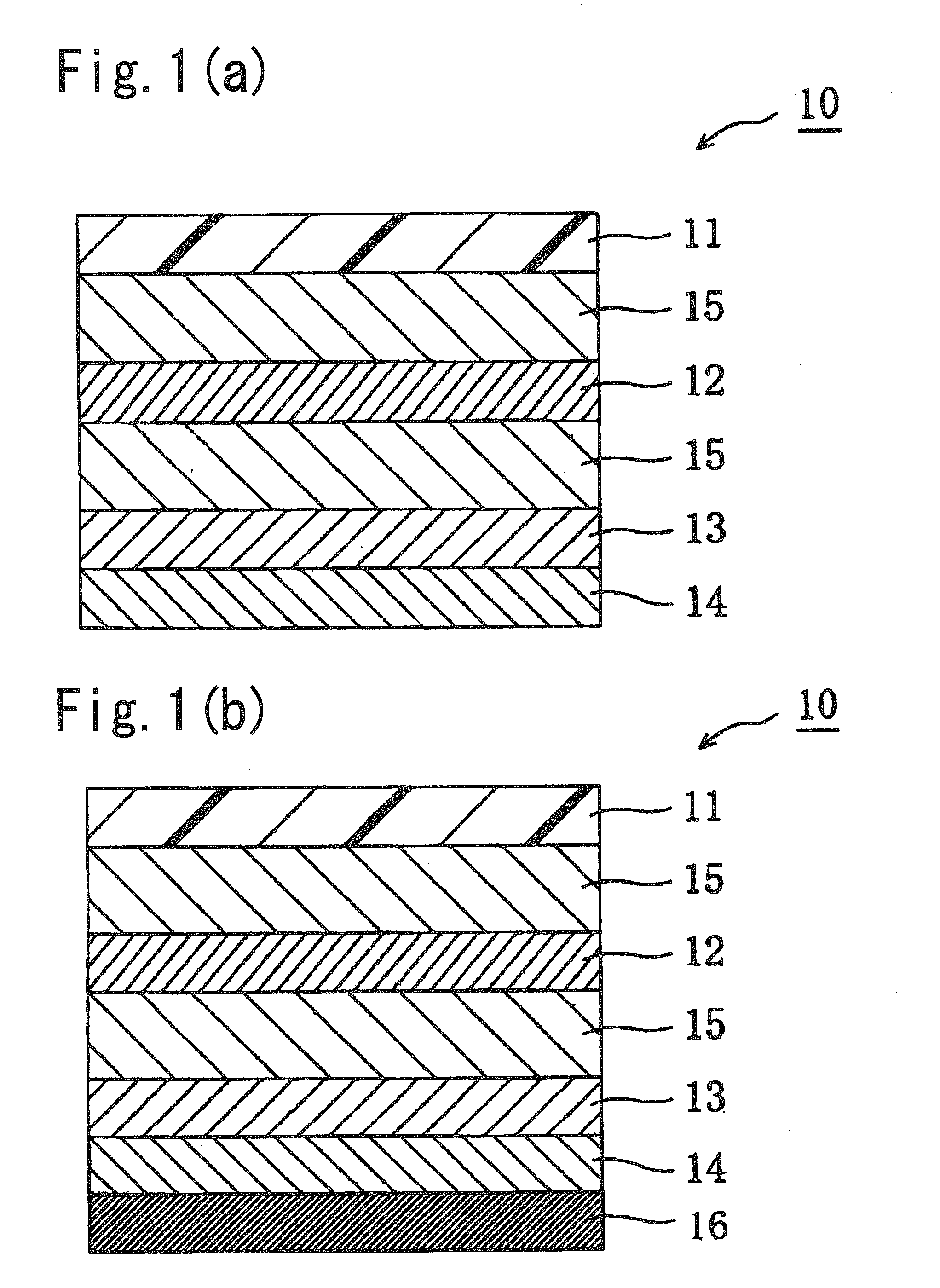

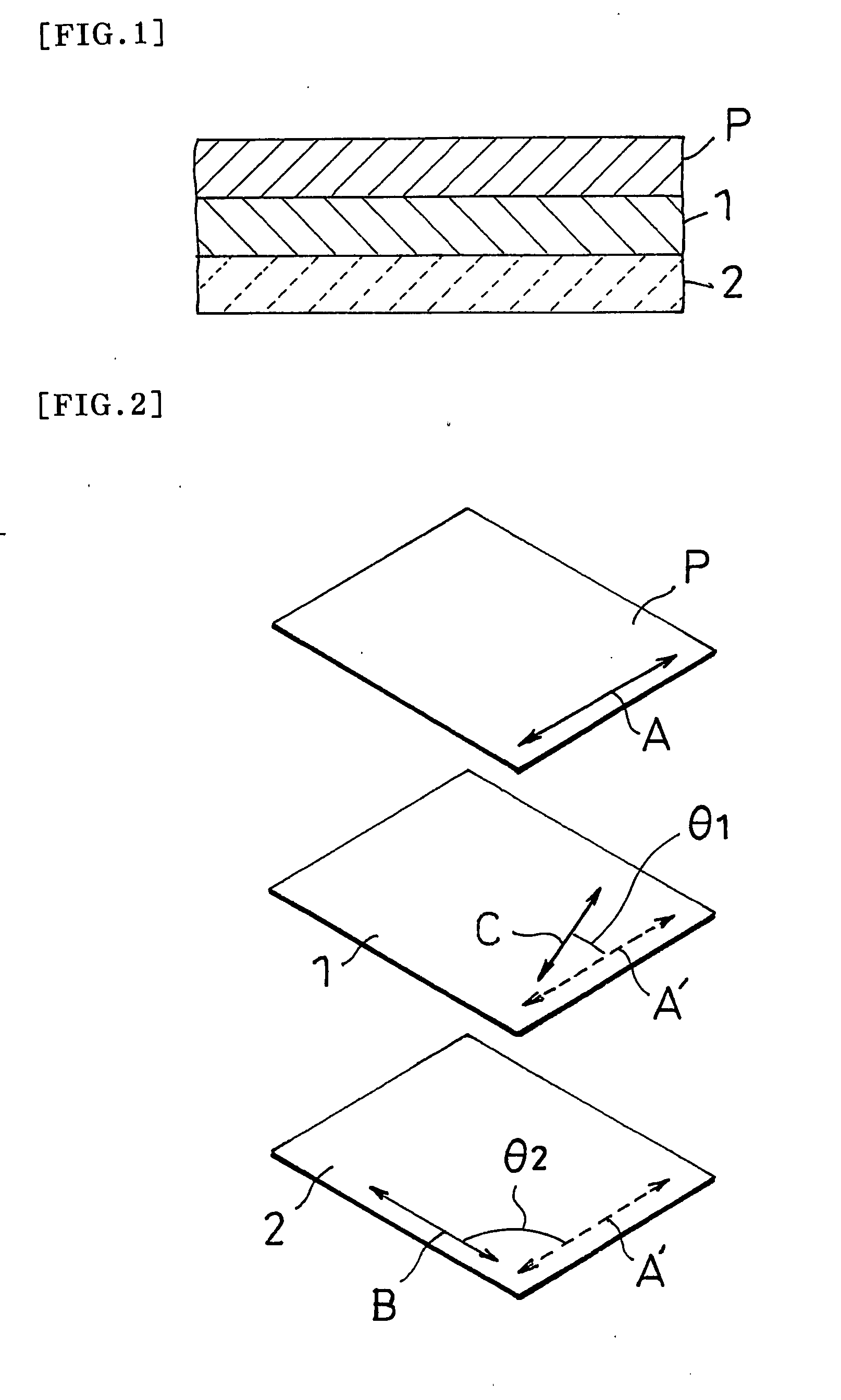

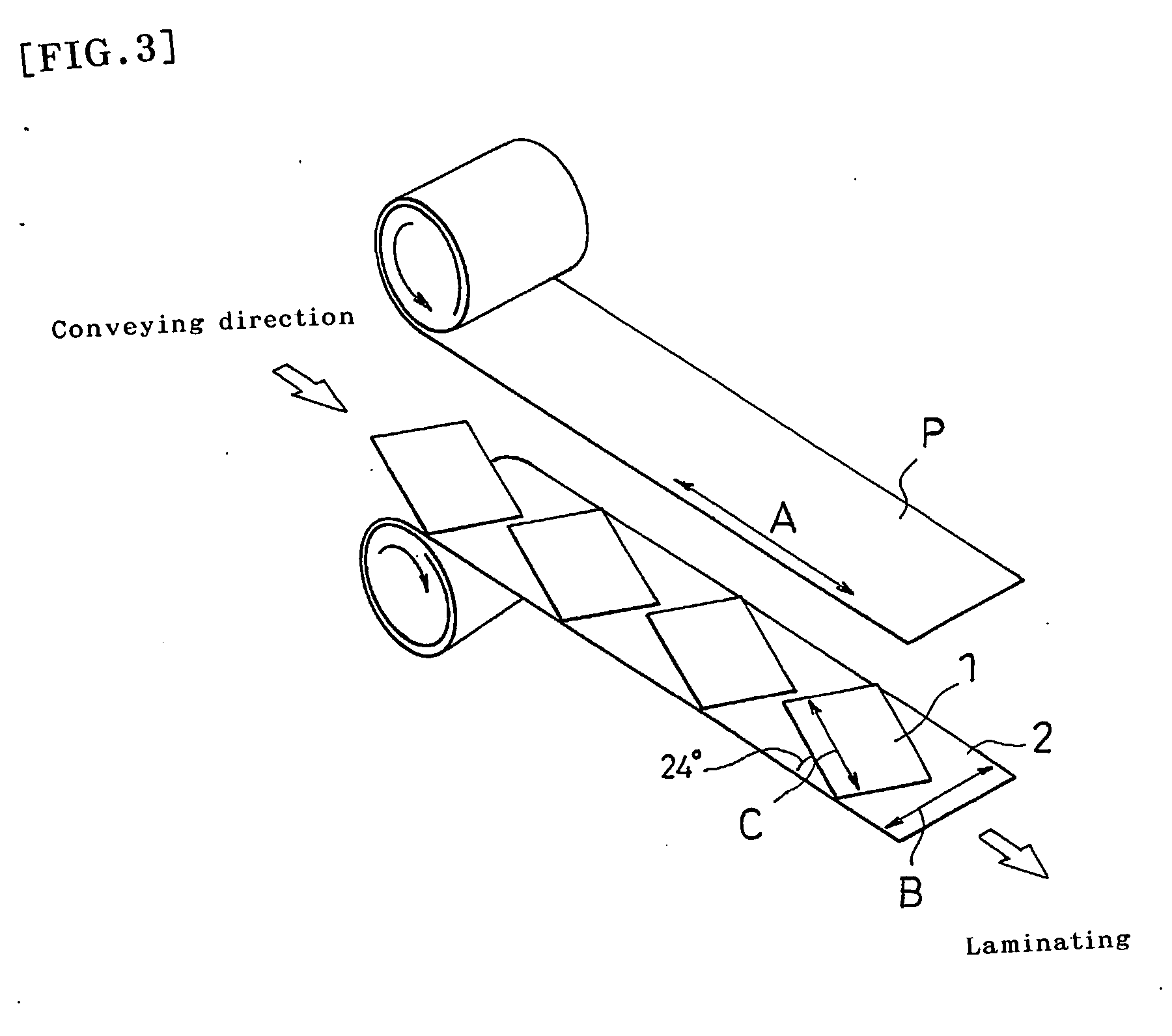

Polarizing plate with optical compensation layer and image display apparatus using the same

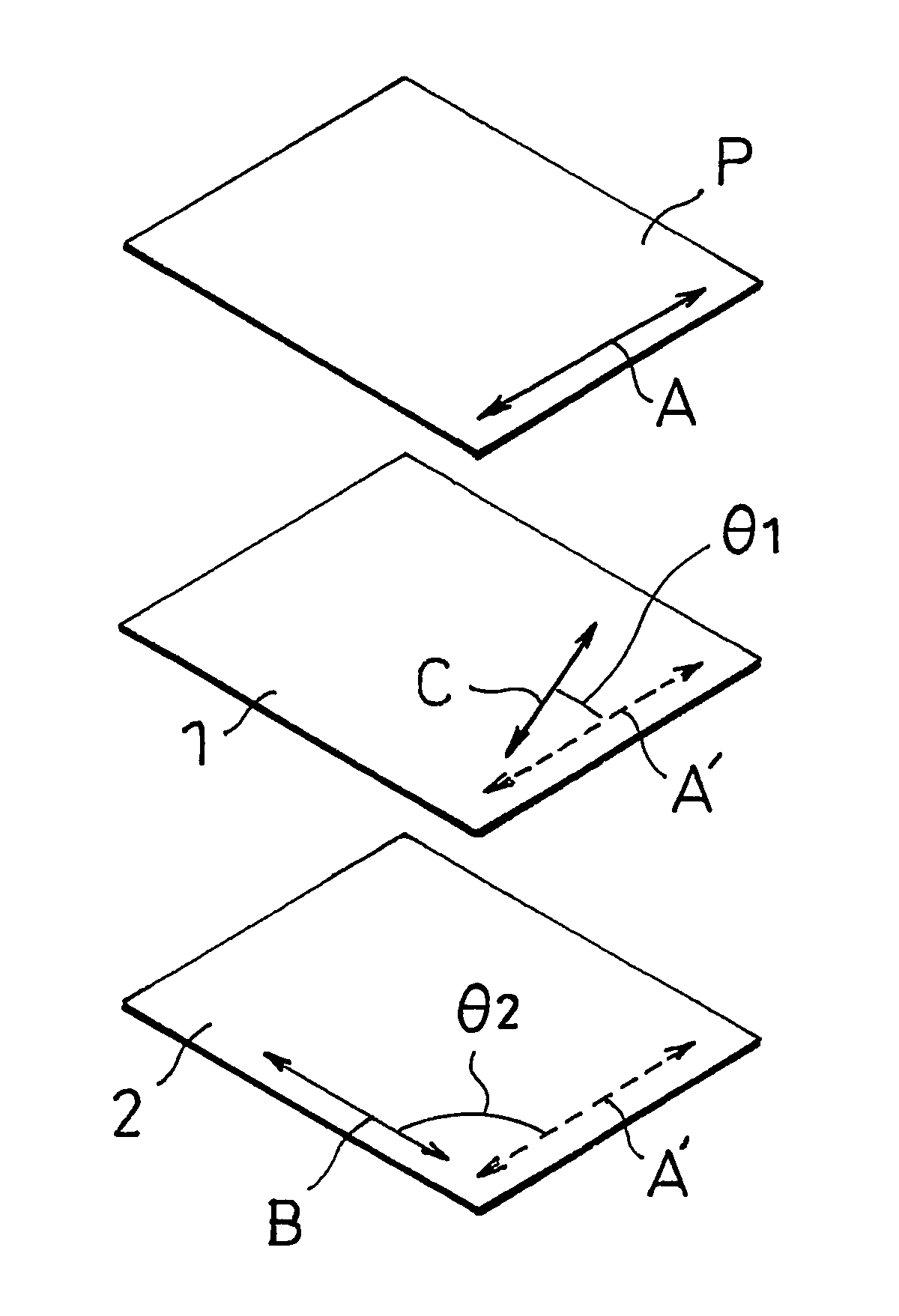

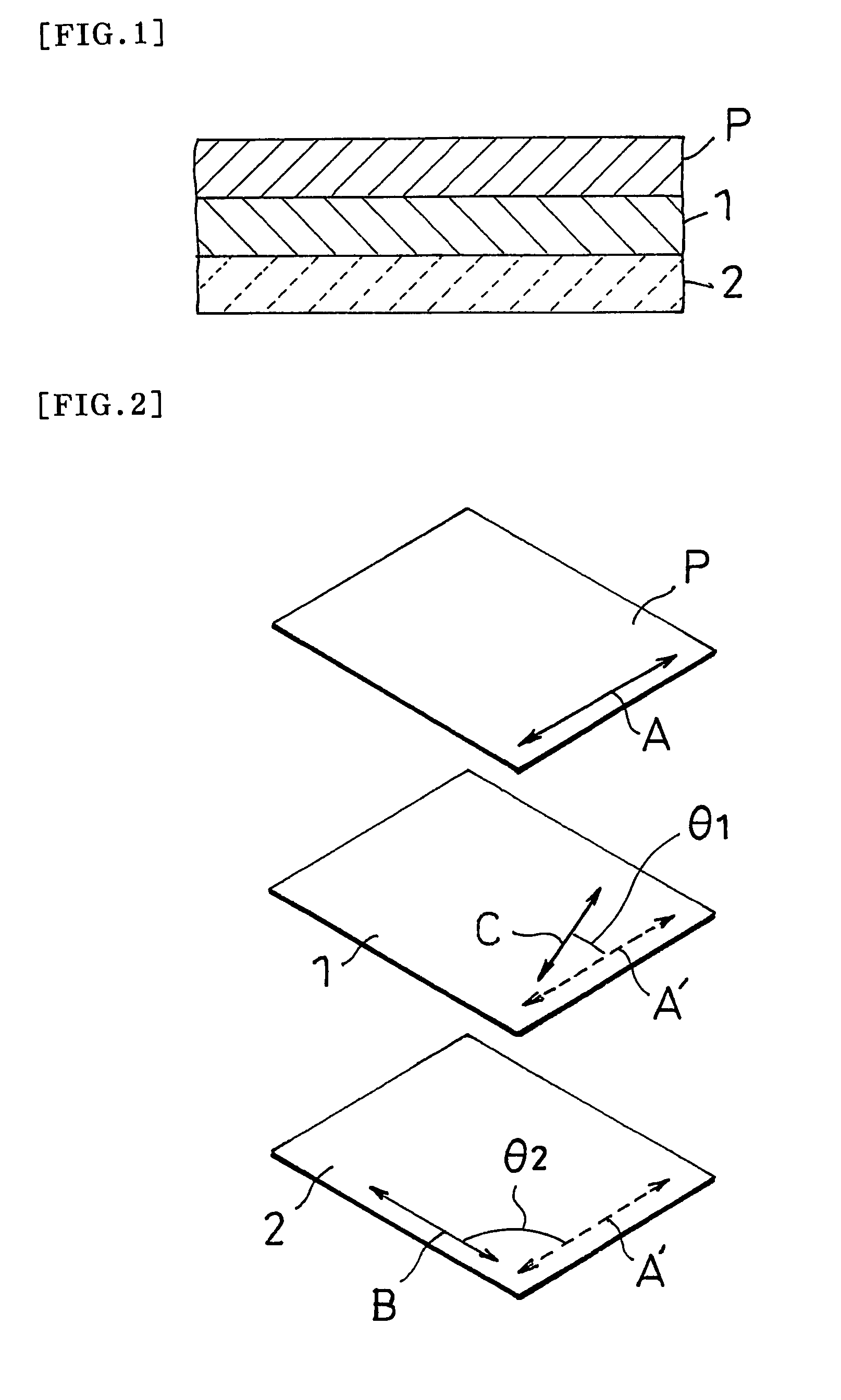

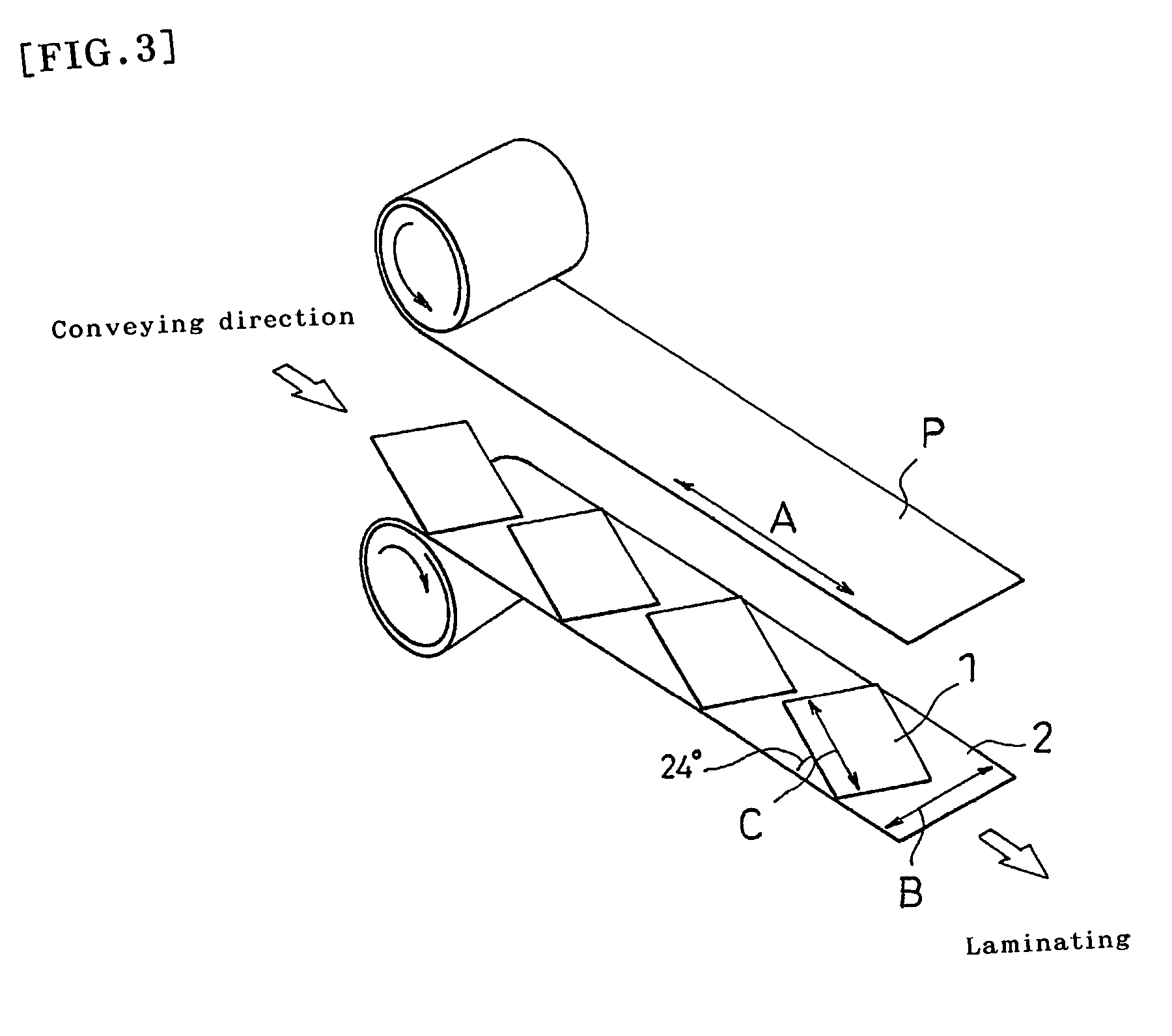

InactiveUS20090135343A1Improve wear resistanceHigh hardnessLiquid crystal compositionsPolarising elementsMeth-Polyol

The polarizing plate with an optical compensation layer of the present invention includes: a hardcoat layer; a polarizer; a first optical compensation layer placed so that a slow axis thereof intersects with an absorption axis of the polarizer; and a second optical compensation layer placed so that a slow axis thereof intersects with the absorption axis of the polarizer in the stated order, wherein: the first optical compensation layer provides a substantially ½ retardation with respect to a wavelength of monochromatic light; the second optical compensation layer provides a substantially ¼ retardation with respect to a wavelength of monochromatic light; and the hardcoat layer contains urethaneacrylate, polyol (meth)acrylate, and (meth) acrylic polymer having an alkyl group containing at least two hydroxyl groups. The polarizing plate with an optical compensation layer of the present invention may suitably be used for various image display apparatuses (such as a liquid crystal display apparatus and a self-luminous display apparatus).

Owner:NITTO DENKO CORP

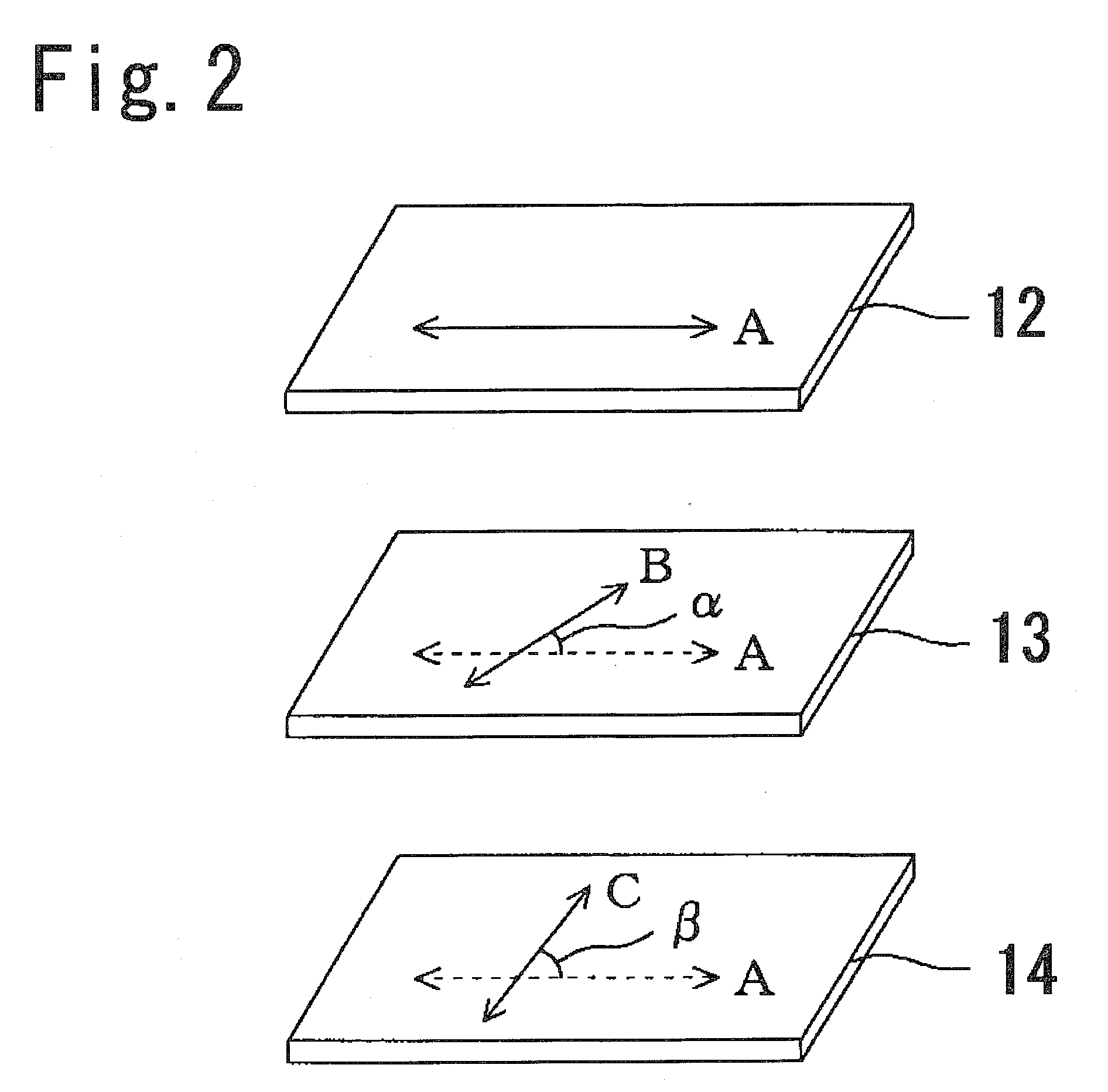

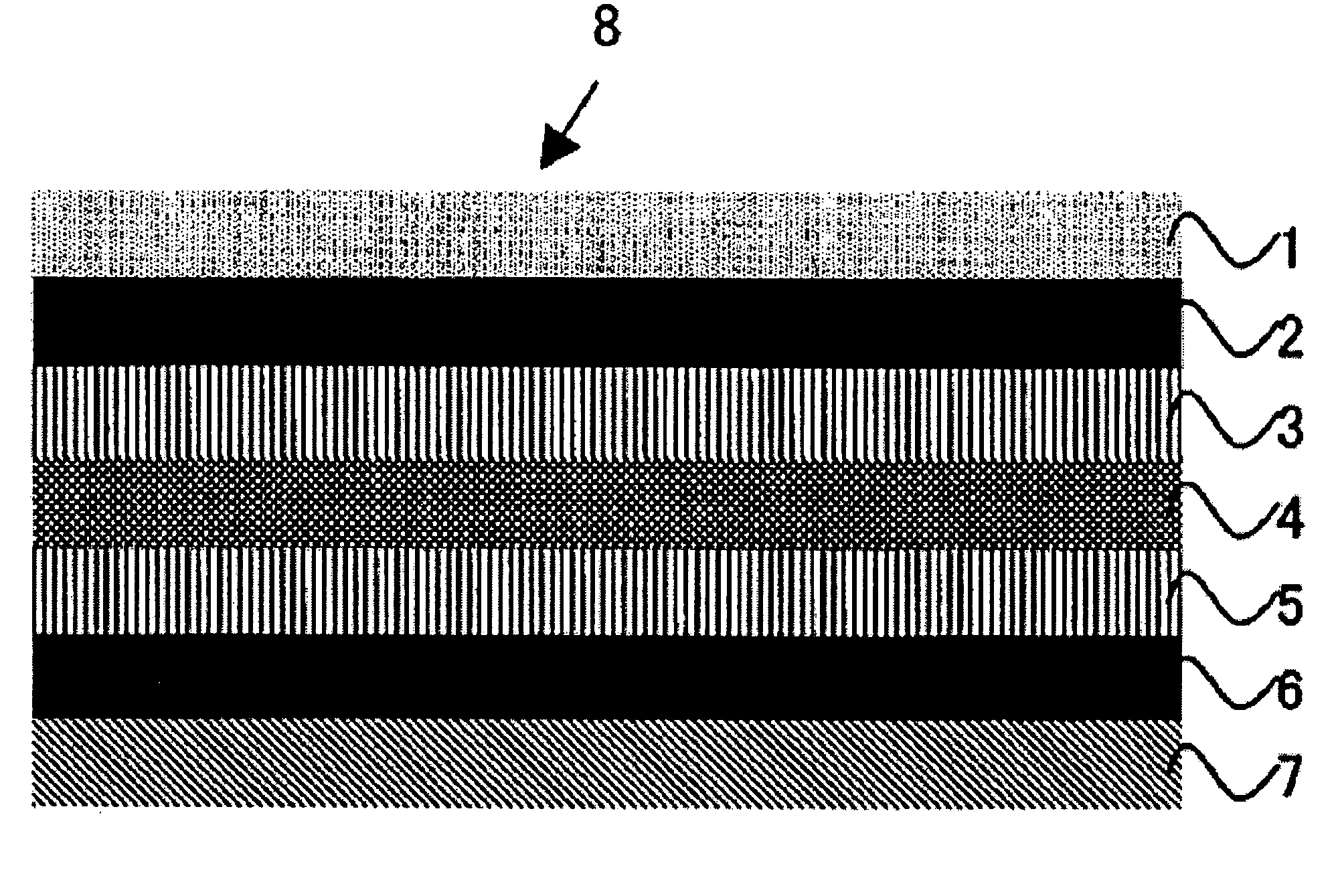

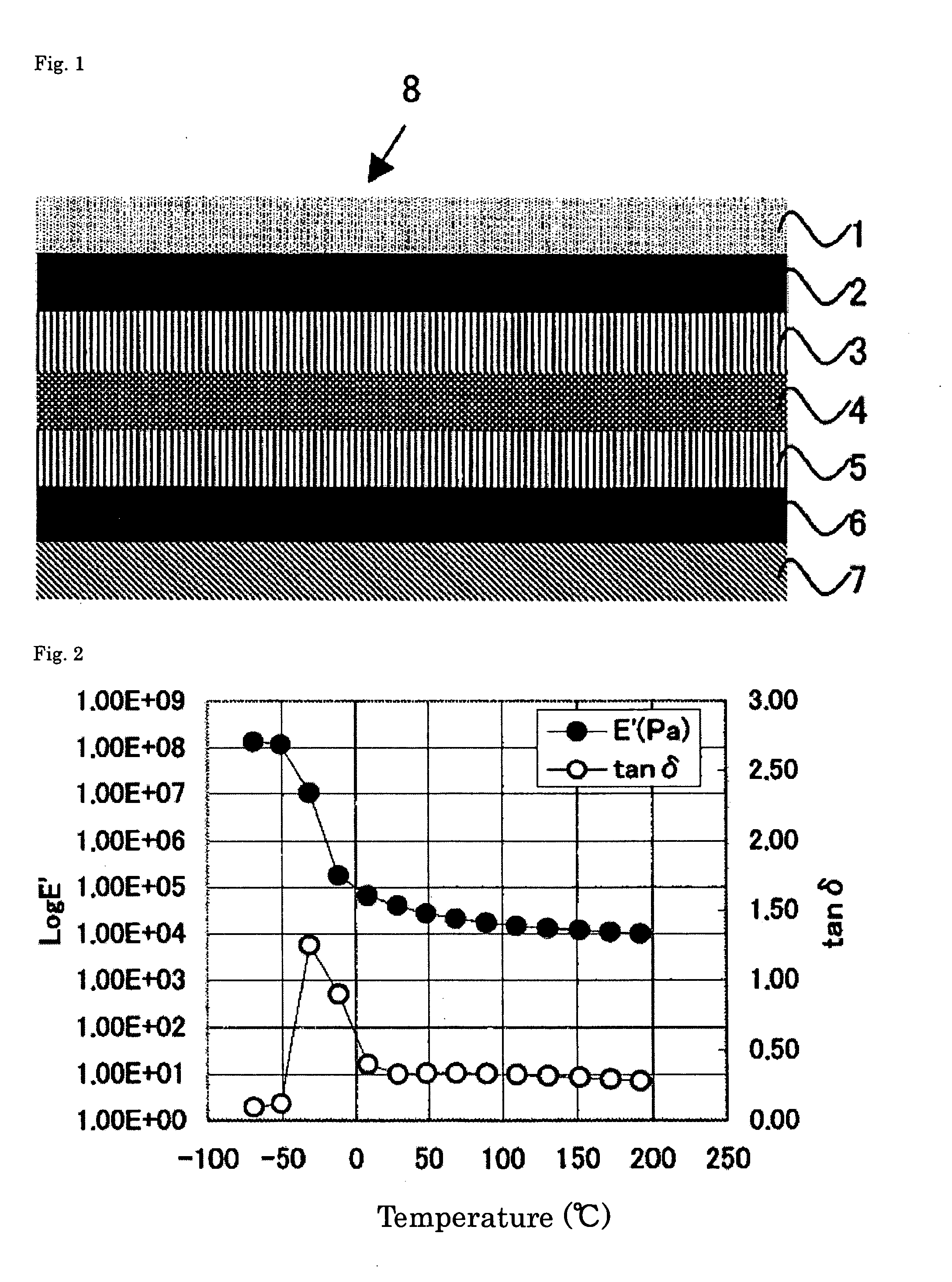

Optical laminate

ActiveUS20060062938A1Suppress light leakageIncreased durabilityLiquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayChemistry

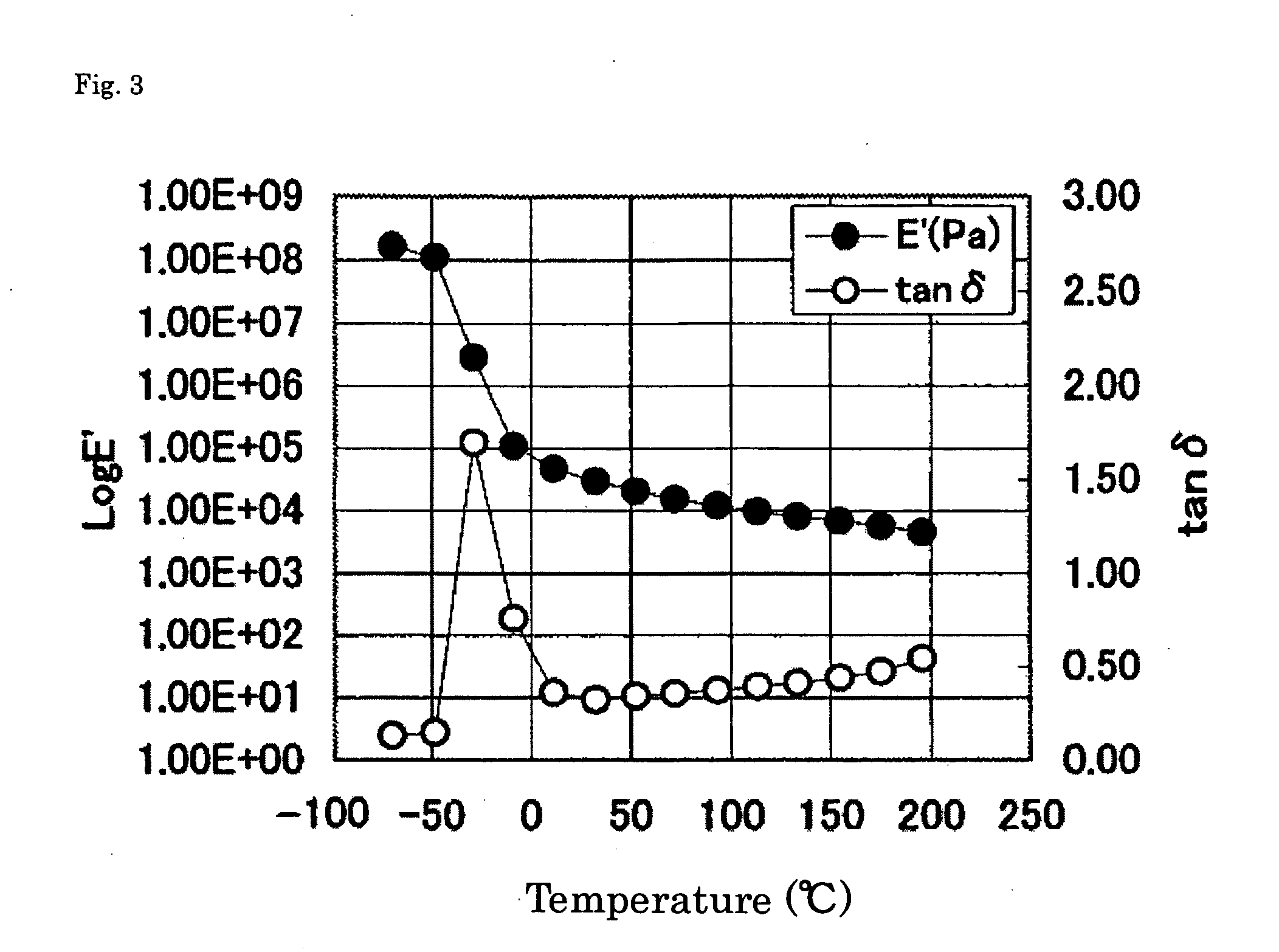

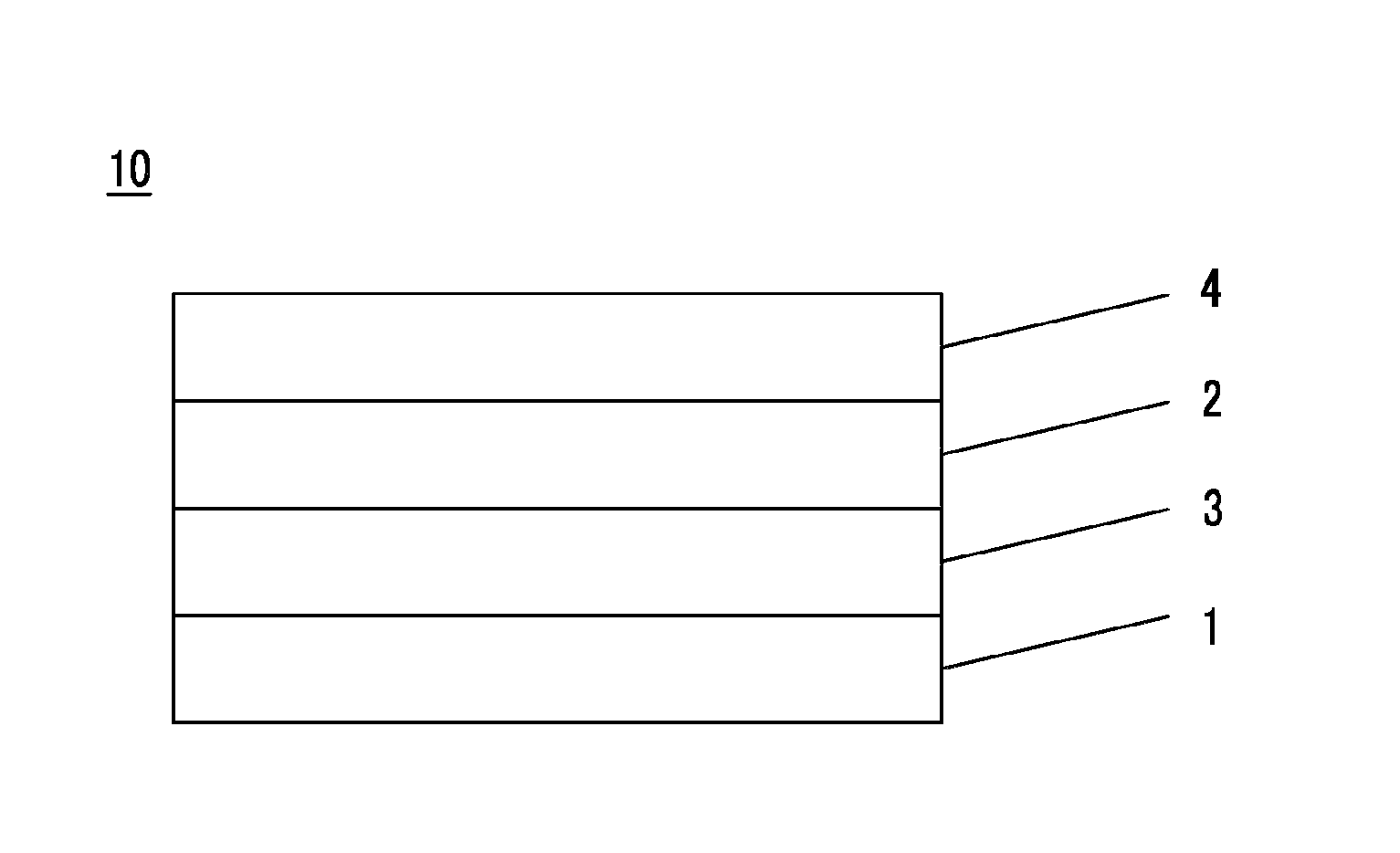

An optical laminate comprising an anti-reflection film 1, polarizing film 2, adhesive layer 3, glass cell for liquid crystal display 4, adhesive layer 5 and polarizing film 6 laminated sequentially, wherein the ratio (A / B) of the maximum value A of the loss tangent of the adhesive layer 3 to the maximum value B of the loss tangent of the adhesive layer 5 is 1.1 or more. The maximum value of the loss tangent means the maximum value of loss modulus (E″) / storage modulus (E′) (=tan δ), each measured by heating the adhesive layer in a temperature range of −70° C. to 200° C. at a temperature rising rate of 4° C. / min and a frequency of 1 Hz.

Owner:SUMITOMO CHEM CO LTD

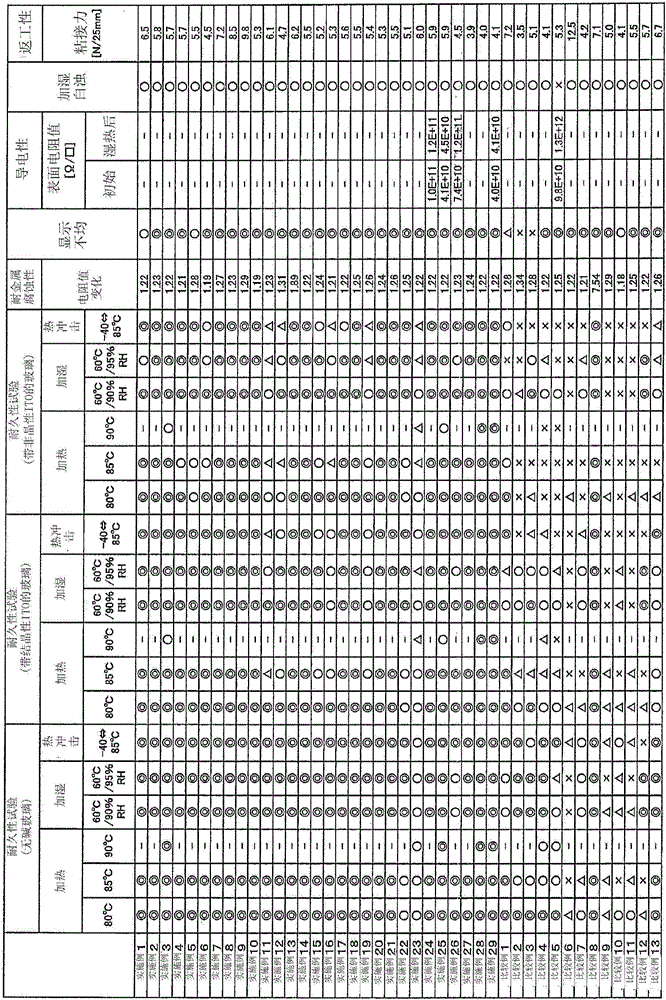

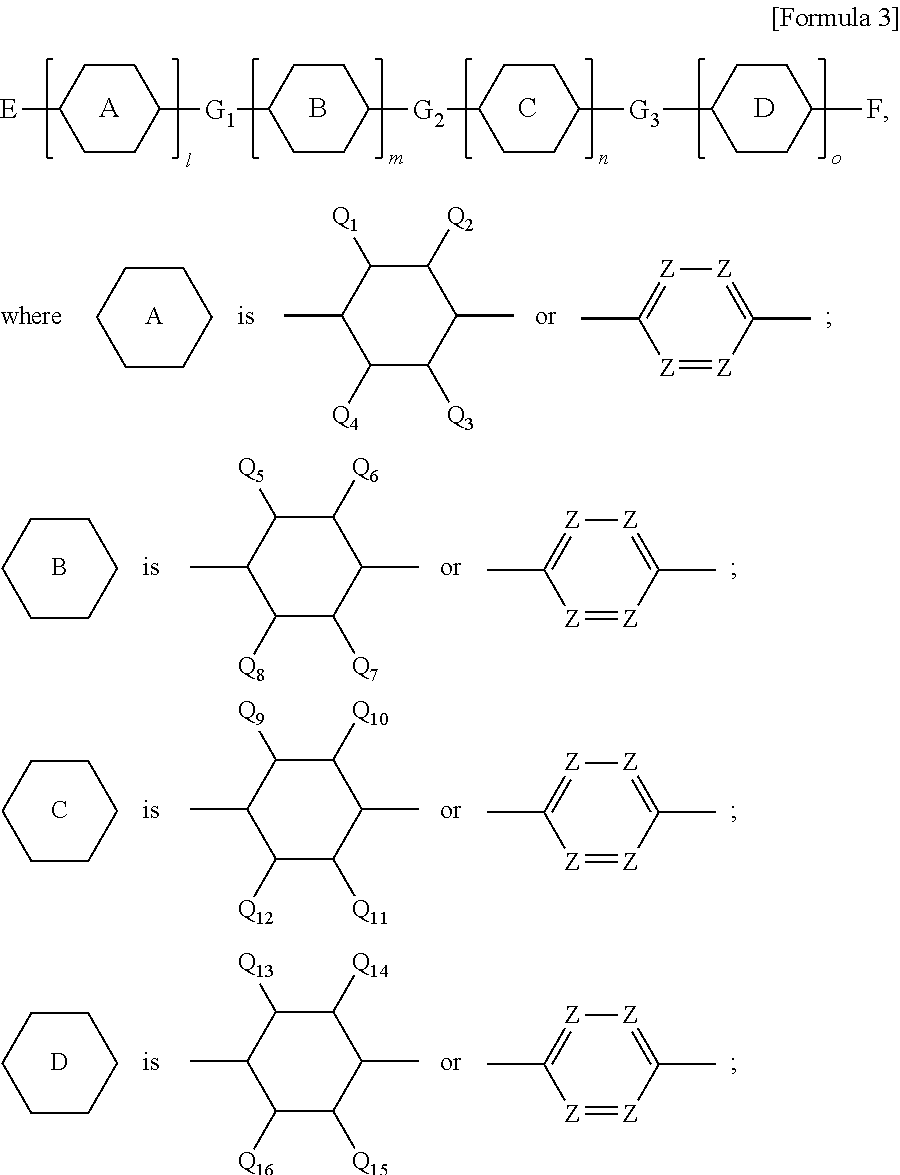

Pressure- sensitive adhesive compositions, polarizers and liquid crystal displays comprising the same

ActiveUS20110007244A1Excellent endurance reliabilityGood physical propertiesLayered productsPolyureas/polyurethane adhesivesDisplay devicePolarizer

The present invention relates to pressure-sensitive adhesive compositions which contain (A) hydroxyl group and alkylene oxide group containing acrylic copolymer and (B) a multifunctional isocyanate-based hardener, and form interpenetrating network structures when hardened, and polarizers and liquid crystal displays comprising the same. The pressure-sensitive adhesive compositions of the present invention exhibit superior durability, reliability, and workability and effectively prevent light leakage under high temperature and / or high humidity conditions. Particularly, the present invention provides pressure-sensitive adhesive compositions capable of significantly suppressing light leakage even in large size display devices, and polarizers and liquid crystal displays comprising the same.

Owner:LG CHEM LTD

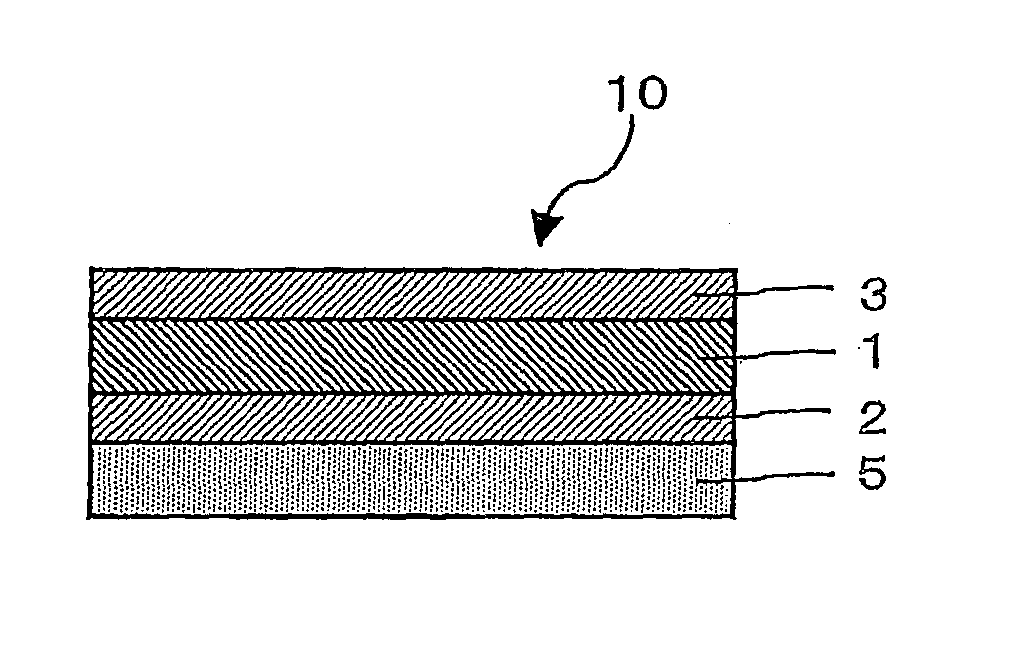

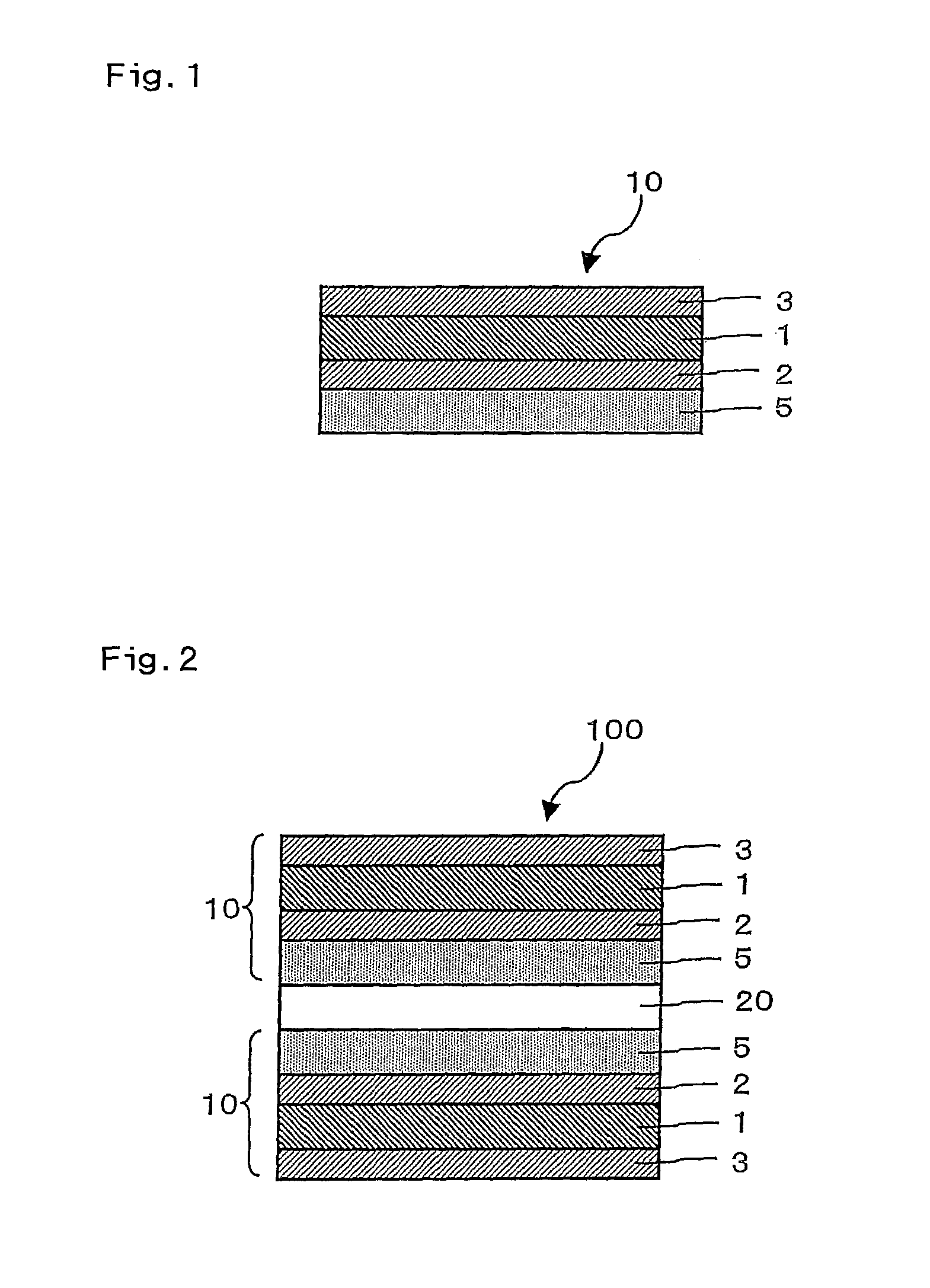

Polarizing plate and liquid crystal display

ActiveUS20140098331A1Suppress light leakageLow moisture permeabilityPolarising elementsNon-linear opticsCelluloseTectorial membrane

A polarizing plate according to the invention includes a first protective film; a polarizer; a second protective film; and an adhesive layer in this order, in which a moisture vapor permeability of the first protective film is less than or equal to 200 g / m2 / 24 hours, the second protective film contains cellulose acylate as a major component, a creep amount of the adhesive layer is less than 100 μm, and a shrinkage force of the polarizing plate in an absorption axis direction thereof which is represented by the following expression (A) is lower than or equal to 2000 N / m. Expression (A) is the Shrinkage Force (N / m) of Polarizing Plate in Absorption Axis Direction=Elastic Modulus (GPa) of Polarizing Plate in Absorption Axis Direction×|Humidity Dimensional Change Rate (%) of Polarizing Plate in Absorption Axis Direction|×Thickness (μm) of Polarizing Plate×10.

Owner:FUJIFILM CORP

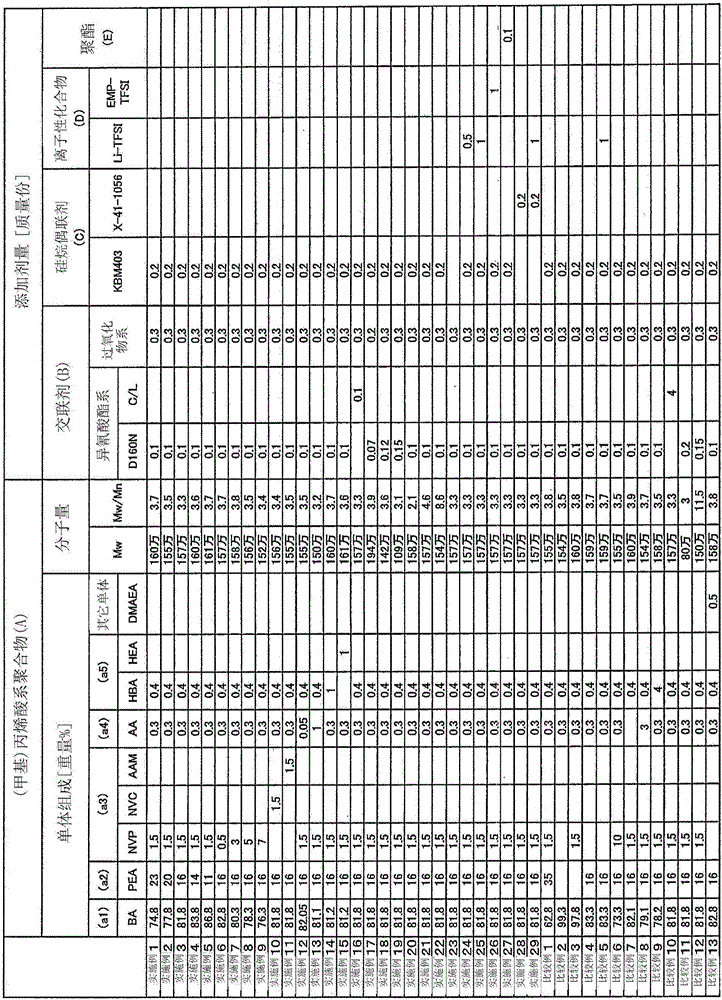

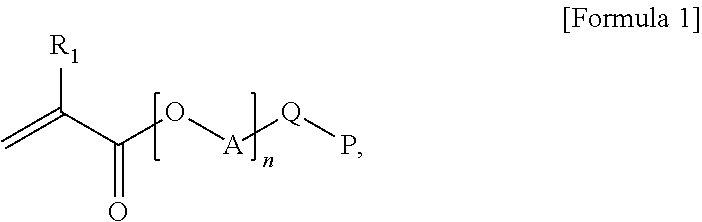

Pressure sensitive adhesives for optical film, manufacturing methods for pressure sensitive adhesive layer for optical film, pressure sensitive adhesive layers for optical film, pressure sensitive adhesion type optical films and image displays

ActiveUS20060121273A1Suppressing bowingSuppress light leakagePolyureas/polyurethane adhesivesSynthetic resin layered productsMeth-Hydroxy group

It is an object of the invention to provide a pressure sensitive adhesive for an optical film with which a pressure sensitive adhesive type optical film capable of suppressing bowing and light leakage caused by a stress accompanying a dimensional change of members such as an optical film, high in durability, excellent in handling ability in an aspect of a fabrication process thereof and good in quality can be obtained. There is provided a pressure sensitive adhesive for an optical film comprising: 100 parts by weight of a (meth)acrylic-based polymer (A) including an alkyl (meth)acrylate (a1) and a (meth)acrylic-based monomer containing a hydroxyl group (a2), as a copolymerizable component, in content in the range of from 0.01 to 5 parts by weight relative to 100 parts by weight of the alkyl (meth)acrylate (a1); 0.02 to 2 parts by weight of a peroxide (B); and 0.001 to 2 parts by weight of an isocyanate-based compound (C), the contents of the peroxide (B) and the isocyanate-based compound (C) being values relative to 100 parts by weight of the (meth)acrylic-based polymer (A).

Owner:NITTO DENKO CORP

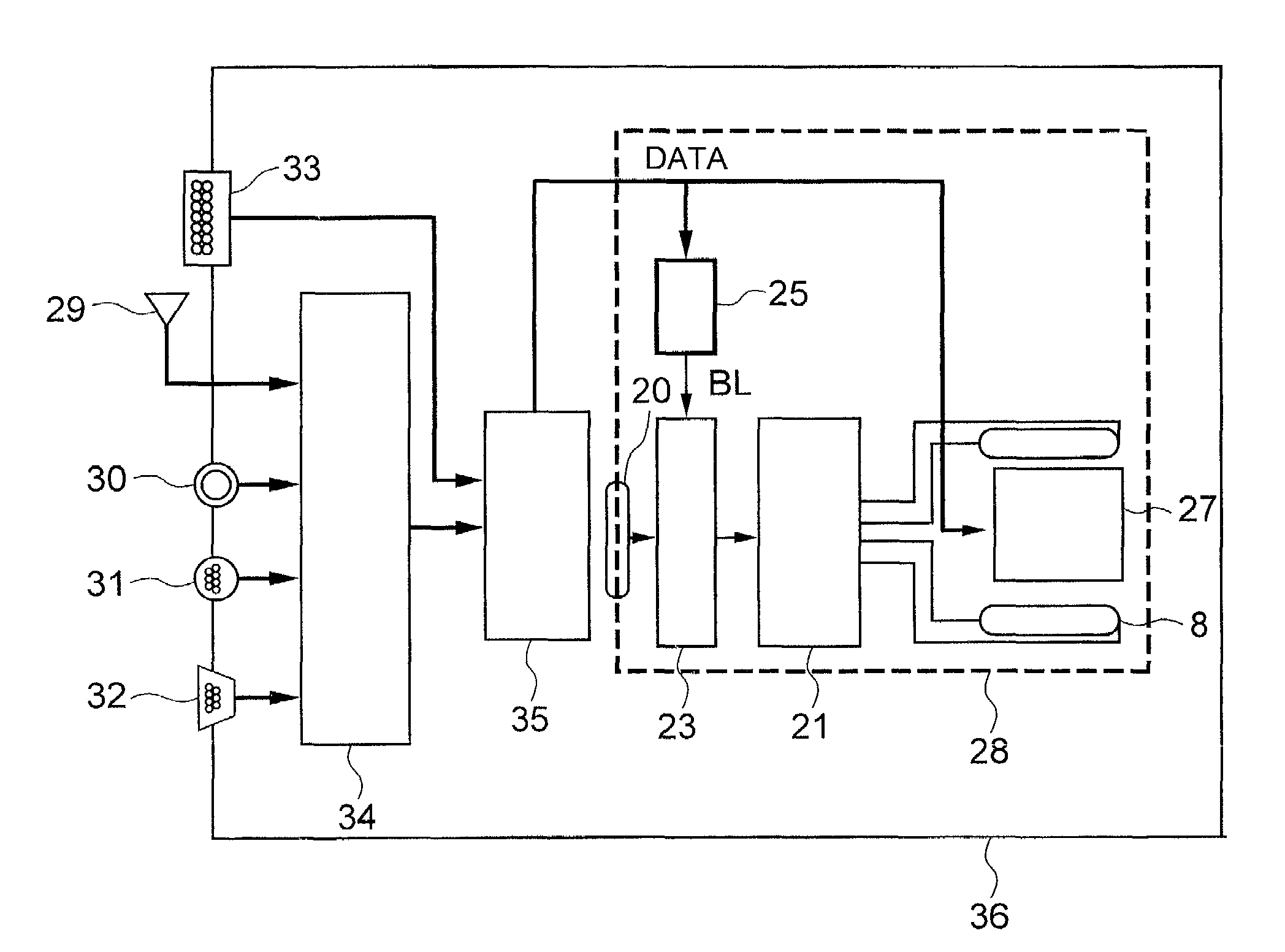

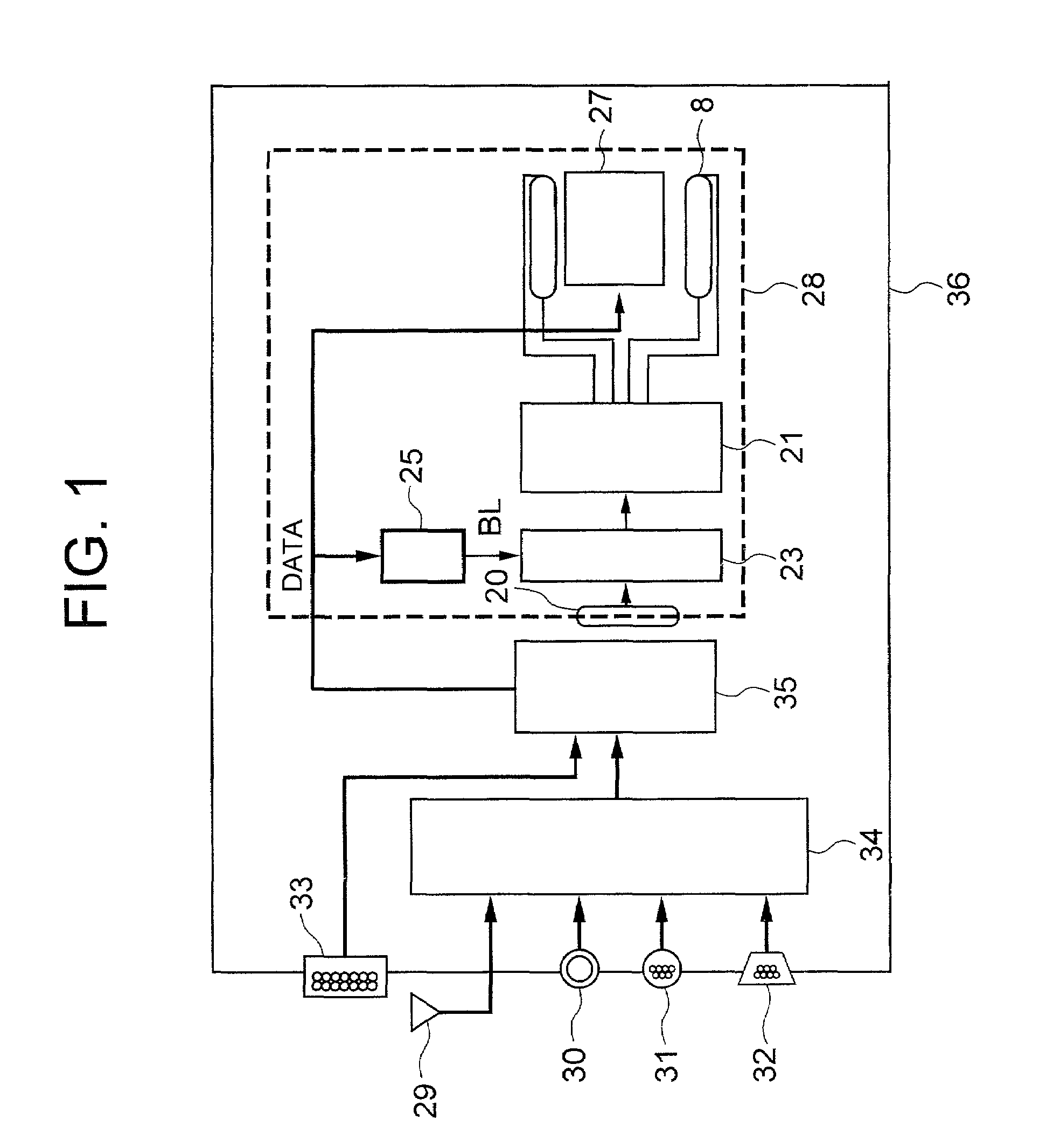

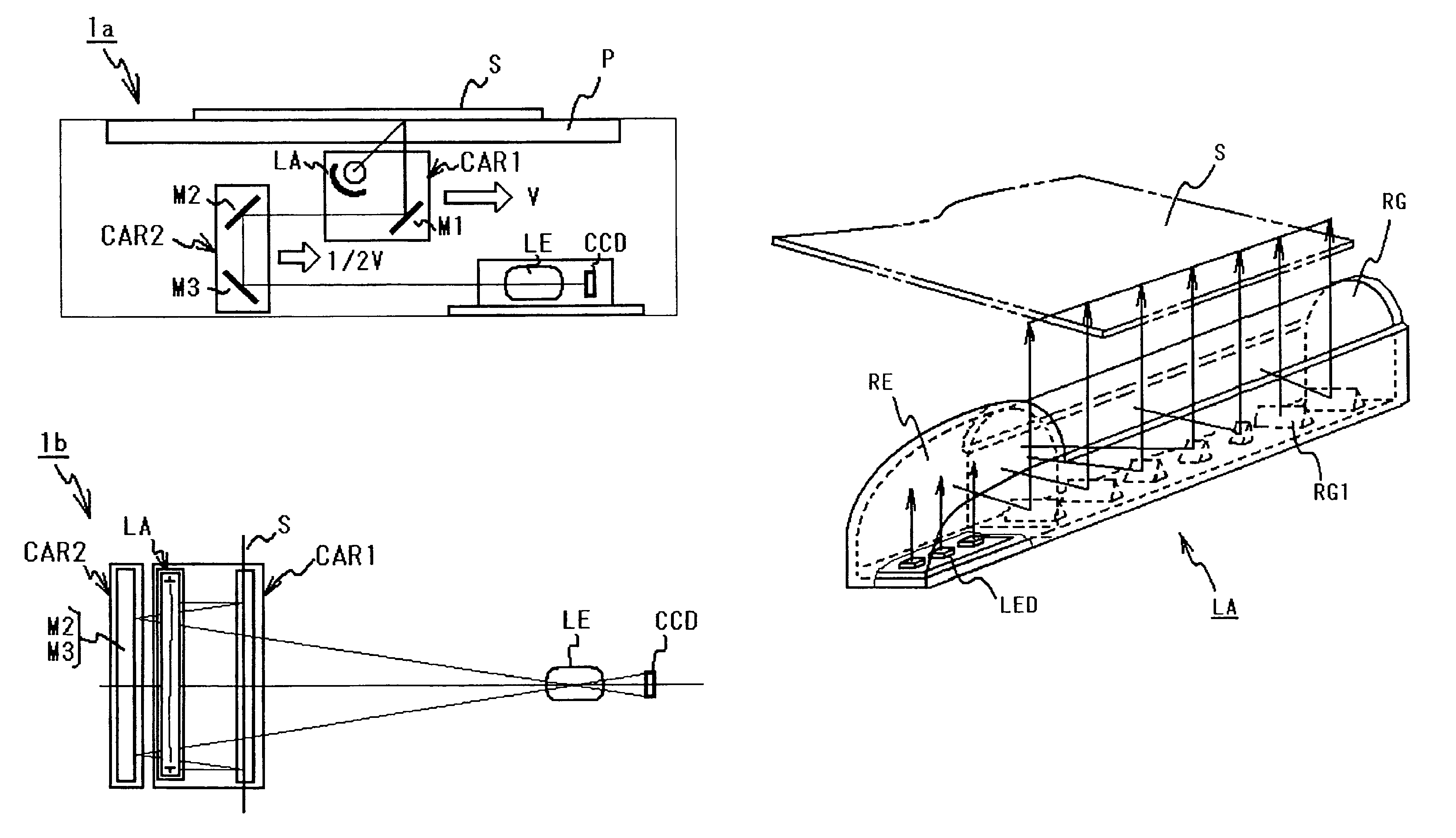

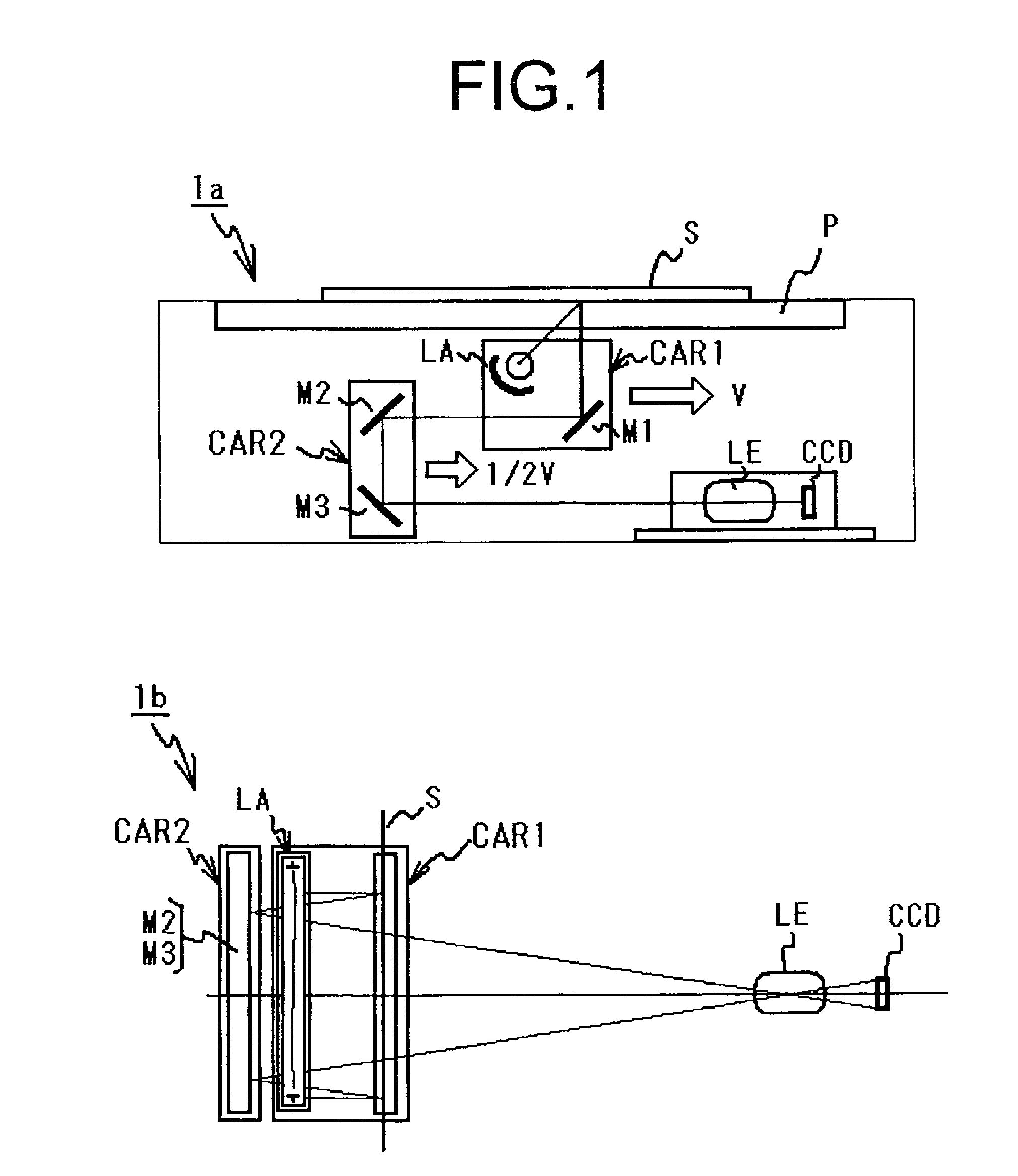

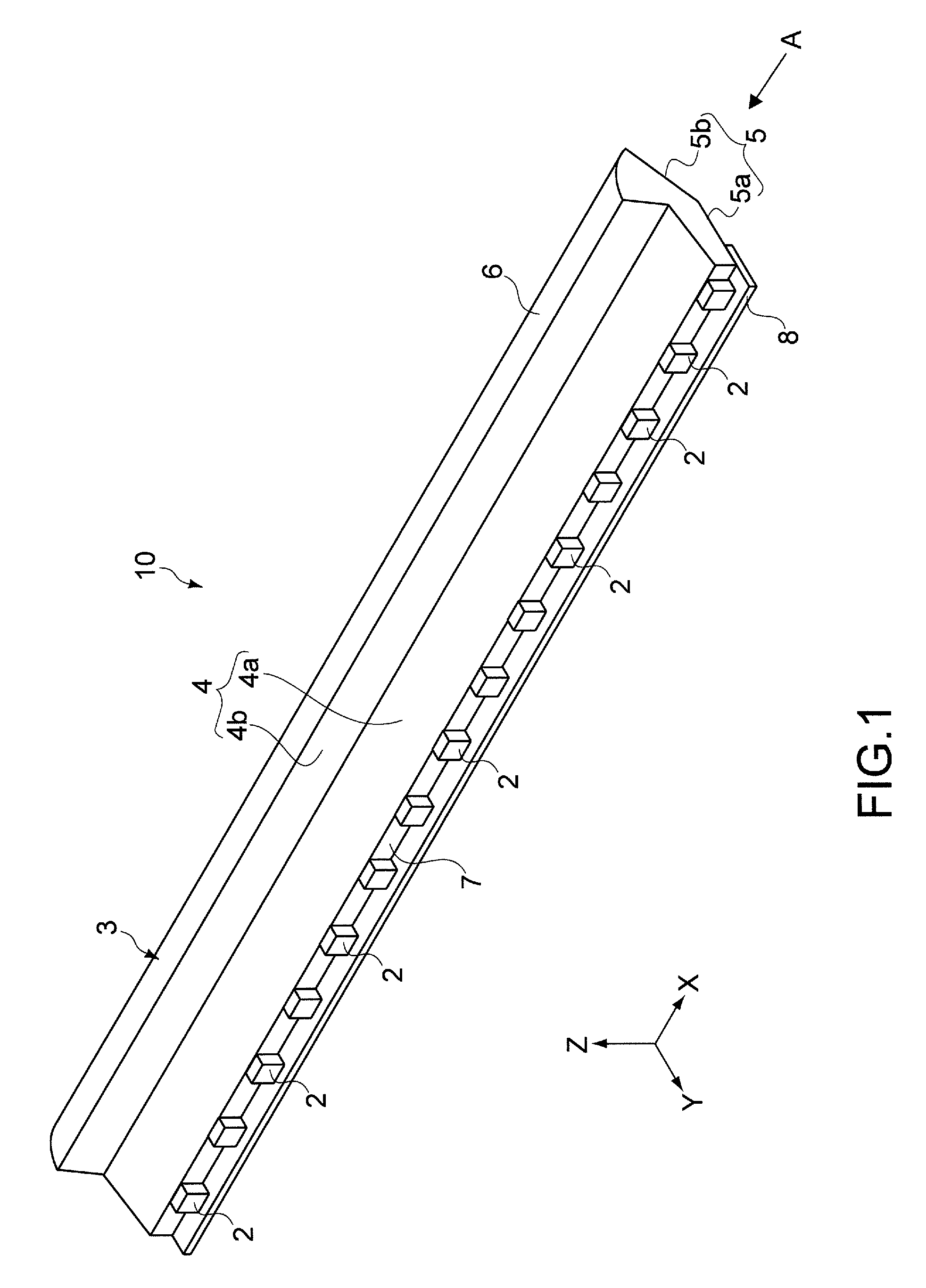

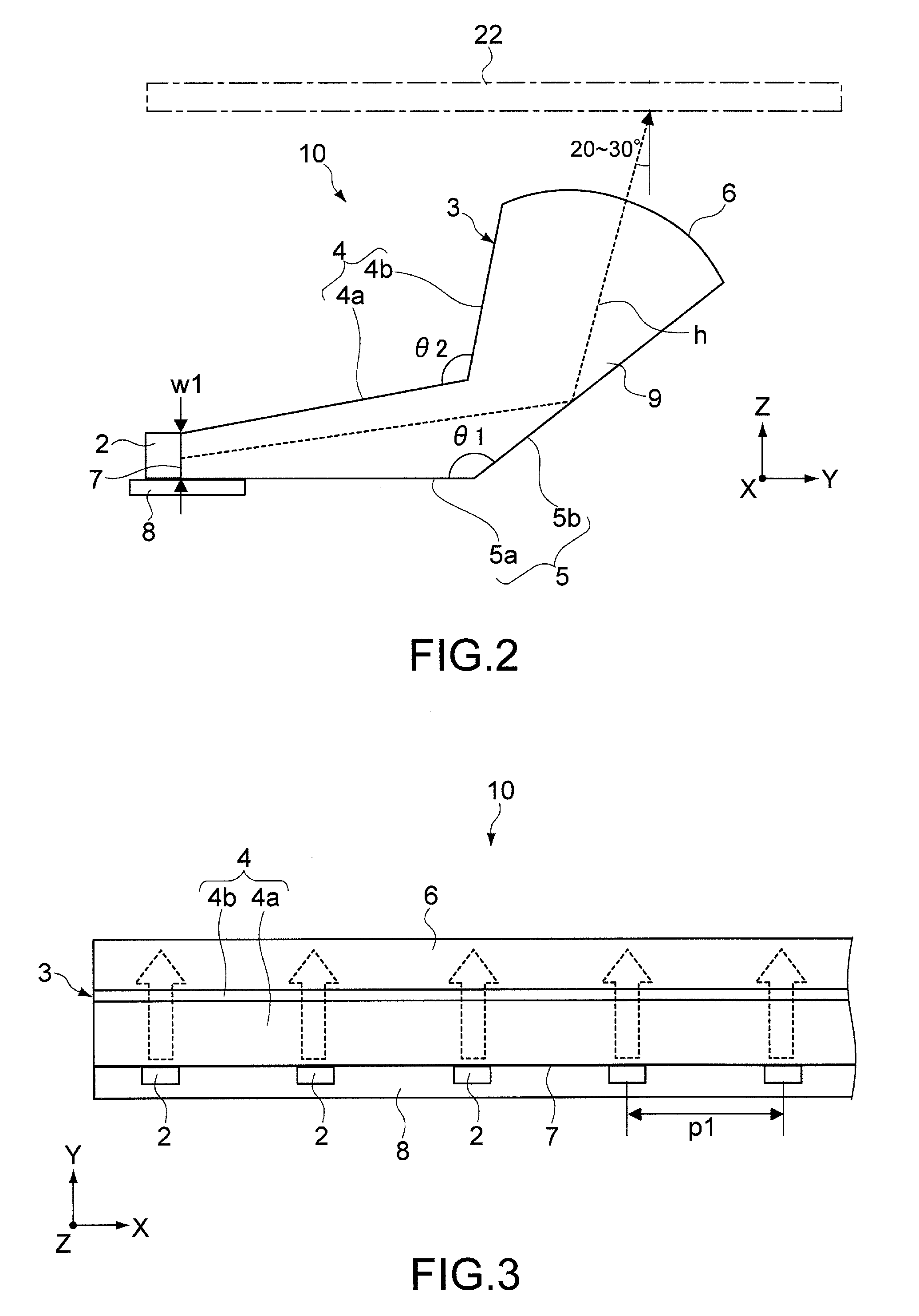

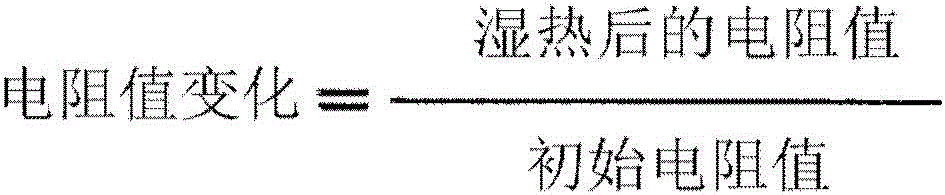

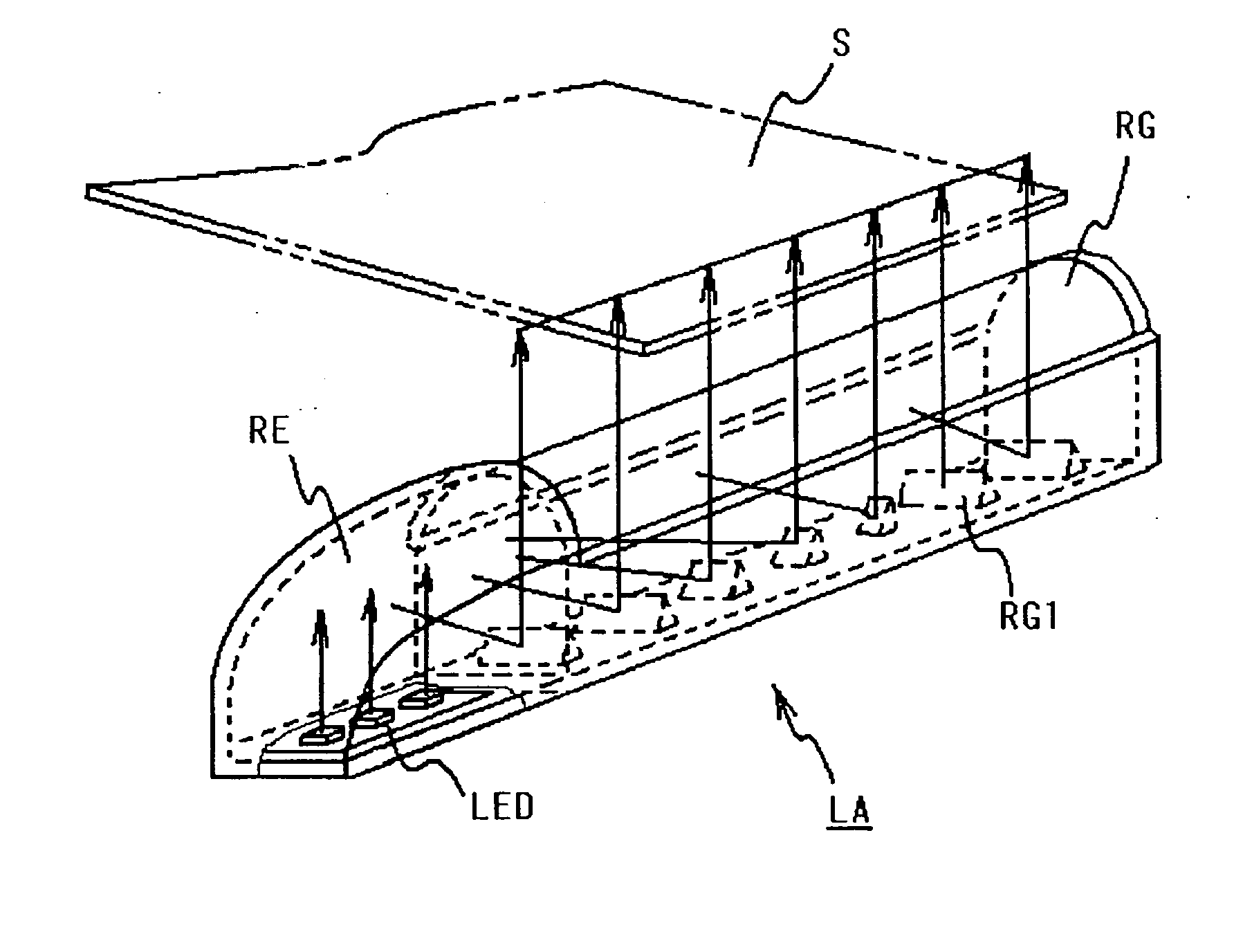

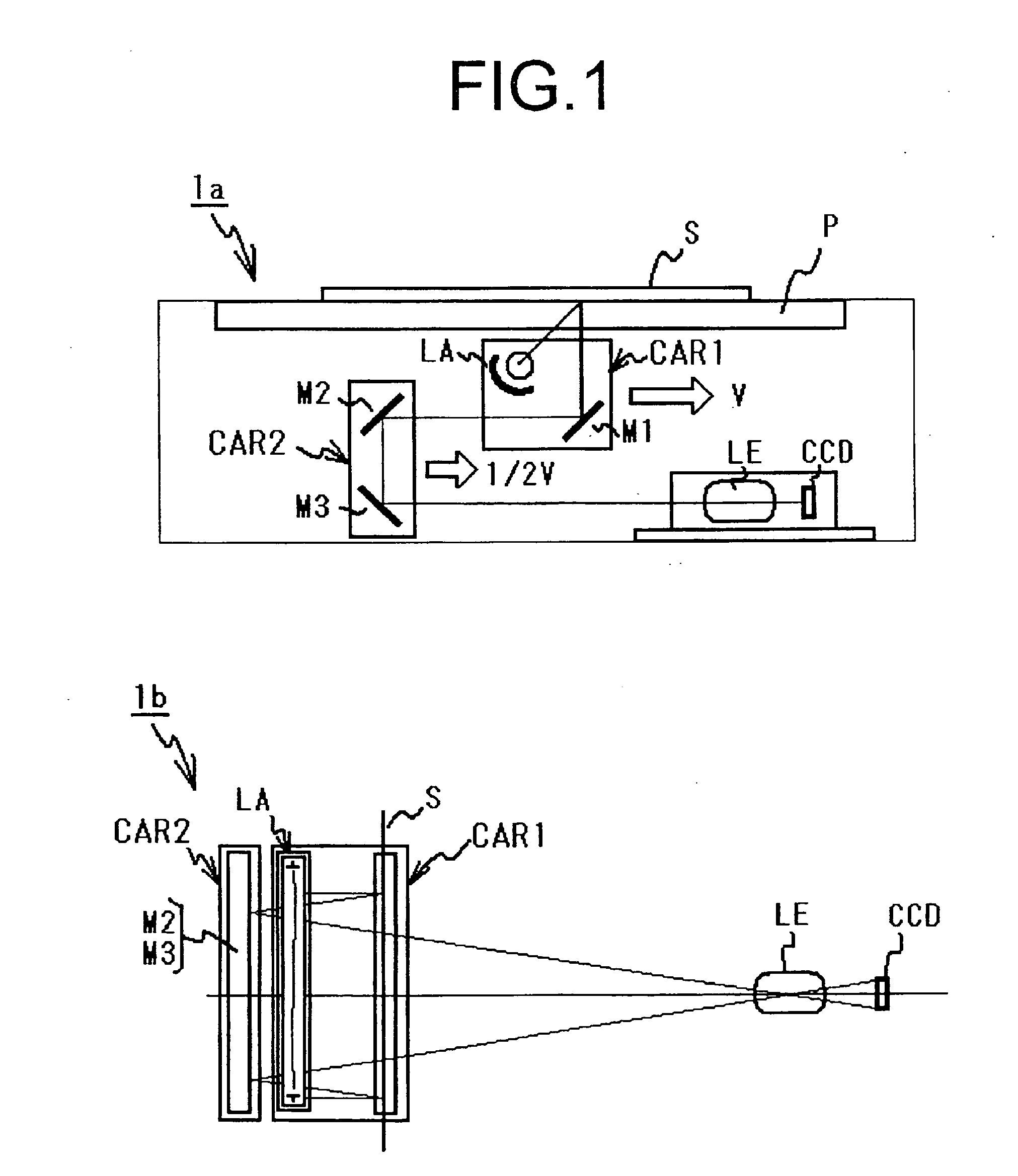

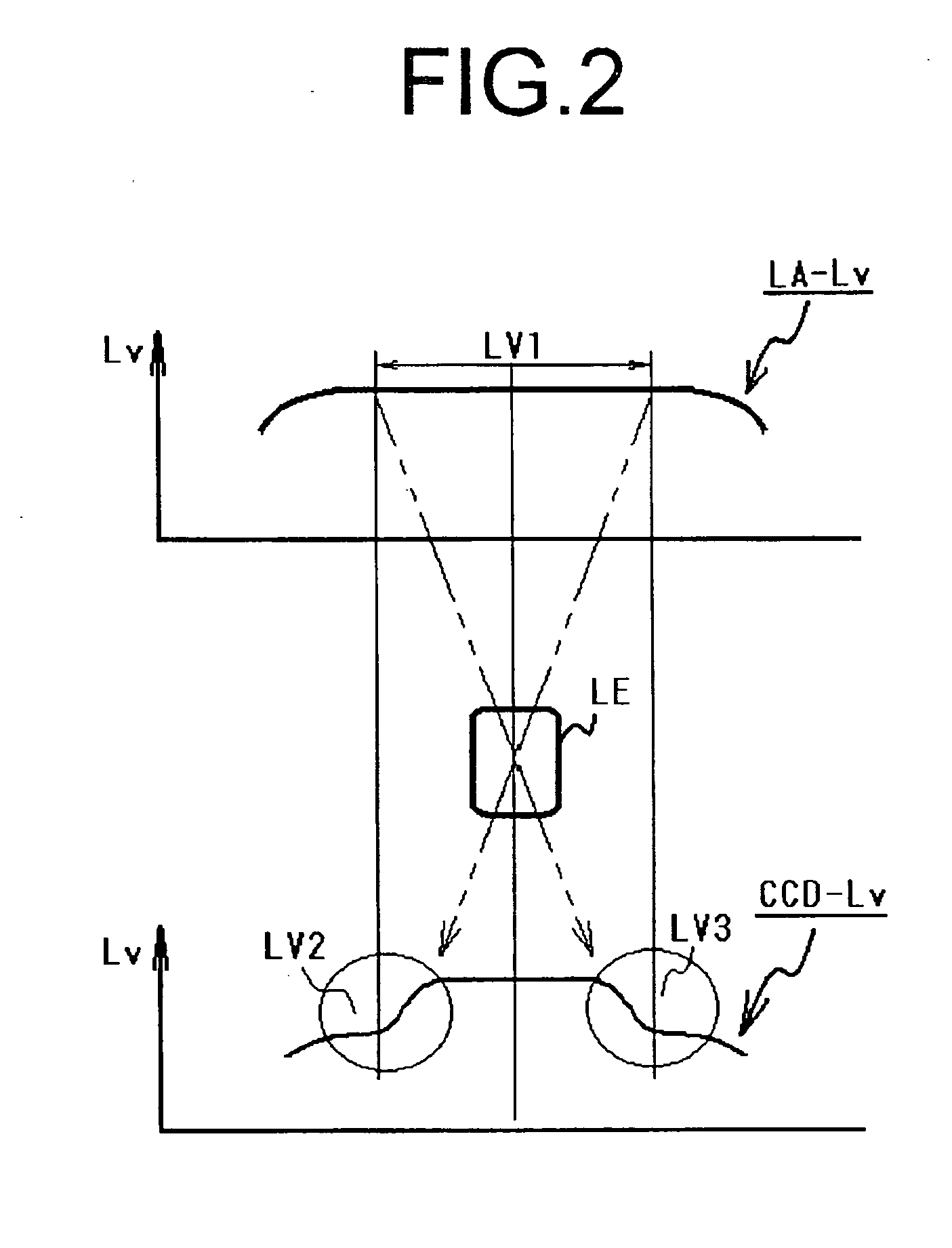

LED light source and image reading apparatus

InactiveUS8488216B2Suppress light leakageIncrease production capacityOptical light guidesSpectral modifiersLight guideOptoelectronics

An LED light source device installed in an image reading apparatus, includes an LED that is a light-emitting source; and a light guide for reflecting light of the LED by an inner surface thereof to diffuse along a main scanning line direction and irradiating the light reflected by the light guide to a surface of a sheet. The light guide has a plurality of reflecting surface bodies spaced at predetermined pitches in the main scanning line direction inside an inner surface reflection optical path to reflect the light from the LED toward an outside along the main scanning line direction. The plurality of reflecting surface bodies includes a first reflecting surface body and a second reflecting surface body, and a length in a perpendicular direction to the main scanning line direction of the second reflecting surface body is different from that of the first reflecting surface body.

Owner:NISCA KK

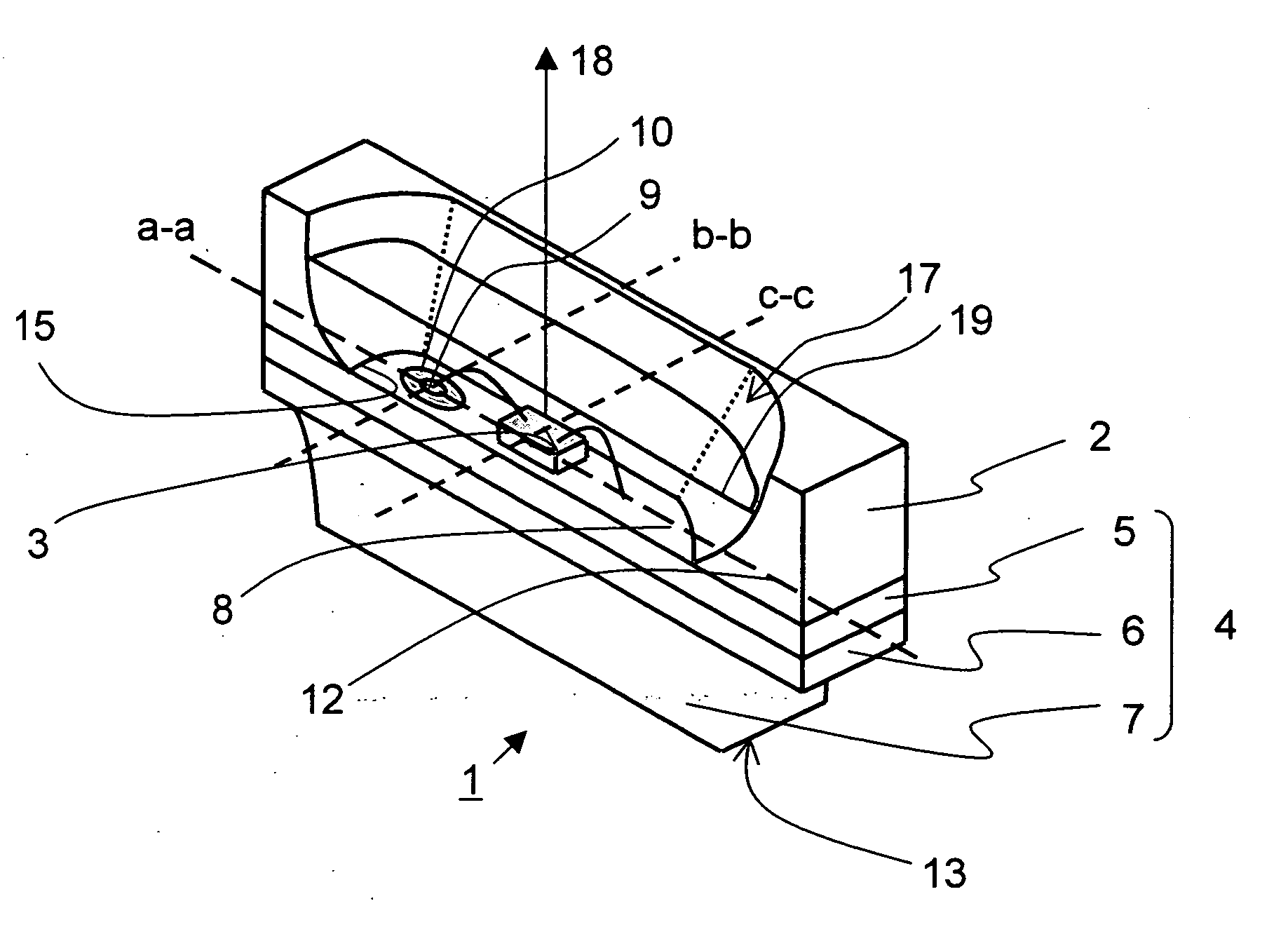

Light guide, light source apparatus, and electronic apparatus

InactiveUS7717598B2Effective guidanceSuppress light leakageMechanical apparatusLighting support devicesLight guideLight emitting device

A light guide is disclosed. The light guide includes an incident surface, an exit surface, and a light guide section. Light emitted from a plurality of light emitting devices disposed in line enters from the incident surface. The exit surface is formed in a shape causing light to be concentrated. The light which has entered from the incident surface exits from the exit surface. The light guide section is bent. The volume of the light guide gradually increases in a direction from the incident surface to the exit surface.

Owner:SONY CORP

Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

ActiveCN106133096AIncreased durabilityPrevent peelingNon-macromolecular adhesive additivesPolarising elementsPolymer scienceMeth-

An adhesive agent composition for optical films, which comprises: a (meth)acrylic polymer (A) that contains, as monomer units, 70% by weight or more of an alkyl (meth)acrylate (a1), 3 to 25% by weight of an aromatic-ring-containing (meth)acrylate (a2), 0.1 to 8% by weight of an amide-group-containing monomer (a3), 0.01 to 2% by weight of a carboxyl-group-containing monomer (a4) and 0.01 to 3% by weight of a hydroxyl-group-containing monomer (a5) and meets such requirements that the weight average molecular weight (Mw) is 1,000,000 to 2,500,000 and the Mw / (number average molecular weight (Mn)) ratio is 1.8 to 10 inclusive; and a cross-linking agent (B) in an amount of 0.01 to 3 parts by weight relative to 100 parts by weight of the (meth)acrylic polymer (A). The adhesive agent composition can be formed into an adhesive agent layer which satisfies durability to such an extent that the adhesive agent layer does not undergo foaming, is not detached or does not get clouded under humidified conditions when applied onto a glass or a transparent conductive layer, and which can prevent the occurrence of display unevenness due to leakage of light, and which has excellent metal corrosion resistance.

Owner:NITTO DENKO CORP

Optical film, method for manufacturing the same, and phase difference film and polarizing plate using the same

ActiveUS20050074564A1Excellent display qualitySuppress light leakageLiquid crystal compositionsPolarising elementsPolarizerChemistry

A method for preparing an optical film, which comprises applying and developing an application liquid mixture containing a liquid crystal monomer, a chiral agent and a polymerization initiator on an orientation substrate, subjecting the resultant developed layer to a heat treatment, to orient the monomer to a cholesteric structure, and then subjecting the developed layer to a poltmerization treatment, to polymerize the oriented liquid crystal monomer, thereby forming an optical film exhibiting a selective reflection wave length of 100 to 320 nm. An optical film prepared by the above method is reduced in the coloring due to selective reflection.

Owner:NITTO DENKO CORP

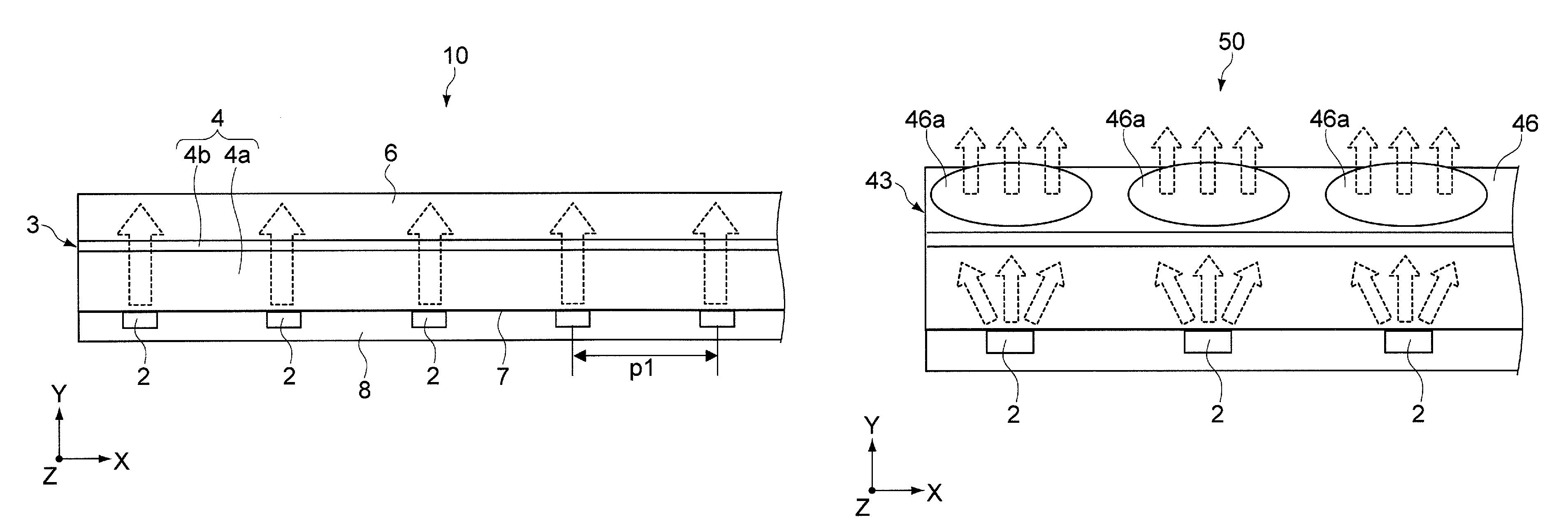

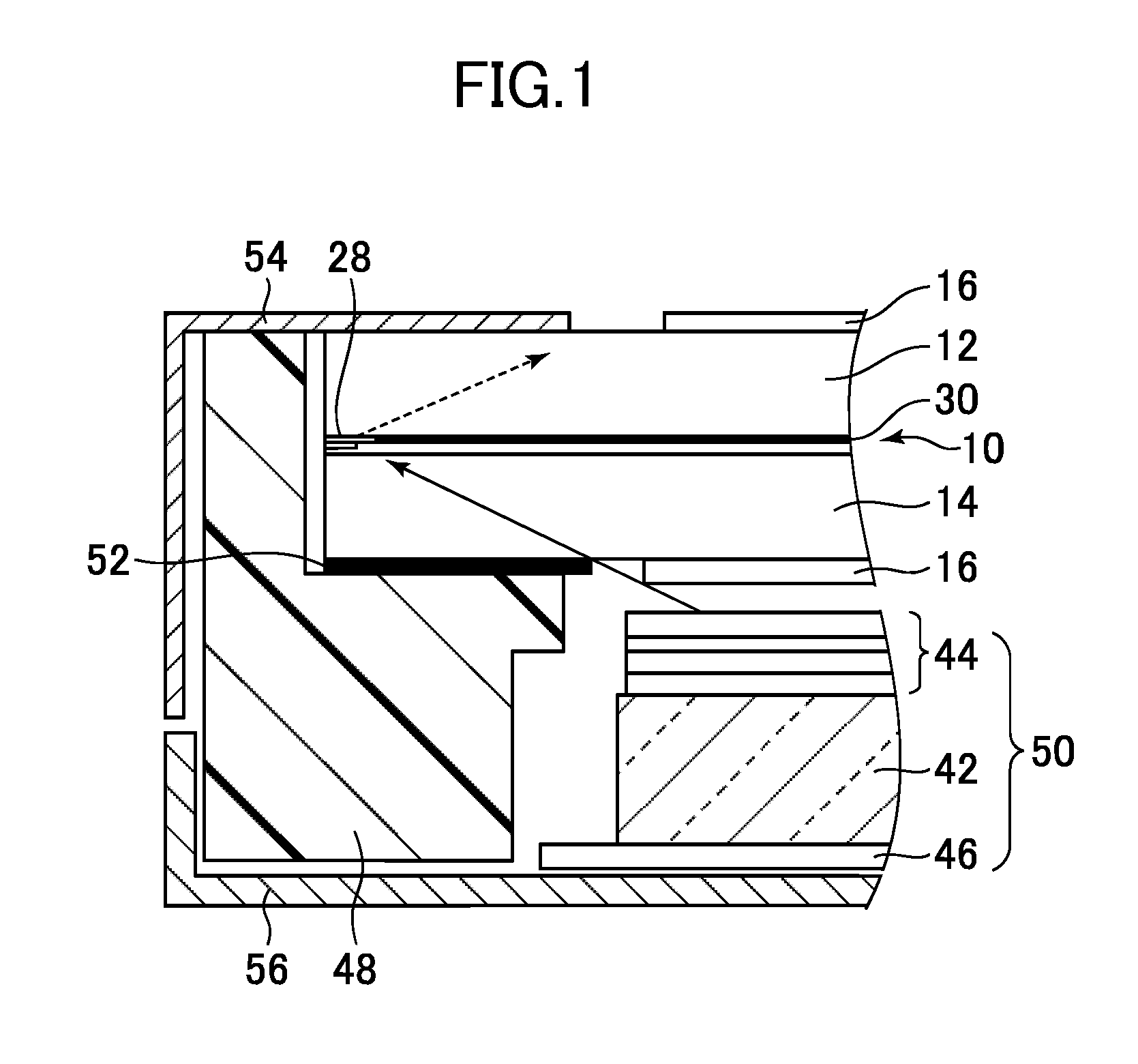

Liquid crystal display unit having a field sequential driven backlight unit

ActiveUS7286193B2Improve display performanceSuppress light leakageMechanical apparatusStatic indicating devicesLiquid-crystal displayEngineering

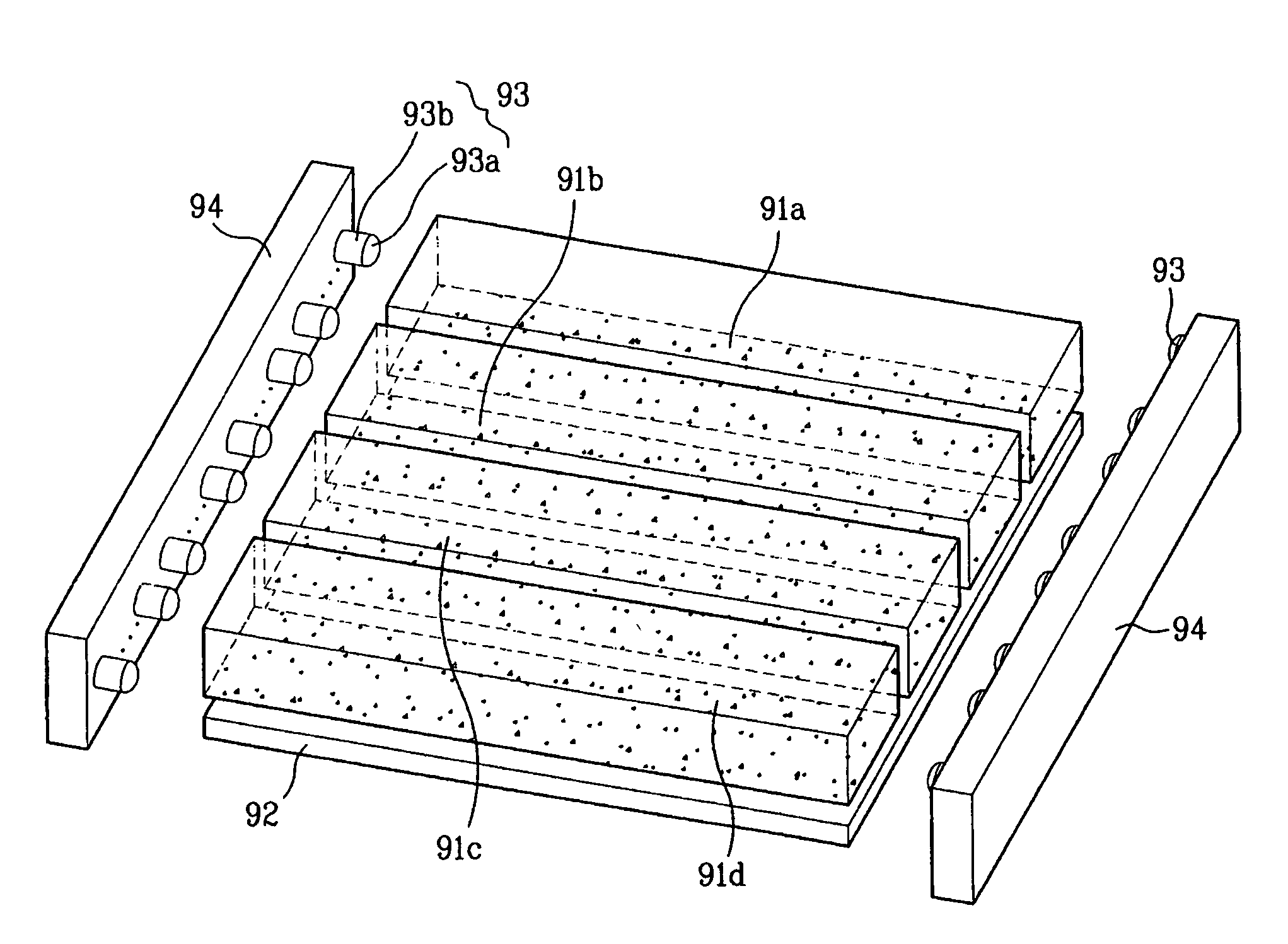

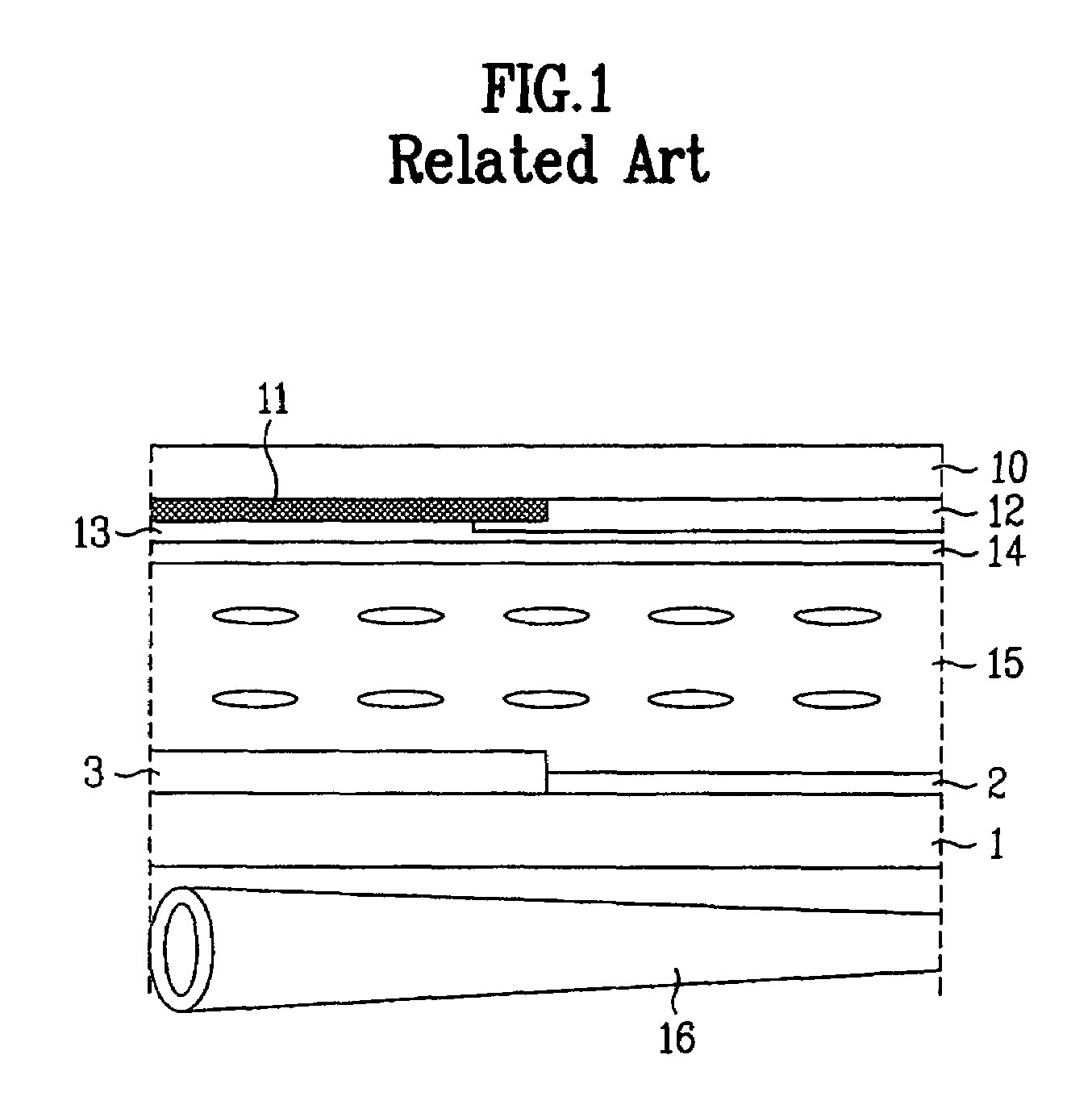

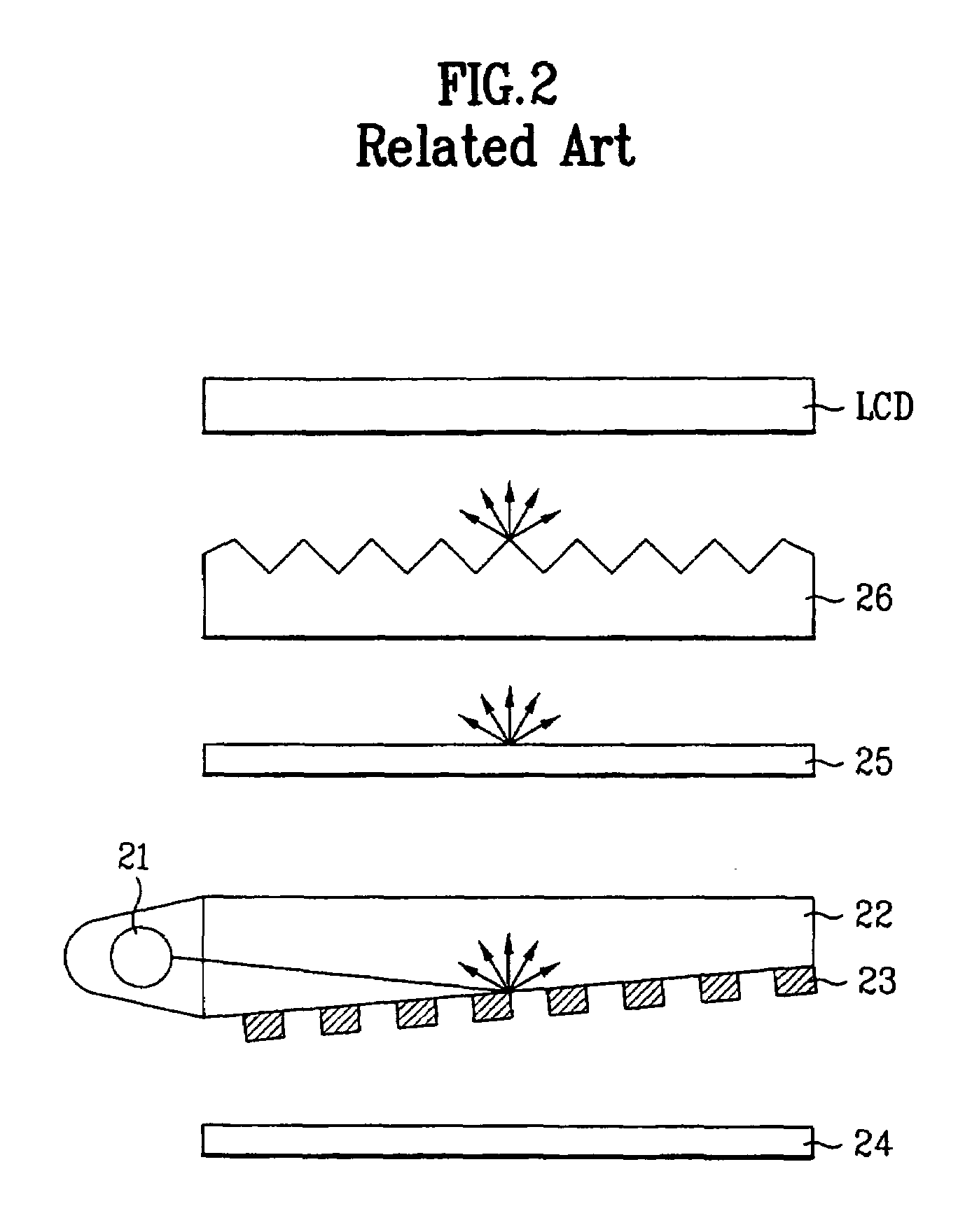

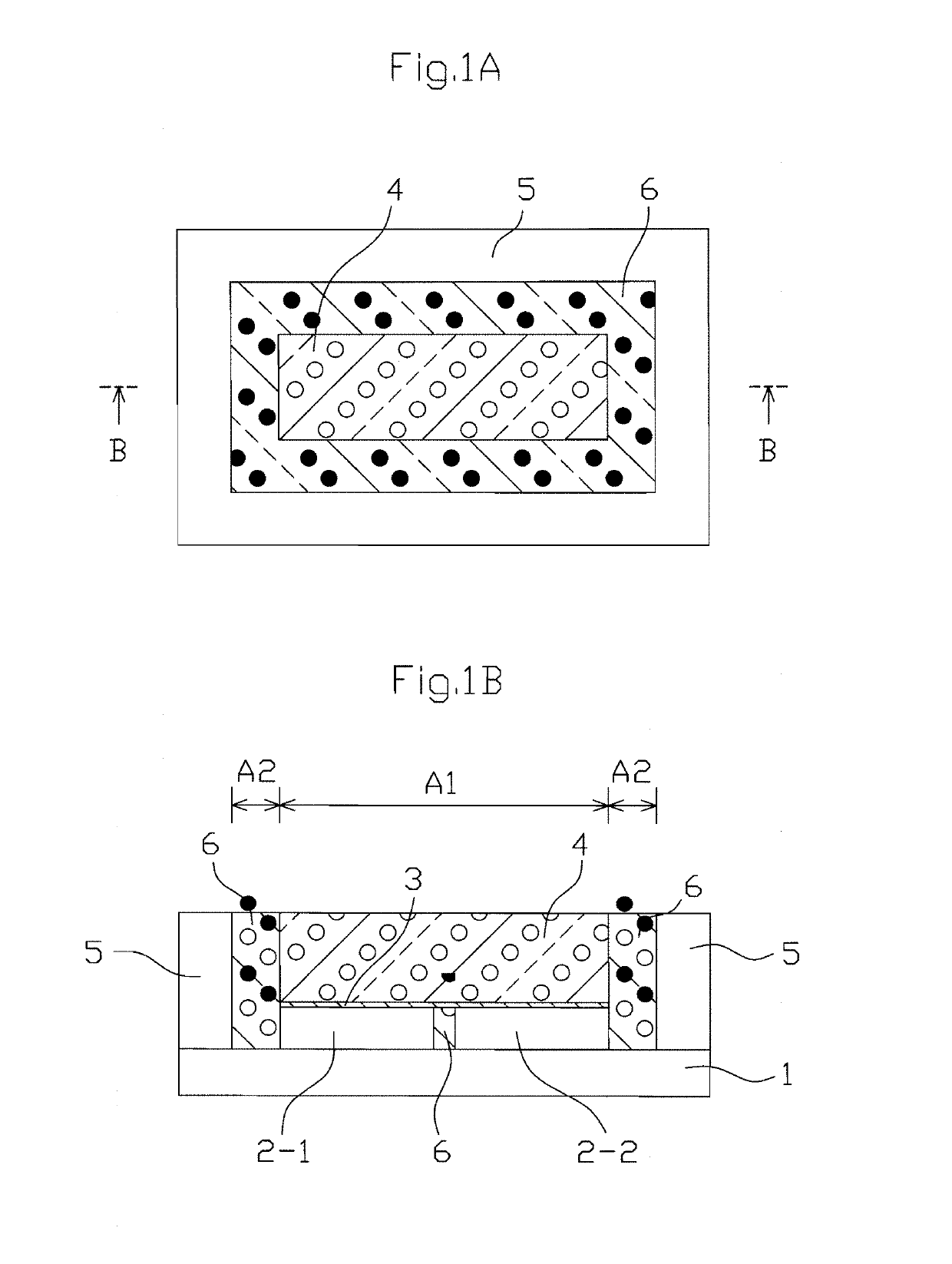

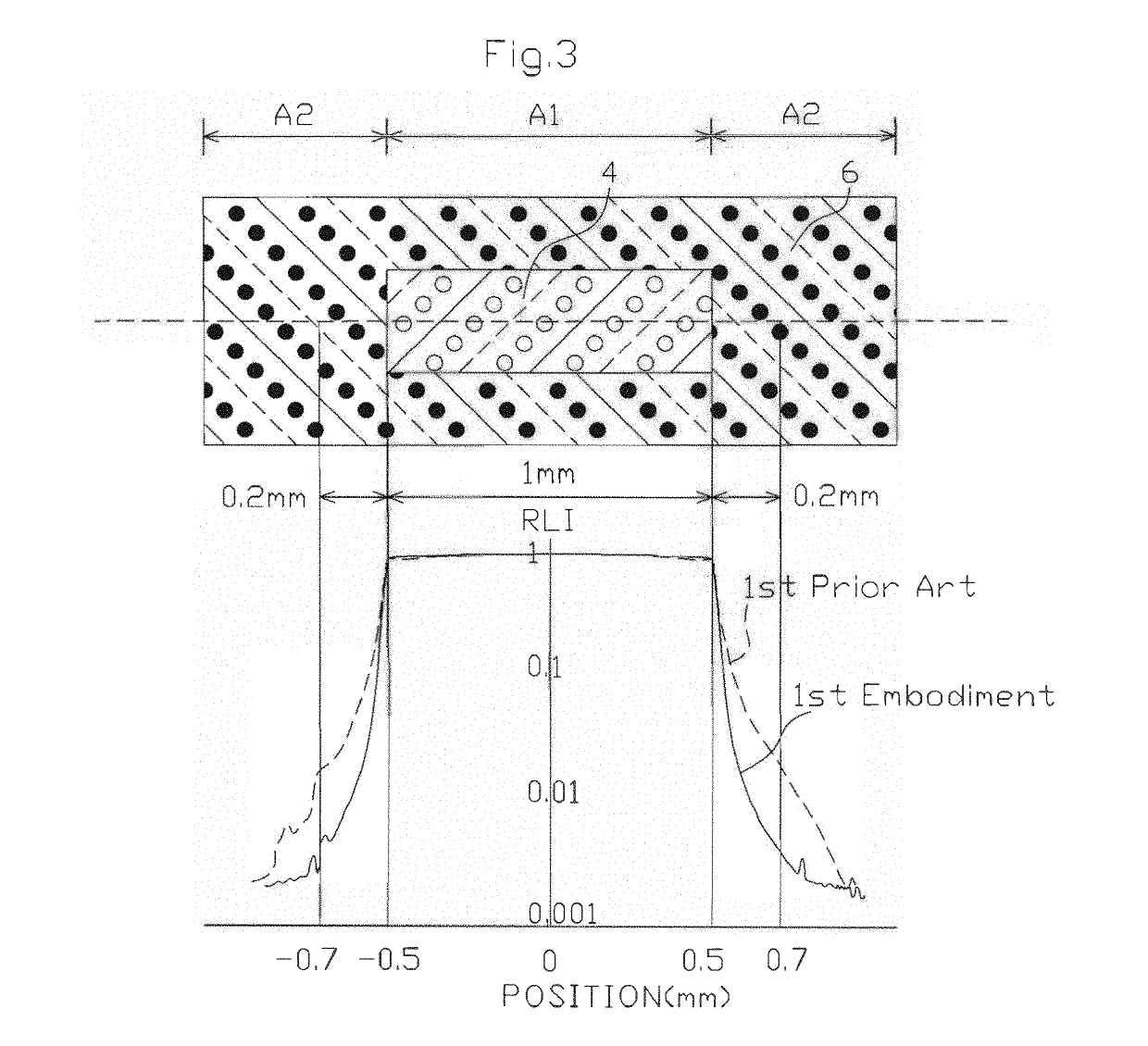

A backlight unit for a display device and a liquid crystal display device using the backlight unit suppresses light leakage to a neighboring region with a display area that is divided and driven by a DDAM (Divided Display Area Method). The backlight unit in one aspect includes a main light guide plate defined by an n number of regions for a field sequential driving, auxiliary light guide plates arranged below edges of the main light guide plate, first and second reflection plates arranged below the main light guide plate and the auxiliary light guide plate, a plurality of light source parts arranged at a predetermined interval at both sides of the auxiliary light guide plate, and a housing configured to enclose a side of the main light guide plate, the auxiliary light guide plate and side and lower portion of the light source parts.

Owner:LG DISPLAY CO LTD

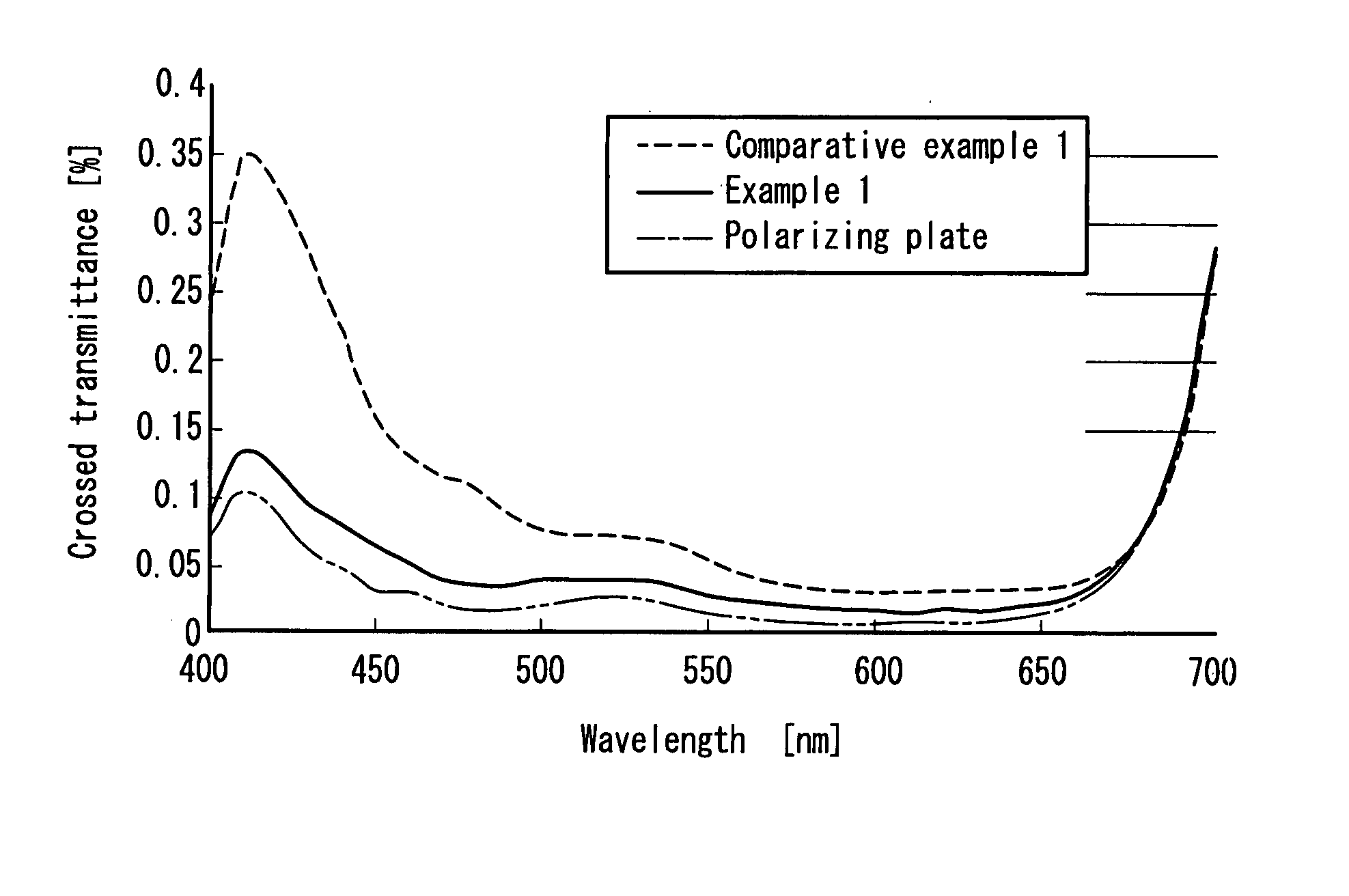

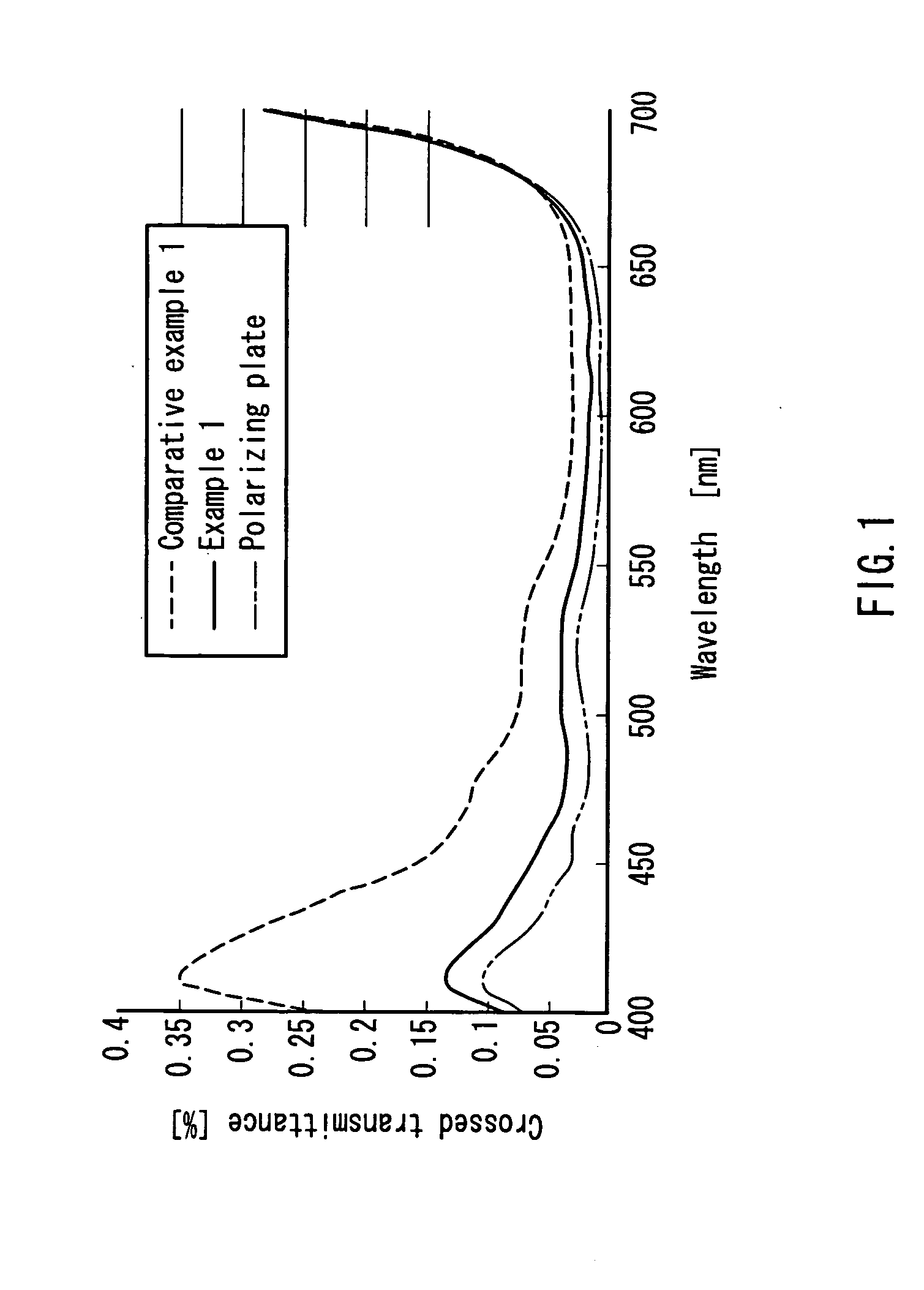

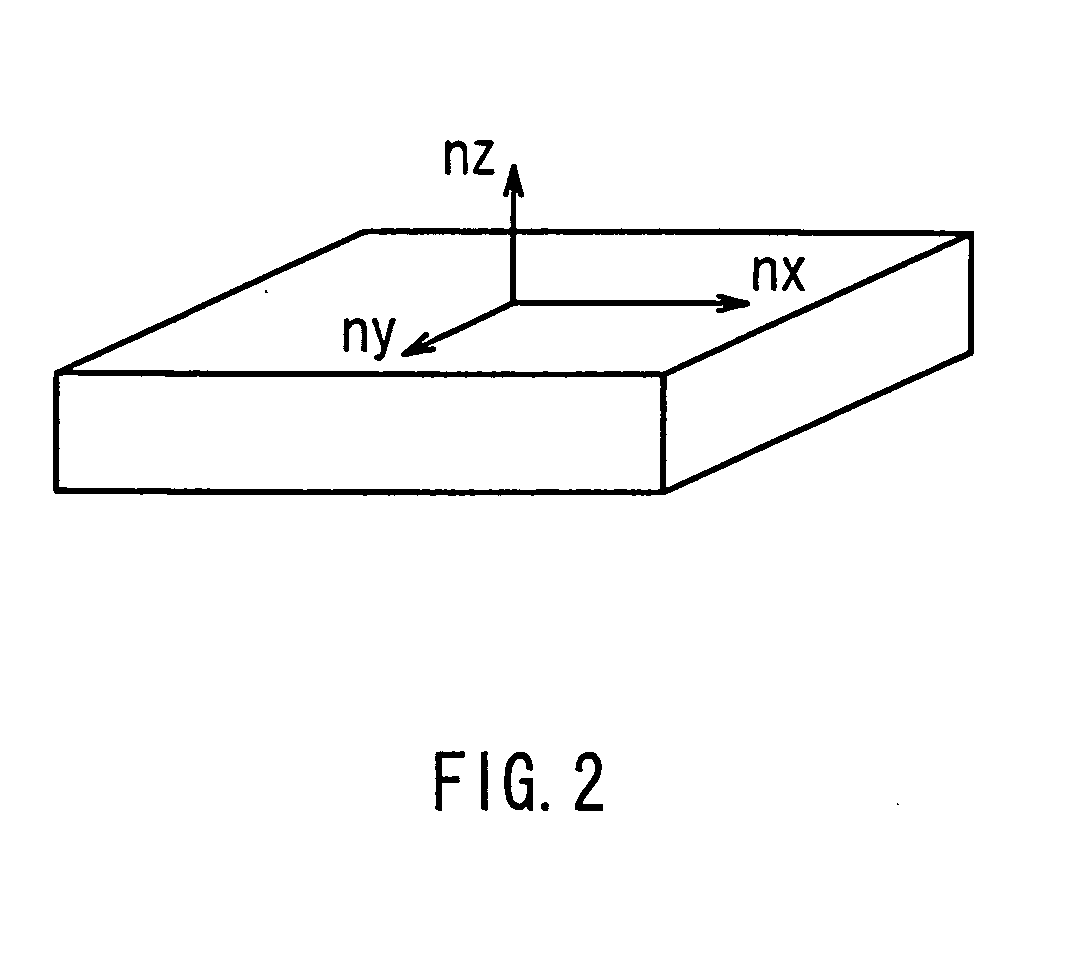

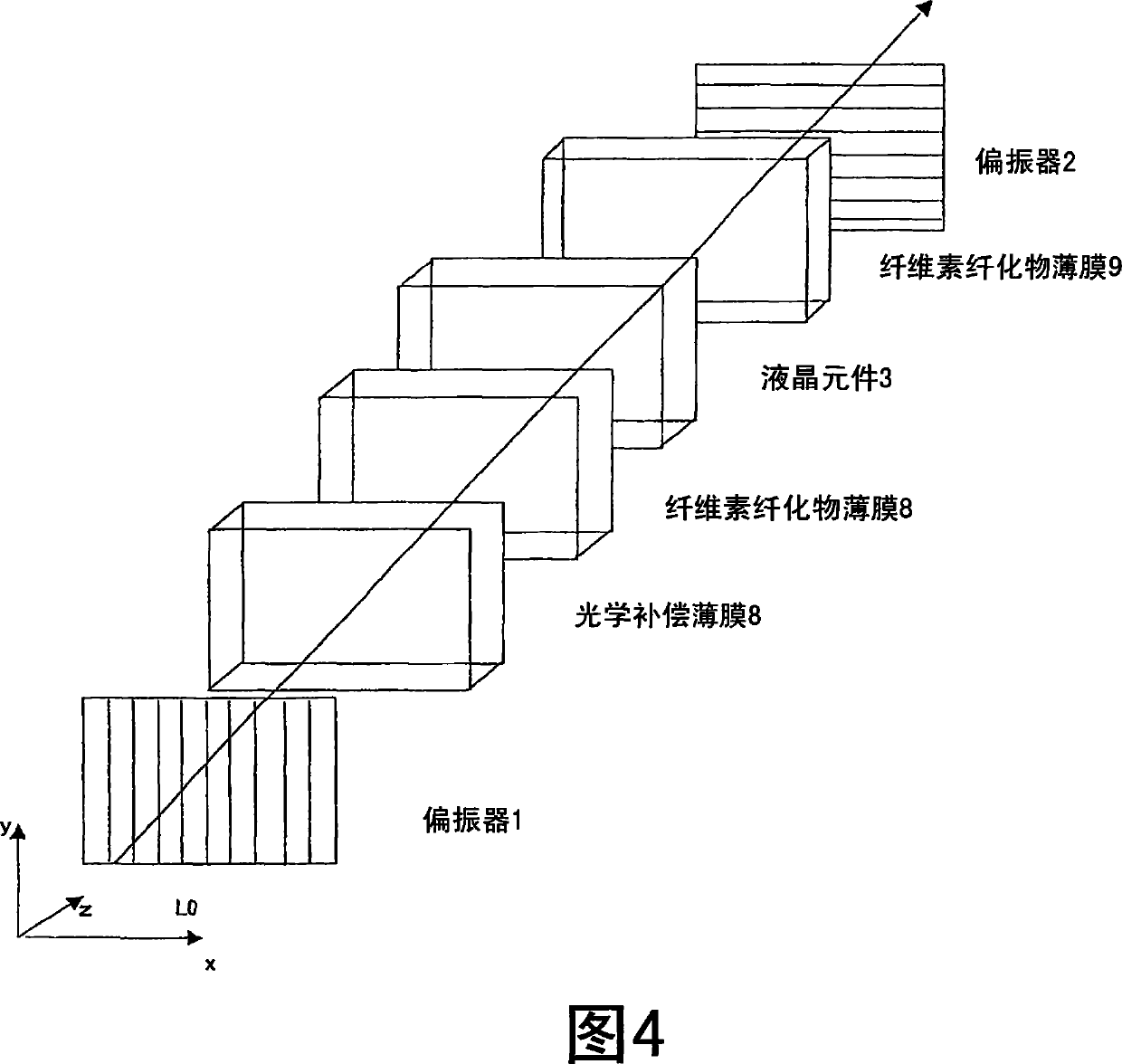

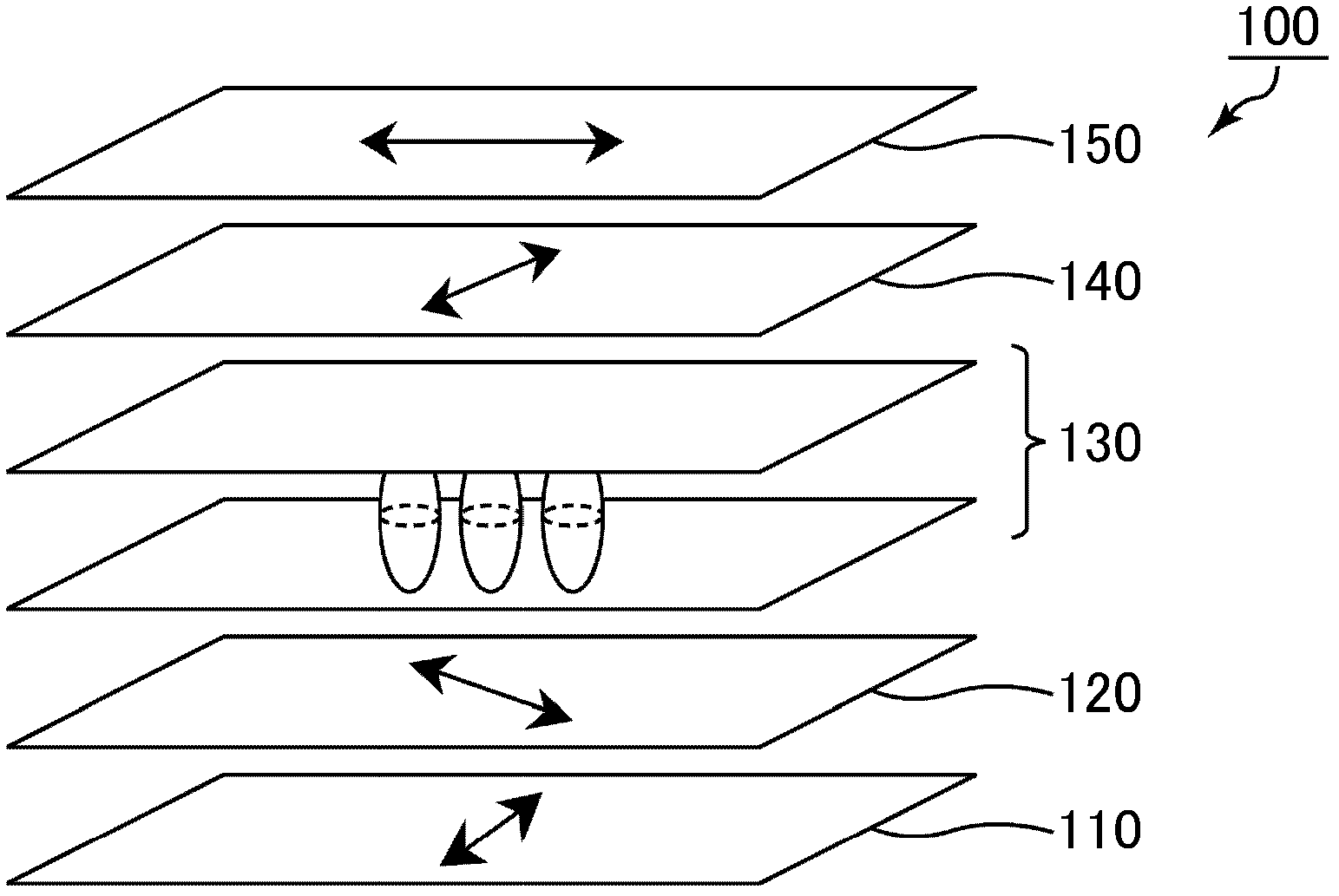

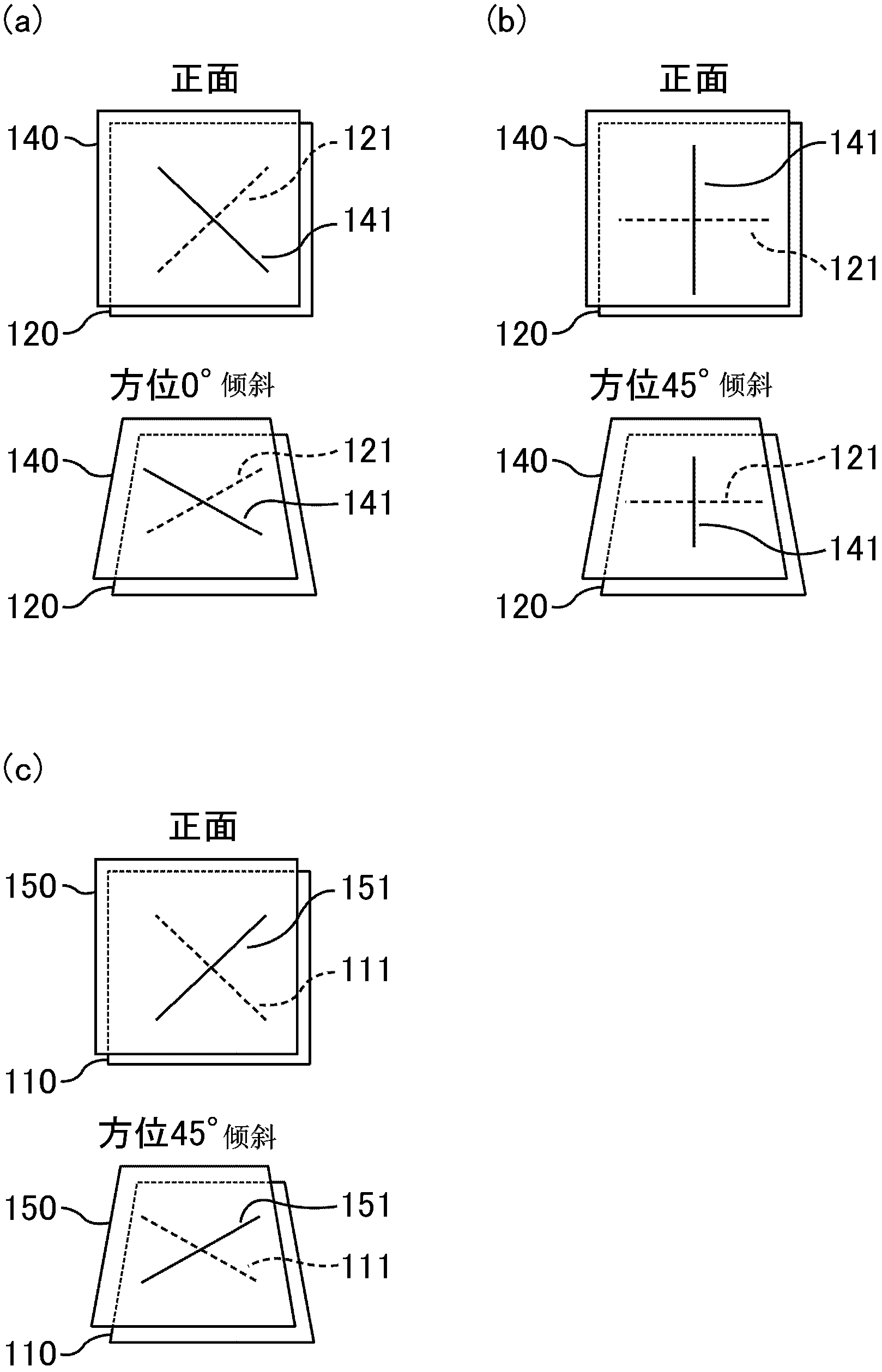

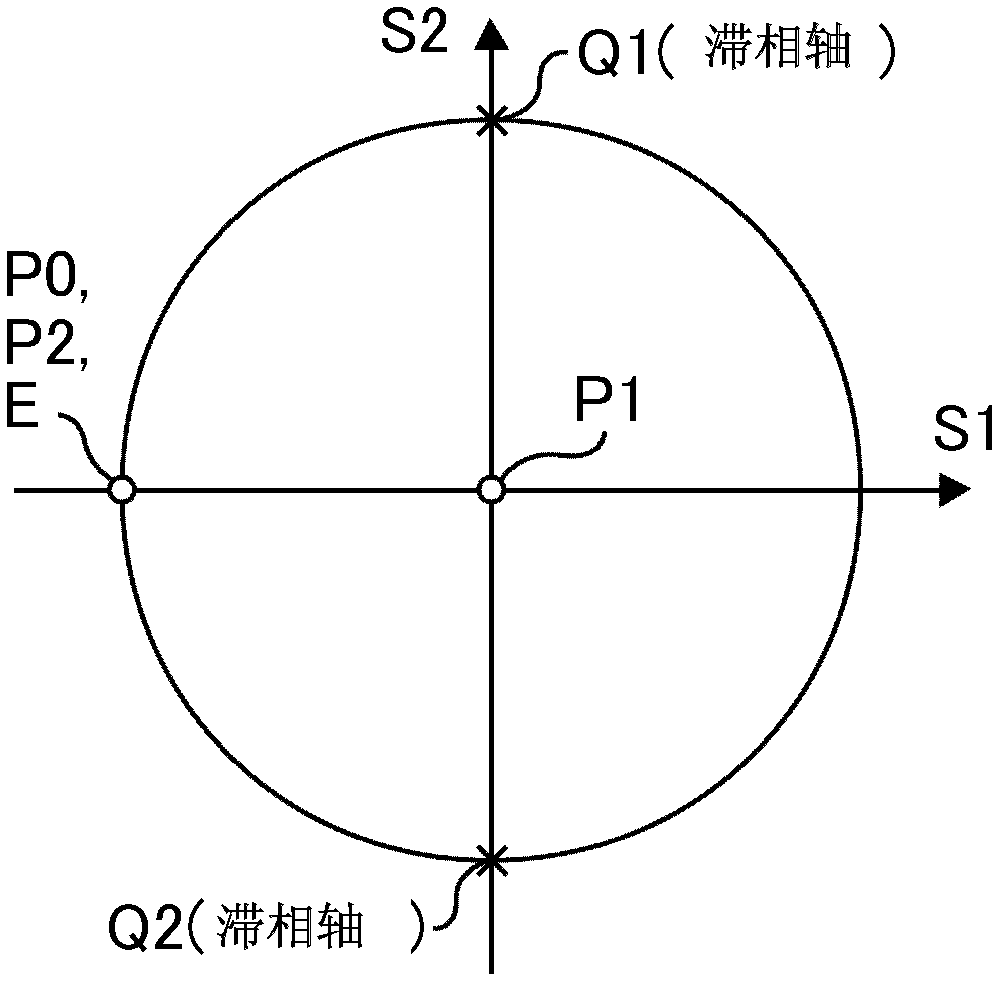

Optical Compensation Layer-Attached Polarizing Plate, Liquid Crystal Panel, Liquid Crystal Display, Image Display, and Method for Producing Optical Compensation Layer-Attached Polarizing Plate

InactiveUS20080043332A1Improve productivityLow costPolarising elementsNon-linear opticsIn planePolarizer

An optical compensation layer-attached polarizing plate of the invention comprises a polarizing plate, an optical compensation layer (1) and another optical compensation layer (2) that are laminated in this order, wherein the optical compensation layer (1) has the relation nx1>ny1=nz1, comprises a resin with a photoelastic coefficient absolute value of at most 2.0×10−11 m2 / N, and has an in-plane retardation (nx1−ny1)d1 in the range of 200 nm to 300 nm, the optical compensation layer (2) has the relation nx2>ny2>nz2, comprises a resin with a photoelastic coefficient absolute value of at most 2.0×10−11 m2 / N, and has an in-plane retardation (nx2−ny2)d2 in the range of 90 nm to 160 nm, a slow axis of the optical compensation layer (1) makes an angle of 10° to 30° with an absorption axis of the polarizing plate, and a slow axis of the optical compensation layer (2) makes an angle of 75° to 95° with the absorption axis of the polarizing plate. The optical compensation layer-attached polarizing plate can provide viewing angle compensation and broadband circular polarization for a VA mode liquid crystal cell, can form a thin product, and can reduce uneven heat-up.

Owner:NITTO DENKO CORP

Adhesive composition, polarizing plate, and liquid crystal display

InactiveUS20110111140A1Excellent endurance reliabilityImprove machinabilityLiquid crystal compositionsFilm/foil adhesivesHigh humidityLiquid-crystal display

The present invention relates to a pressure-sensitive adhesive composition, a polarizer, and a liquid crystal display (LCD). According to the present invention, it is possible to provide a pressure-sensitive adhesive composition, which shows excellent endurance reliability in a high-temperature or high-humidity condition, has superior workability such as a superior re-cutting or re-peeling property, and is capable of effectively suppress light leakage occurring in an LCD, and a polarizer and an LCD which include a cured product of the pressure-sensitive adhesive composition.

Owner:LG CHEM LTD

Optical compensation layer-attached polarizing plate, liquid crystal panel, liquid crystal display, image display, and method for producing optical compensation layer-attached polarizing plate

InactiveUS7852561B2Thin structureUneven heat-up can be reducedPolarising elementsNon-linear opticsIn planeLiquid-crystal display

Owner:NITTO DENKO CORP

Adhesive composition, polarizing plate, and liquid crystal display

InactiveUS20110117296A1Improve removabilityImprove workabilityLiquid crystal compositionsFilm/foil adhesivesLiquid-crystal displayHigh humidity

The present invention relates to a pressure-sensitive adhesive composition, including an interpenetrating polymer network structure in a cured state and comprising a pressure-sensitive adhesive strength stabilizer; a polarizer; and a liquid crystal display. In the present invention, by using the stabilizer having a functional group capable of rapidly reacting with a multifunctional crosslinking agent, the change of the pressure-sensitive adhesive strength over time is quickly terminated right after preparation, thereby the pressure-sensitive adhesive strength is rapidly stabilized. The pressure-sensitive adhesive of the present invention has an excellent removability in a room-temperature or warming condition. Also, the pressure-sensitive adhesive can efficiently suppress light leakage, and has an excellent workability and durability in a high-temperature and / or high-humidity condition.

Owner:LG CHEM LTD

Pressure sensitive adhesive composition for polarization film

InactiveUS20060128925A1High performanceIncreased durabilityPolyureas/polyurethane adhesivesEster polymer adhesivesPressure sensitiveChemistry

A pressure sensitive adhesive composition for polarization films used for the front and rear sides of a liquid crystal cell of a system such as IPS (In-Plane Switching), MVA (Multi-Domain Alignment) and the like. The pressure sensitive adhesive composition is made up of: 1) an acrylic copolymer of a (meth)acrylic ester and a monomer having a crosslinkable functional group; and 2) a crosslinking agent; where the storage elasticity of the composition after crosslinking at 0 to 50° C. is in the range of 105 to 109 Pa, and the glass transition temperature (Tg) is −20° C. or higher. The pressure sensitive adhesive composition provides optically functional films imparted with excellent light leakage resistance. Films adhered with the pressure sensitive adhesive composition do not experience floating peeling under conditions of high temperature and high humidity when the composition is used for pasting polarization films by means of crossed Nicols at ∠0 and 90 degrees.

Owner:LINTEC CORP

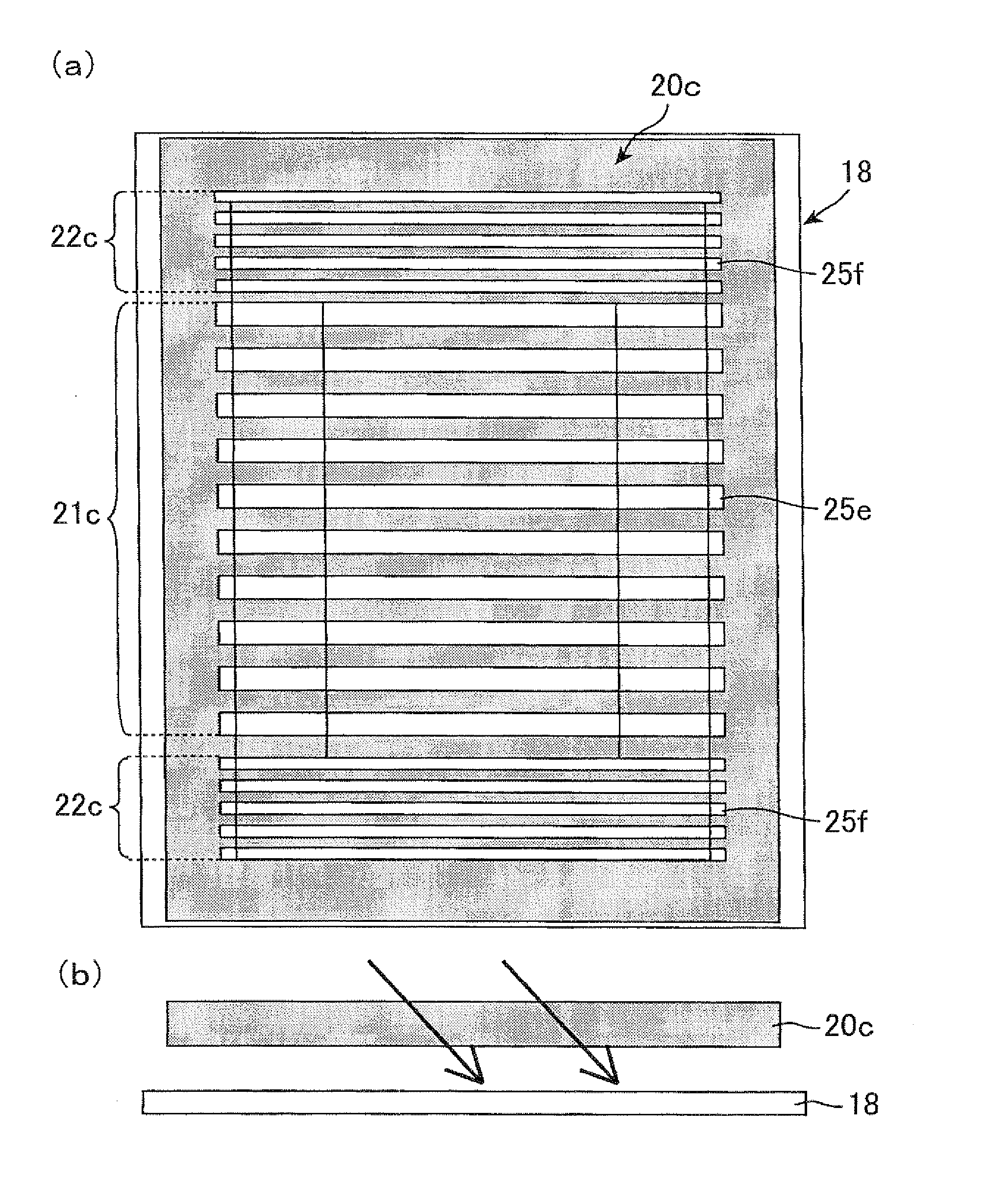

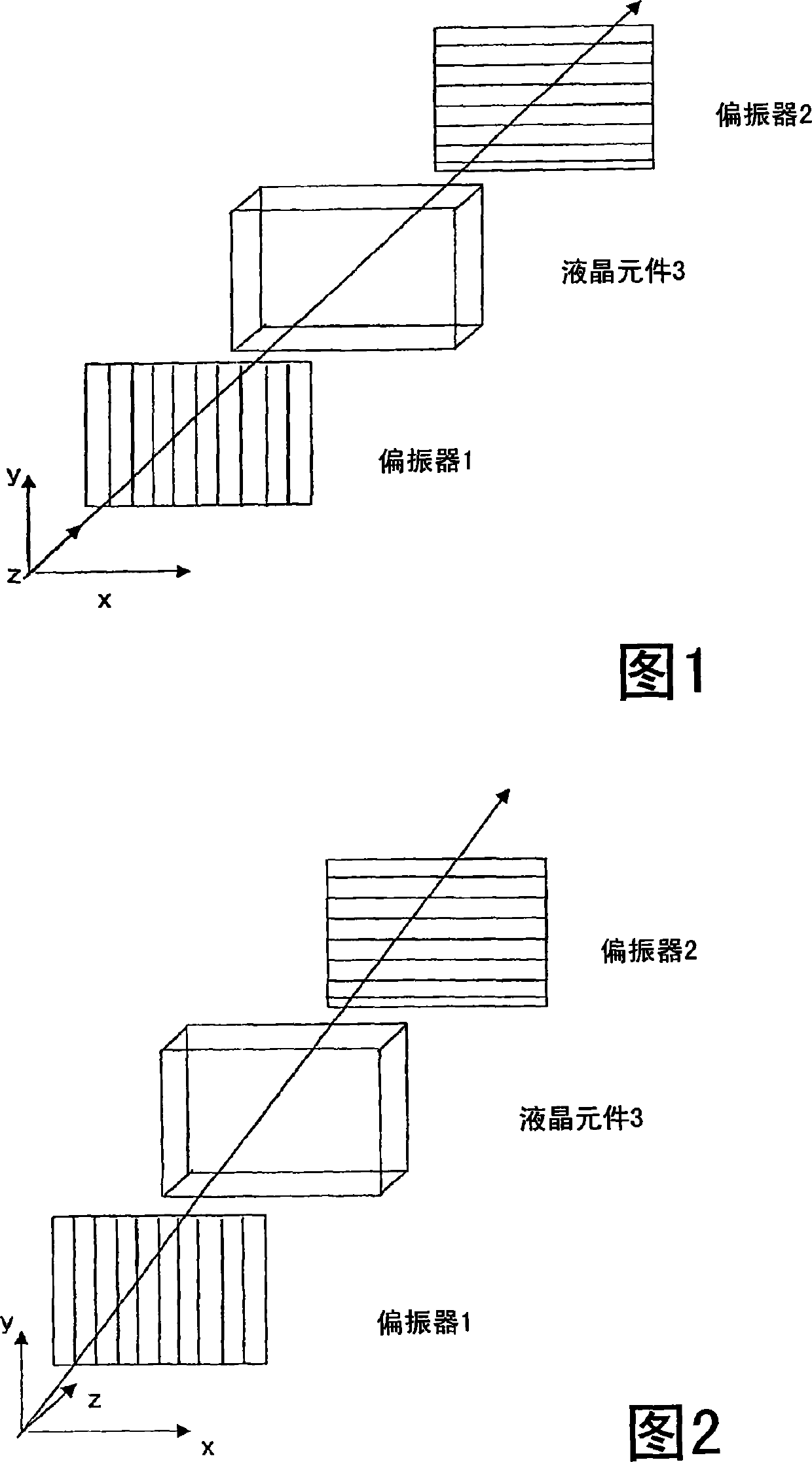

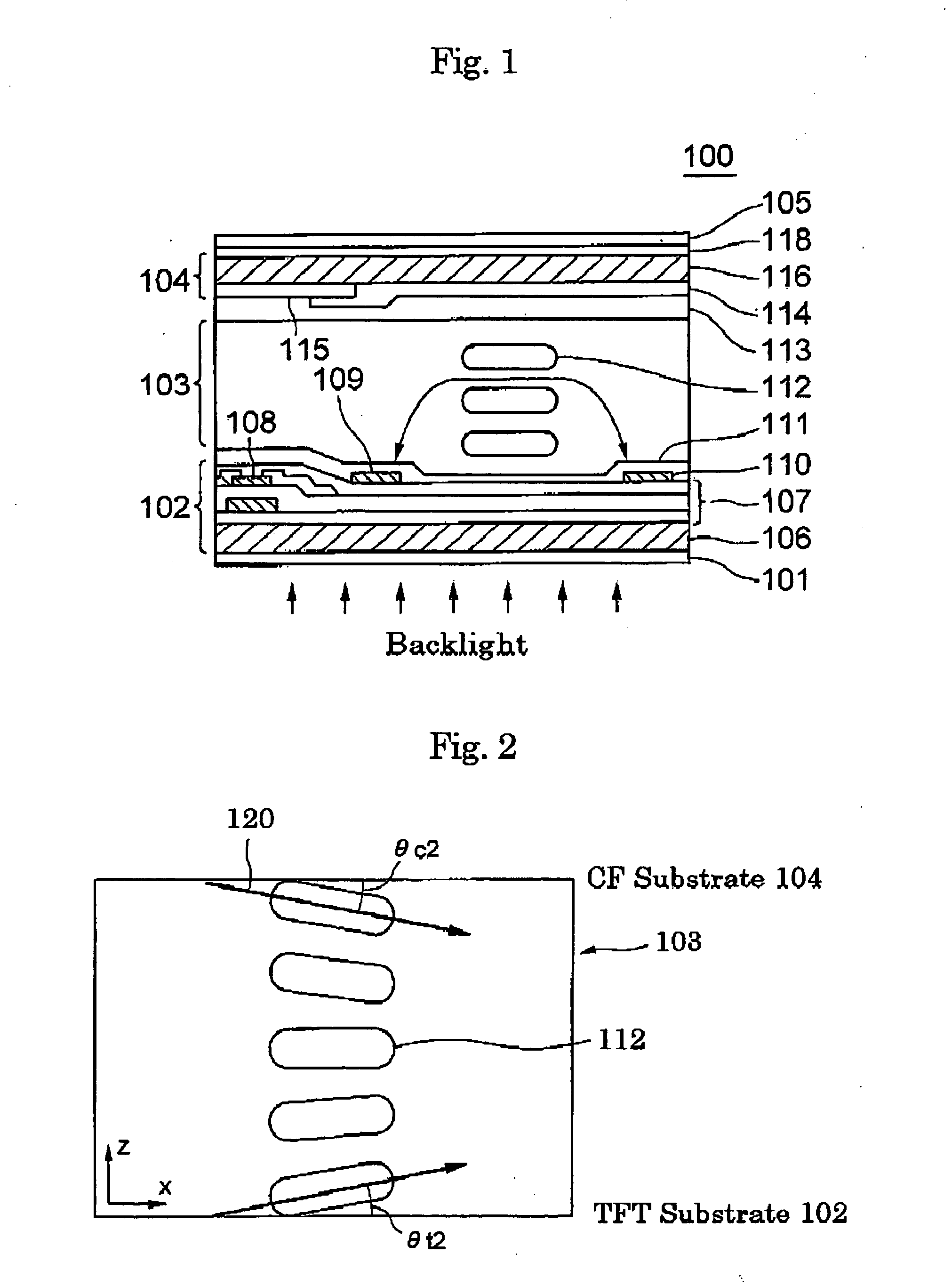

Production method of liquid crystal display device and liquid crystal display device

ActiveUS20100118246A1Increase the number ofSuppress light leakagePhotomechanical apparatusNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display device and a production method of a liquid crystal display device, capable of improving display qualities in a display region close to a frame region without causing any defects.The present invention is a production method of a liquid crystal display device,the liquid crystal display device including:a pair of substrates facing each other;a liquid crystal layer arranged between the pair of substrates;an alignment film arranged on a liquid crystal layer-side surface of at least one of the pair of substrates; anda pixel including two or more domains,the production method including an exposure step of exposing the alignment film using a photomask having a first mask part and a second mask part,the first mask part having a plurality of transmissive parts formed within a light-shielding region,the second mask part having a plurality of transmissive parts formed within the light-shielding region in a form different from a form of the plurality of transmissive parts in the first mask part,wherein the alignment film in a display region is exposed through the first mask part, andthe alignment film in a frame region is exposed through the second mask part.

Owner:SHARP KK

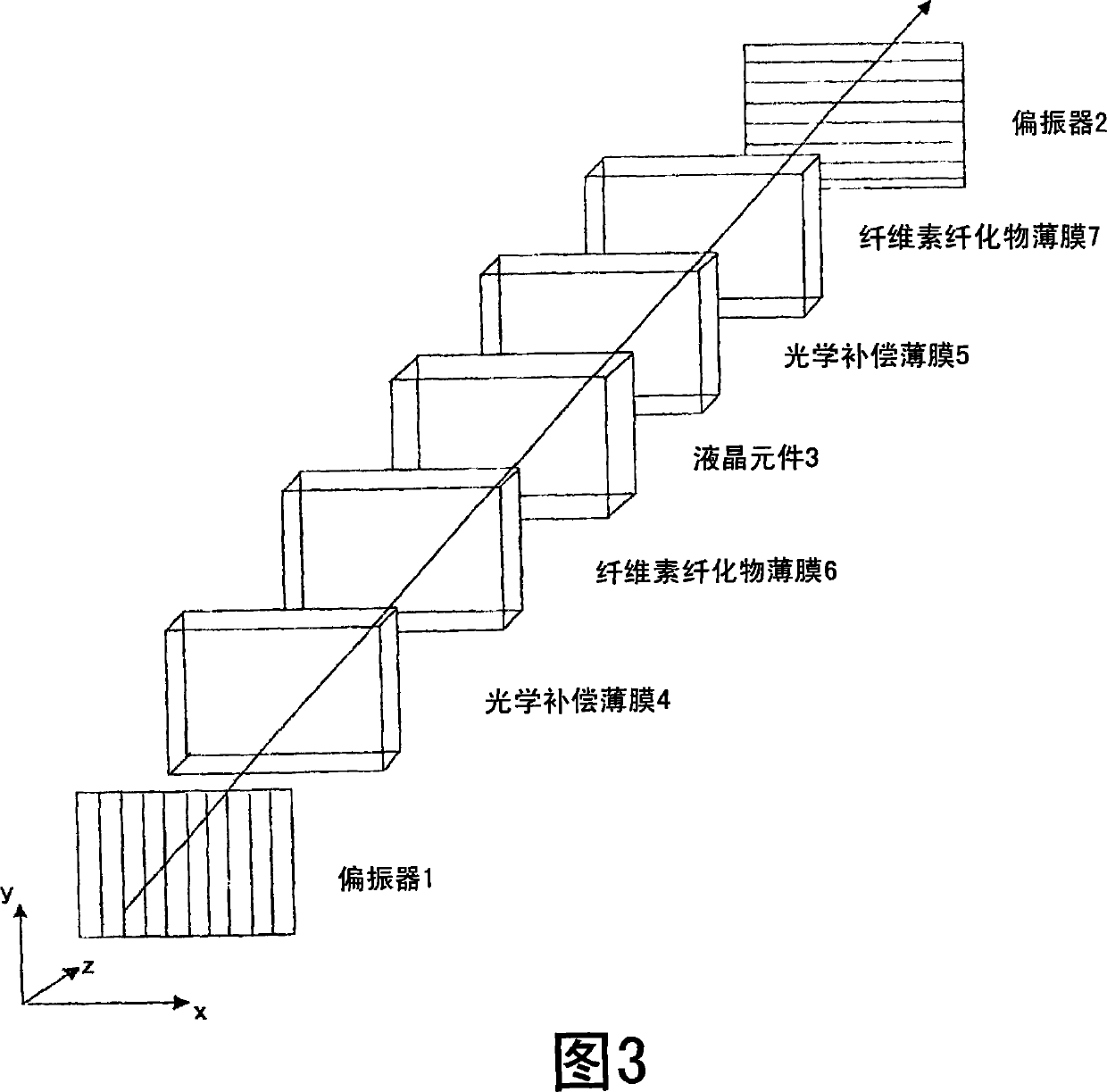

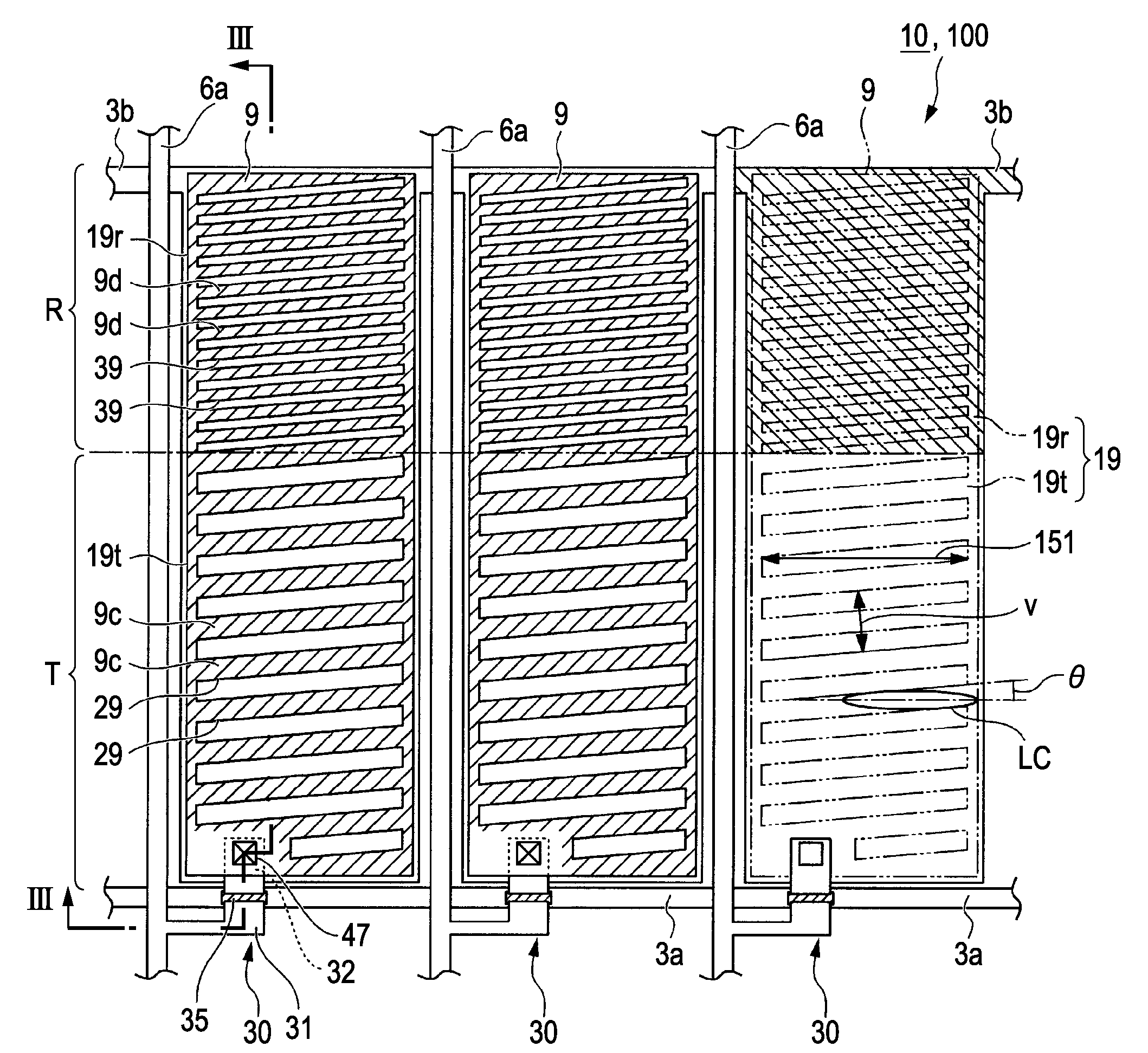

Liquid crystal display device, optical compensatory sheet, and polarizer and liquid crystal display device employing the same

ActiveCN101107559AReduce light leakageSuppress light leakagePolarising elementsNon-linear opticsCelluloseDielectric anisotropy

A liquid crystal display device comprising a liquid crystal panel in which liquid crystals having negative dielectric anisotropy are interposed between upper substrate and lower substrate that have been vertically oriented on the surface, the orientation of the liquid crystals being almost vertical with no applied voltage, almost horizontal when a predetermined voltage is applied, and tilted when a smaller voltage than the predetermined voltage is applied; a first polarizer and a second polarizer disposed on both sides of the liquid crystal panel such that the absorption axes of the polarizers are perpendicular to each other; a first retardation film disposed between the liquid crystal panel and the first polarizer; and a second retardation film disposed between the liquid crystal panel and the second polarizer, wherein the polarizer comprises a polarizing film and a pair of protective films having the polarizing film in between, and wherein at least one of the protective films is a cellulose acylate film satisfying: 0 = Re(630) = 10 and |Rth(630)| = 25.

Owner:FUJIFILM CORP

Polarizing plate having pressure-sensitive adhesive layer and image display device

InactiveUS20120327510A1Suppress light leakageReduce light leakageFilm/foil adhesivesPolarising elementsTectorial membraneMeth-

Provided is a polarizing plate having pressure-sensitive adhesive layer, including a polarizer, a transparent protective film placed on at least one surface of the polarizer, and a pressure-sensitive adhesive layer placed on a surface of the transparent protective film on a side where the polarizer is not placed. The pressure-sensitive adhesive layer is formed from pressure-sensitive adhesive including acryl-based polymer including alkyl (meth)acrylate monomer unit and aromatic ring structure-containing (meth)acrylate monomer unit. The transparent protective film has an absolute value of photoelastic coefficient of 50×10−12 (m2 / N) or less, and X and Y satisfy the relation −1×1011X+3Y-1×1011X+23. X represents the photoelastic coefficient (m2 / N) of the transparent protective film, and Y represents the content (%) of the aromatic ring structure-containing (meth)acrylate monomer unit in the acryl-based polymer.

Owner:NITTO DENKO CORP

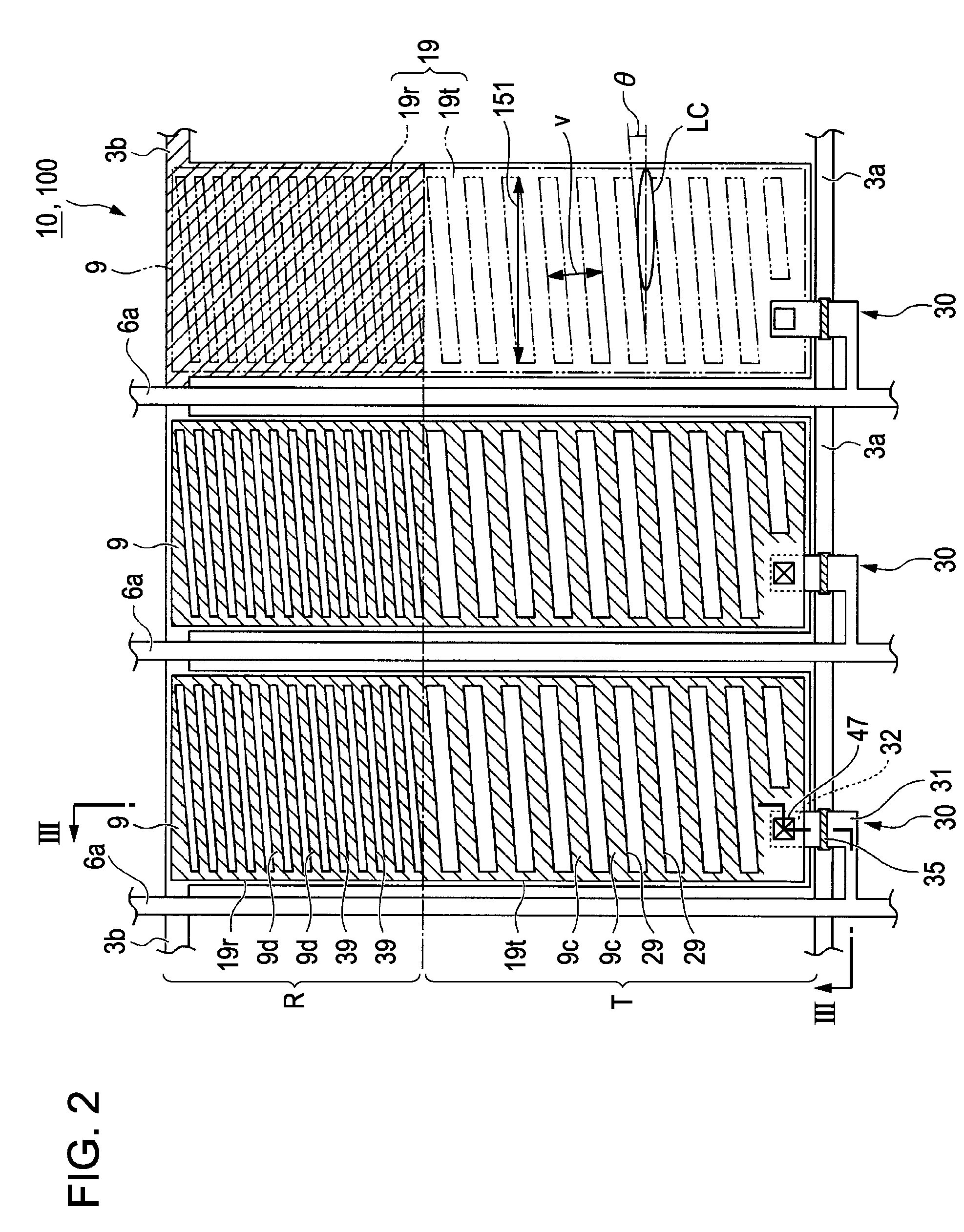

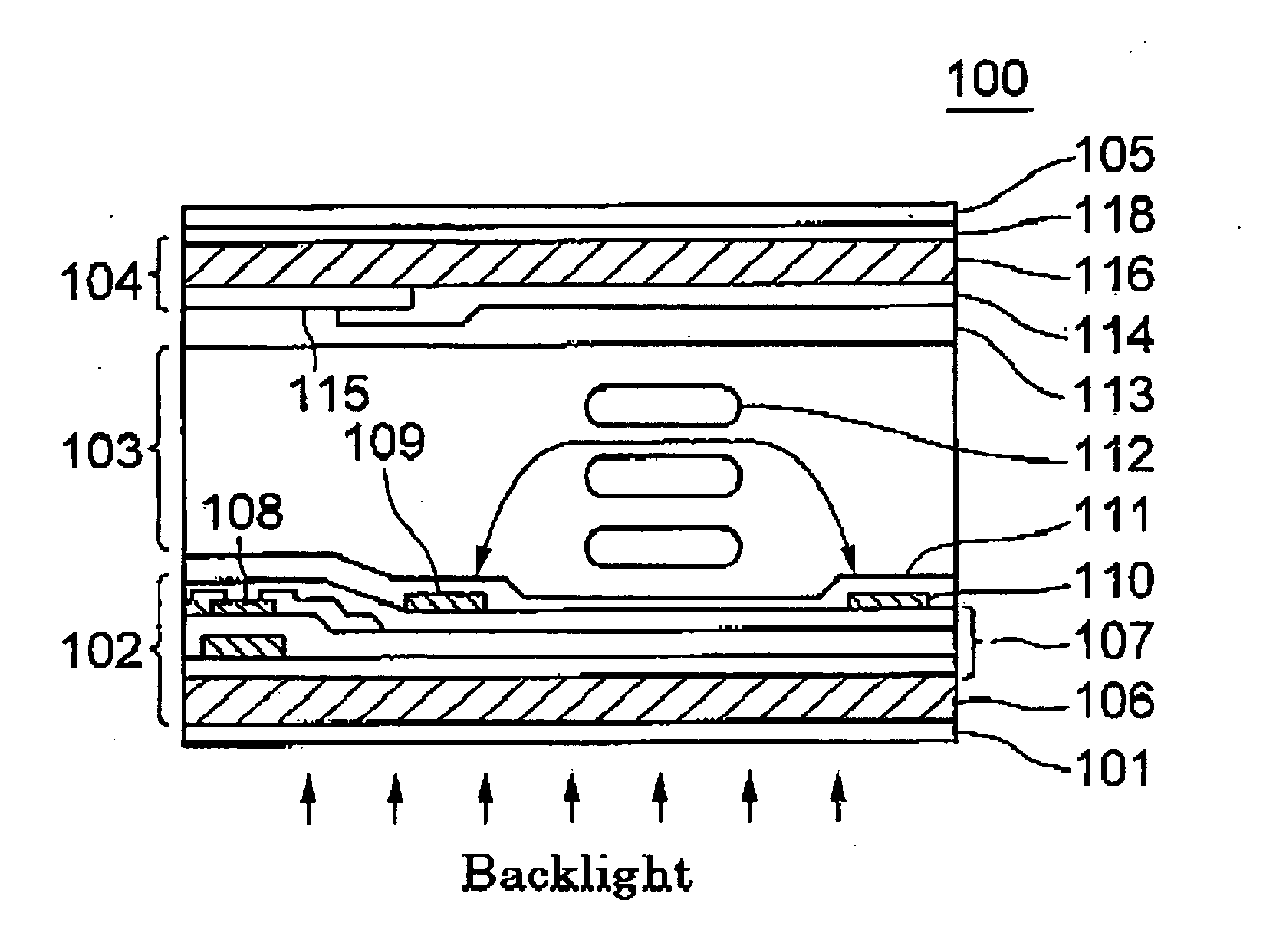

Liquid crystal display and electronic apparatus

InactiveUS20090262288A1Increase contrastShow vividlyNon-linear opticsLiquid-crystal displayPhase difference

A liquid crystal display includes a first substrate and a second substrate opposite to each other with a liquid crystal layer interposed therebetween, first and second electrodes provided on a side of the first substrate facing the liquid crystal layer to drive the liquid crystal layer, and a reflecting layer provided on a part of the side of the first substrate facing the liquid crystal layer. Each pixel region includes a reflective display region where light incoming from the second substrate is reflected by the reflecting layer toward the second substrate to perform display and a transmissive display region where light incoming from the first substrate is transmitted toward the second substrate to perform display. The liquid crystal layer has horizontal alignment in an initial alignment state. A first polarizing plate is provided on a side of the first substrate opposite the liquid crystal layer, the first polarizing plate having a transmission axis parallel or perpendicular to an alignment direction of the liquid crystal layer in the initial alignment state. A second polarizing plate is provided on a side of the second substrate opposite the liquid crystal layer, the second polarizing plate having a transmission axis perpendicular to the transmission axis of the first polarizing plate. A resin layer is provided on a side of the second substrate facing the liquid crystal layer, the resin layer having a first resin layer provided in the transmissive display region and a second resin layer provided in the reflective display region. The first resin layer is a λ / 2 phase layer giving a phase difference of approximately ½ wavelength (wavelength: λ) with respect to visible light, and a slow axis of the first resin layer and the transmission axis of the first polarizing plate are disposed so as to be parallel or perpendicular to each other. The second resin layer is a λ / 2 phase layer giving a phase difference of approximately ½ wavelength with respect to visible light, and a slow axis of the second resin layer is set in a direction intersecting the alignment direction of the liquid crystal layer. A step portion is provided between the first substrate and the resin layer in order to make the thickness of the liquid crystal layer in the reflective display region smaller than the thickness of the liquid crystal layer in the transmissive display region. A slope portion having a continuously changing thickness is provided in an end portion of the step portion. The slope portion is disposed in the transmissive display region.

Owner:JAPAN DISPLAY WEST

Display device and method for manufacturing the same

InactiveUS20130278858A1Avoid light leakageLeakage of light can be suppressed moreNon-linear opticsCold cathode manufactureDisplay deviceColor mixing

A display device includes: a first substrate which has an image display region; colored layers of plural colors which are arranged in rows on the first substrate and constitute a color filter in the image display region; and a black matrix which is provided for preventing leakage of light as well as color mixing between the colored layers arranged adjacent to each other. The black matrix includes a frame-shaped portion which surrounds the image display region. The frame-shaped portion is formed such that the frame-shaped portion has a notch on an outer side thereof and covers a periphery of the first substrate except for the notch where the frame-shaped portion does not cover the periphery of the first substrate. The colored layer of at least one color is arranged in the notch.

Owner:JAPAN DISPLAY INC

Led light source and image reading apparatus

InactiveUS20100214803A1Reduce the amount of lightSuppress light leakageOptical light guidesSpectral modifiersLight guideOptoelectronics

The present invention provides an LED light source optimal as a light source of image reading apparatuses, and the light source is used in an image reading apparatus comprised of a platen for mounting a read original, a light source for lighting the read original mounted on the platen, a lens means for condensing reflected light from a main scanning line of the read original lighted by the LED light source, and a light-receiving means for receiving the reflected light from the main scanning line of the read original condensed by the lens means, and has an LED that is a light-emitting source, and a light guide for reflecting the light of the LED by an inner surface thereof to diffuse in the shape of the main scanning line, where the LED is disposed in an end portion in the main scanning line direction of the light guide, the light guide has an inner surface opposed to a light-emitting surface of the LED forming a curved reflecting surface for reflecting in the main scanning line direction, the LED is disposed out of a critical angle region at the end in the main scanning line direction of the curved reflecting surface, the light guide has a plurality of reflecting surface bodies spaced at predetermined pitches in the main scanning line direction with the bodies surface-opposed to the LED side inside an inner surface reflection optical path of the light guide to reflect the light of the LED toward the outside of the light guide along the main scanning line, and a length in the perpendicular direction to the main scanning line direction of each of the reflecting surface bodies is adjusted corresponding to a light amount to reflect.

Owner:NISCA KK

Liquid-crystal display device

ActiveCN102549485AIncrease contrastSuppress light leakageNon-linear opticsOptical elementsEngineeringPolarizer

Provided is a liquid-crystal display device having a high contrast ratio over a wide viewing angle range and having little coloration occurring when black is displayed. The liquid-crystal display device has, in this order, a polarizer, a first [lambda] / 4 plate satisfying the condition nx > ny >= nz, a vertically oriented liquid-crystal cell, a second [lambda] / 4 plate having a substantially same Nz coefficient as the first [lambda] / 4 plate and satisfying the condition nx > ny >= nz, a double refraction layer satisfying the condition nx < ny <= nz, and another polarizer. The liquid-crystal cell has a liquid-crystal layer and blue, green, and red CF layers and satisfies at least one of the following equations. R(B) / R(G) > [delta]n(B) / [delta]n(G) R(R) / R(G) < [delta]n(R) / [delta]n(G) In the equation, R(B), R(G), and R(R) indicate retardations in the thickness direction of the liquid-crystal cell at wavelengths of 450nm, 550 nm, and 650 nm, respectively, and [delta]n(B), [delta]n(G), and [delta]n(R) indicate the double refractions of a liquid-crystal material of the liquid-crystal layer at wavelengths of 450nm, 550 nm, and 650 nm, respectively.

Owner:SHARP KK

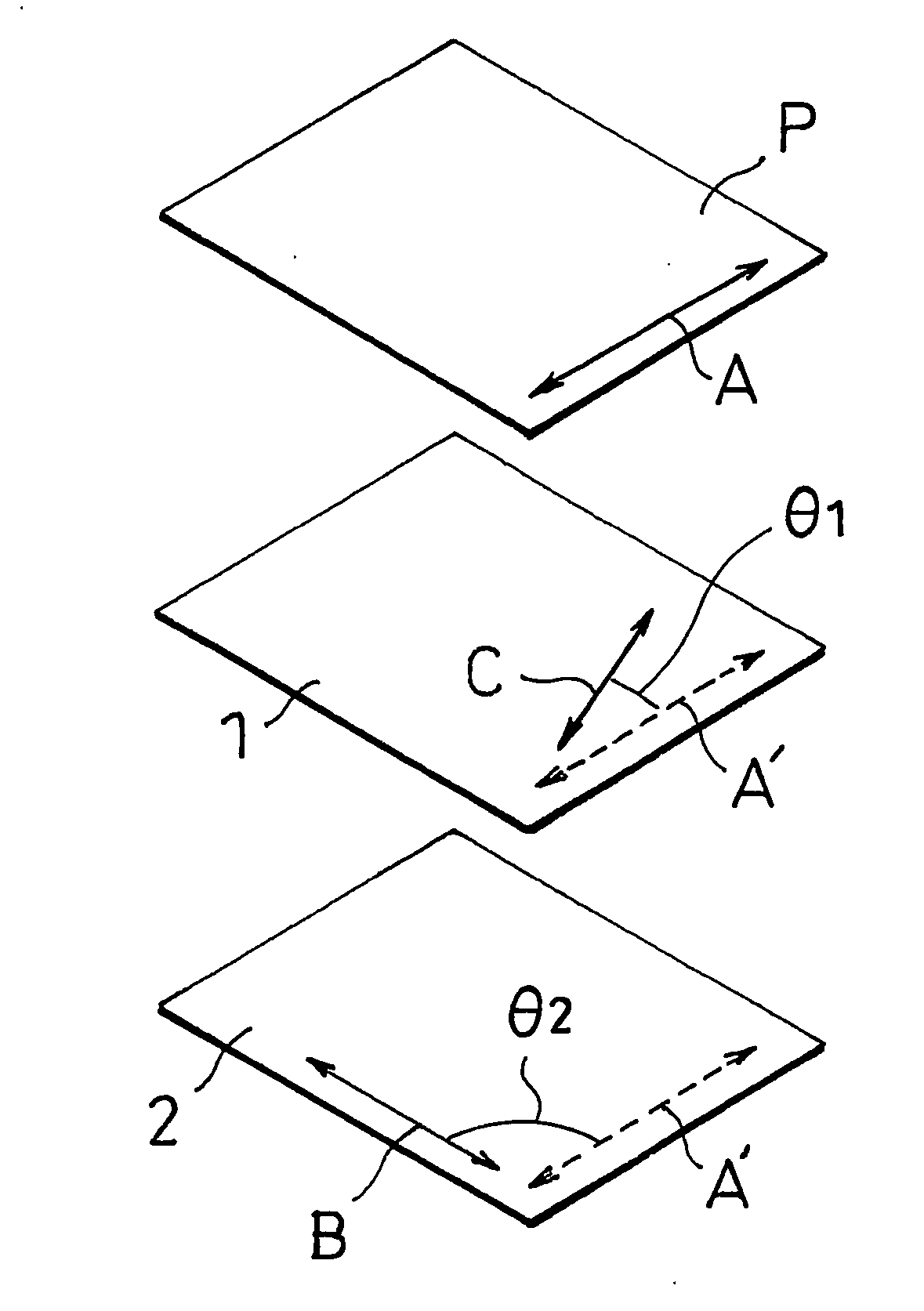

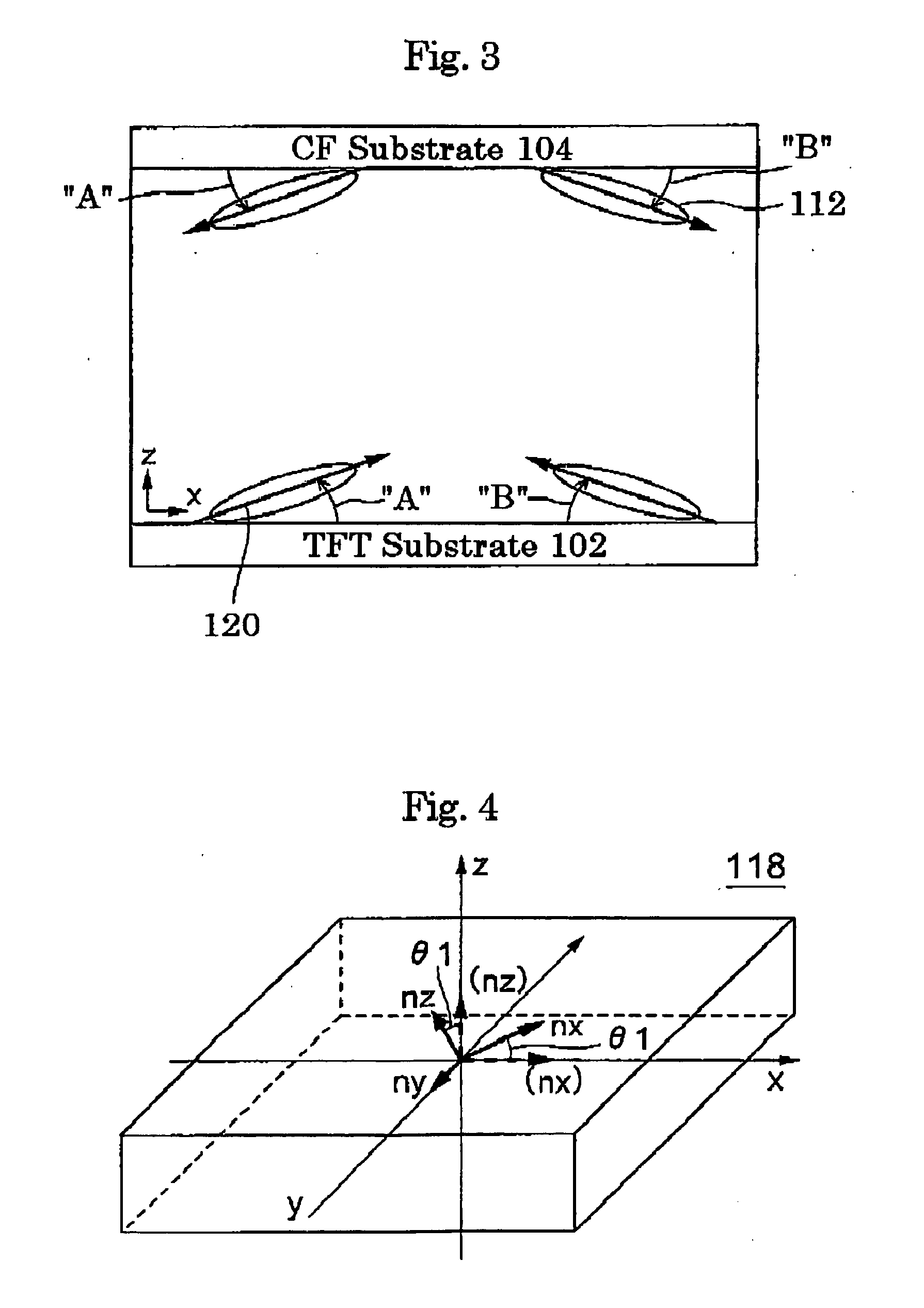

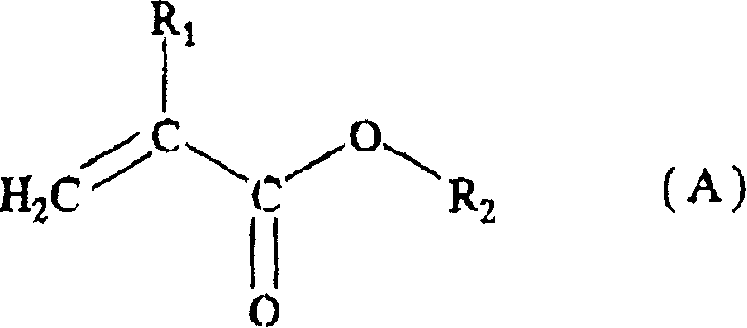

LCD device reducing asymmetry in the leakage light

An LCD device includes therein a splay-oriented LC layer, first and second substrates sandwiching therebetween the LC layer, and an optical compensation film for reducing leakage light upon display of a black color. The optical compensation film has three optical elastic axes including a fast axis coinciding the Y-axis, a slow axis rotated from the X-axis by a positive rotational angle θ1, and another axis rotated from the Z-axis by the positive rotational angle θ1. The positive rotational direction coincides with a counter-clockwise direction within the substrate surface, as viewed from minus side toward the positive side of the Y-axis.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

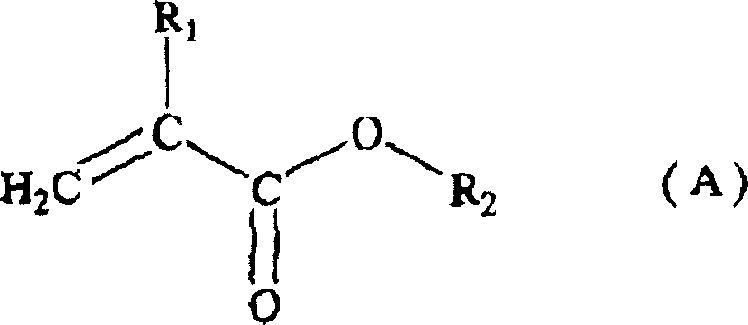

Acrylic resin

InactiveCN1690097ASuppress light leakageIncreased durabilityFilm/foil adhesivesPolyureas/polyurethane adhesivesHydrogen atomAcrylic resin

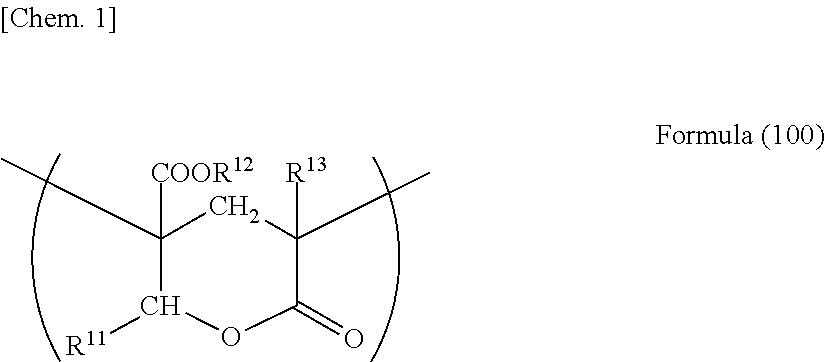

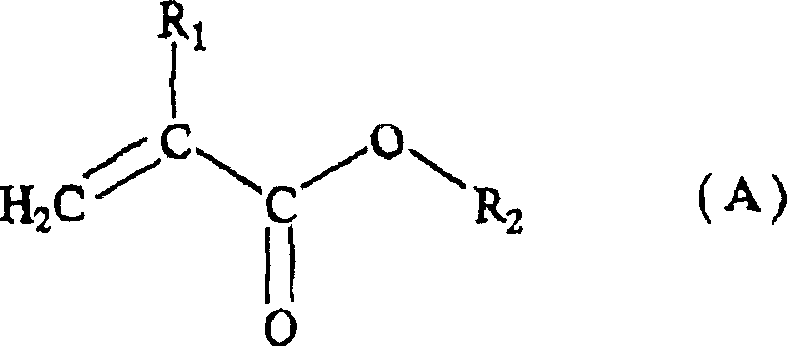

An acrylic resin (1) comprising a structural unit (structural unit (a)) derived from the following monomer (a) and a structural unit (structural unit (b)) derived from the following monomer (b): (a ): (meth)acrylic acid ester of general formula (A): (wherein R1 represents a hydrogen atom or a methyl group, R2 represents an alkyl group of 1 to 14 carbon atoms or an aralkyl group of 1 to 14 carbon atoms group, and the hydrogen atom in the alkyl group R2 or the hydrogen atom in the aralkyl group R2 may be replaced by an alkoxy group of 1 to 10 carbon atoms), and (b): in the molecule (The ethylenic double bond contained in (b) may be contained in the alicyclic structure).

Owner:SUMITOMO CHEM CO LTD

Semiconductor light-emitting apparatus having light reflection adjusting member of gray resin and its manufacturing method

ActiveUS20190312187A1Suppress light leakageSolid-state devicesSemiconductor devicesSemiconductorLight reflection

A semiconductor light-emitting apparatus is constructed by a wiring substrate, at least one semiconductor light-emitting element provided on the wiring substrate, at least one wavelength-converting member provided on the semiconductor light-emitting element, and a light reflection adjusting member directly covering a sidewall of the semiconductor light-emitting element and a sidewall of the wavelength-converting member. The light reflection adjusting member is formed of gray resin including light reflecting fillers and light absorbing fillers for visible light.

Owner:STANLEY ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com