Liquid crystal display device, optical compensatory sheet, and polarizer and liquid crystal display device employing the same

A liquid crystal display device, optical compensation film technology, applied in optics, polarizing elements, nonlinear optics, etc., can solve problems such as unsatisfactory performance, no consideration of differences, and inability to completely suppress light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0144] A first embodiment of the present invention is described below.

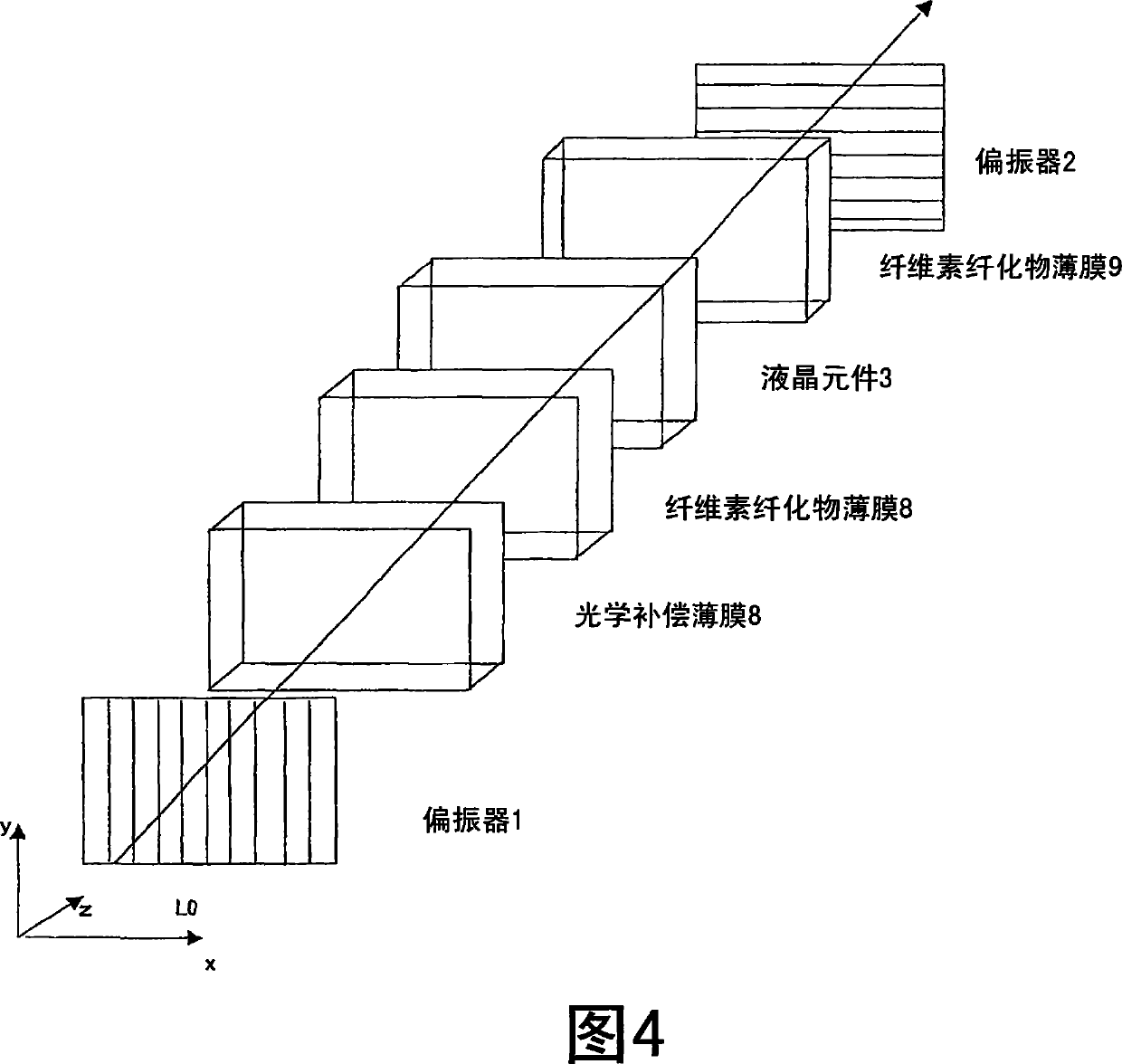

[0145] The liquid crystal display device of the first embodiment includes: a liquid crystal panel in which a liquid crystal with negative dielectric anisotropy is interposed between an upper substrate and a lower substrate, the liquid crystal has been vertically aligned on the surface, so that The orientation of the liquid crystal is almost vertical when no voltage is applied, almost horizontal when a predetermined voltage is applied, and tilted when a voltage smaller than the predetermined voltage is applied; the first polarizer and the second polarizer placed on both sides of the liquid crystal panel a polarizer, wherein absorption axes of the polarizers are perpendicular to each other; a first retardation film placed between the liquid crystal panel and the first polarizer; and a first retardation film placed between the liquid crystal panel and the second polarizer and a second retardation film betwee...

Embodiment approach

[0542] According to the first embodiment, the manufacturing method of the polarizer is not particularly limited, and a conventional manufacturing method can be used. There may be mentioned a method of subjecting the obtained cellulose acylate film to an alkali treatment, and adhering the treated cellulose acylate film to both sides of a polarizer with an aqueous solution of a completely saponified polyvinyl alcohol solution, which Polarizers are made by dipping and stretching a polyvinyl alcohol film in an iodine solution. Cellulose acylate films may be subjected to good adhesion processing as described in JP-A 6-94915 and 6-118232 instead of alkali treatment.

[0543] Adhesives for bonding the treated surface of the protective film and the polarizing film can be exemplified by polyvinyl alcohol-based adhesives such as polyvinyl alcohol or polyvinyl butyral, or vinyl latex such as butyl acrylate, and the like.

[0544] The polarizer is composed of a polarizing film and a prot...

no. 2 approach

[0575] Next, a second embodiment of the present invention is described.

[0576] Next, the operation of the second embodiment will be described with reference to the drawings.

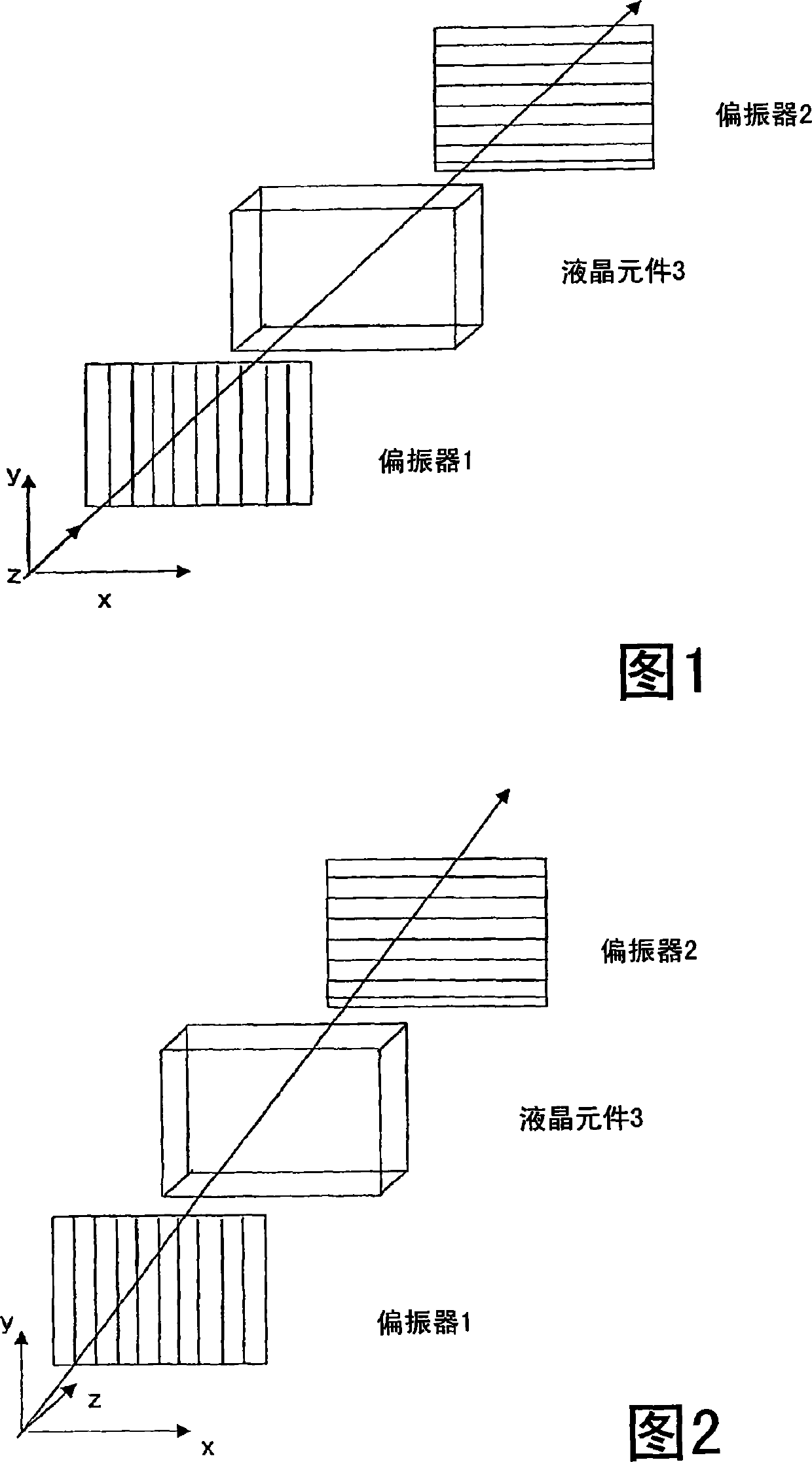

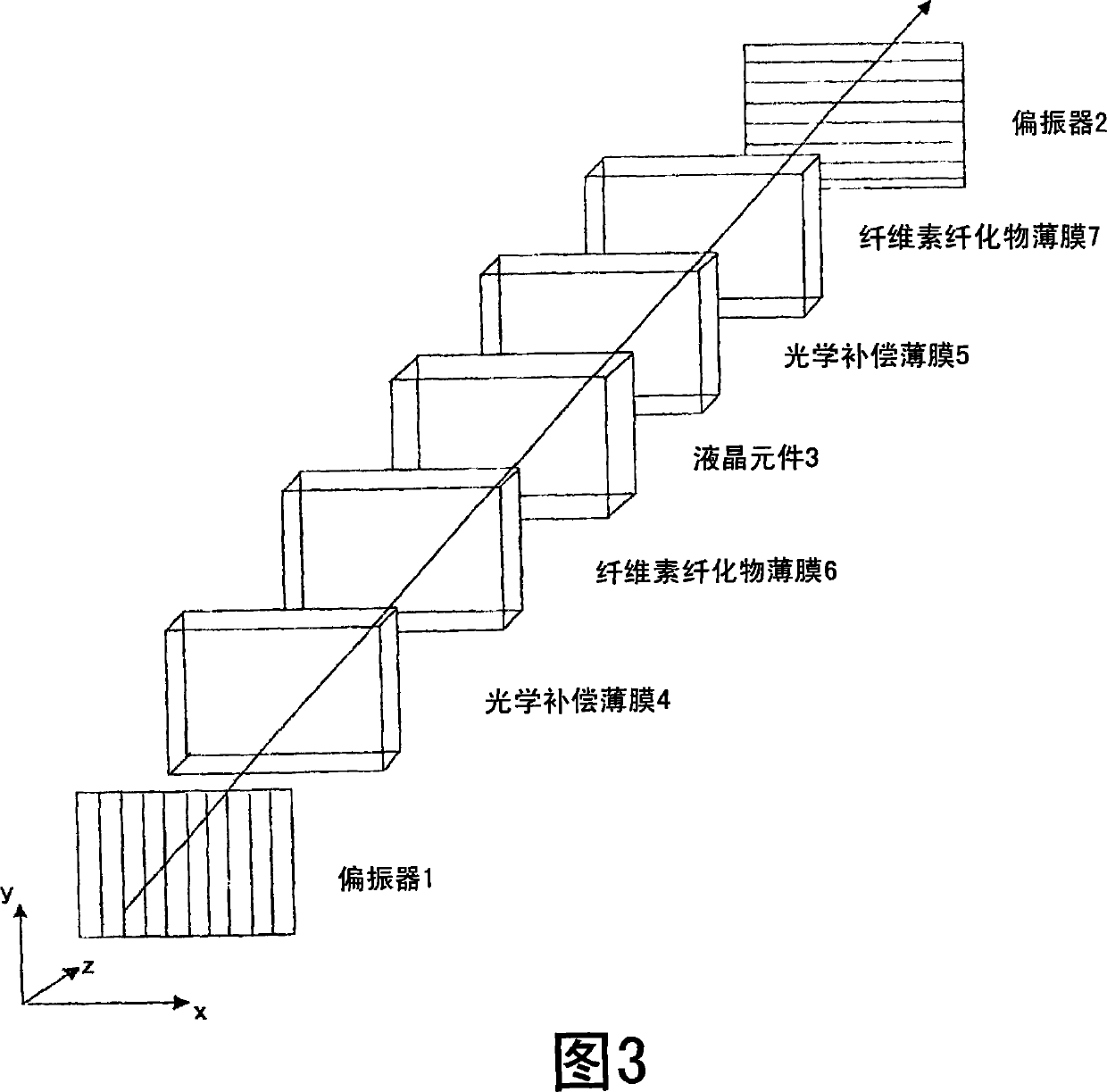

[0577] FIG. 1 is a schematic diagram describing the structure of a conventional VA type liquid crystal display device. The VA type liquid crystal display device has a liquid crystal element 3 with a liquid crystal layer in which the liquid crystal is vertically aligned with respect to the substrate surface when no voltage is applied, that is, during a black state; and the polarizer 1 and the polarizer in which the liquid crystal element 3 is inserted. 2, and installed so that their transmission axes (shown by the arrows in Figure 1) are placed perpendicular to each other. In FIG. 1 , light is incident from the polarizer 1 side. When no voltage is applied, when light traveling along the normal direction, that is, the z-axis direction is incident, the light passing through the polarizer 1 maintains a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com