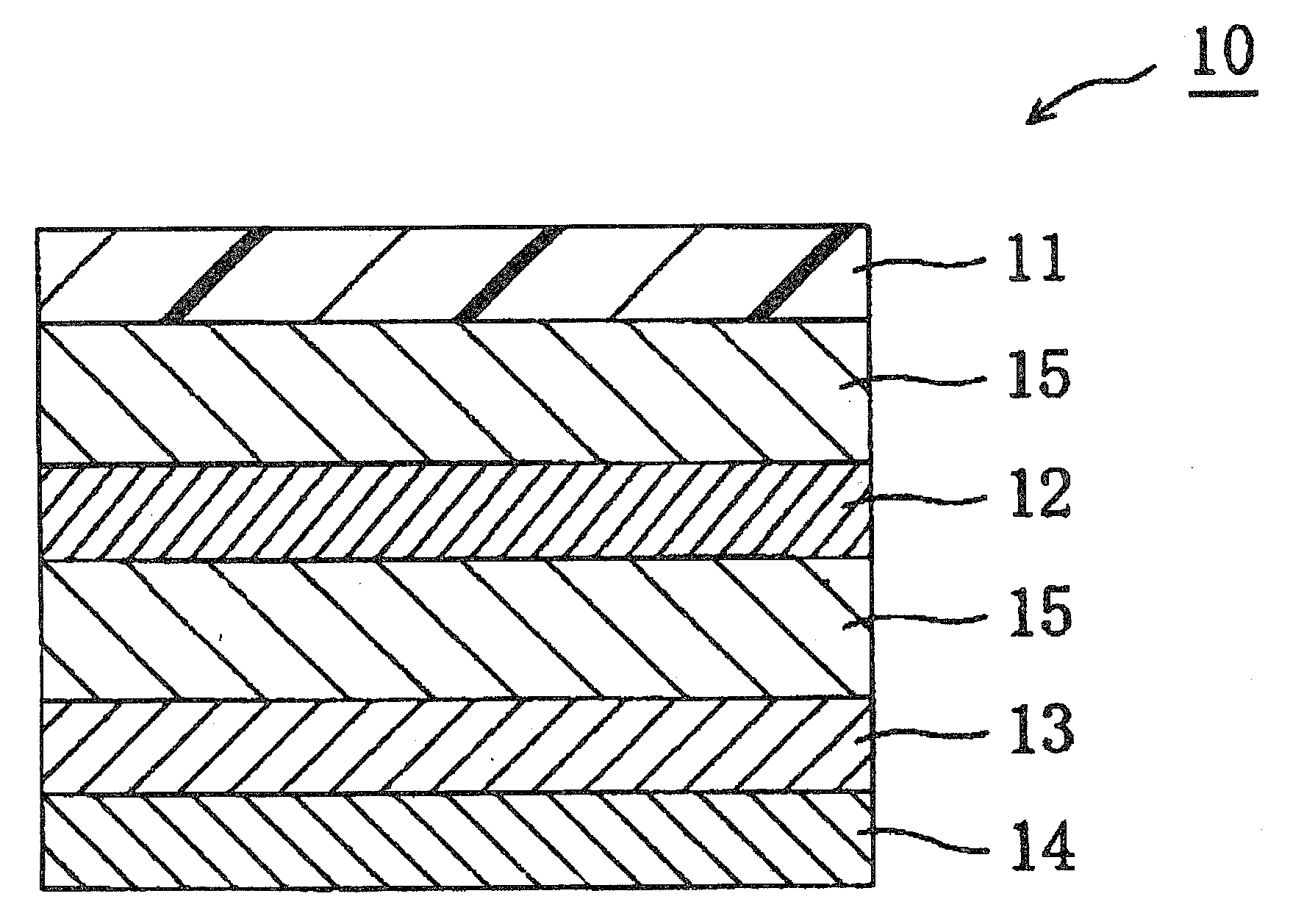

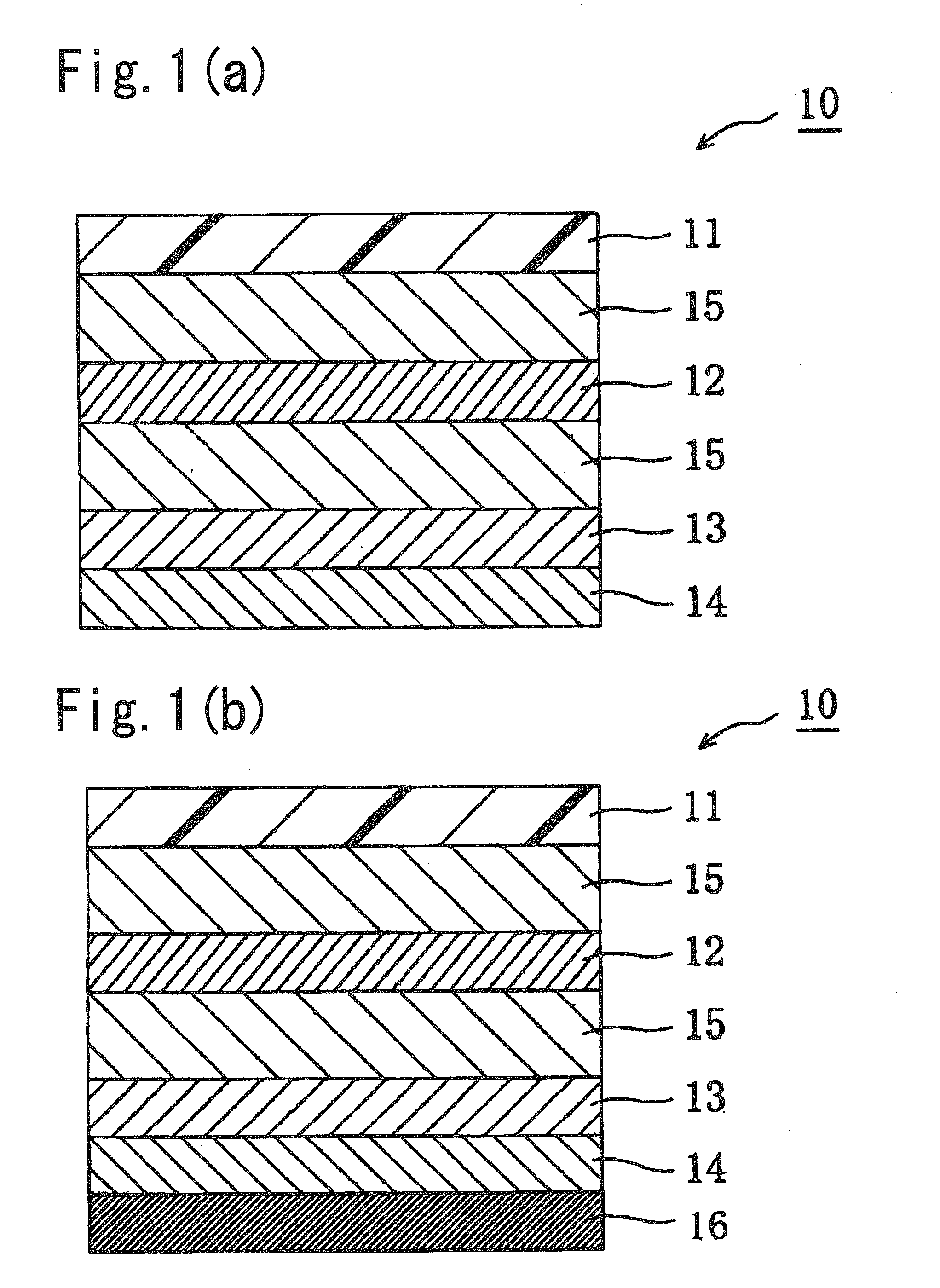

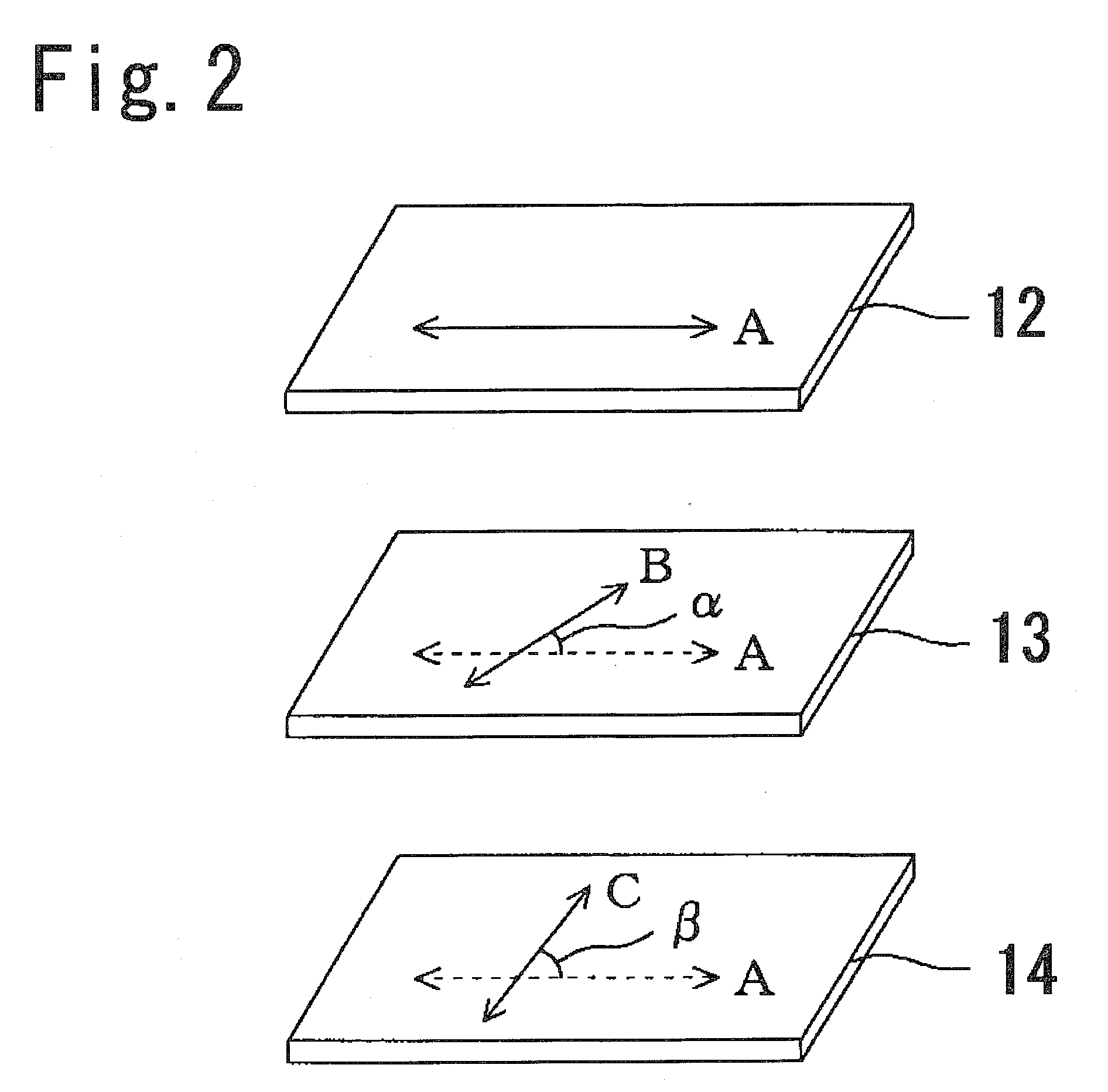

Polarizing plate with optical compensation layer and image display apparatus using the same

a technology of optical compensation layer and polarizing plate, which is applied in the direction of polarizing elements, thin material handling, instruments, etc., to achieve excellent hardness, excellent abrasion resistance, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of a Hardcoat Layer

[0200]First, 100 parts of urethane acrylate composed of pentaerythritol-based acrylate and hydrogenated xylenediisocyanate as urethane acrylate (herein after, referred to as A component), 49 parts of dipentaerythritol hexaacrylate (herein after, referred to as B1 component), 41 parts of pentaerythritol tetraacrylate (herein after, referred to as B2 component), and 24 parts of pentaerythritol triacrylate (herein after, referred to as B3 component) as polyol (meth)acrylate (herein after, referred to as B component), and 59 parts of a (meth) acrylic polymer having 2-hydroxyethyl group and 2,3-dihydroxypropyl group as a (meth)acrylic polymer having an alkyl group containing at least two hydroxyl groups (herein after, referred to as C component) were added. Then, 3 parts of a polymerization initiator (Irgacure 184) and 0.5 parts of a reactive leveling agent were mixed with respect to those total resin components, whereby a solid content of a hardcoat layer-f...

example 2

[0211]First, 100 parts by weight of urethane acrylate (herein after, referred to as A1 component) composed of pentaerythritol-based acrylate and isophorone diisocyanate as an A component, 59 parts by weight of a B1 component, 37 parts by weight of a B2 component, and 15 parts by weight of a B3 component as B components, 26 parts by weight of a (meth) acrylic polymer having a 2-hydroxyethyl group and a 2,3-dihydroxypropyl group as a C component, and 2 parts by weight of a polymerization initiator (Irgacure 184) with respect to the total resin components were used to produce a hardcoat layer in the same way as in Example 1. The thickness of the obtained hardcoat layer was 20 μm, and the pencil hardness thereof was 4H. A polarizing plate with an optical compensation layer was produced in the same way as in Example 1, except for using the obtained hardcoat layer.

example 3

[0212]A hardcoat layer was produced in the same way as in Example 1, except for using 100 parts by weight of the A1 component as an A component, 38 parts by weight of the B1 component, 40 parts by weight of the B2 component, and 16 parts by weight of the B3 component as B components, 30 parts by weight of a (meth) acrylic polymer having a 2-hydroxyethyl group and a 2,3-dihydroxypropyl group as a C component, and 3.5 parts by weight of a polymerization initiator (mixture of 1 part by weight of Irgacure 184 and 2.5 parts by weight of 2,4,6-trimethylbenzoinphenylphosphin oxide) with respect to the total resin components. The thickness of the obtained hardcoat layer was 20 μm, and the pencil hardness thereof was 4H. A polarizing plate with an optical compensation layer was produced in the same way as in Example 1, except for using the obtained hardcoat layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com