Patents

Literature

184results about How to "Reduce asymmetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

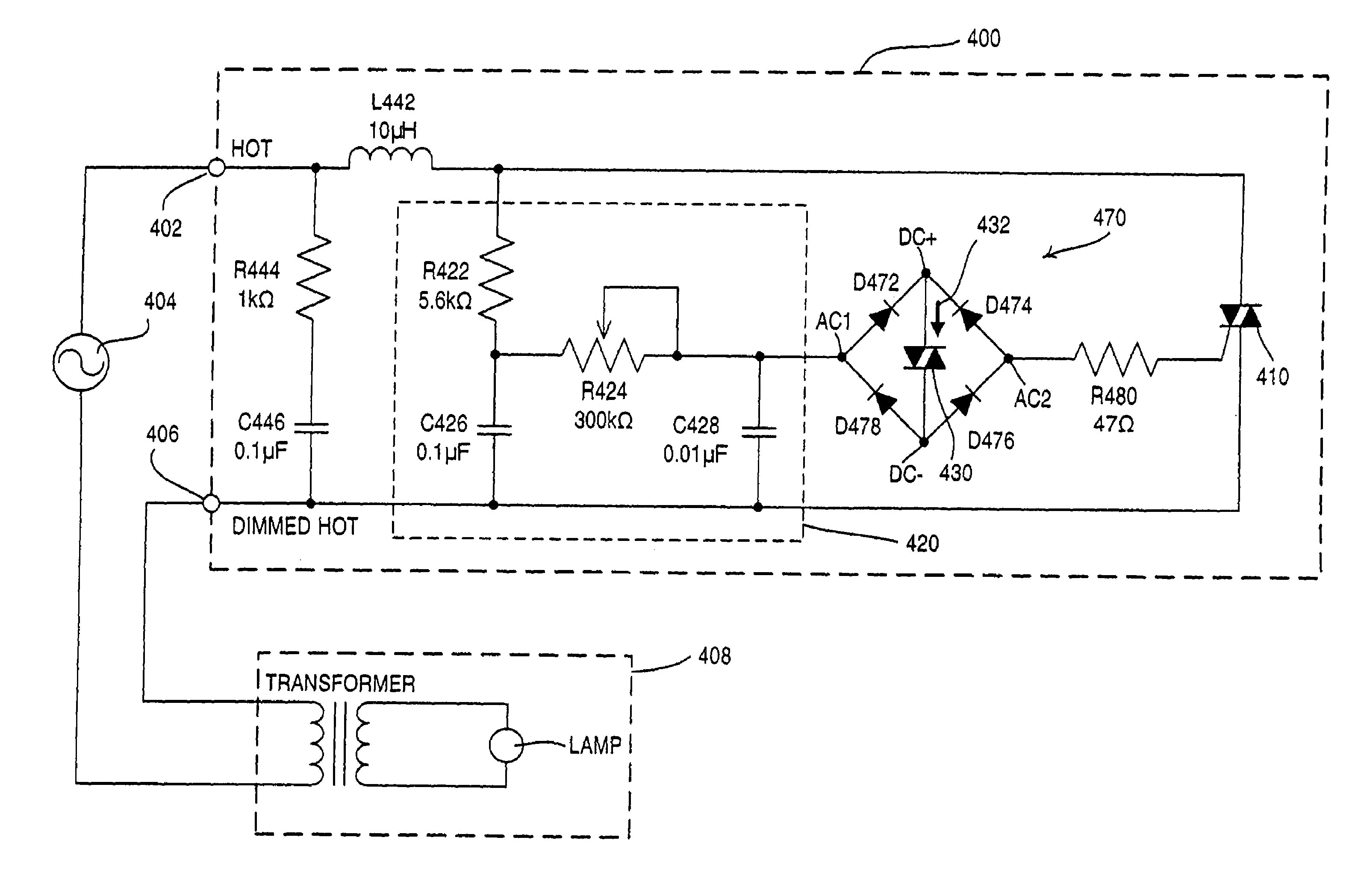

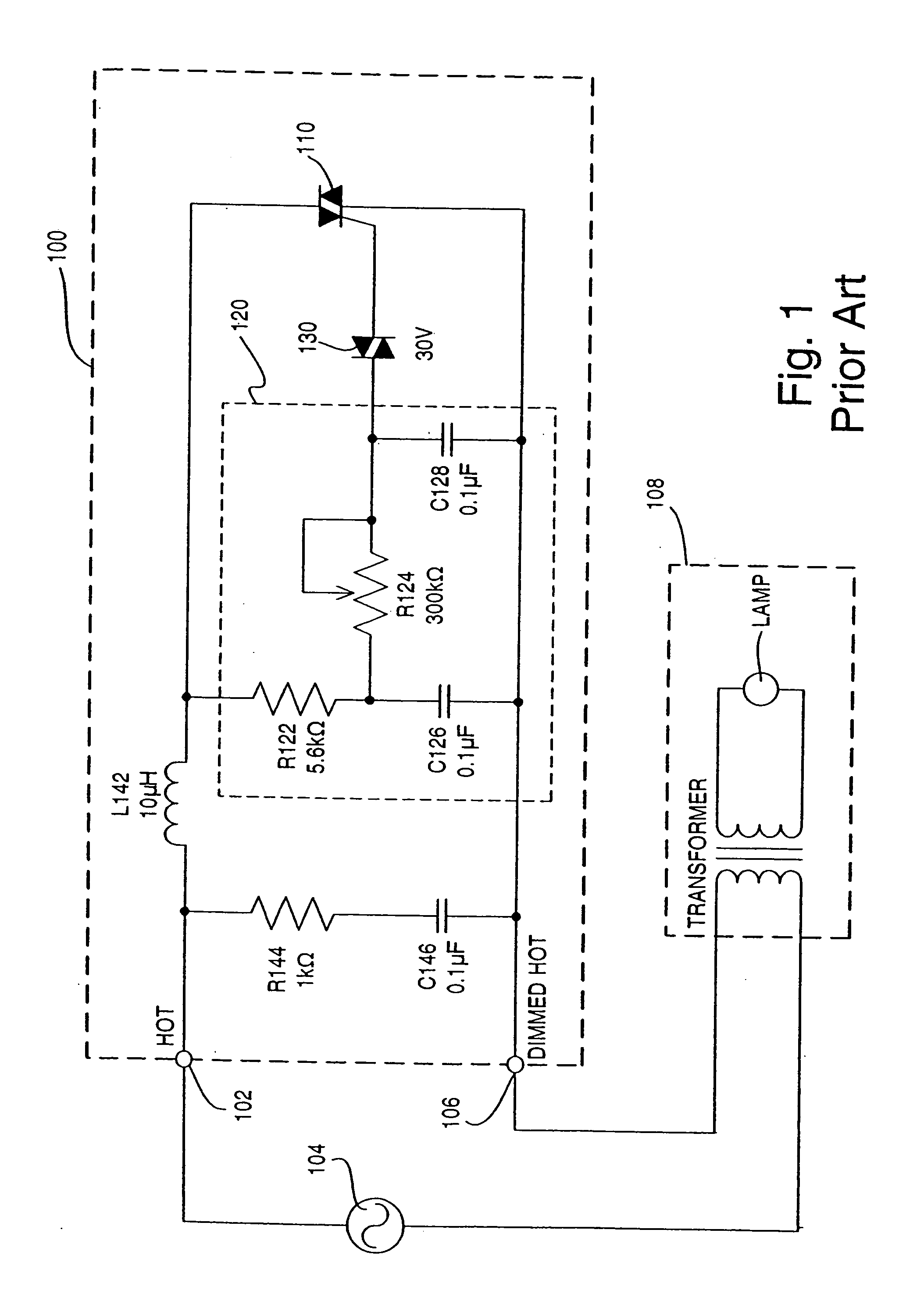

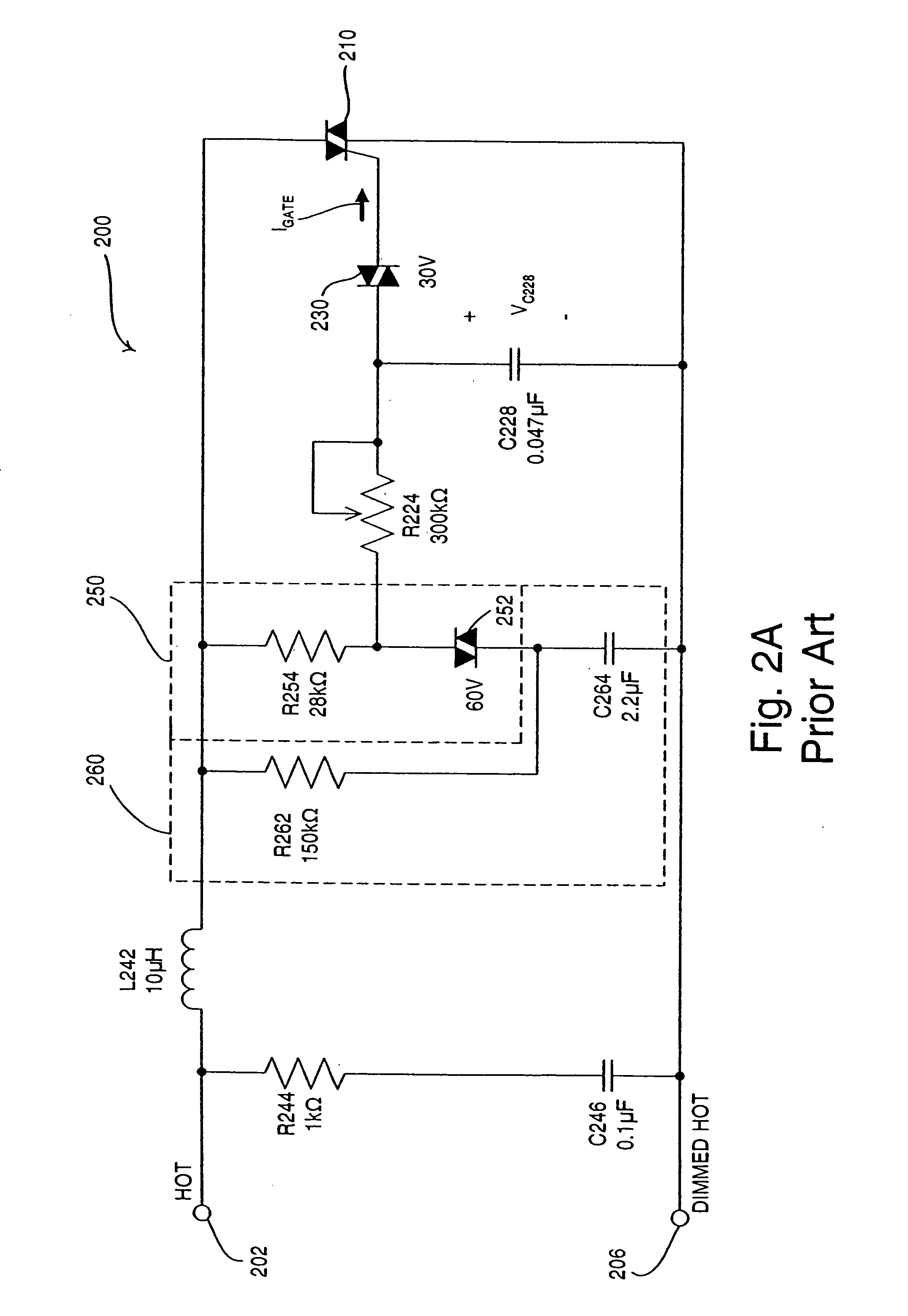

Load control circuit and method for achieving reduced acoustic noise

ActiveUS20060109702A1Reduce noiseReduce asymmetryDc network circuit arrangementsElectric light circuit arrangementTransformerLow voltage

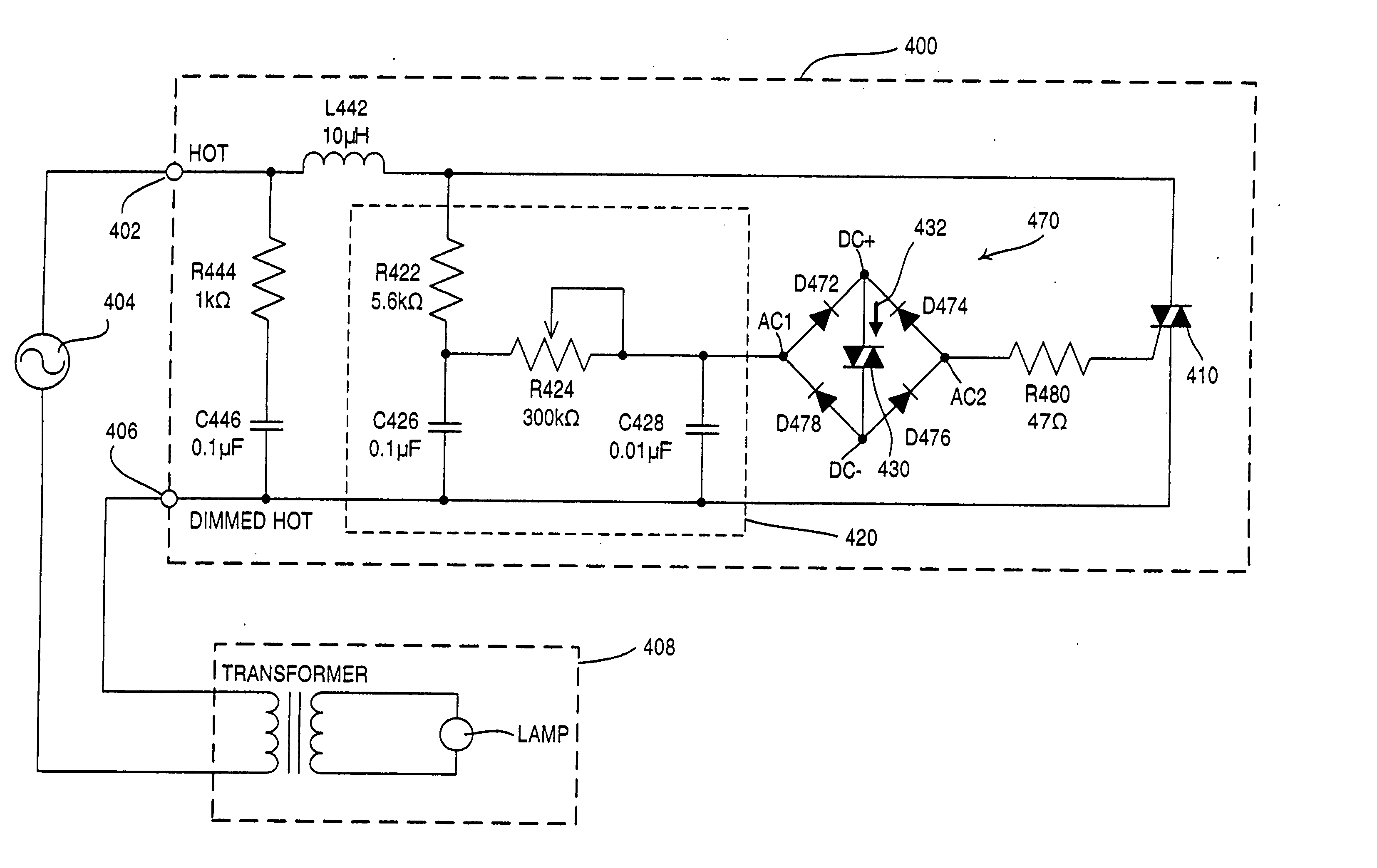

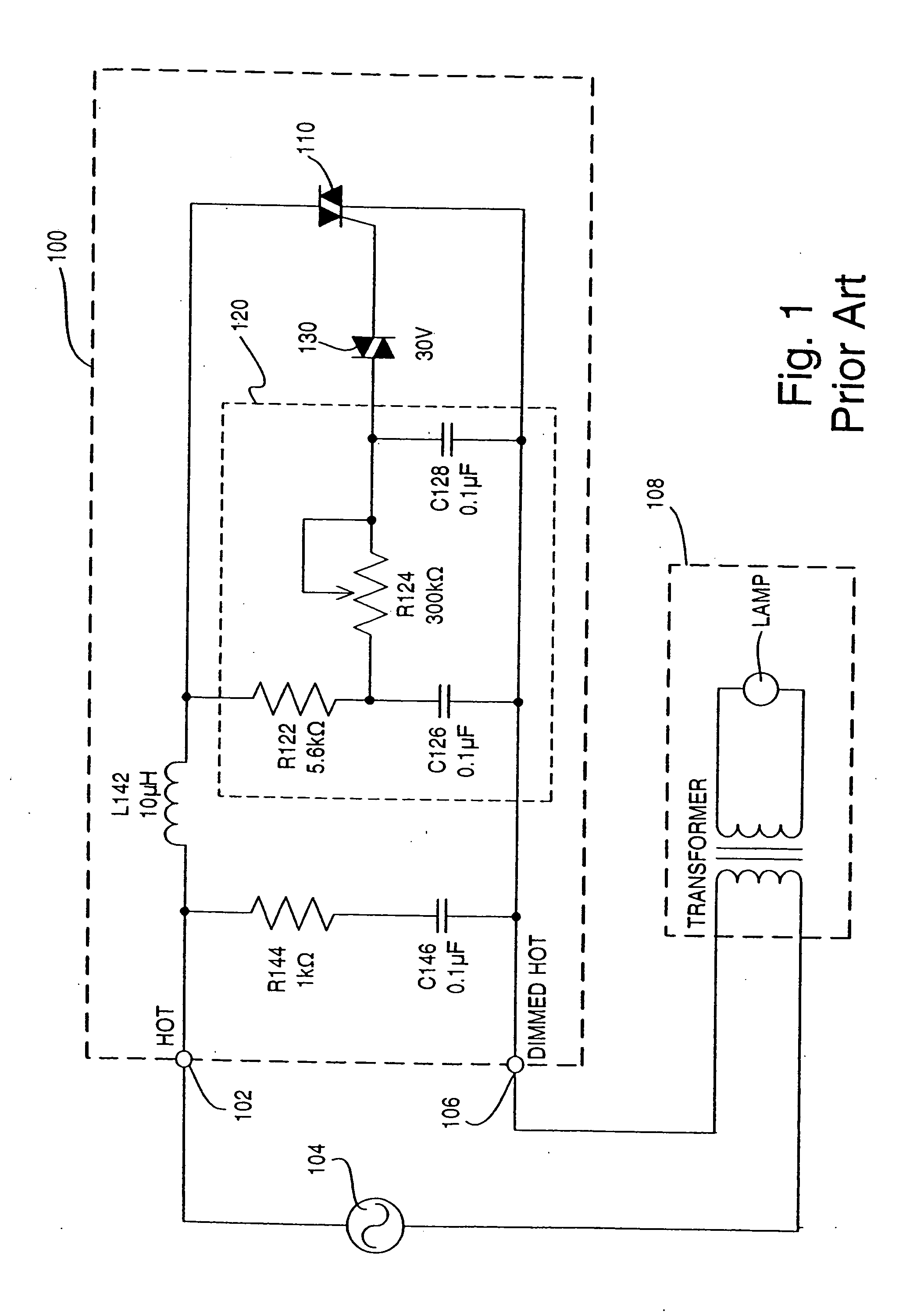

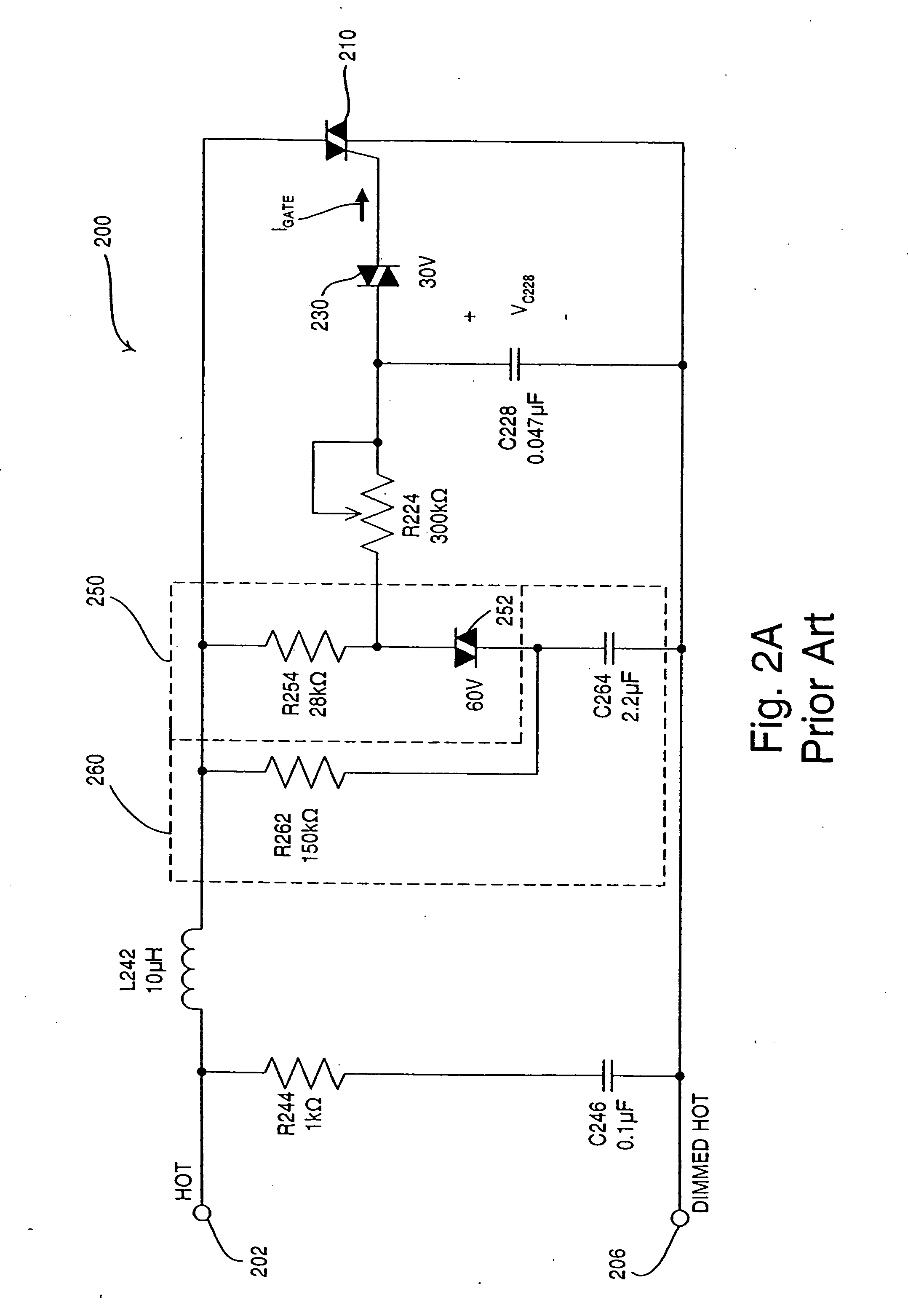

A load control circuit having first and second terminals for connection in series with a controlled load comprises a bidirectional semiconductor switch for switching at least a portion of both positive and negative half cycles of an alternating current source waveform to the load. The bidirectional semiconductor switch has a control electrode. The load control circuit includes a phase angle setting circuit, including a timing circuit, which sets the phase angle during each half cycle of the AC source waveform when the bidirectional semiconductor switch conducts. The phase angle setting circuit includes a voltage threshold trigger device connected in series with the control electrode of the switch. The phase angle setting circuit further comprises a rectifier bridge connected in series between an output of the timing circuit and the control electrode of the semiconductor switch, wherein the rectifier bridge has a first pair of terminals and a second pair of terminals, the first pair of terminals connected in series between an output of the timing circuit and the control electrode of the semiconductor switch, and the second pair of terminals connected to the voltage threshold trigger device. The load control circuit further includes an impedance in series electrical connection with the semiconductor switch control electrode. Acoustic noise generated in the load connected in series with the load control circuit is reduced, particularly when the load is a toroidal transformer driving a magnetic low voltage lamp and the load control circuit is a two-wire dimmer.

Owner:LUTRON TECH CO LLC

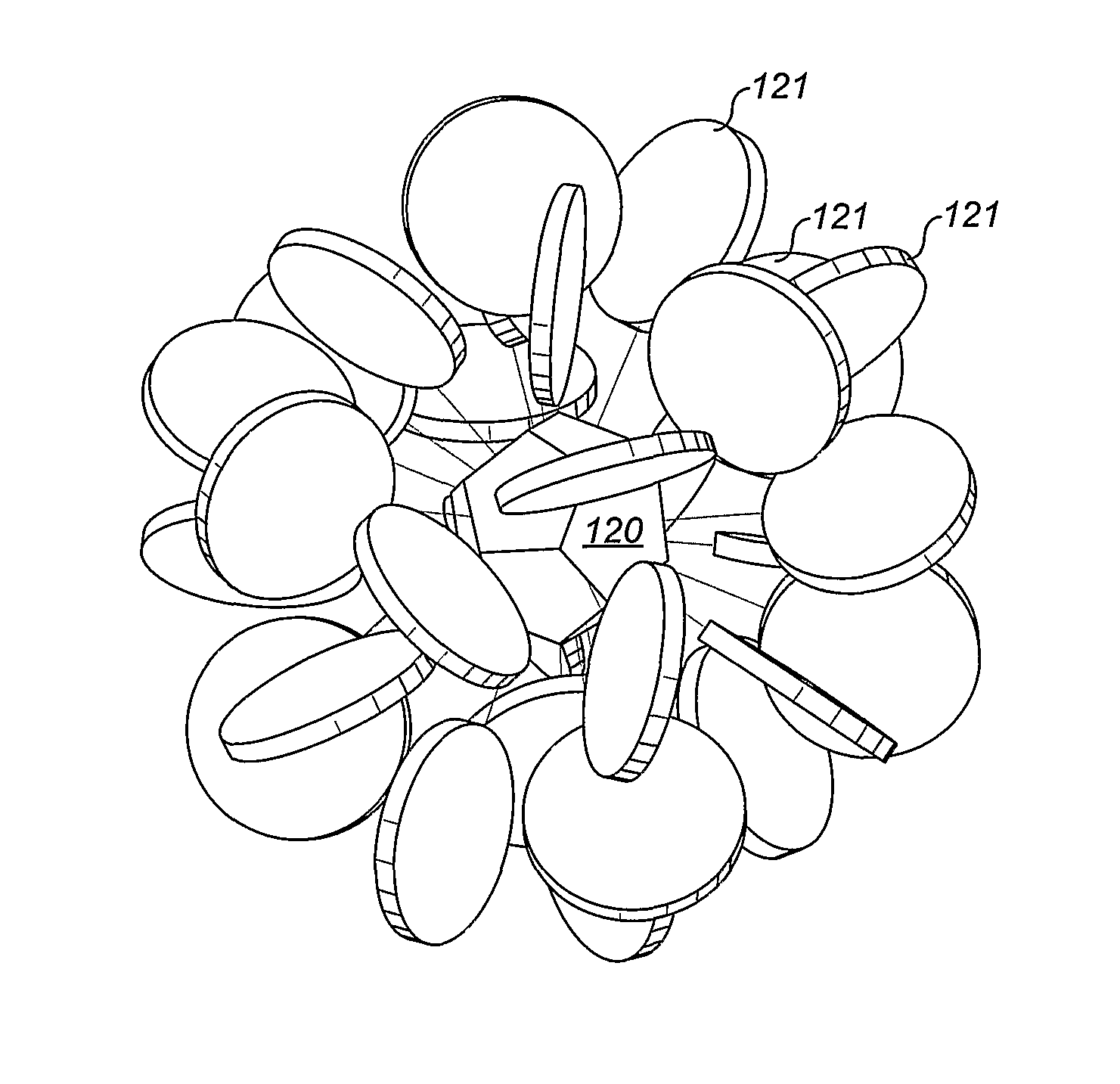

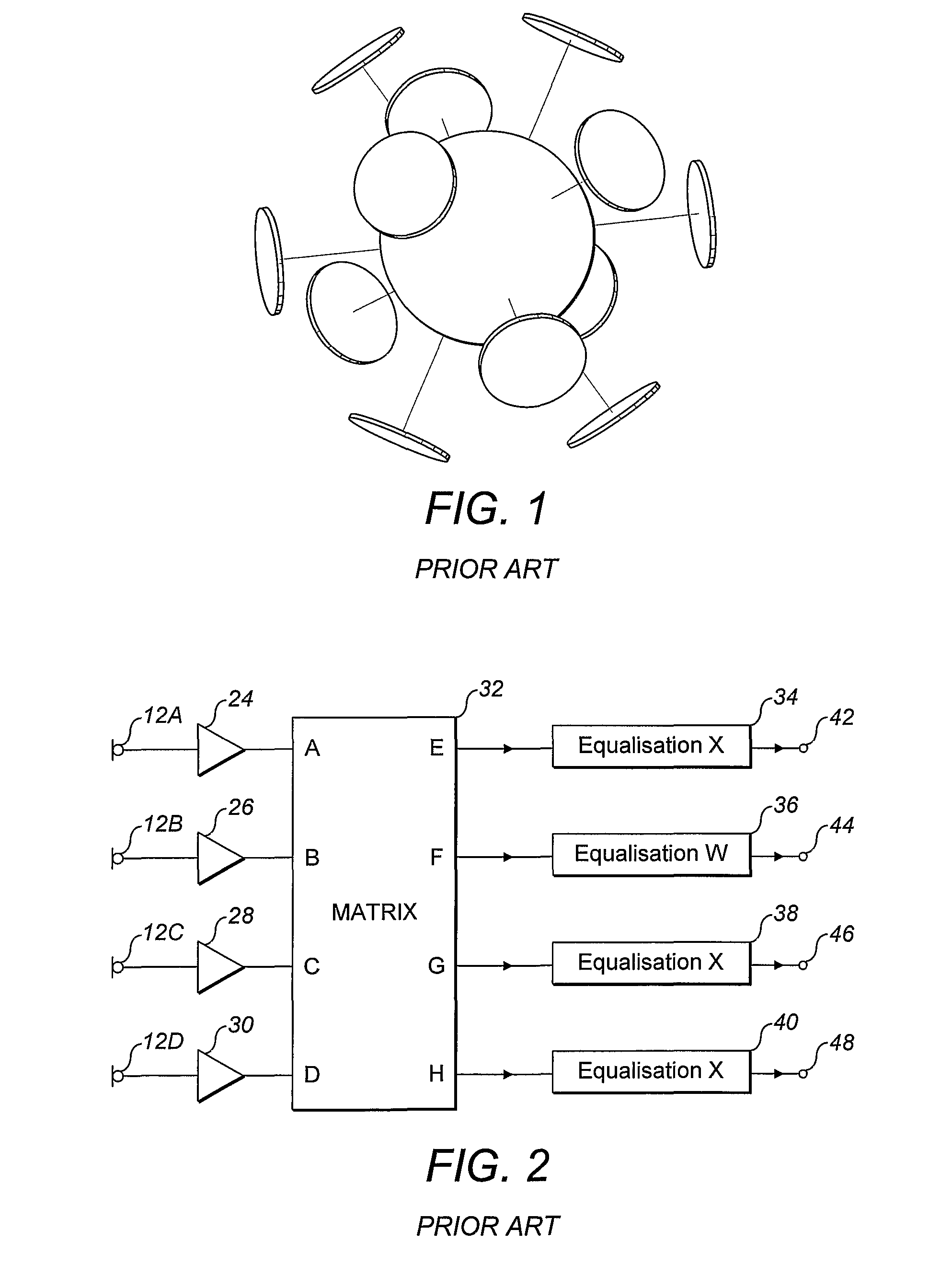

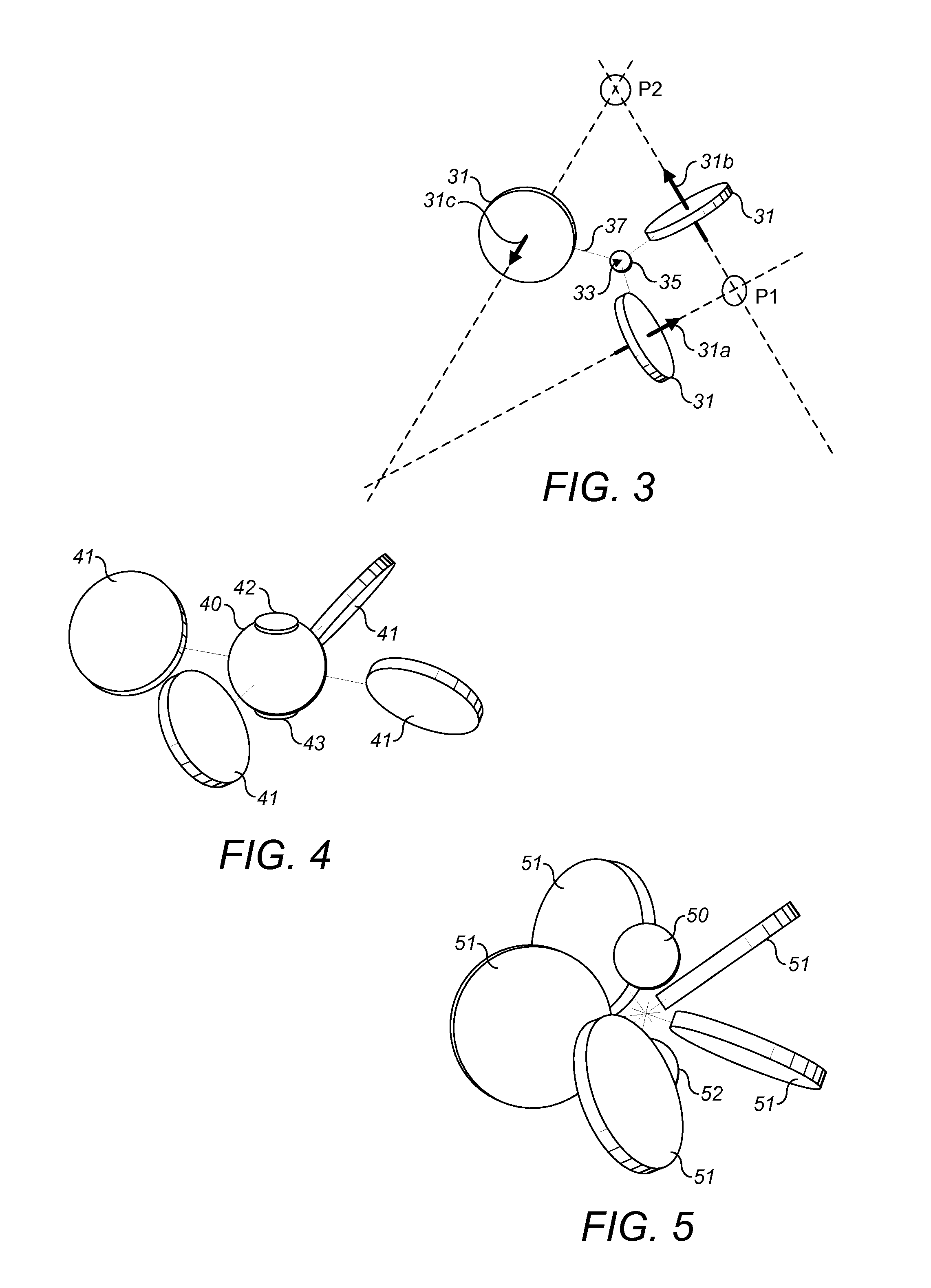

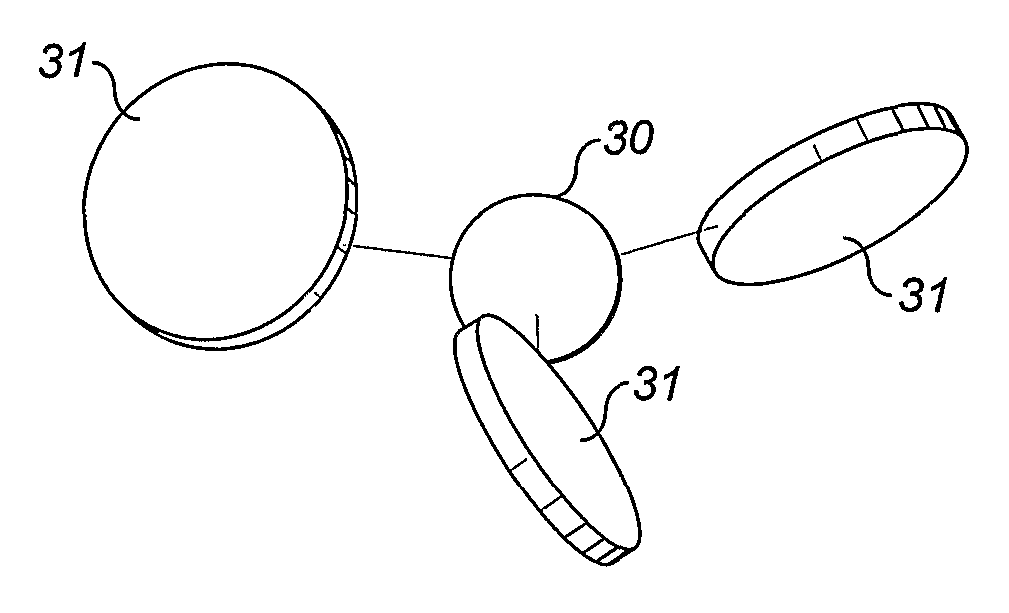

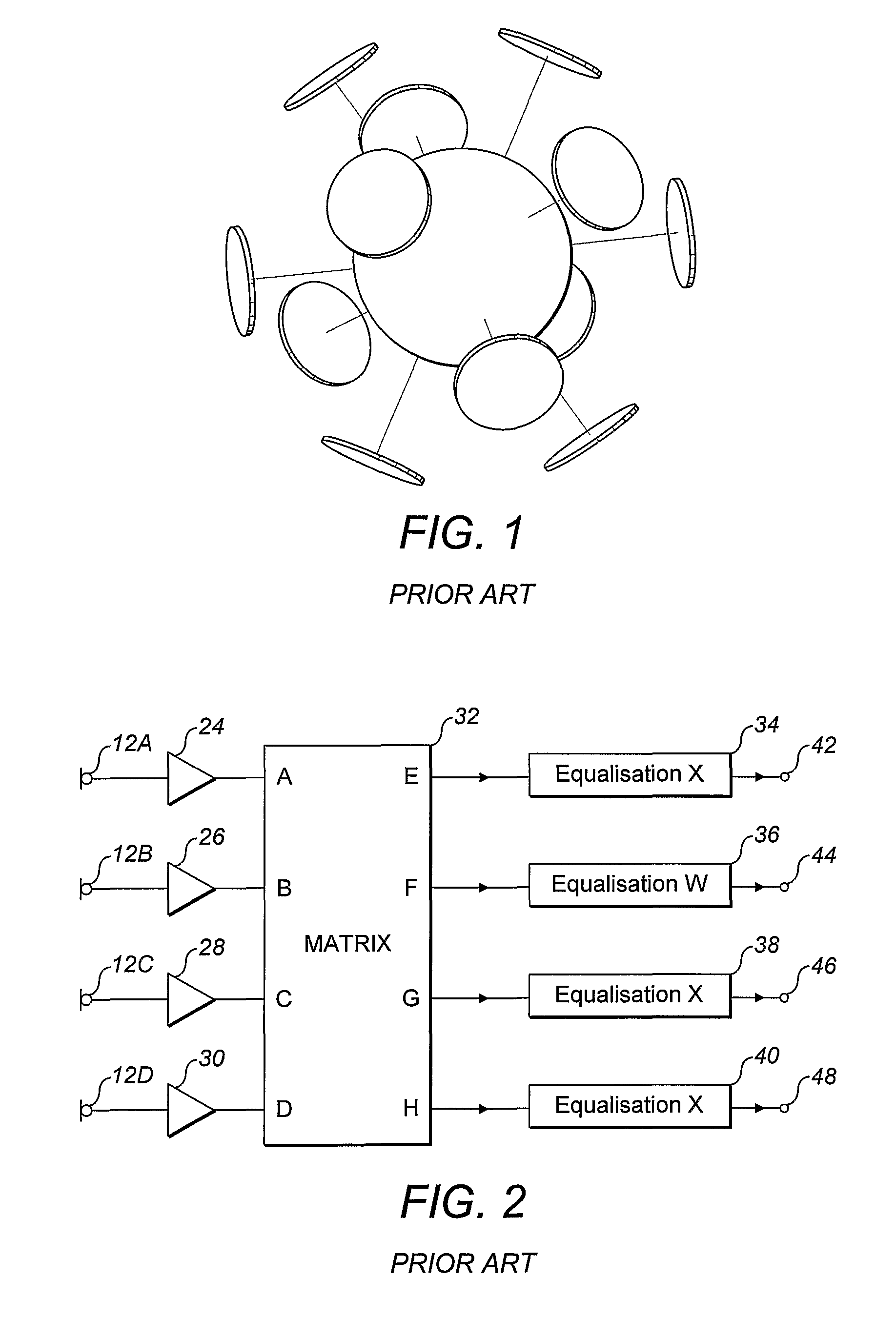

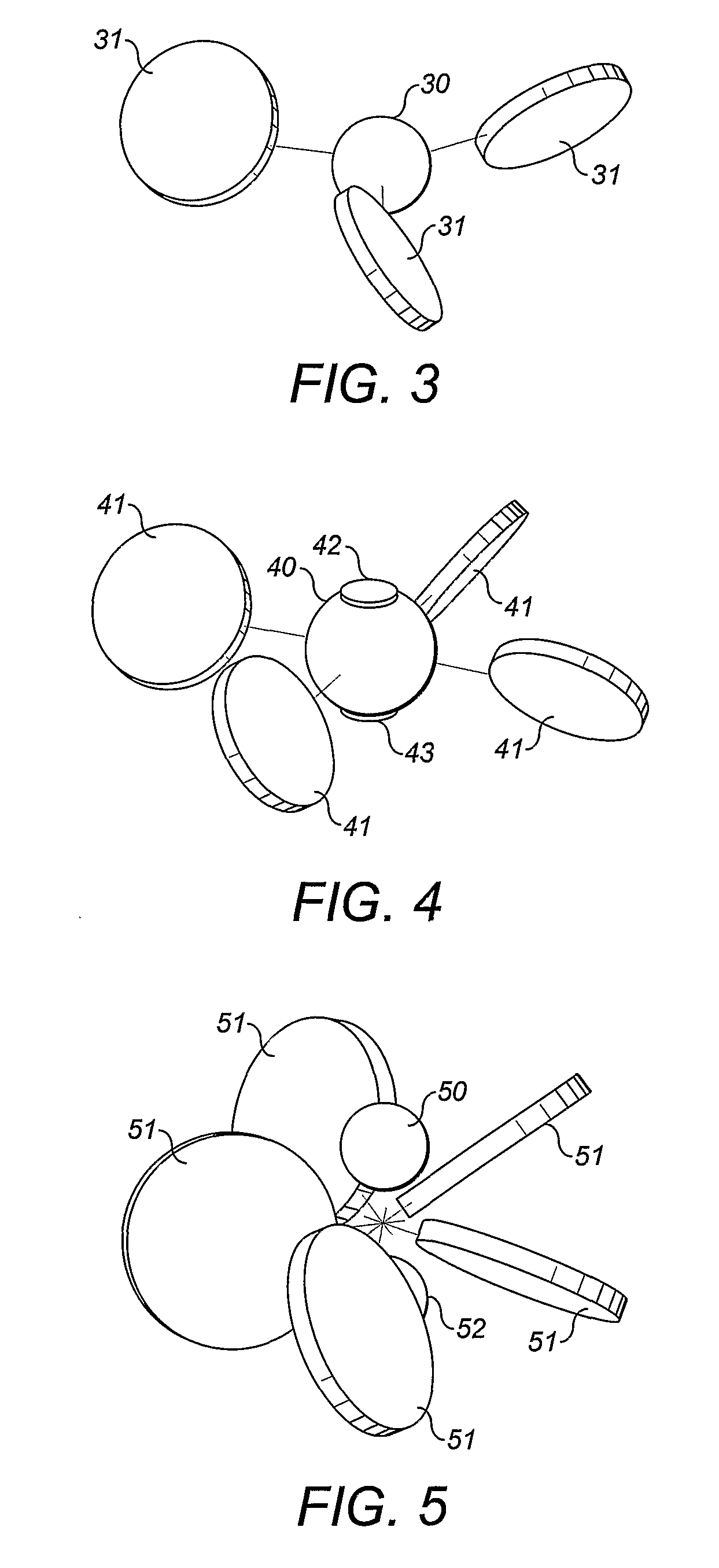

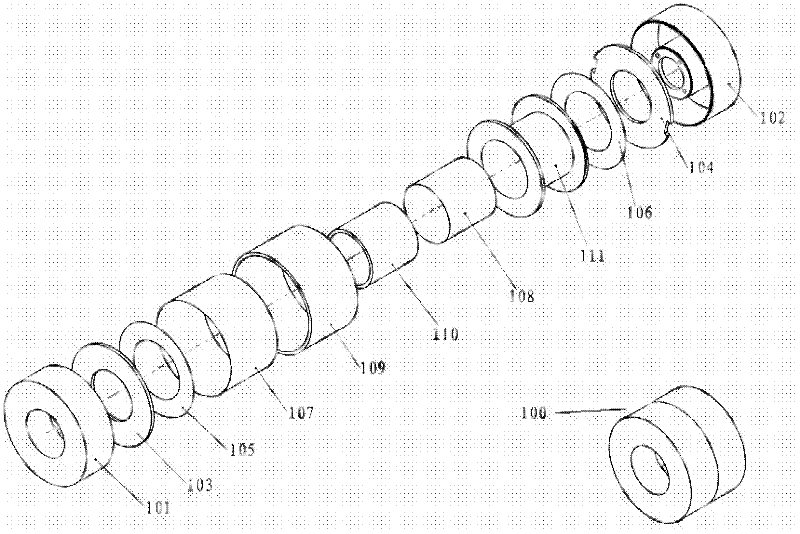

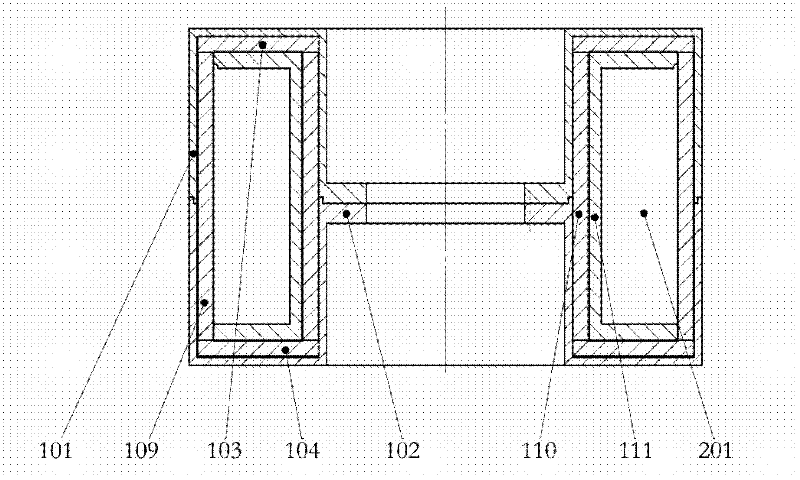

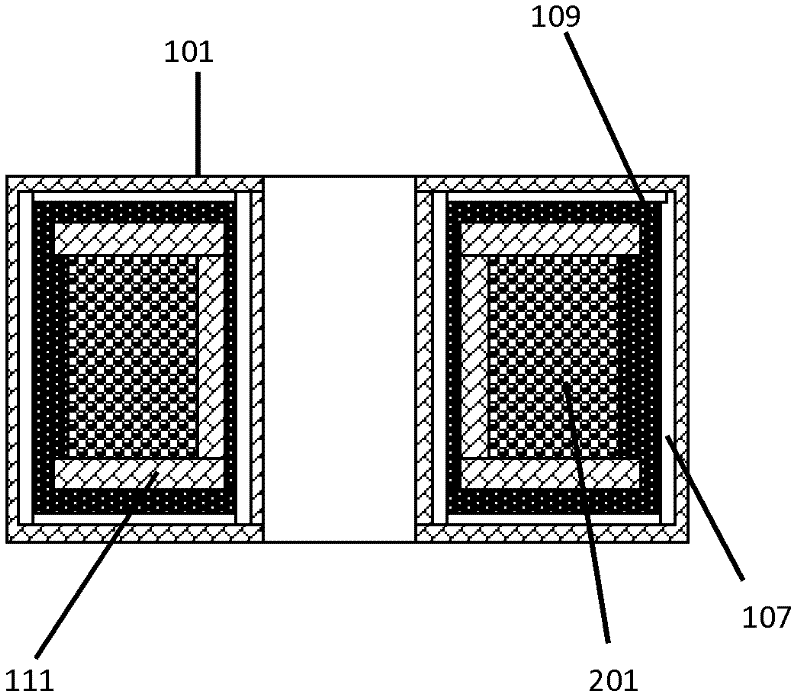

Microphone array

ActiveUS8406436B2Trend downReduce asymmetryMicrophonesTransducer detailsSignal-to-noise ratio (imaging)Spherical harmonics

A sound capture device comprises a symmetric microphone array that includes non-radially-oriented directional sensors (101). The device typically derives a spherical harmonic representation of the incident sound field, and affords higher signal-to-noise ratios and better directional fidelity than prior arrays, across a wide range of audio frequencies.

Owner:CRAVEN PETER G +2

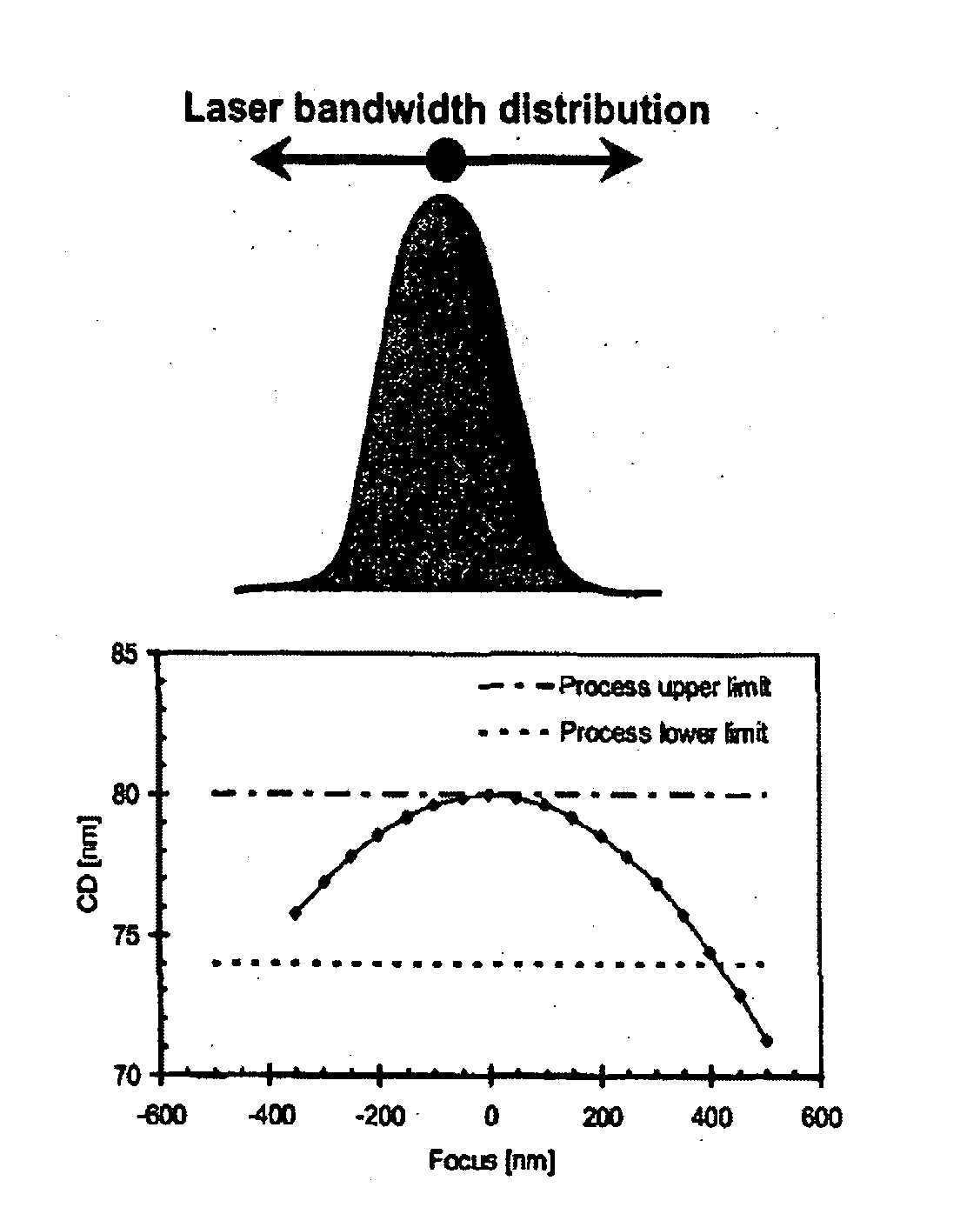

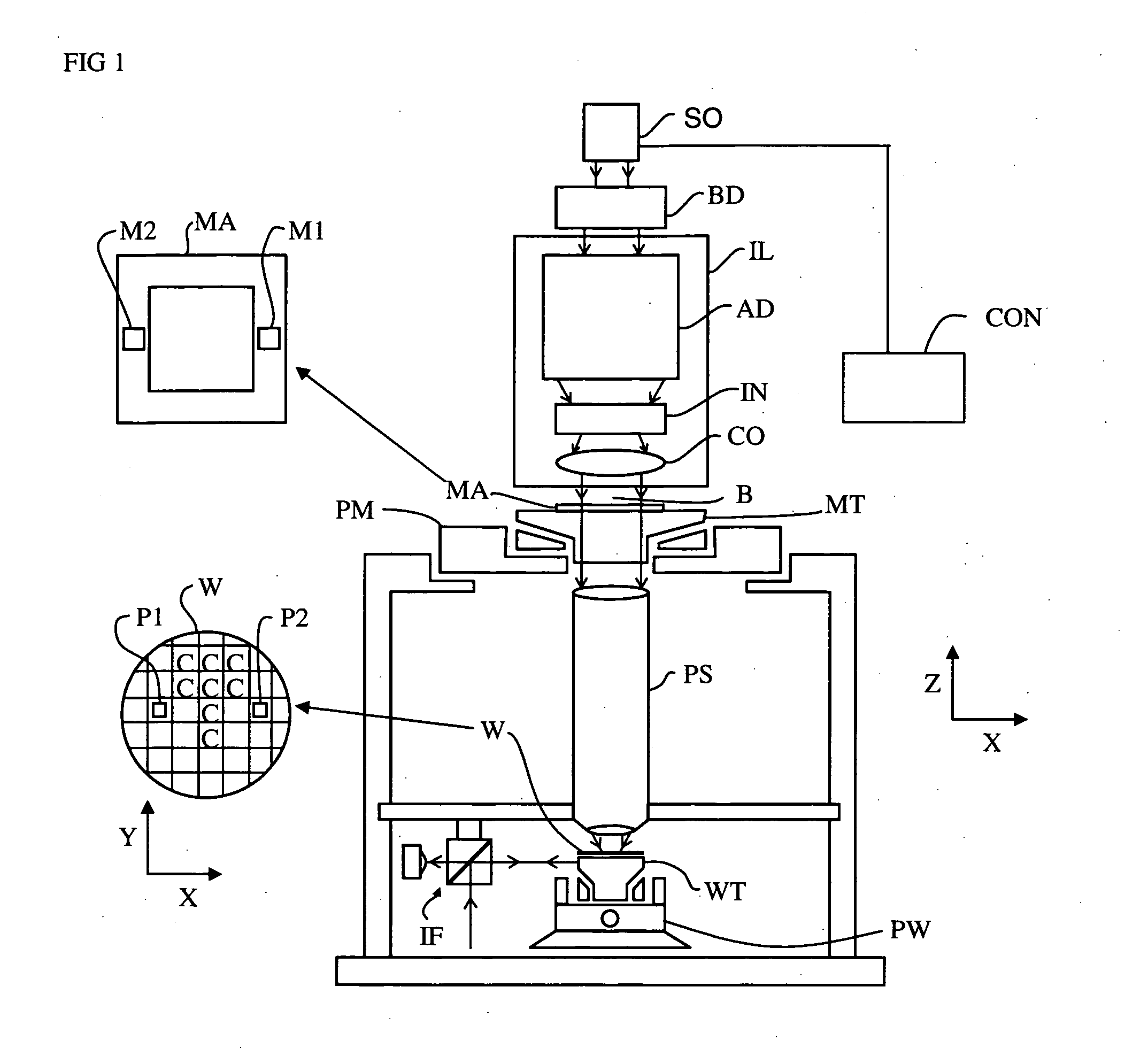

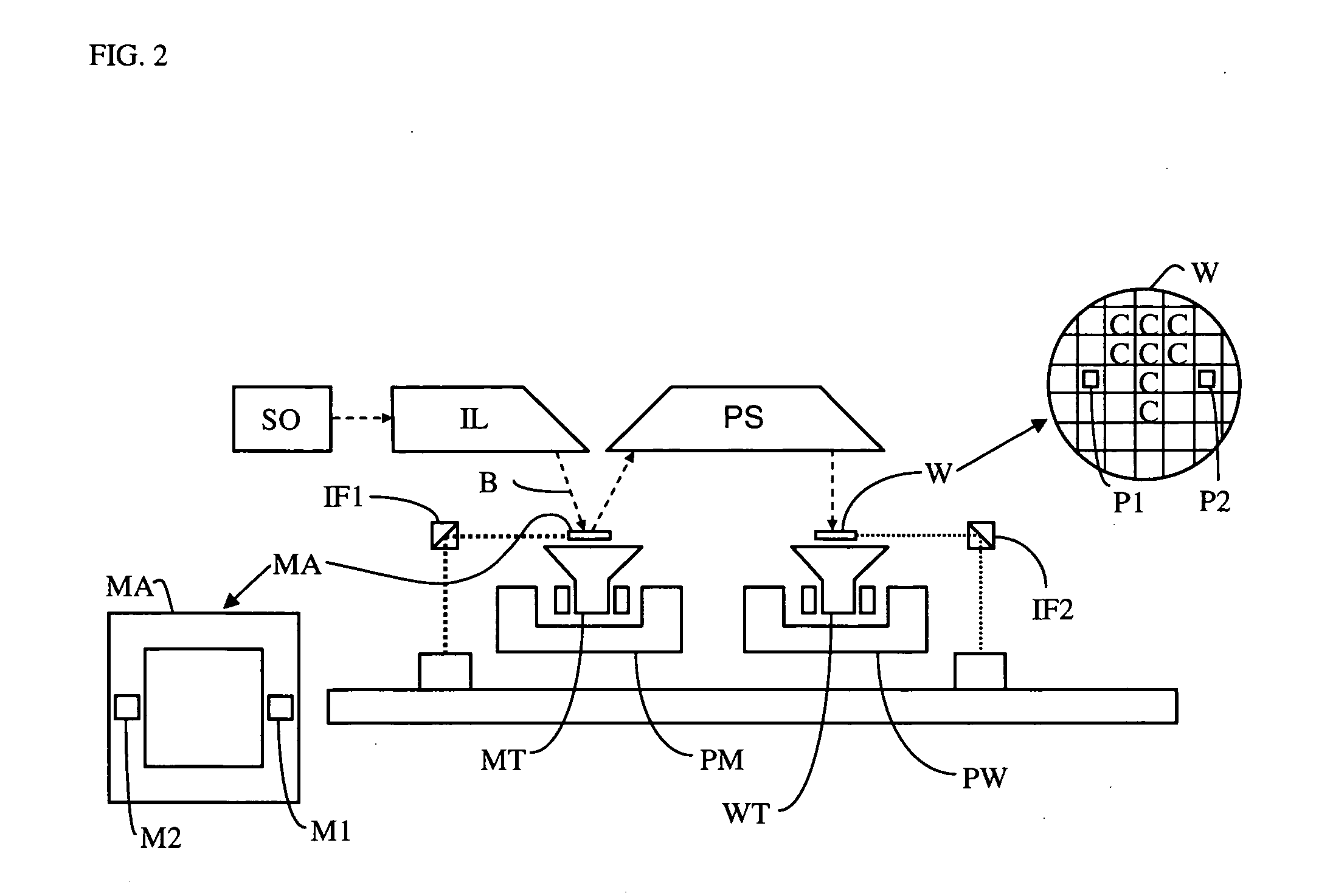

Lithographic apparatus, excimer laser and device manufacturing method

ActiveUS20060146310A1Increase depth of focusEffect on the image contrast at wafer levelPhotomechanical apparatusPhotographic printingLight beamVolumetric Mass Density

Owner:ASML NETHERLANDS BV

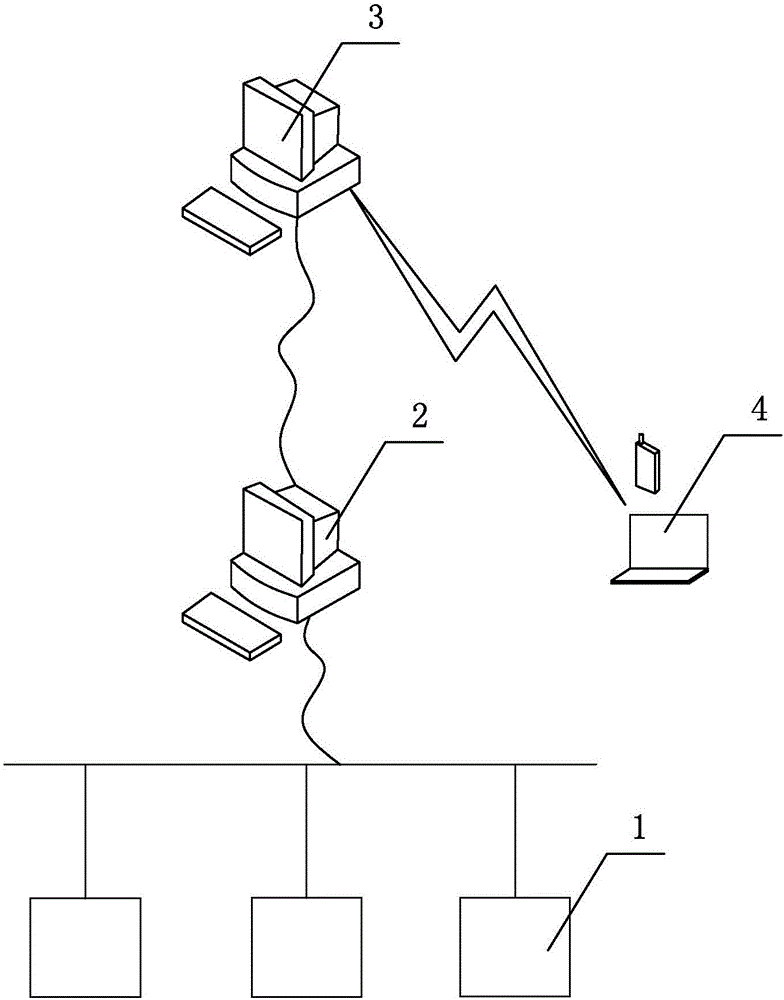

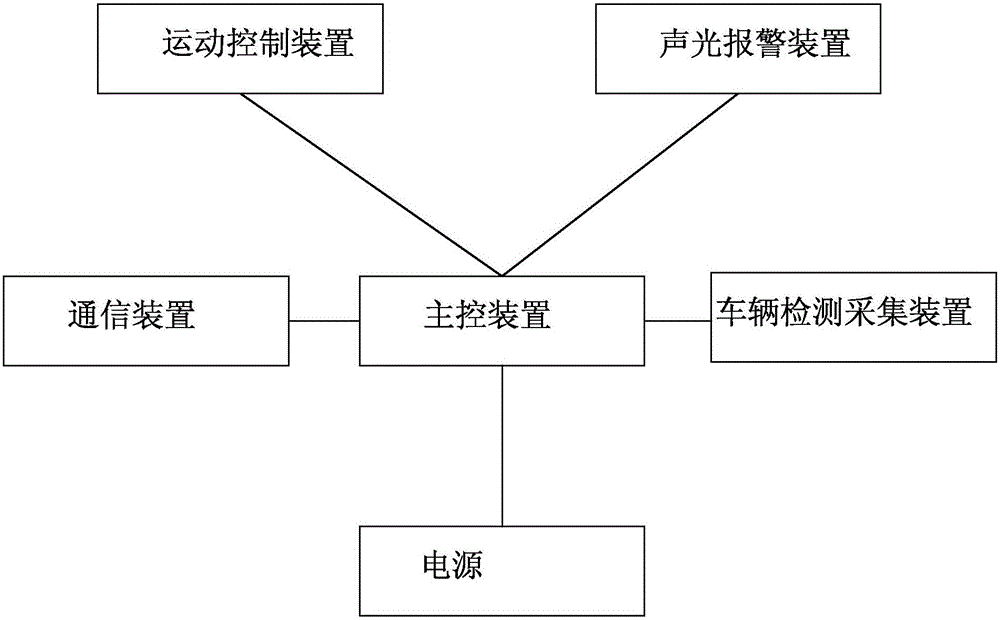

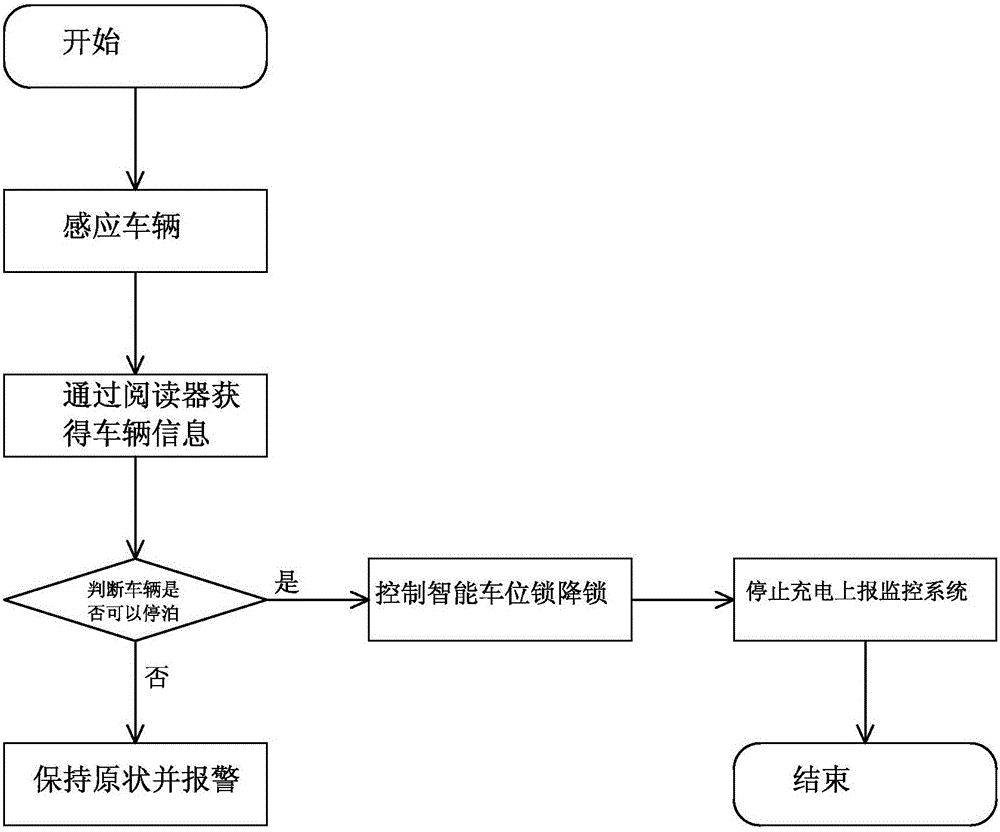

Intelligent parking stall control system and method of charging station

InactiveCN105679086AReal-time access to charging statusIncrease usageAlarms with smoke/gas/colored-powderIndication of parksing free spacesControl systemMonitoring system

An intelligent parking space control system and method for a charging station, including an intelligent parking space lock, a station-level monitoring system, an operation monitoring system, and a client, the intelligent parking space lock including a power supply, a vehicle detection and acquisition device, a communication device, a main control device, and a motion control device, sound and light alarm device. The advantages of the present invention are: the vehicle attributes can be identified through the vehicle detection and acquisition device, and the station-level monitoring system can automatically identify and warn electric vehicles that do not need to be charged or have been fully charged, which can significantly improve the utilization rate of charging parking spaces. The operation monitoring system provides information to the client, and can share the information of the charging parking space of the charging station itself for users to query, so that users can find the optimal charging parking space and its location, and reduce the asymmetry of supply and demand information of charging parking spaces.

Owner:BEIJING FANGZHI TECH CO LTD

Microphone array

ActiveUS20100142732A1Simple processUniform responseMicrophonesTransducer detailsSignal-to-noise ratio (imaging)Spherical harmonics

A sound capture device comprises a symmetric microphone array that includes non-radially-oriented directional sensors (101). The device typically derives a spherical harmonic representation of the incident sound field, and affords higher signal-to-noise ratios and better directional fidelity than prior arrays, across a wide range of audio frequencies.

Owner:CRAVEN PETER G +2

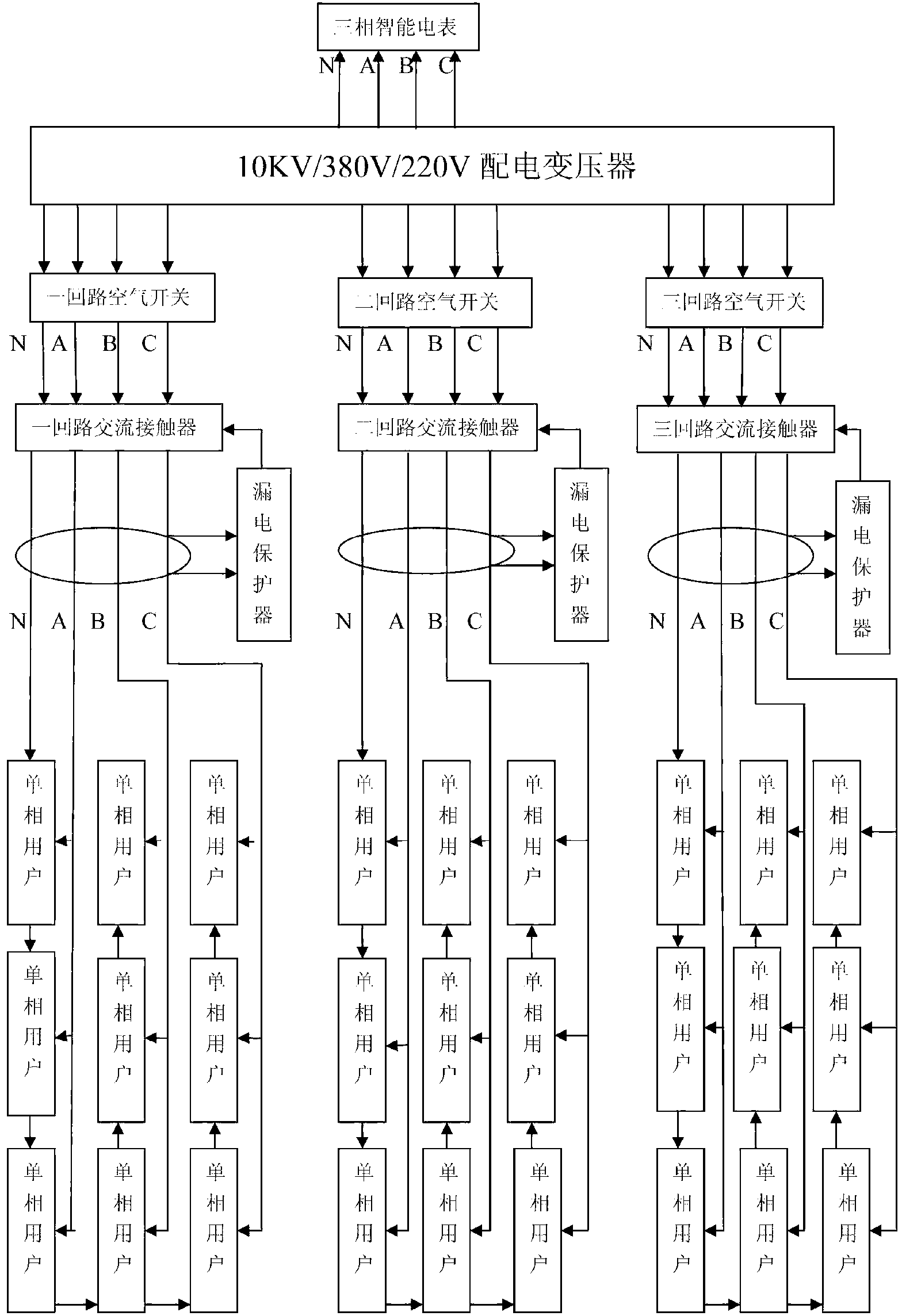

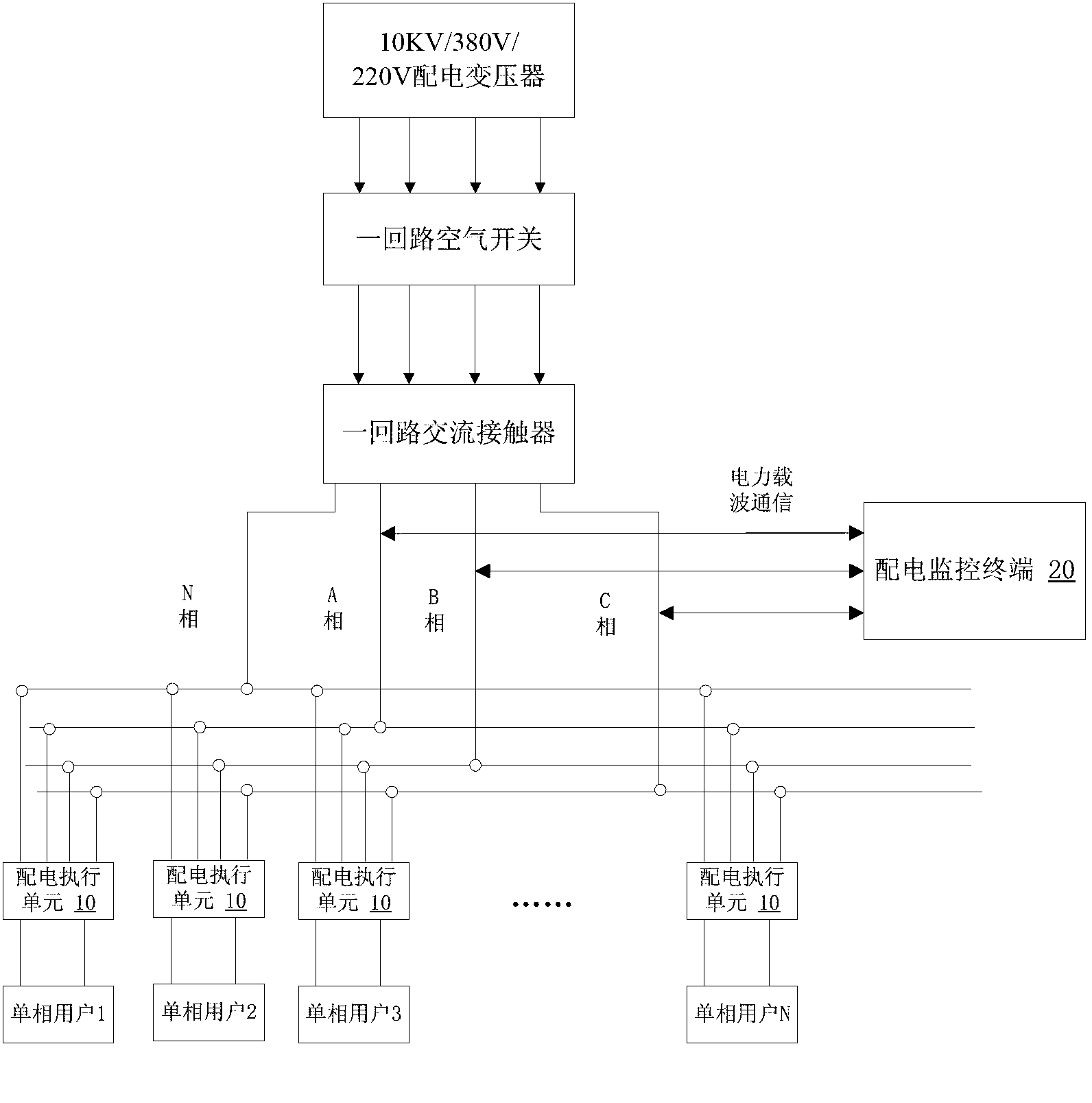

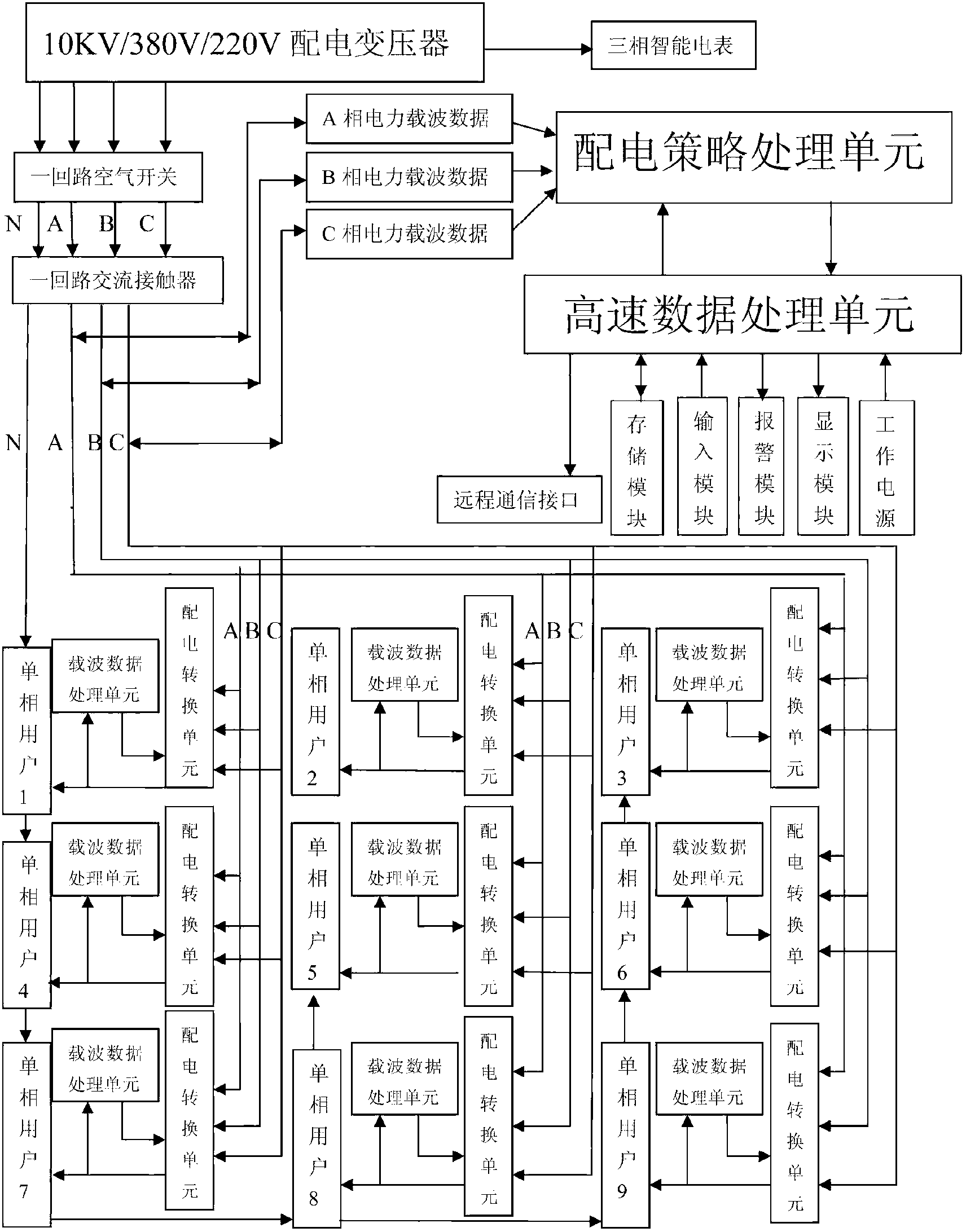

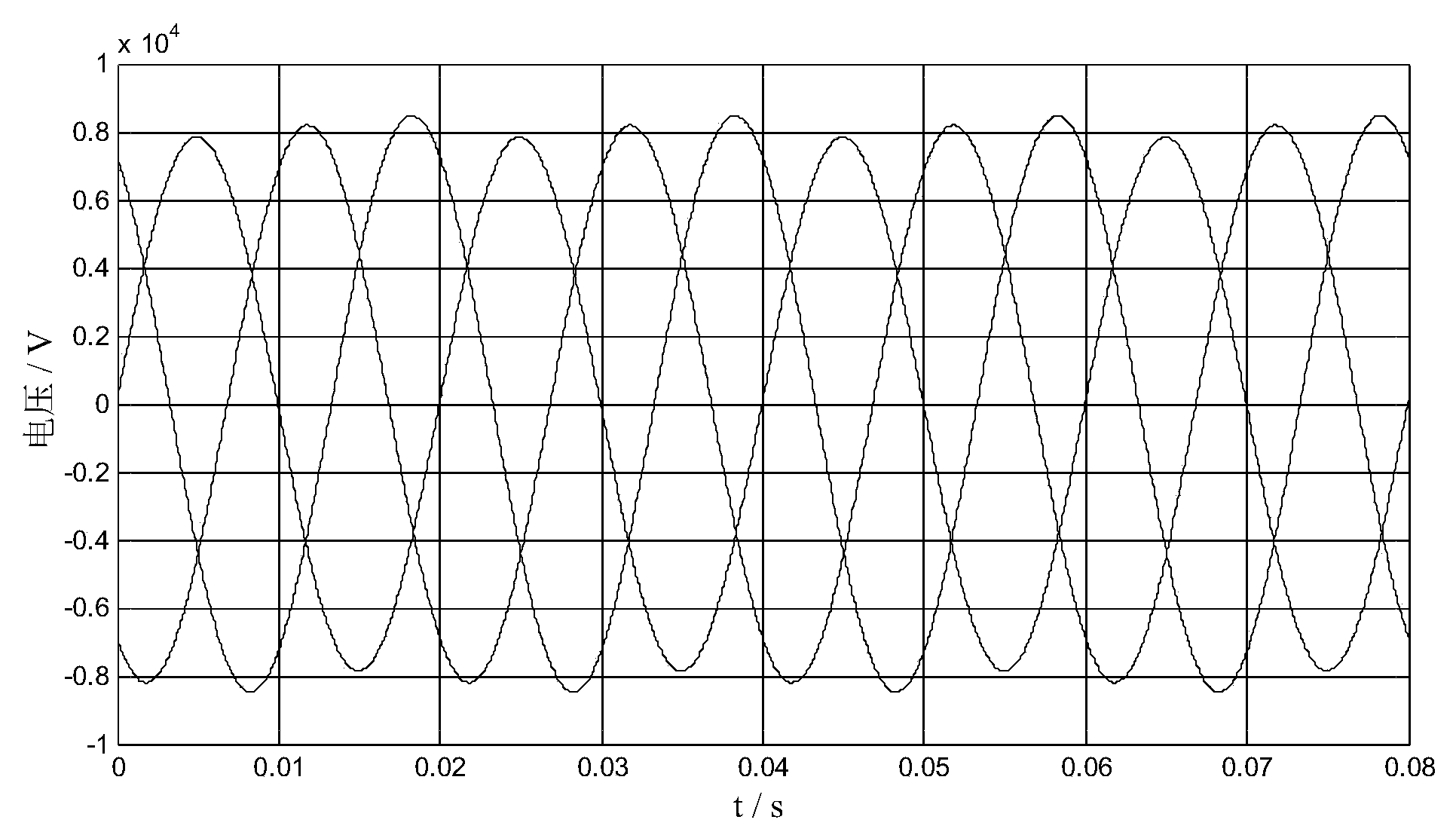

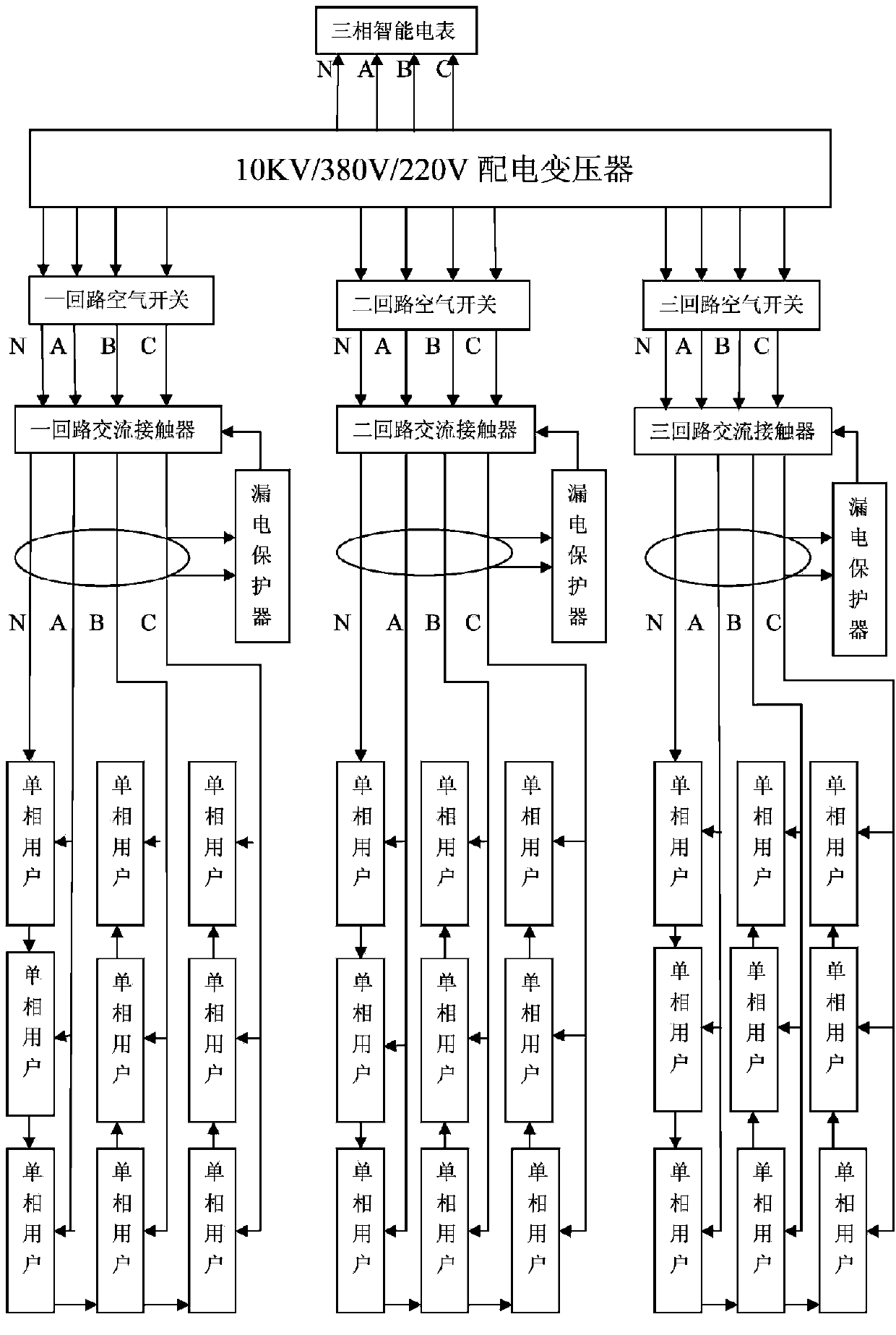

Automatic intelligent power distribution system and power distribution method

ActiveCN103259276AEasy to detectRealize functionPolyphase network asymmetry elimination/reductionEmergency protective arrangements for automatic disconnectionLow voltageDistribution power system

The invention discloses an automatic intelligent power distribution system and a power distribution method. The power distribution system comprises a power distribution executing unit, and the power distribution executing unit receives a power distribution command from a power distribution monitoring terminal and gates a corresponding phase line on a three-phase power transmission line to a single-phase power supply line on an output side of the power distribution executing unit to achieve intelligent power distribution. According to the automatic intelligent power distribution system, low-voltage three-phase disequilibrium distribution on an input side of a single-phase user is achieved through the power distribution executing unit on an input side of an electricity meter of the single-phase user, the power distribution monitoring terminal receives the electrical load information of each single-phase user in a wireless or power line carrier communication mode, and a basis is provided for the equilibrium distribution of single-phase user quantity on each phase line of the three-phase power transmission line on the whole; the power distribution monitoring terminal sends the power distribution command to the power distribution executing unit and the power distribution executing unit enables each single-phase user to be connected to a corresponding power supply phase line in a grouping mode, and therefore equilibrium power distribution is achieved for single-phase users on a low-voltage side.

Owner:长沙高升电子电器科技有限公司

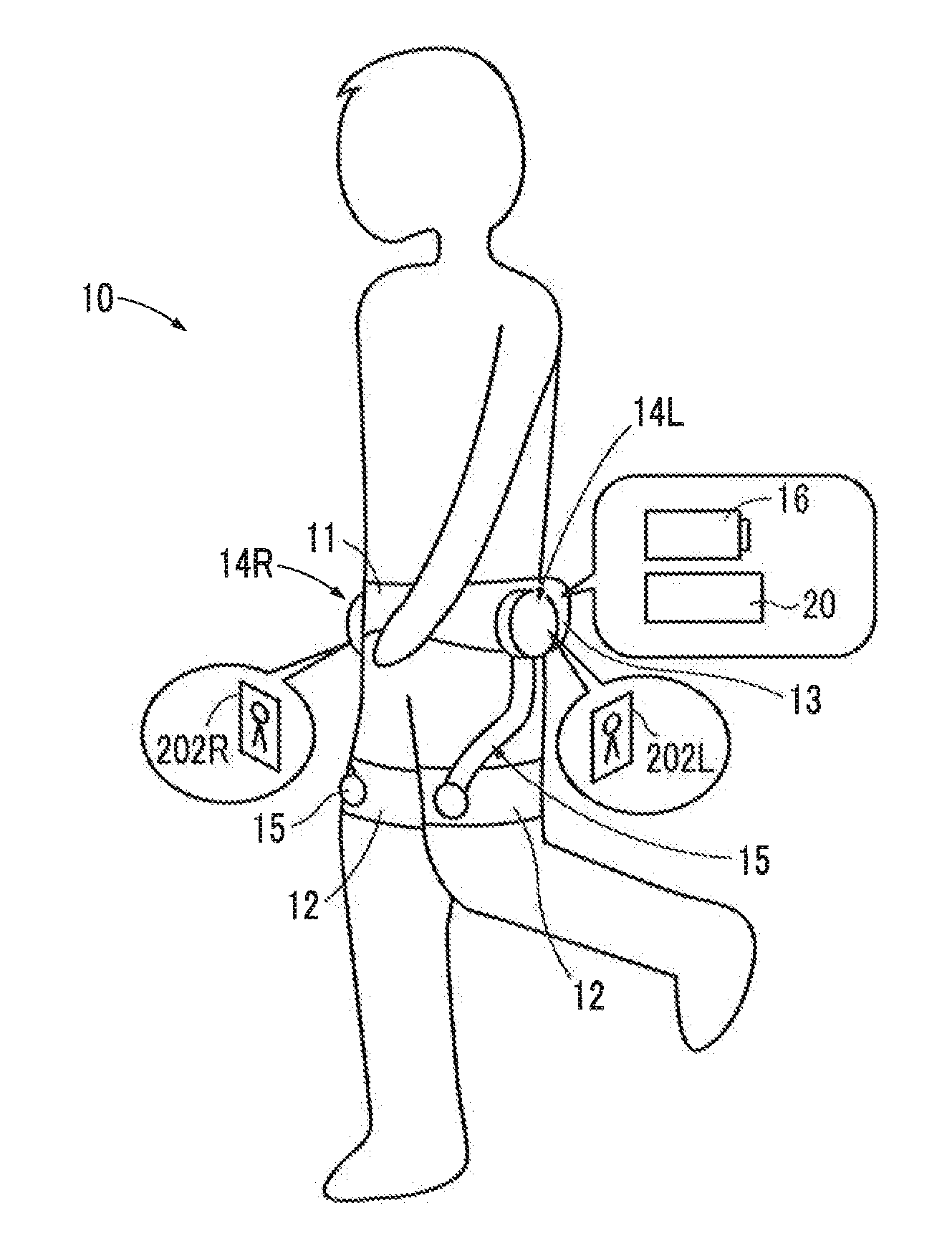

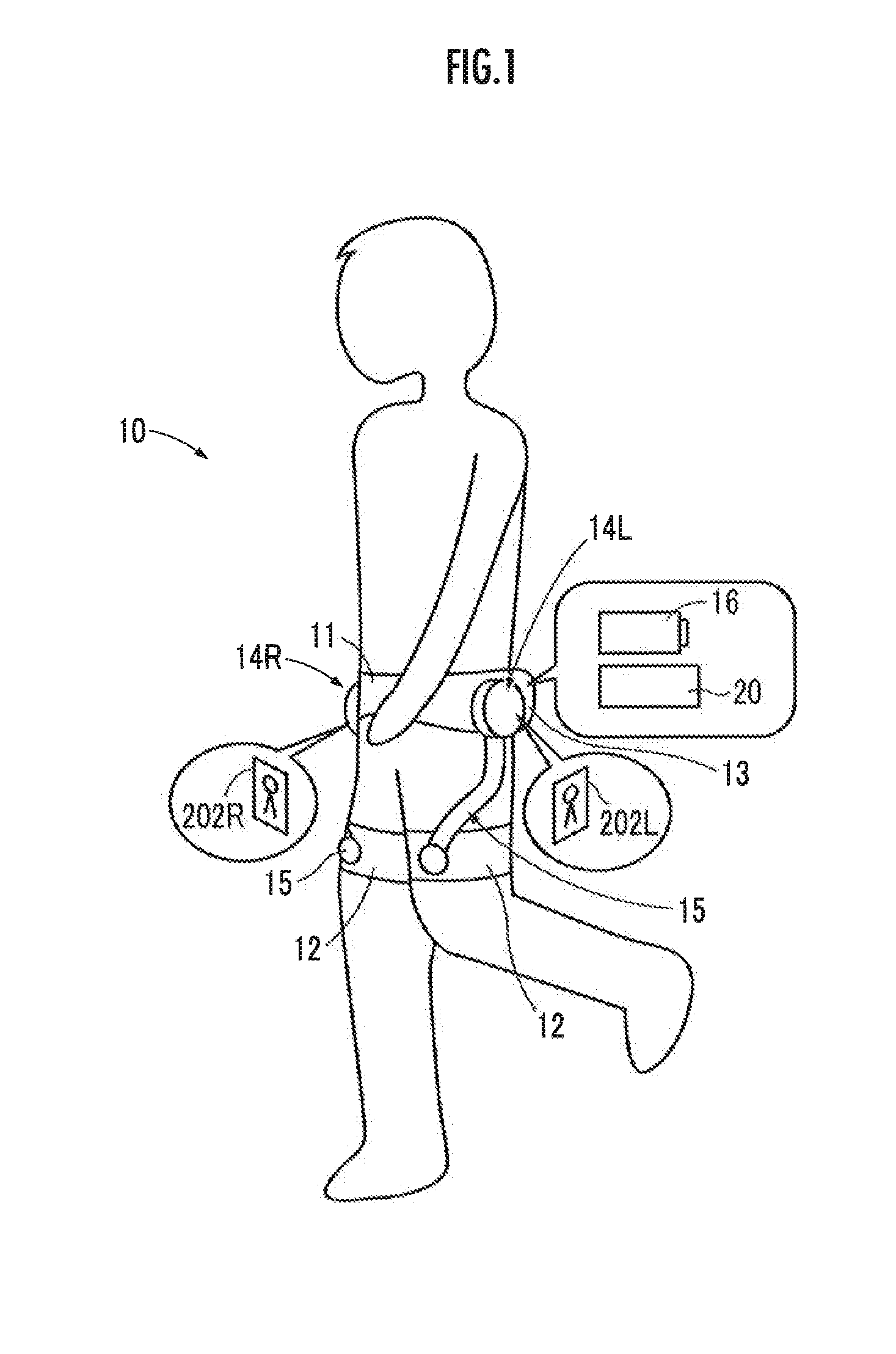

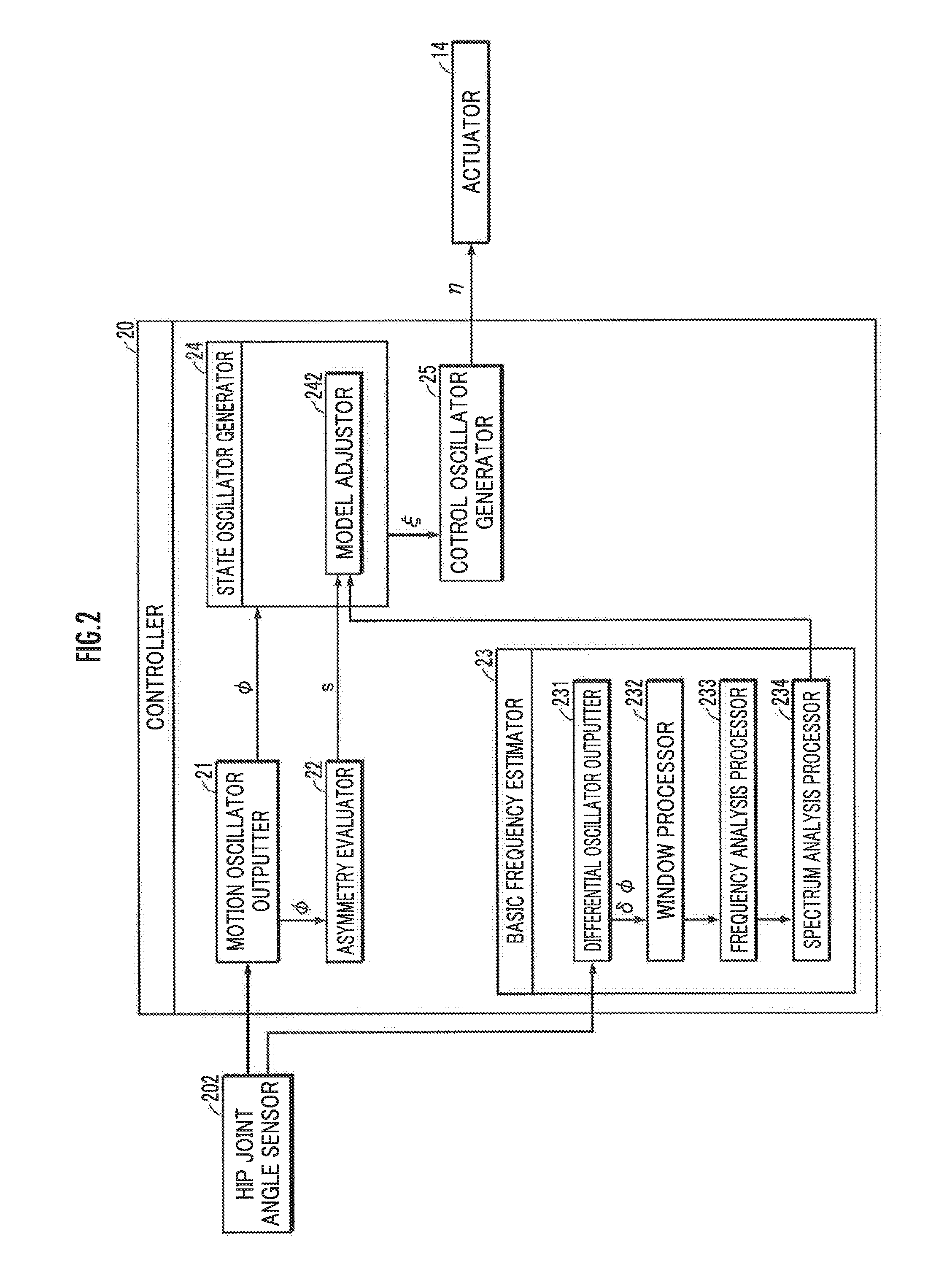

Walking assist device, walking assist method, walking state estimating device and walking state estimating method

ActiveUS20120310122A1Maintain motionDegree of reductionChiropractic devicesWalking aidsTime dependencyEngineering

A walking assist device evaluates the degree of asymmetry between a left motion oscillator, which is a waveform signal indicative of the time-dependent change form of an output of a left hip joint angle sensor, and a right motion oscillator, which is a waveform signal indicative of the time-dependent change form of an output of a right hip joint angle sensor. In order to reduce the degree of asymmetry, the value of at least one of a left bending coefficient, a left stretching coefficient, a right bending coefficient, and a right stretching coefficient is adjusted.

Owner:HONDA MOTOR CO LTD

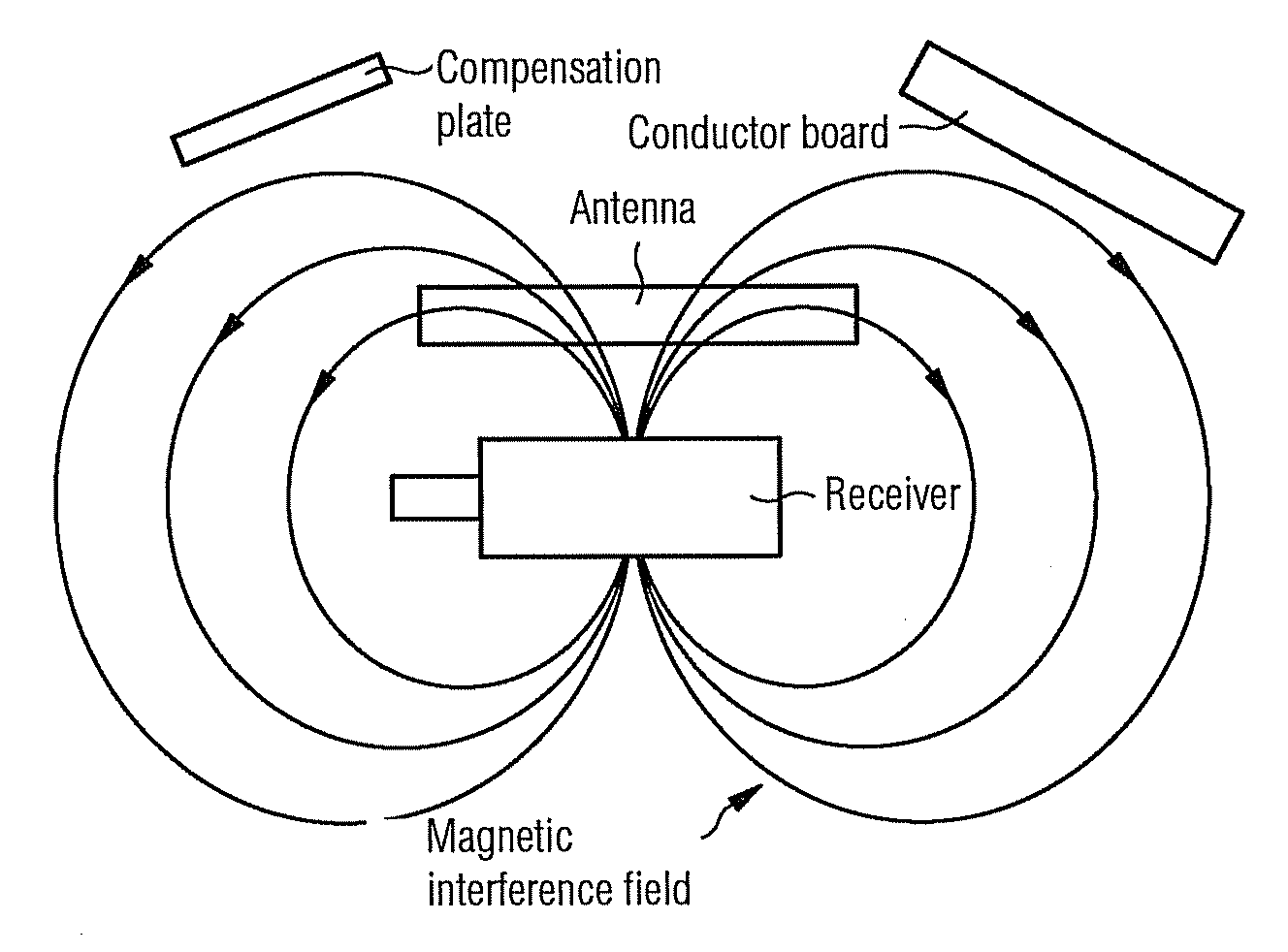

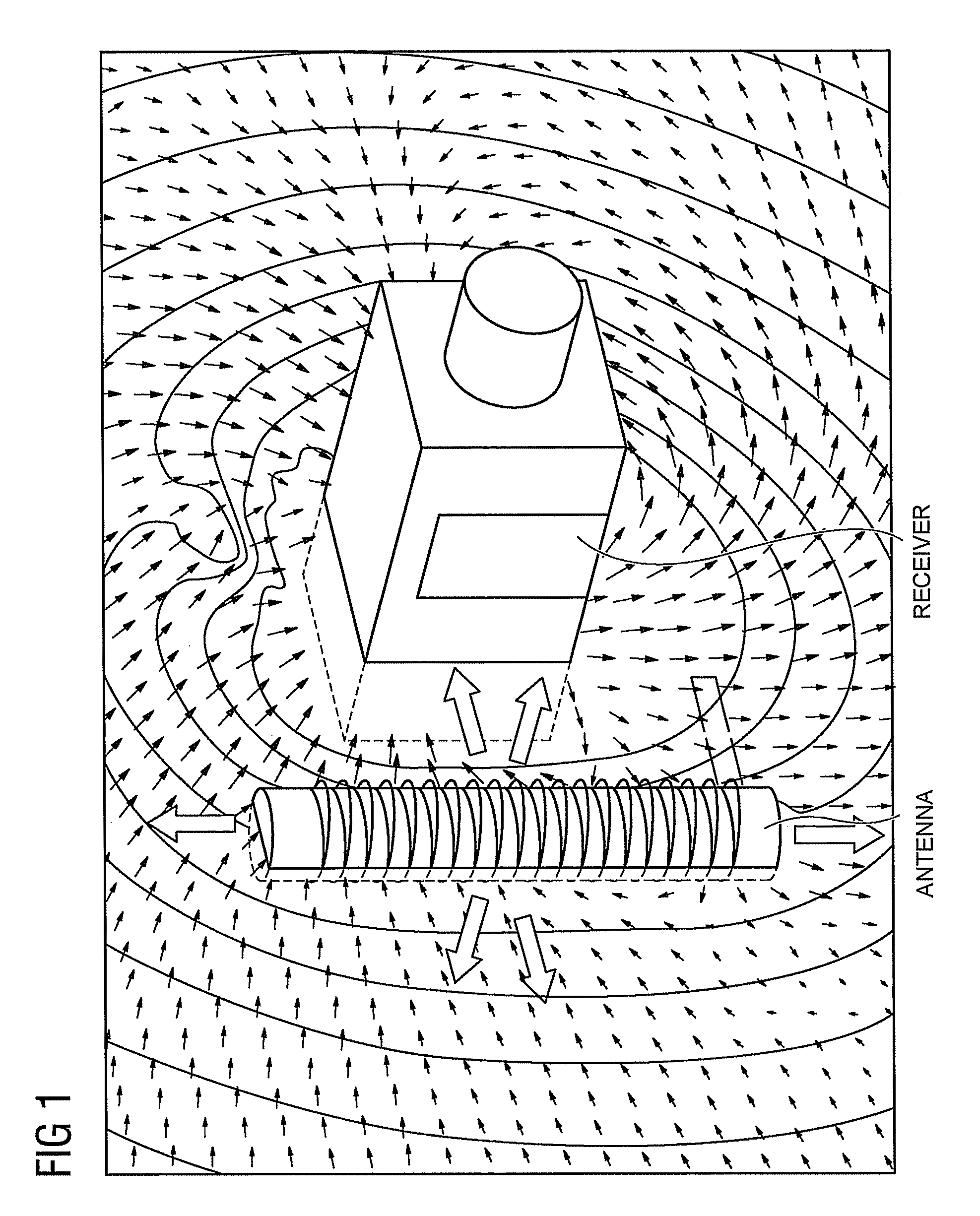

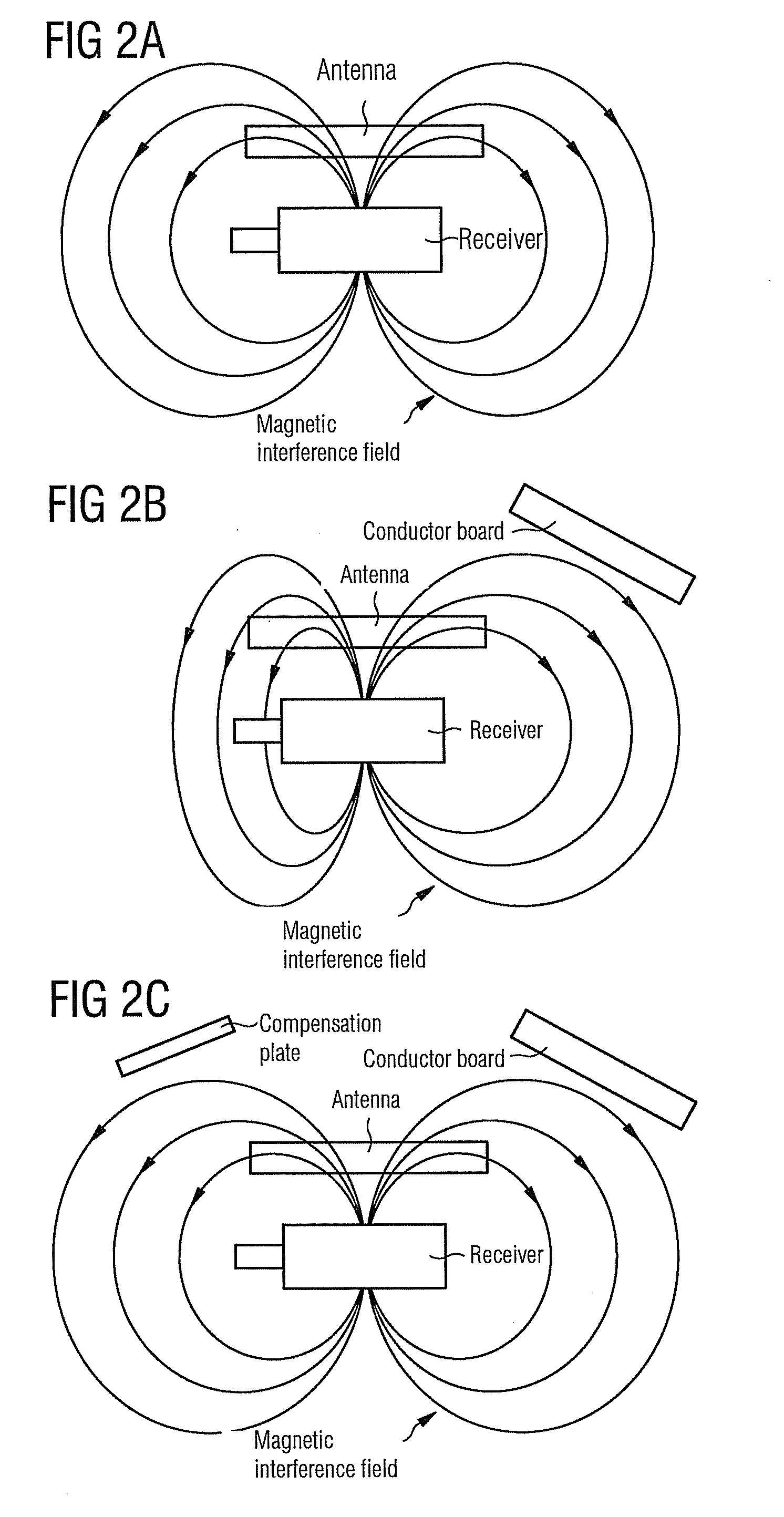

Apparatus and method for reducing interference effects in the case of a wireless data transmission in hearing device applications

InactiveUS20090274328A1Asymmetry of the field lines is reducedCorrect distortionDeaf-aid setsField lineCoupling

An apparatus and a method are provided for reducing an interference input coupling caused by asymmetrically embodied field lines of at least one hearing device component into a receiving antenna of a wireless data transmission facility of a hearing device. The apparatus includes at least one first means arranged in the hearing device, by means of which the asymmetry of the field lines is reduced and the field distortion is corrected. In addition, the receiving antenna can be geometrically adjusted to the outer interference field of the hearing device components such that interference currents induced in the antenna by means of field input coupling compensate.

Owner:SIVANTOS PTE LTD

Silicon micro-resonance type accelerometer

ActiveCN101266259AReduce material unevennessReduce the impactAcceleration measurementPhysicsHelical resonator

The invention discloses a silicon micro-resonant type accelerometer, comprising an upper layer part of the accelerometer formed on the single crystal silicon and a lower layer part of the signal line formed on the glass substrate. The upper layer mechanical structure of the accelerometer is composed of a mass block, a pair of identical resonators and bars. The resonators are vertically and symmetrically disposed in the middle of the mass block. One end of the resonator is connected with the fixed baseplate and another end of the resonator is connected with the mass block by the bar and the mass block is connected with the fixed baseplates by four folded beams. The fixed baseplate is mounted on the fixed basedplate bonding points on the glass substrate, therefore the mechanical structure of the upper layer is hang in the air above the glass substrate of the lower layer. The silicon micro-resonant type accelerometer has features: high sensitivity, good stability and strong resistance to shock.

Owner:NANJING UNIV OF SCI & TECH

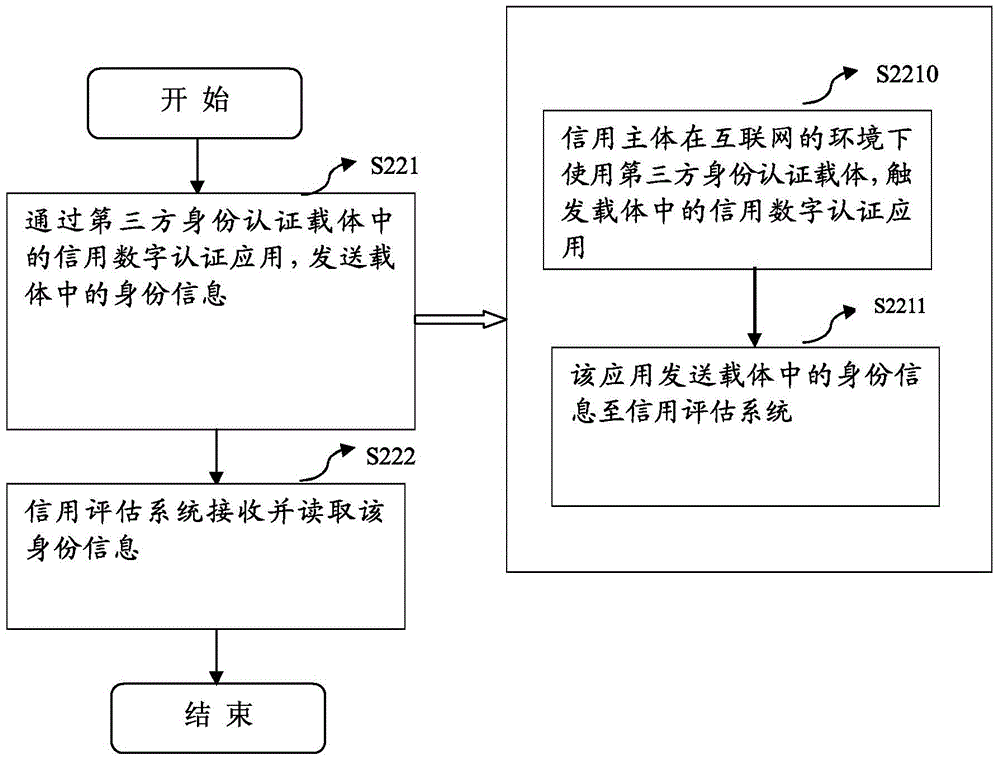

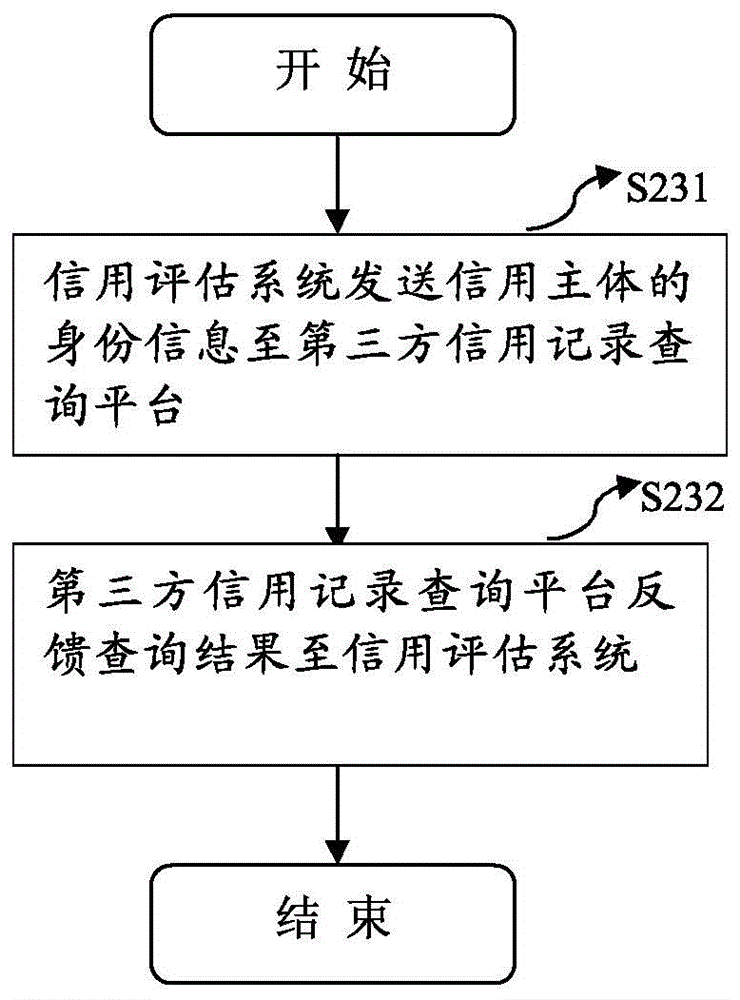

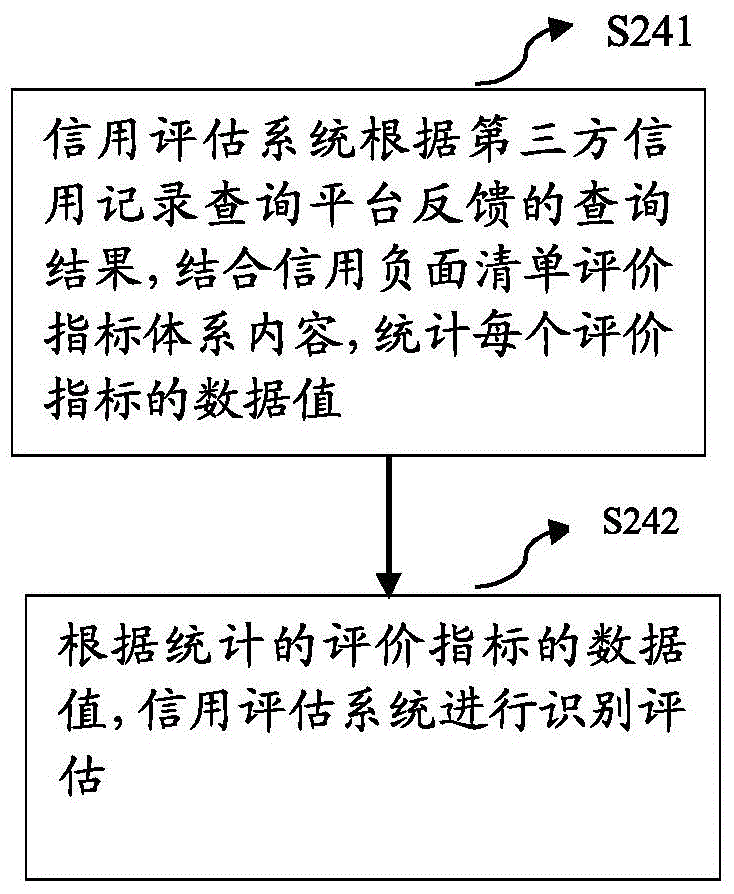

Digital credit authentication method

ActiveCN104574110AAccelerate the transformation of functionsReadableCommerceIndex systemData science

The invention provides a digital credit authentication method which i=is used for identifying a potential credit risk of a credit subject and comprises the following steps: a, reading identity information of the credit subject, b, inquiring a credit record according to the identity information, c, carrying out identification evaluation according to the credit record, d, generating a credit evaluation level identification and a credit evaluation report according to an identification evaluation result, and e, pushing the identification evaluation result in real time. According to the other aspect of the invention, the invention further provides a digital credit authentication processing device. Various evaluation work can be effectively handled by an evaluation index system, an evaluation algorithm and an evaluation processing device, and the accuracy and efficiency are improved in conjunction with arrangement of expert database.

Owner:SHANGHAI FOISON CREDIT RATING CO LTD

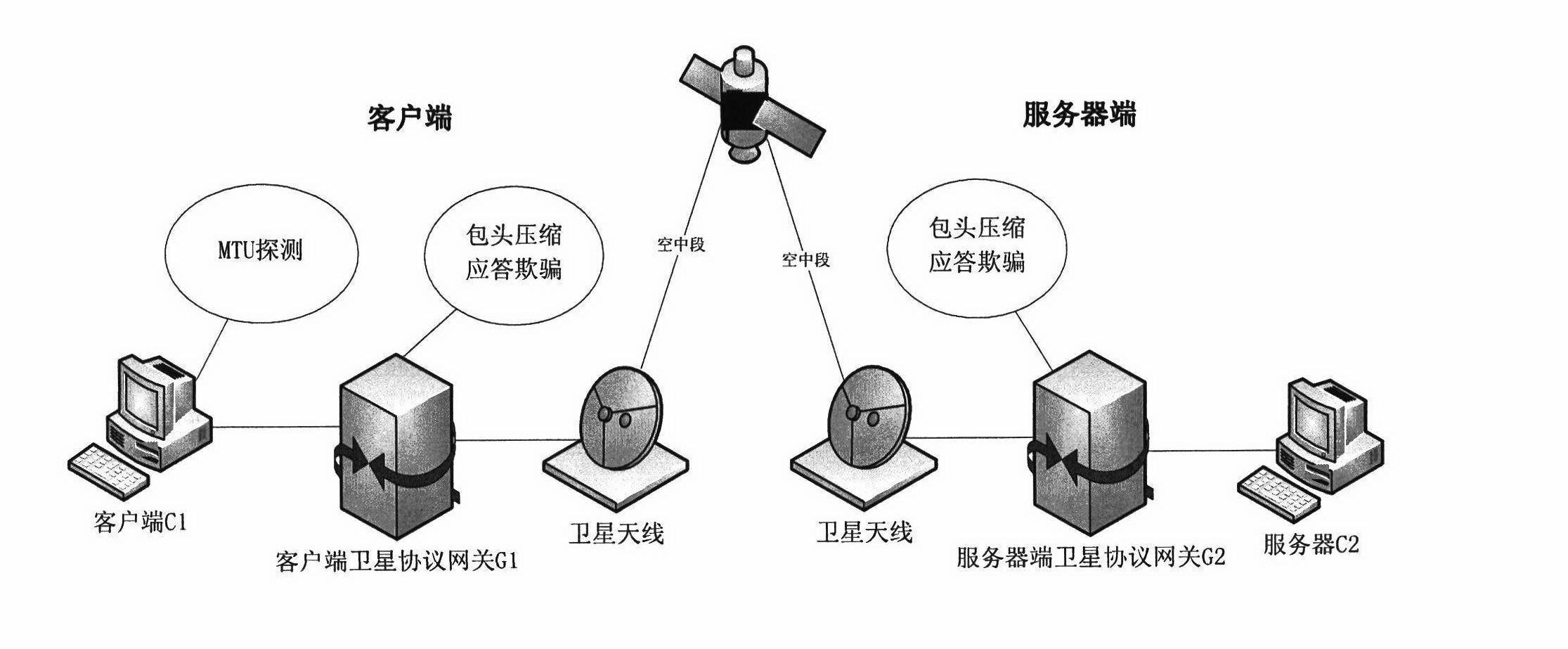

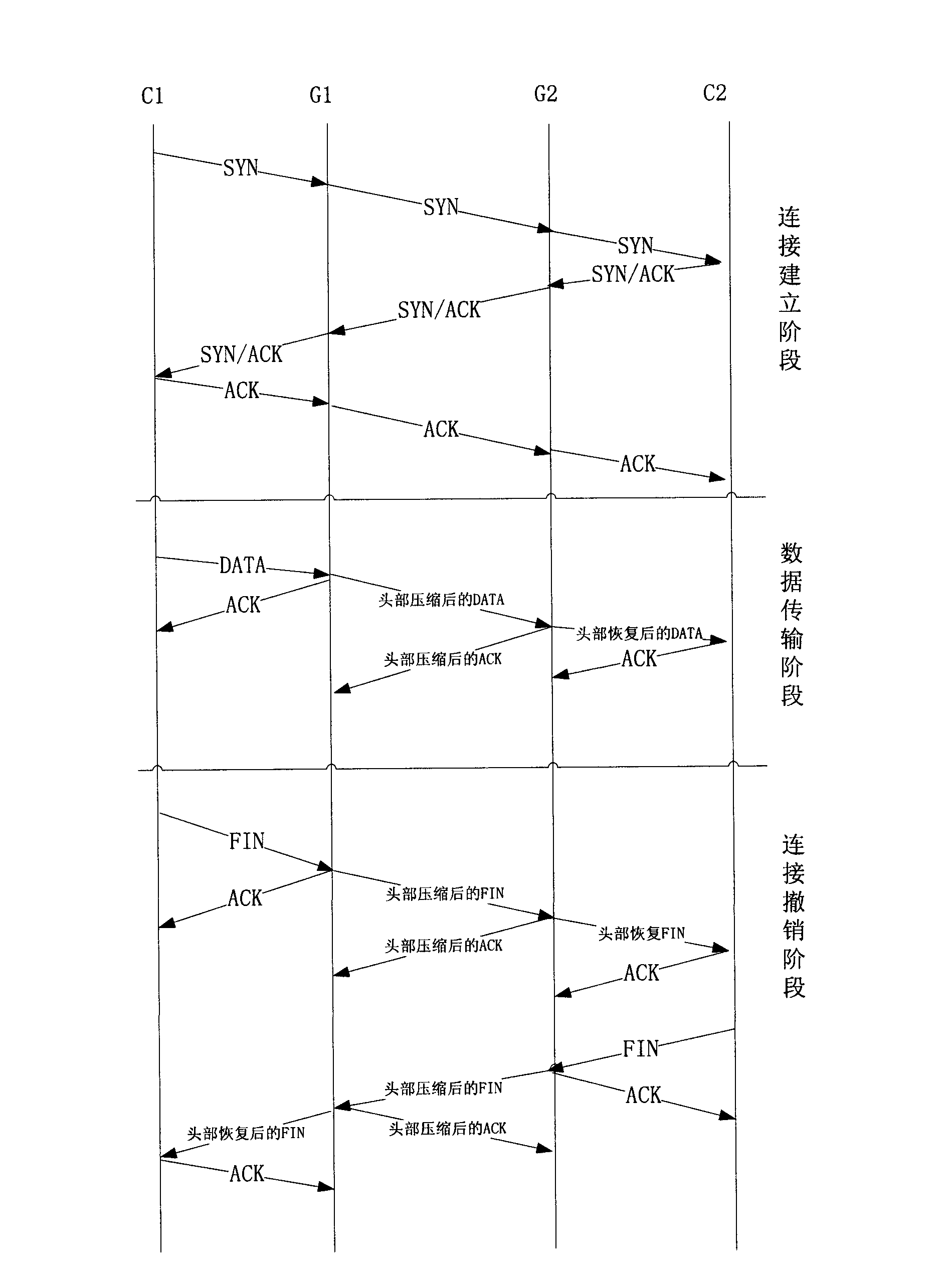

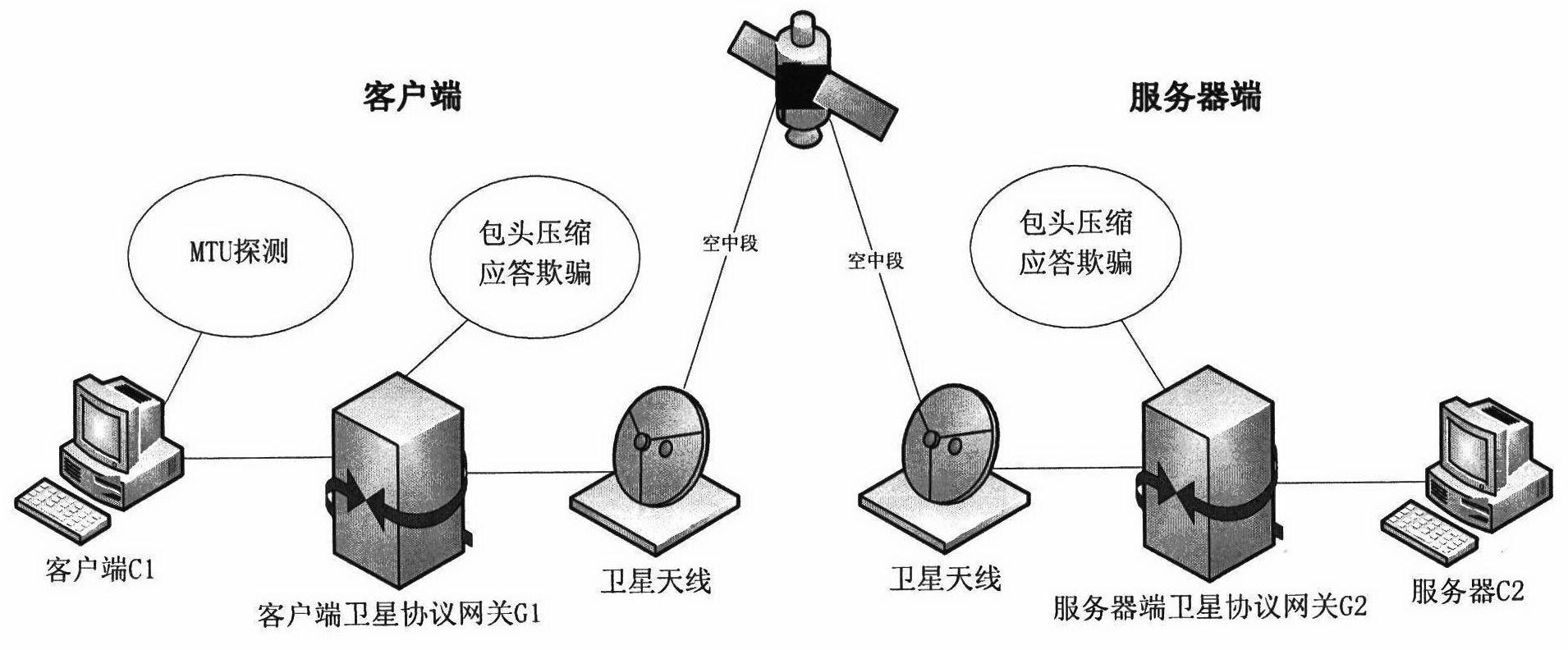

TCP ground acceleration method for satellite network

ActiveCN102694810AImprove effective utilizationReduce asymmetryRadio transmissionBand widthServer-side

The invention discloses a TCP (Transmission Control Protocol) ground acceleration method for a satellite network. According to the method, MTU (Maximum Transmission Unit) initiative detection, protocol fraud and TCP data packet header compression technology are integrated, wherein the header compression and the protocol fraud are realized through a client satellite protocol gateway and a server end satellite protocol gateway, and the MTU initiative detection is carried out at a client C1. The method provided by the invention can improve the throughput of a satellite link, effectively utilizes the band width resource of the satellite link, and improves the TCP transmission rate.

Owner:SPACE STAR TECH CO LTD

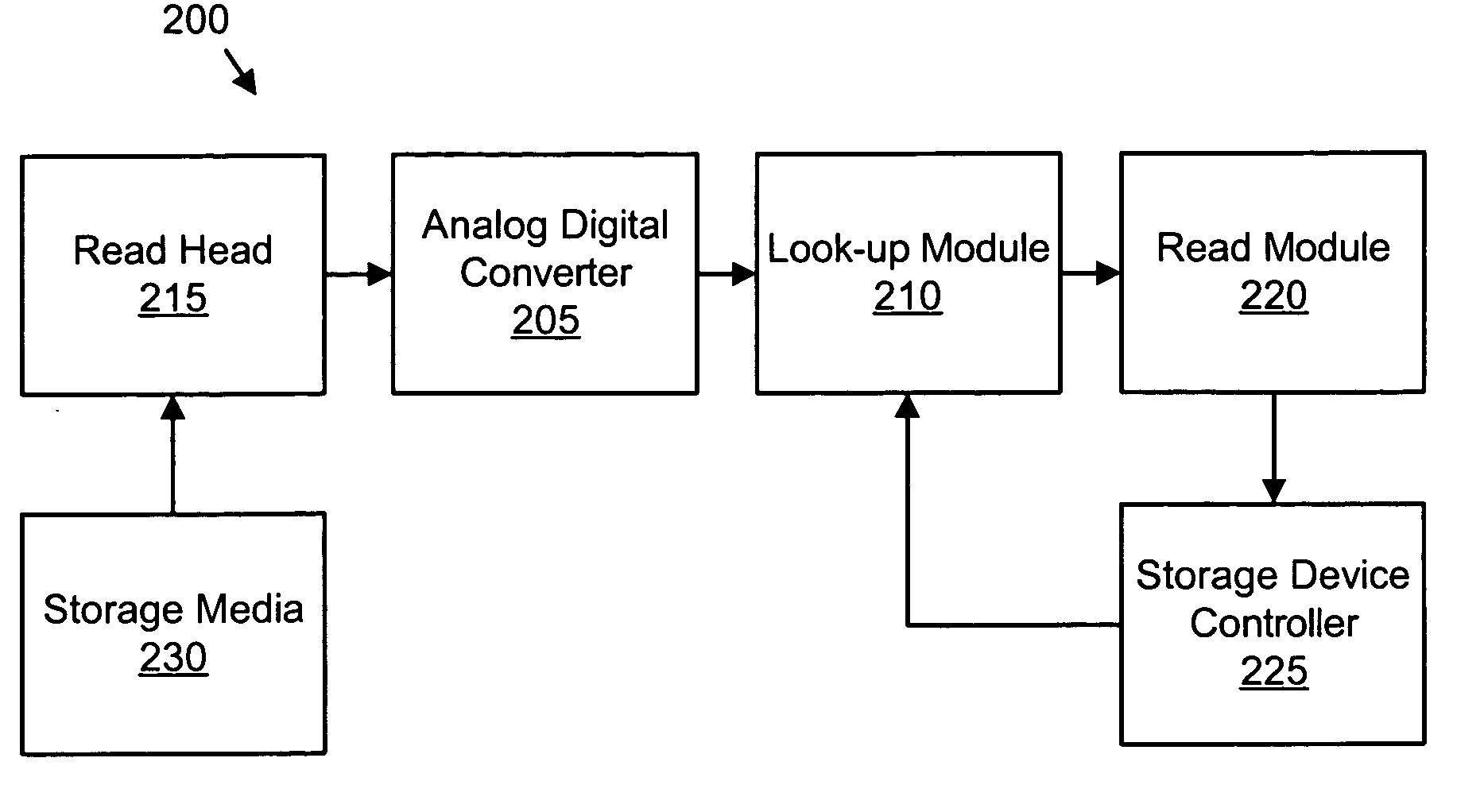

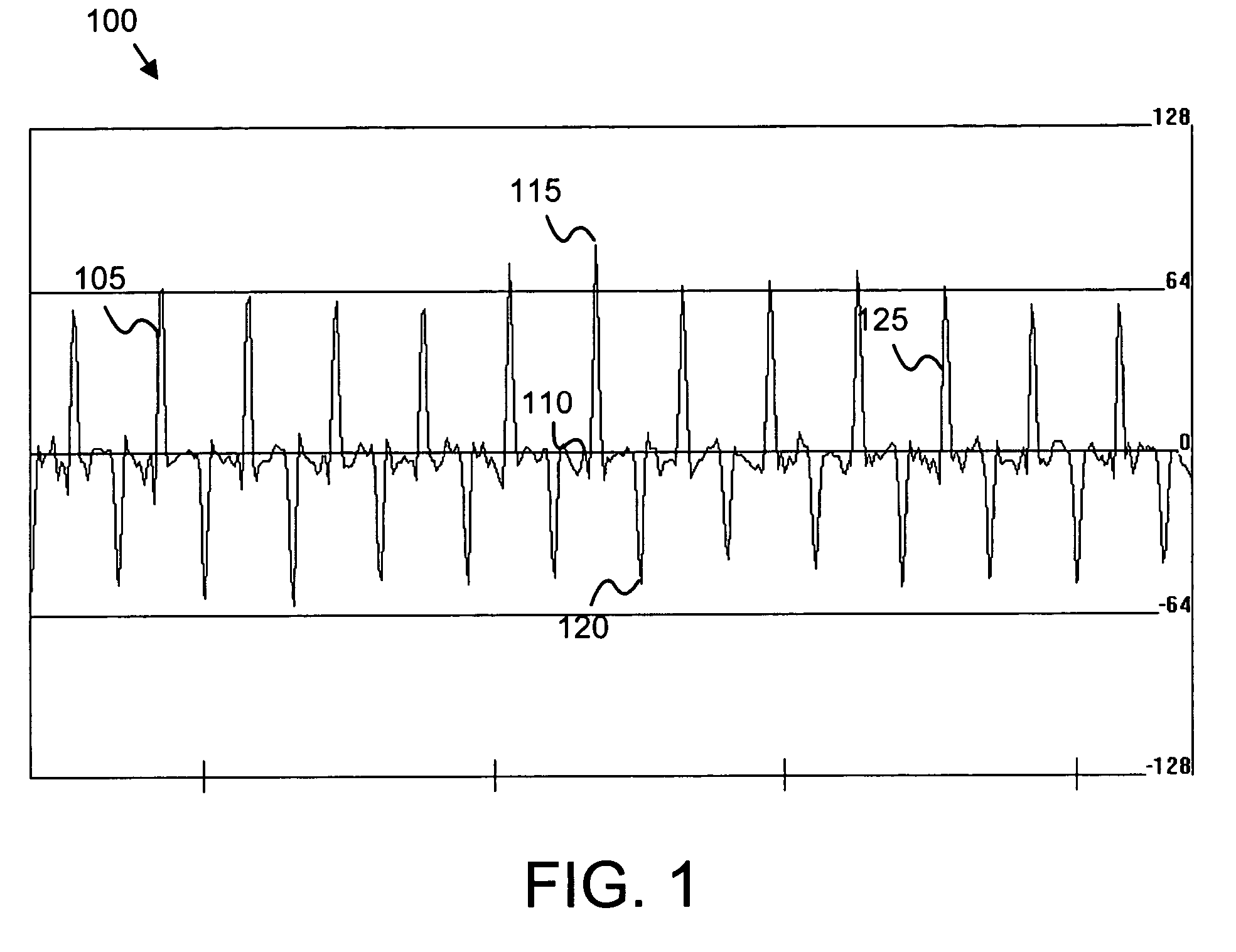

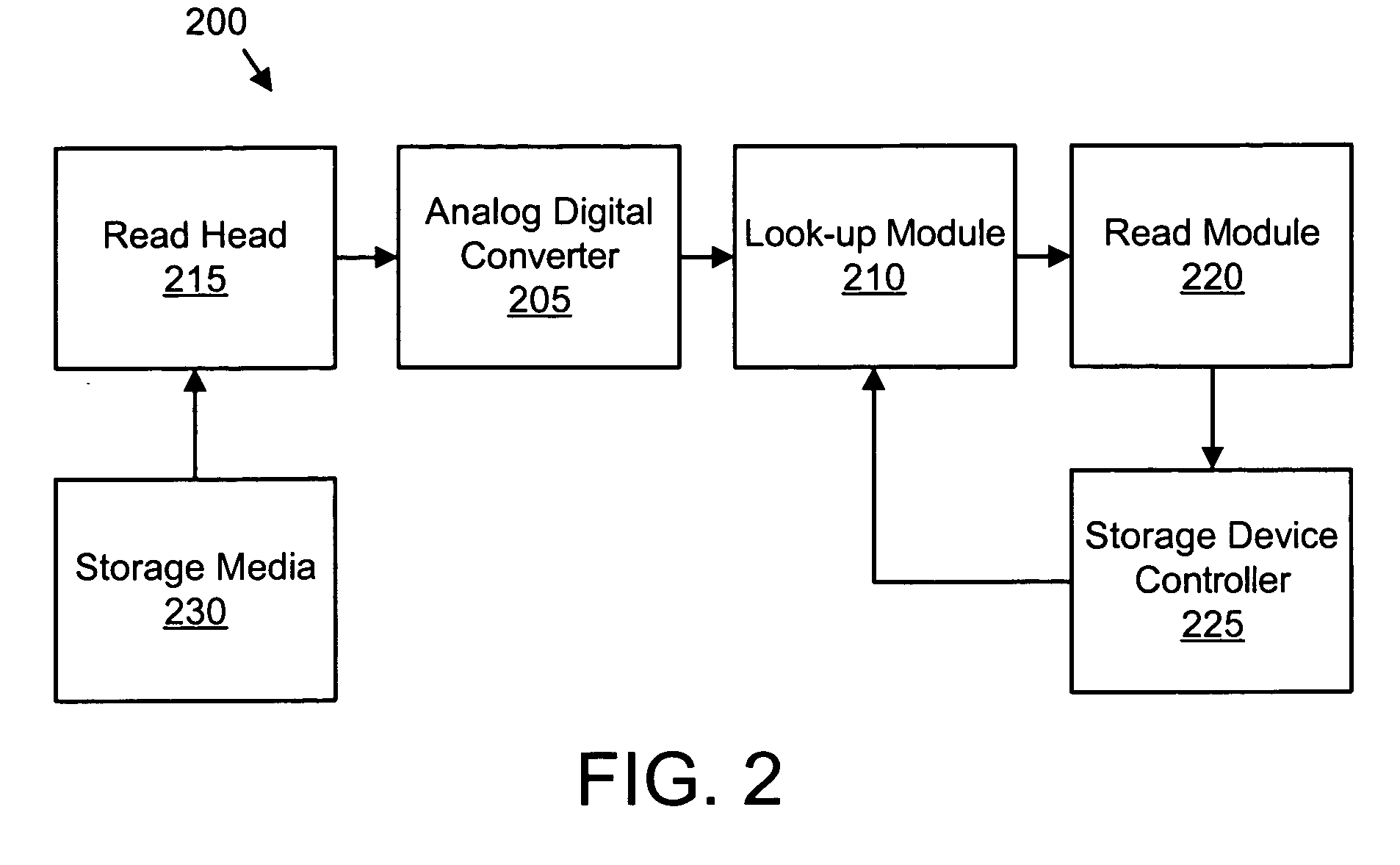

Apparatus, system, and method for mitigating signal asymmetry

InactiveUS20060082915A1Reduce read errorsReduce asymmetryAnalogue/digital conversionDriving/moving recording headsEngineeringAnalog signal

An apparatus, system, and method are disclosed for mitigating signal asymmetry. An analog to digital converter samples an analog signal from a read head and converts the sample to a digital input signal. The digital input signal addresses a look-up module, and the look-up module outputs a modified digital signal. The modified digital signal value is a specified function of the digital input signal value, wherein the specified function is configured to mitigate the asymmetry of the digital input signal. The modified digital signal value may be periodically recalculated to adjust for read head wear.

Owner:IBM CORP

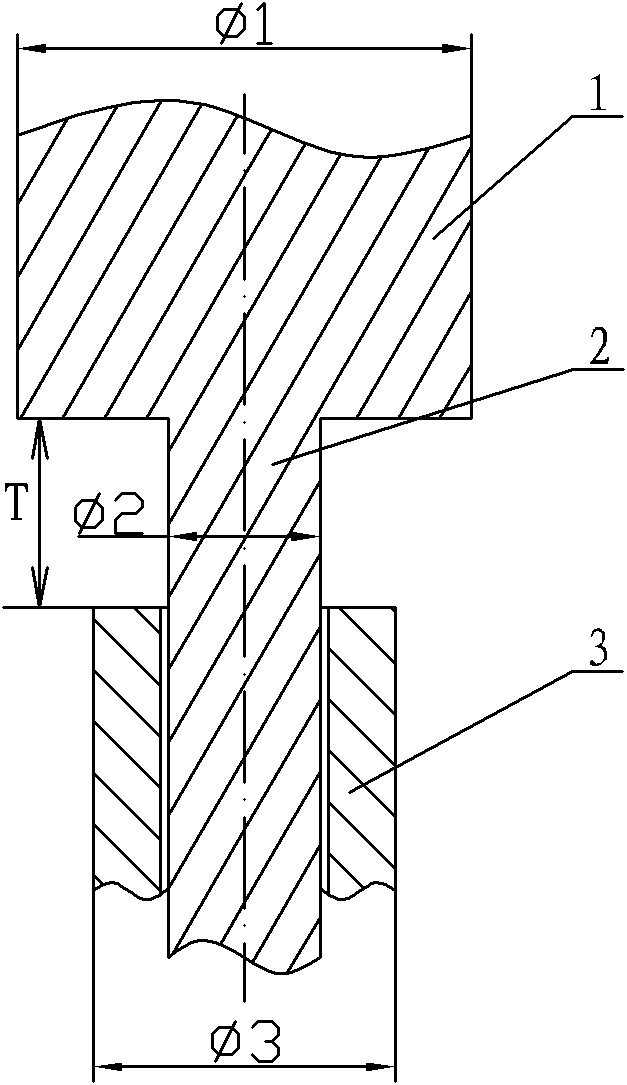

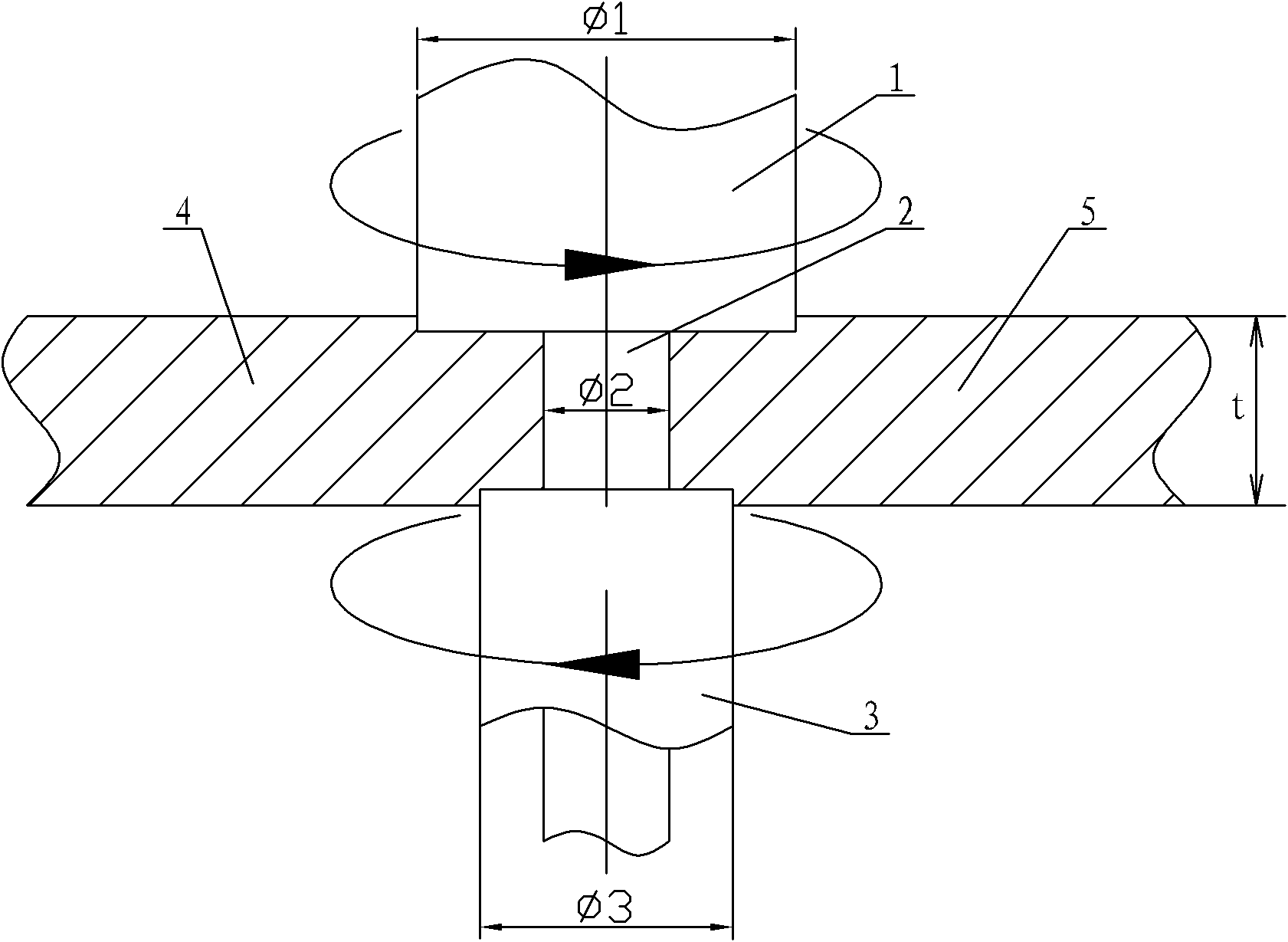

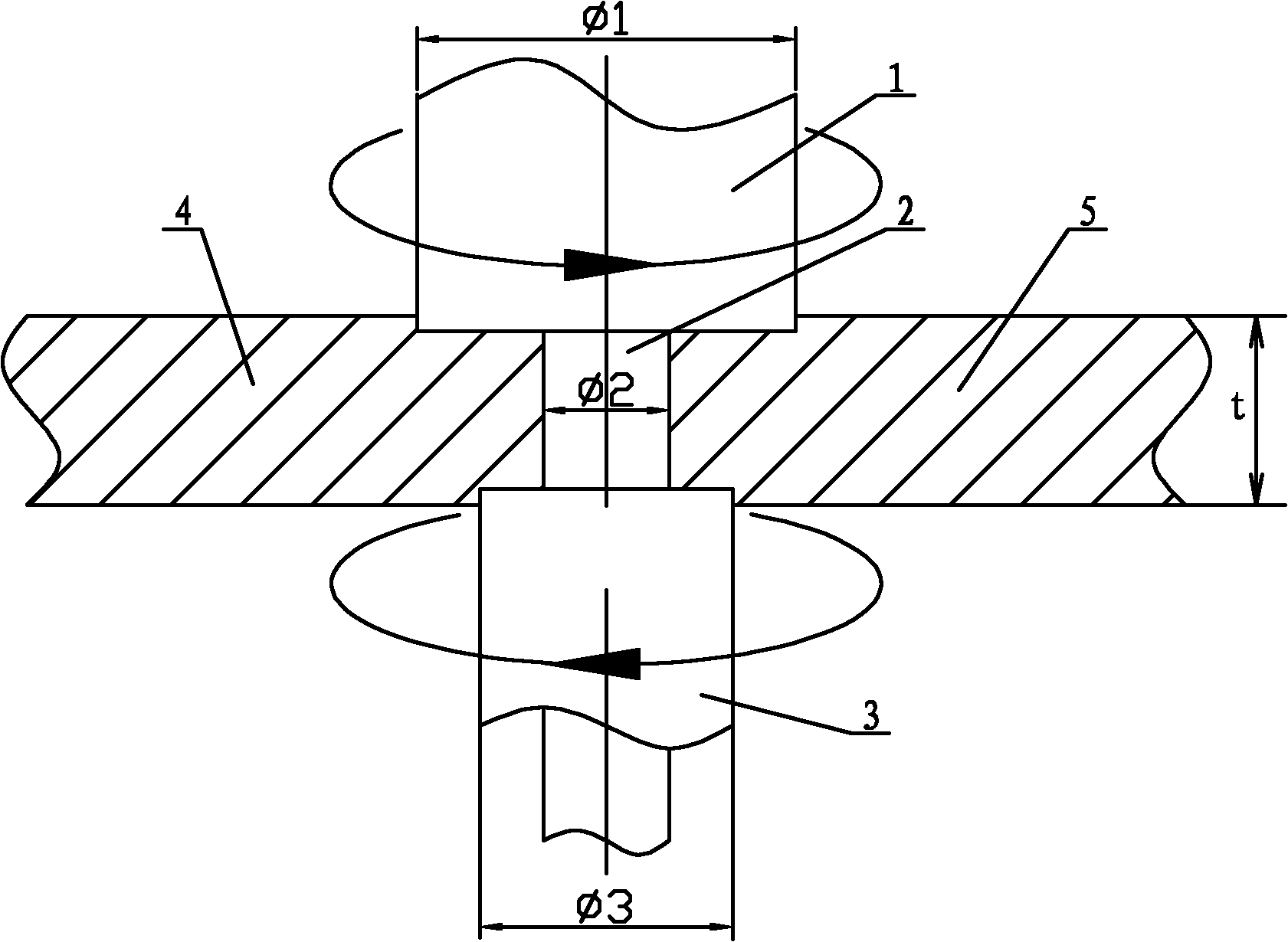

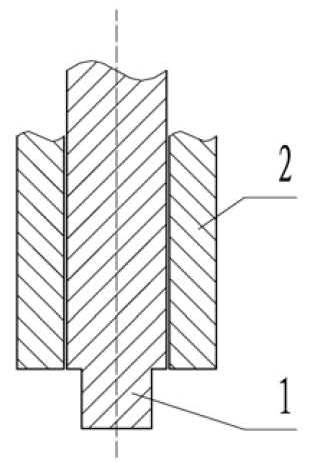

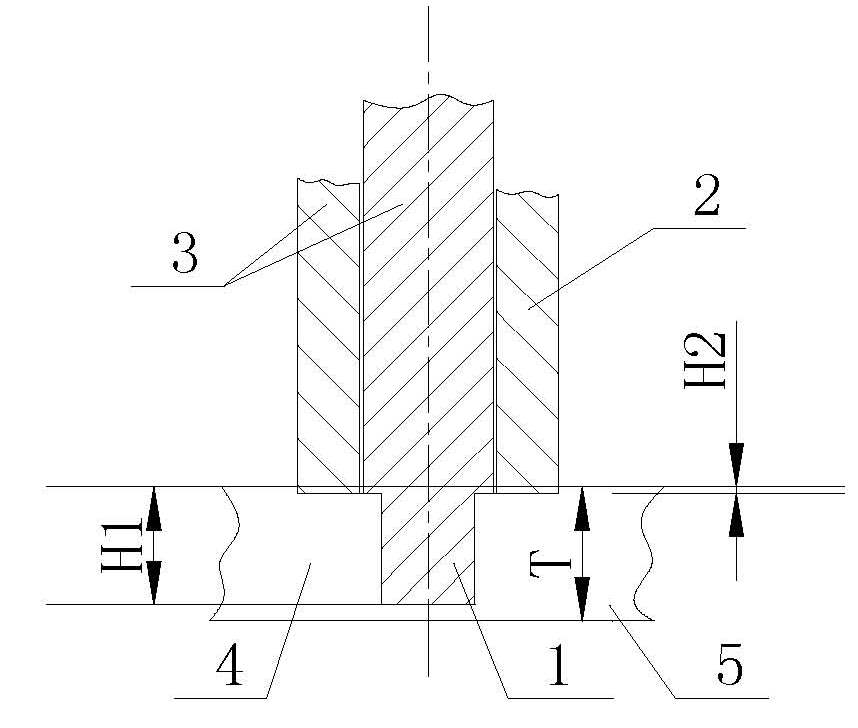

Self-maintained friction stir welding method with reversely rotating upper and lower shaft shoulders

InactiveCN101979209AReduced fracture tendencyReduce torque actionNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses a self-maintained friction stir welding method with reversely rotating upper and lower shaft shoulders, and relates to a self-maintained friction stir welding method to solve the problems that: the upper and lower shaft shoulders have unequal diameters but rotate in the same direction with equal speed, and in the welding process, the weld heat input is large, a workpiece is easy to deform, a mixing needle is inclined to fracture, and the distribution of a weld zone temperature field, a joint structure and residual stress are asymmetric, so that the joint performance is asymmetric, and the bearing capacity of a welding structure is reduced. The method comprises the following steps of: 1, determining the size of a stirring head, namely determining the diameter of the upper shaft shoulder, the stirring needle and the lower shaft shoulder according to the thickness of a first welded workpiece and a second welded workpiece; 2, determining the use length of the stirring needle; 3, fixing the first welded workpiece and the second welded workpiece; 4, positioning the stirring head; and 5, performing friction stir welding on the first welded workpiece and the second welded workpiece, namely integrally forming the upper shaft shoulder and the stirring needle, and allowing the lower shaft shoulder and the upper shaft shoulder to rotate in opposite directions. The self-maintained friction stir welding method is used for self-maintained friction stir welding.

Owner:HARBIN INST OF TECH

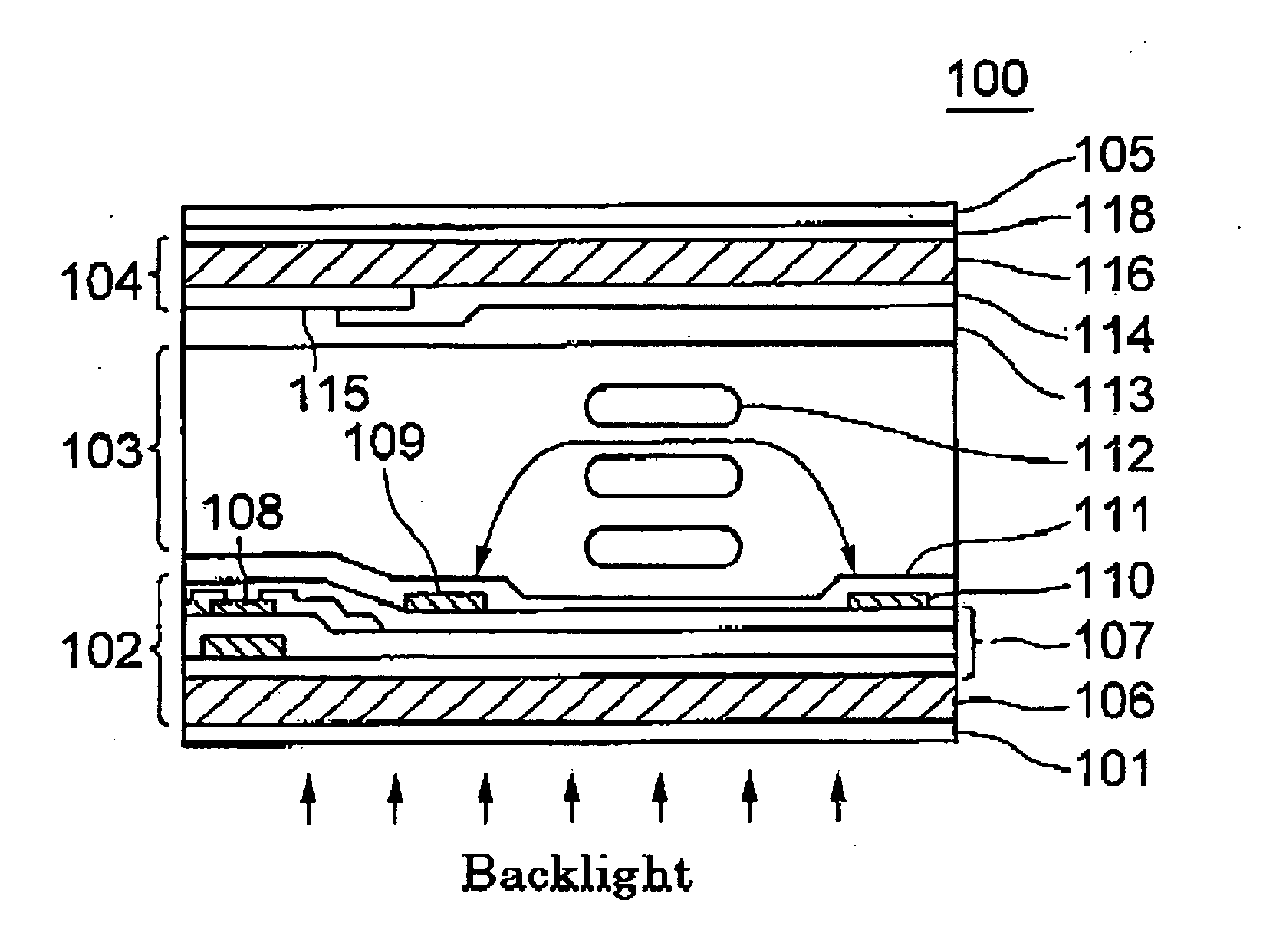

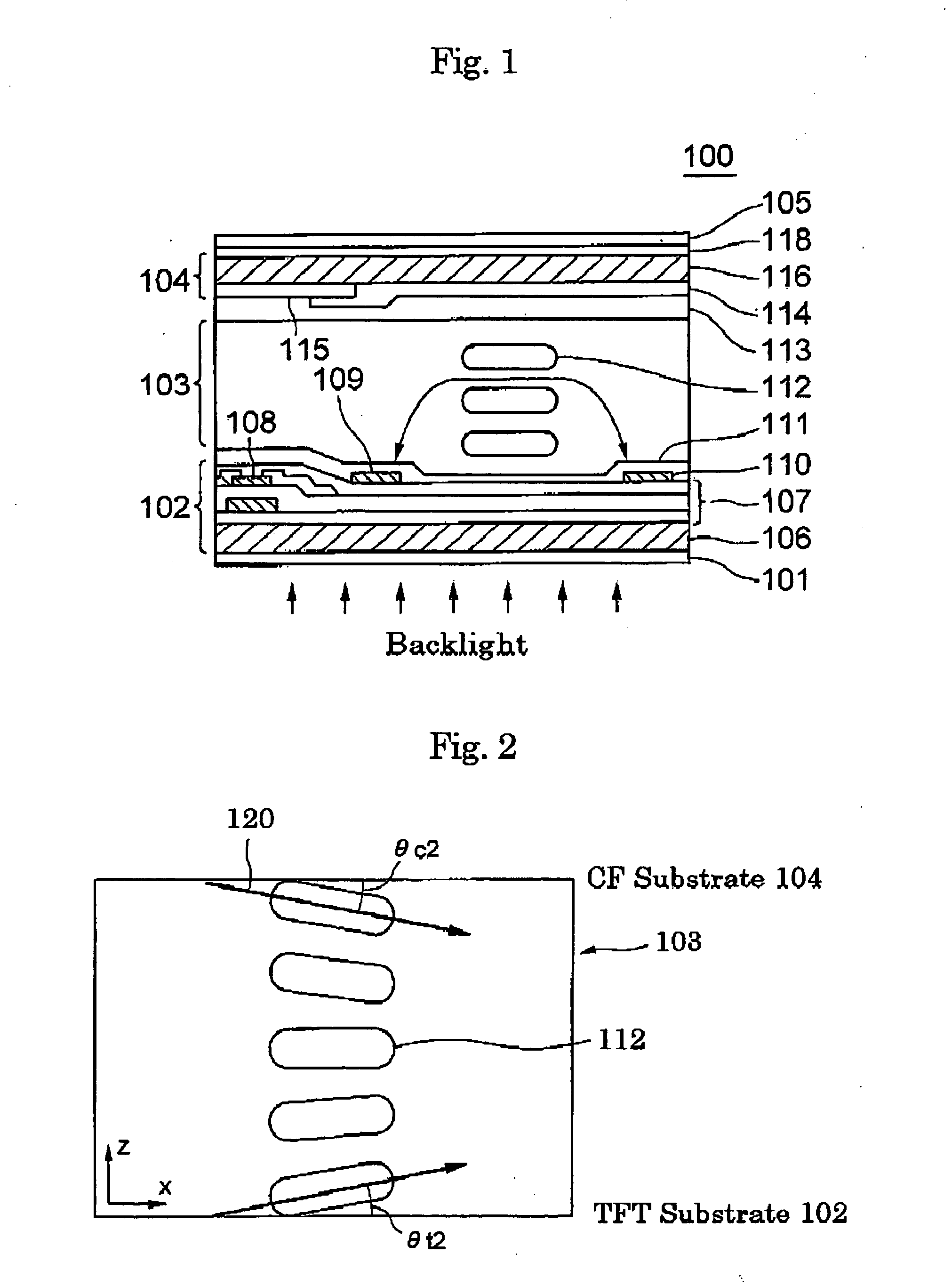

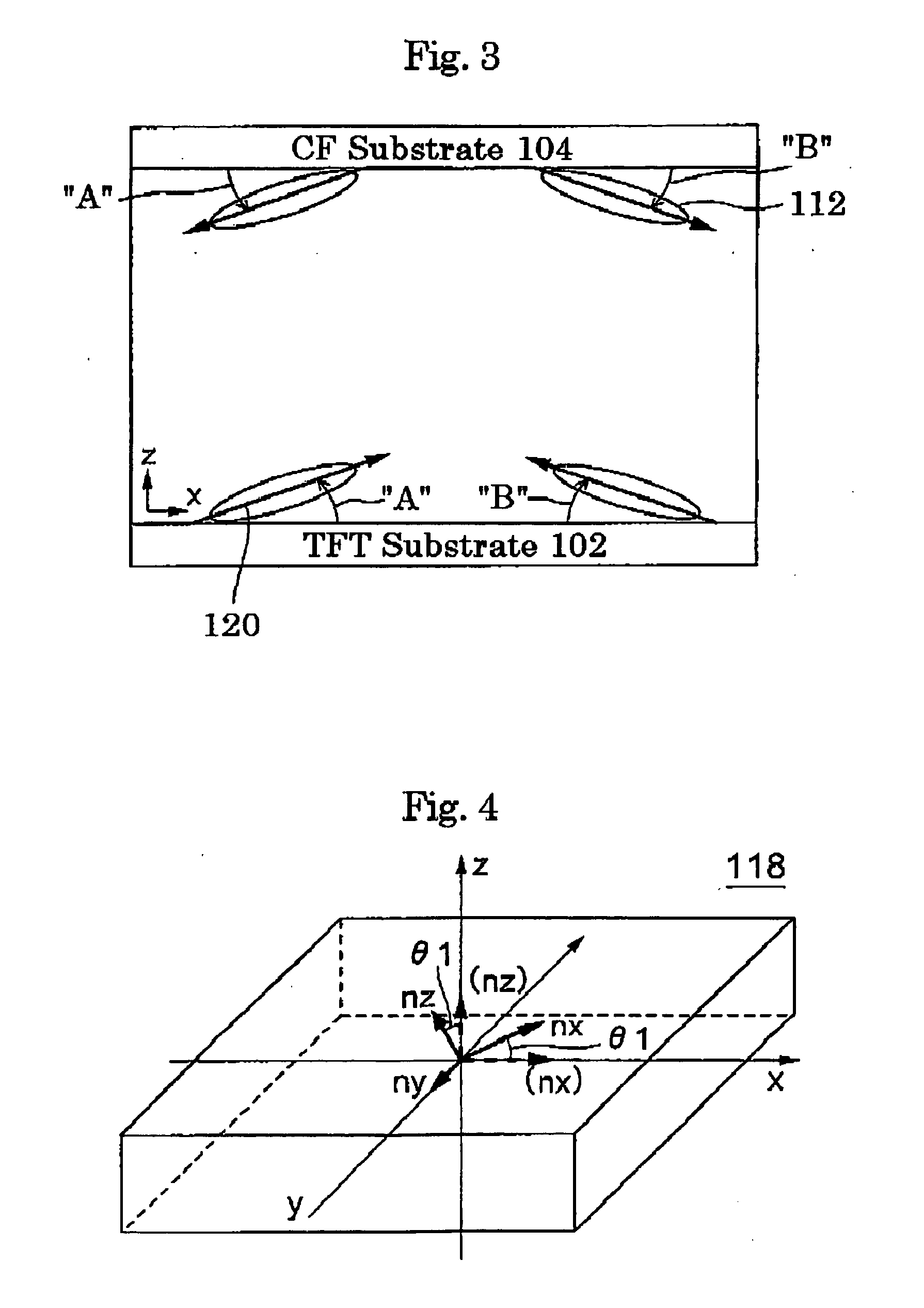

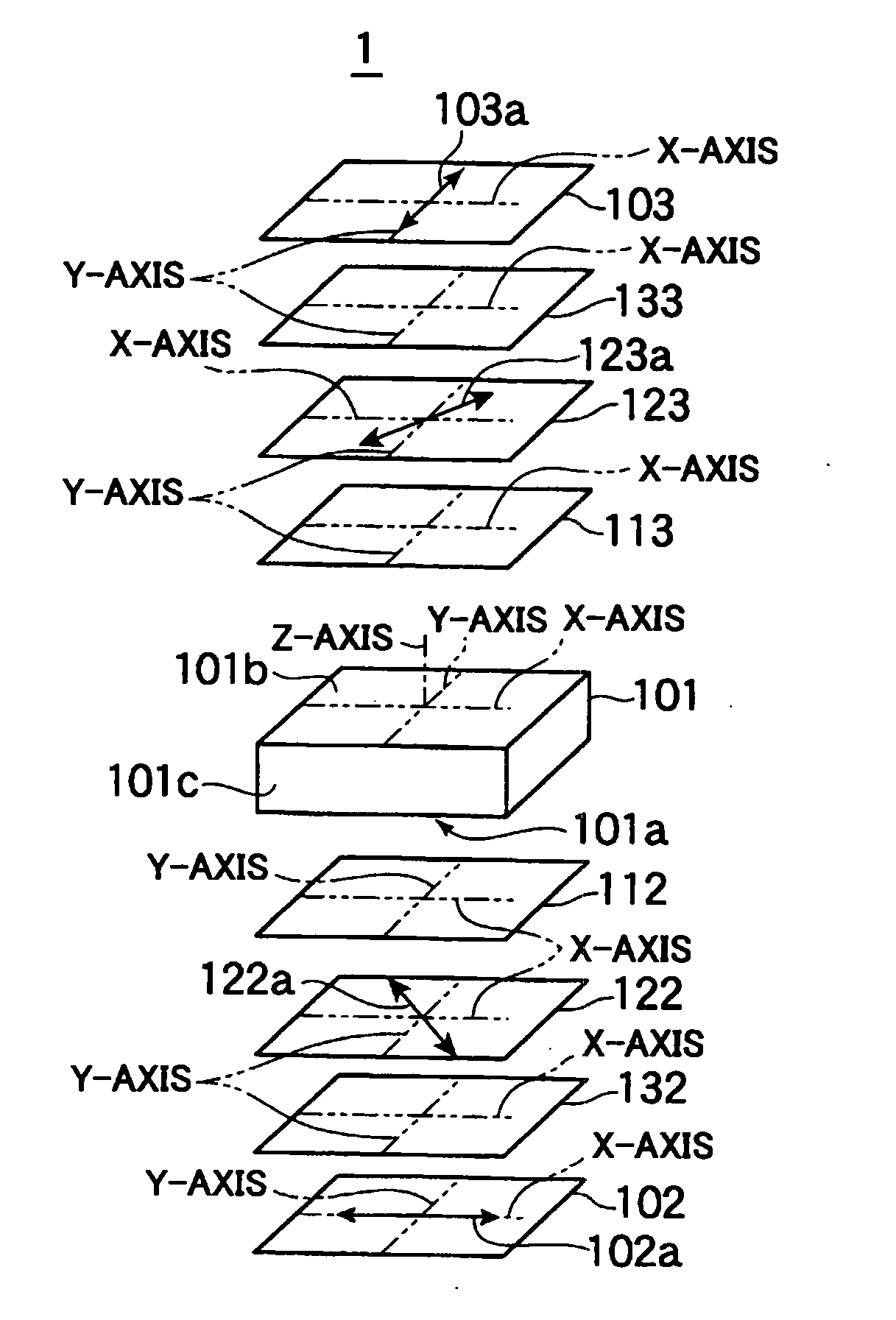

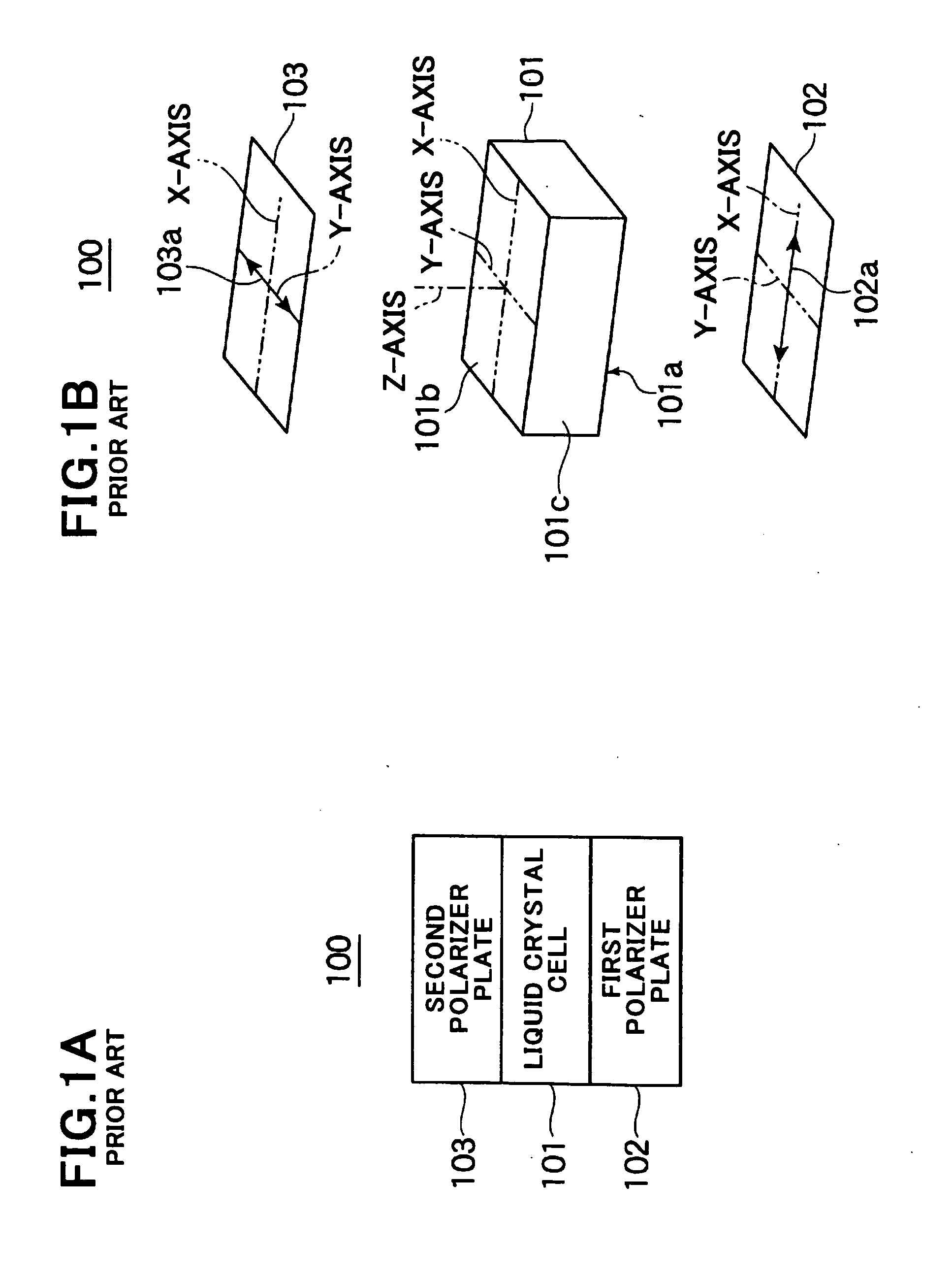

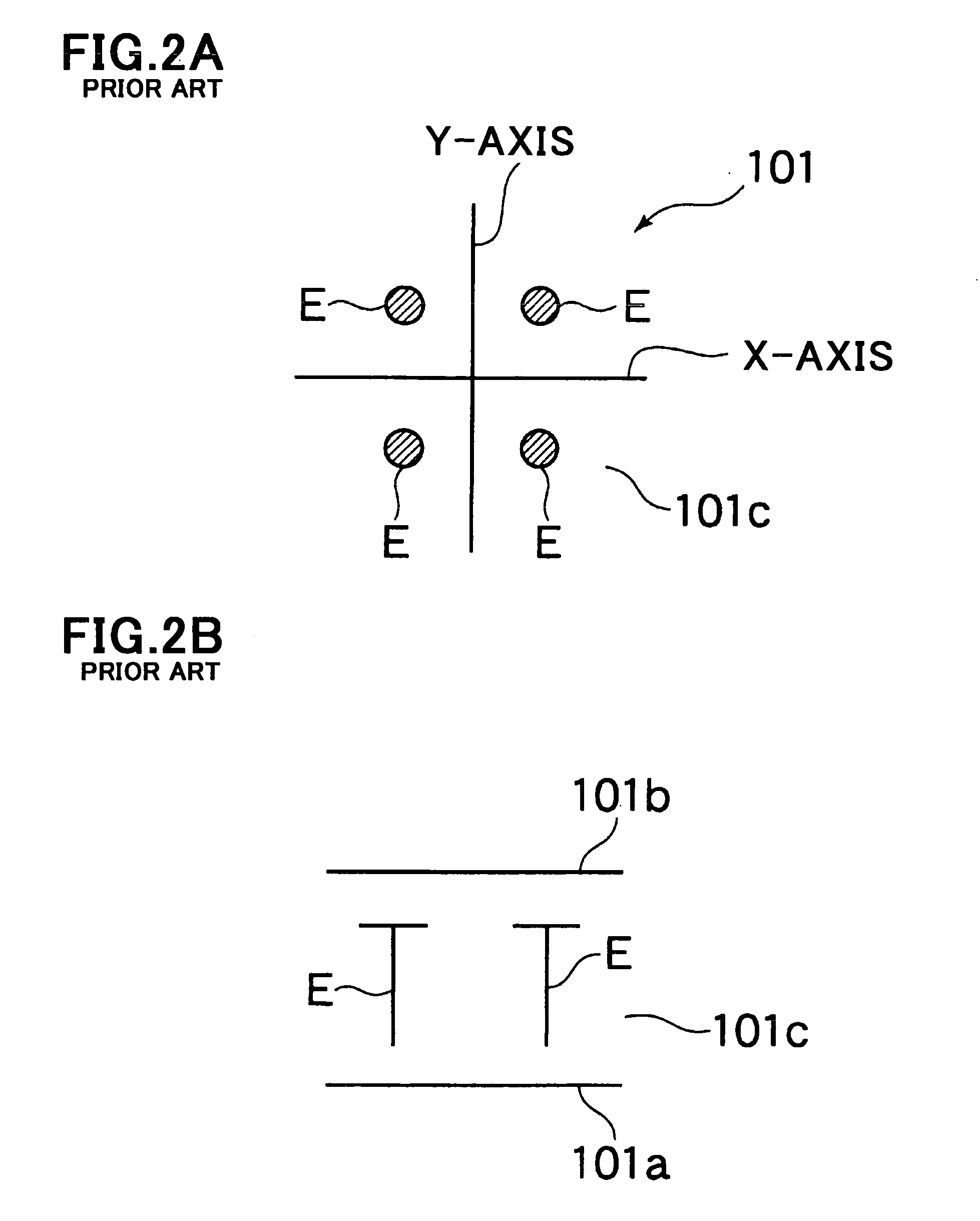

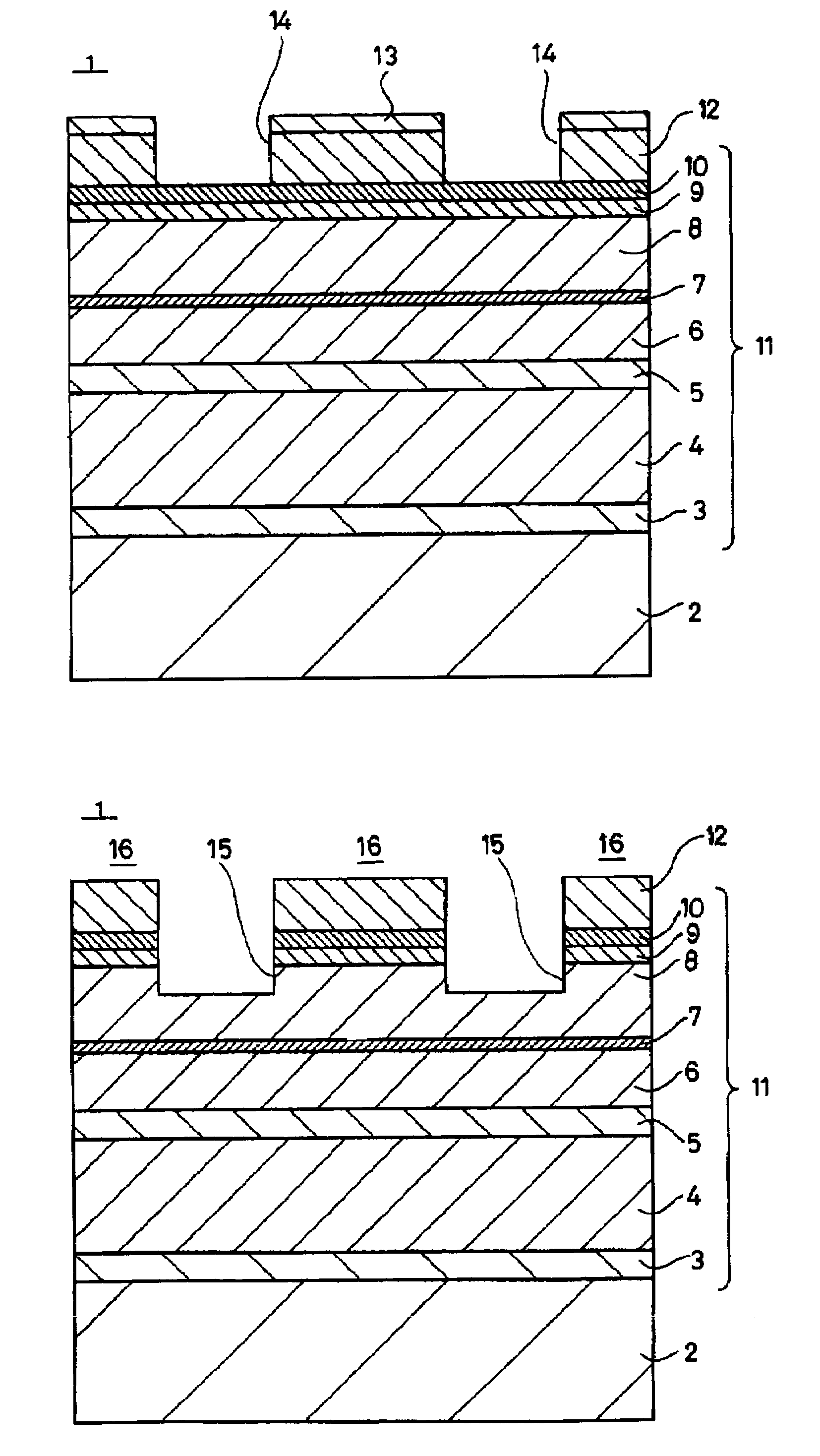

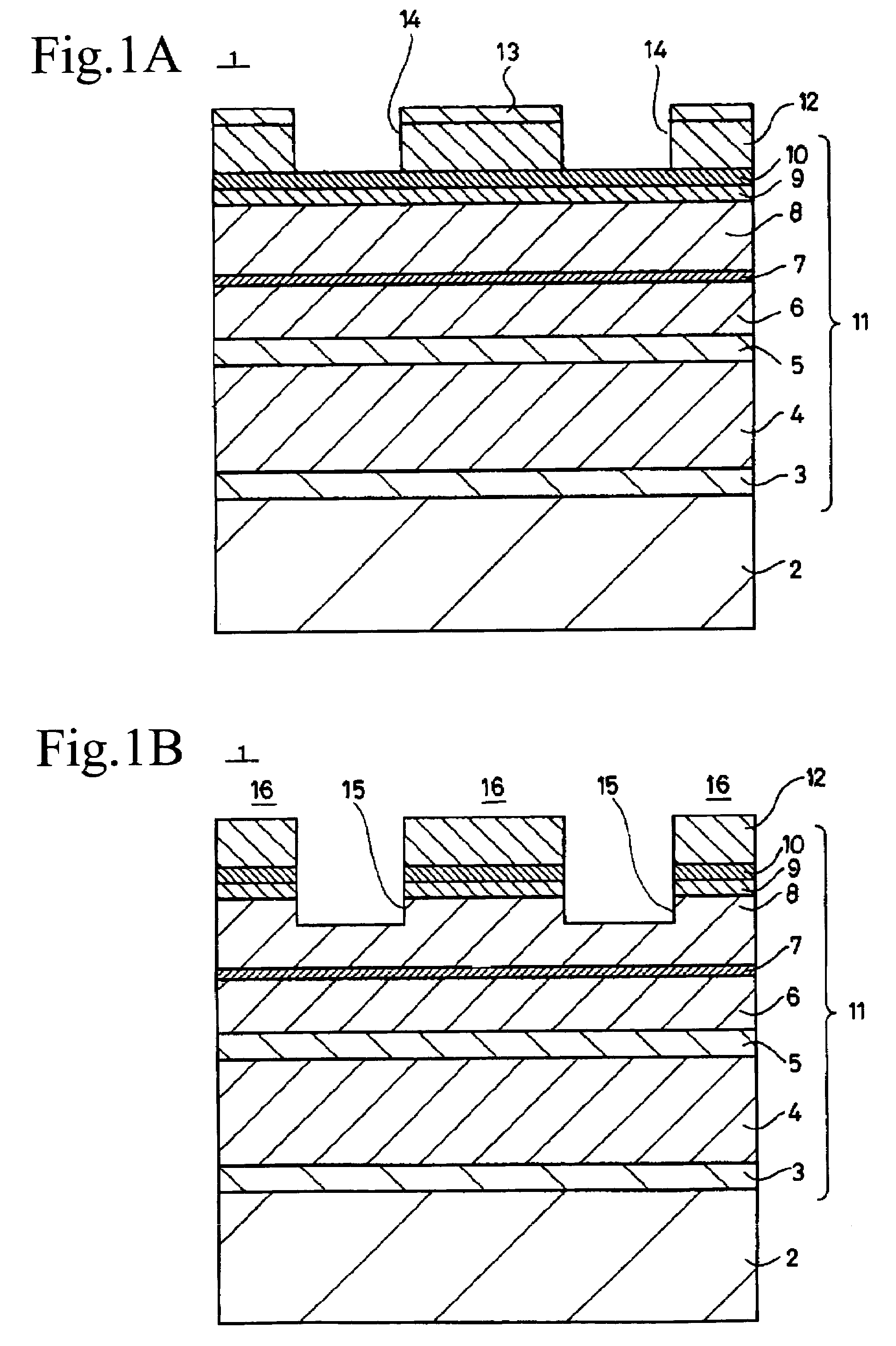

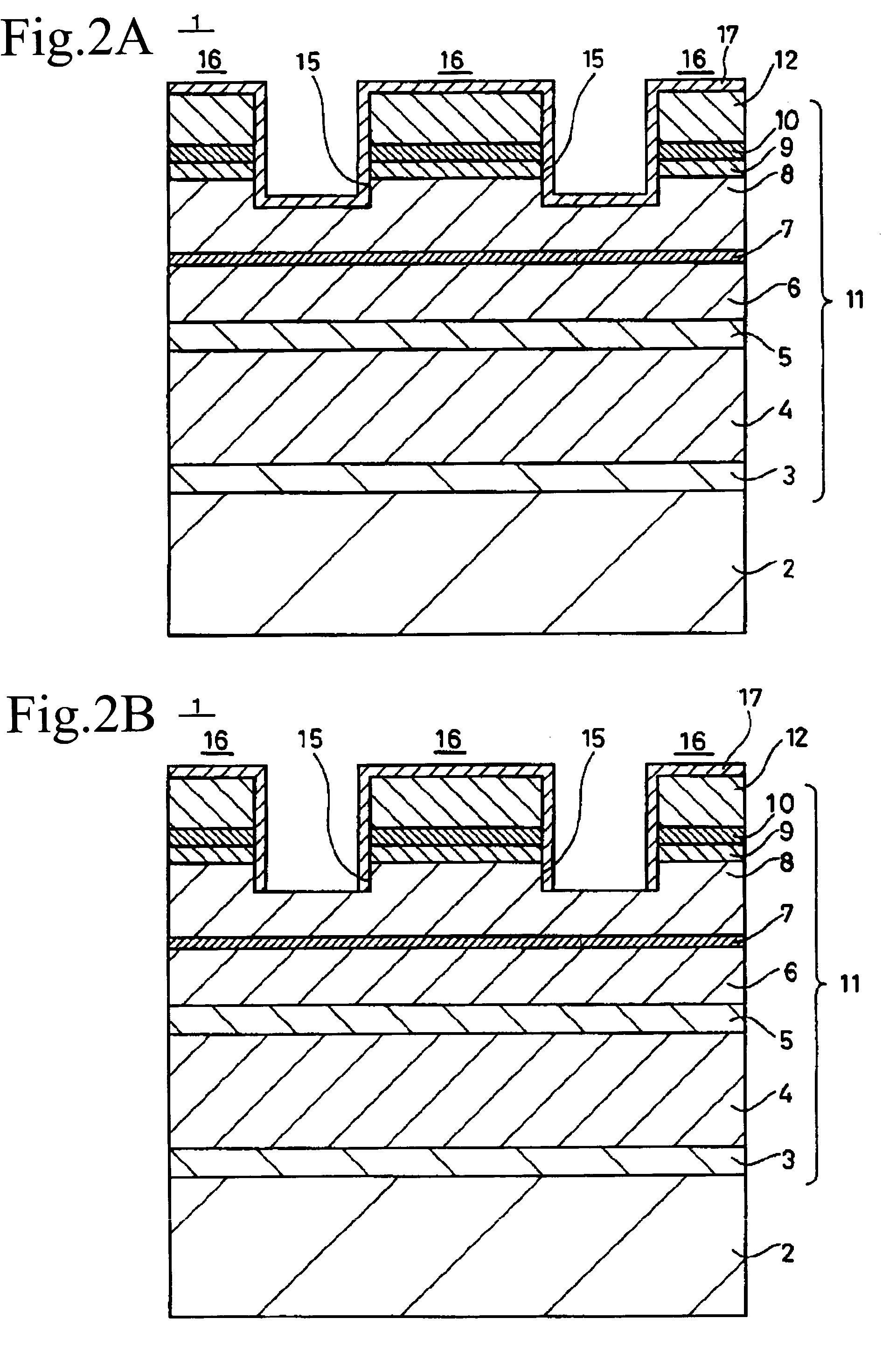

LCD device reducing asymmetry in the leakage light

An LCD device includes therein a splay-oriented LC layer, first and second substrates sandwiching therebetween the LC layer, and an optical compensation film for reducing leakage light upon display of a black color. The optical compensation film has three optical elastic axes including a fast axis coinciding the Y-axis, a slow axis rotated from the X-axis by a positive rotational angle θ1, and another axis rotated from the Z-axis by the positive rotational angle θ1. The positive rotational direction coincides with a counter-clockwise direction within the substrate surface, as viewed from minus side toward the positive side of the Y-axis.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

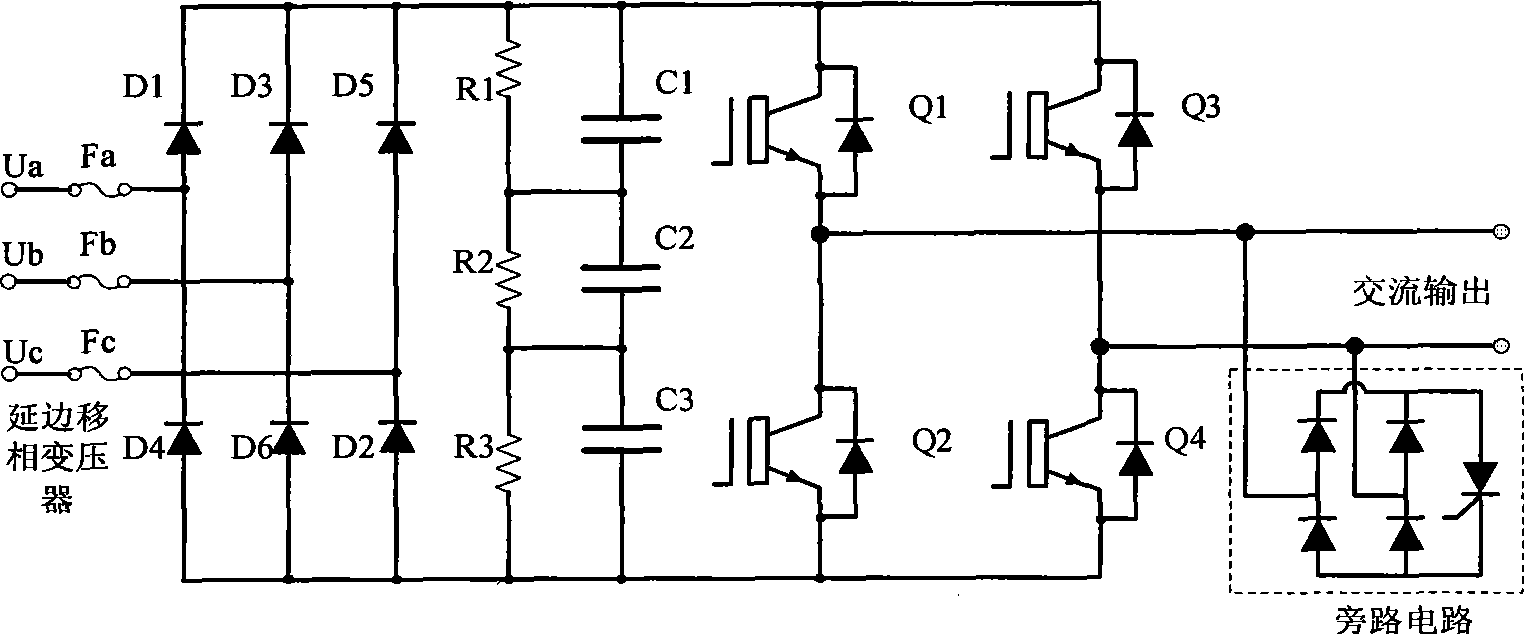

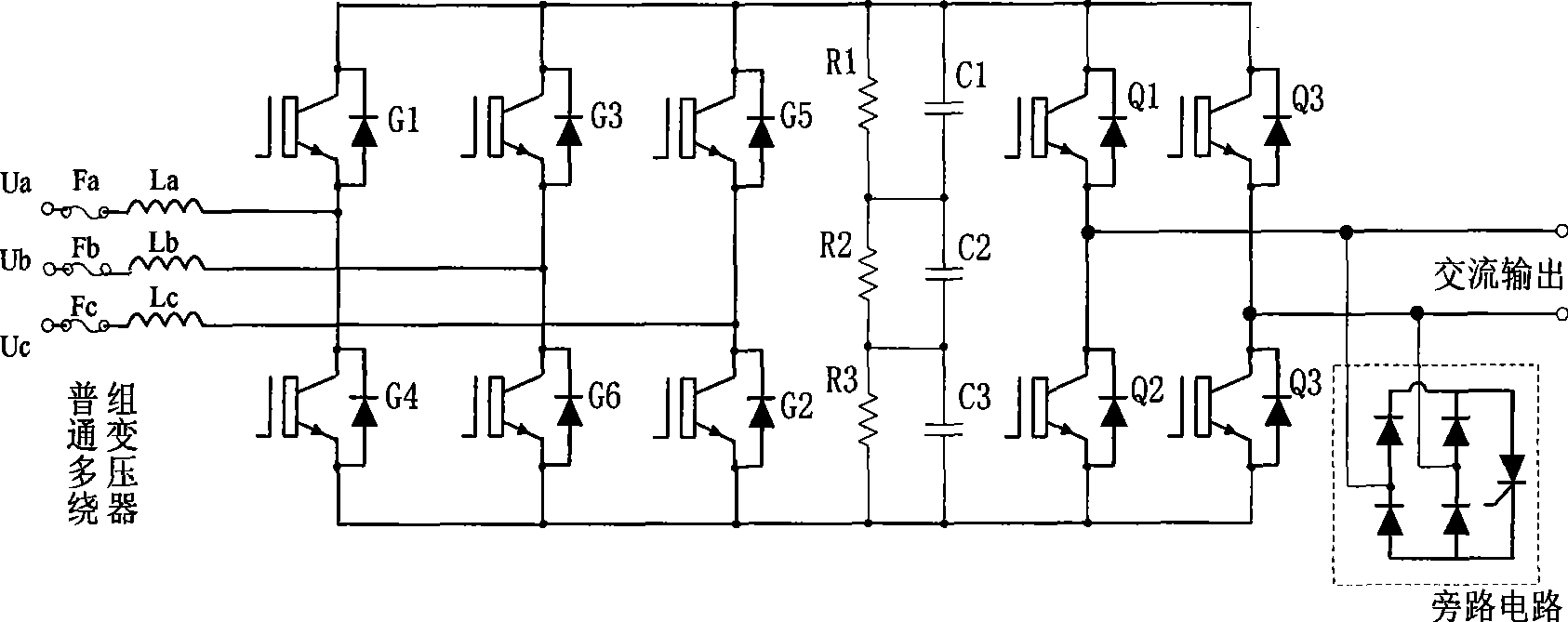

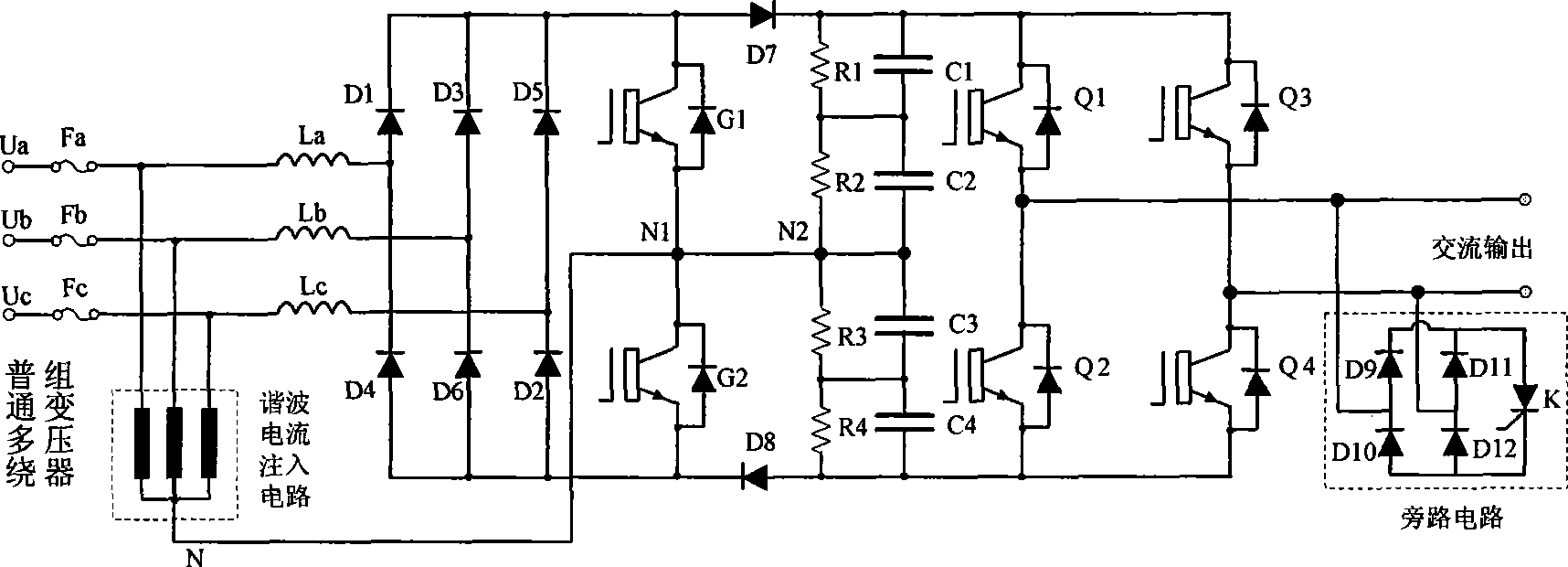

Power unit for cascade apparatus

InactiveCN101378227AImprove stabilityGuaranteed voltage stabilityEfficient power electronics conversionEnergy industryVoltage amplitudeFull bridge

A novel power unit of a cascade unit comprises a DC voltage driver unit, a voltage lifting chopping part and an inverting part. The DC voltage drive of the power unit adopts a three-phase bridge type uncontrolled rectifier system, and two controllable IGBTs and two fast diodes are added at the DC side, thus forming a DC voltage lifting chopping circuit which can control the voltage at the DC link and broaden the scope of AC output voltage amplitude; an inverter adopts IGBT single-phase full bridge controllable output, and a fault bypass circuit is added at the output terminal of the inverter; and a rectifier transformer is of common wiring multi-winding type, and all secondary windings have the same wiring mode. A voltage lifting half-bridge and a neutral point in a filter capacitor set are connected with the neutral point in a harmonic current circuit to provide a channel for injecting zero sequence current so as to achieve the sinusoid of high power factor rectification and the input current.

Owner:SOUTHEAST UNIV

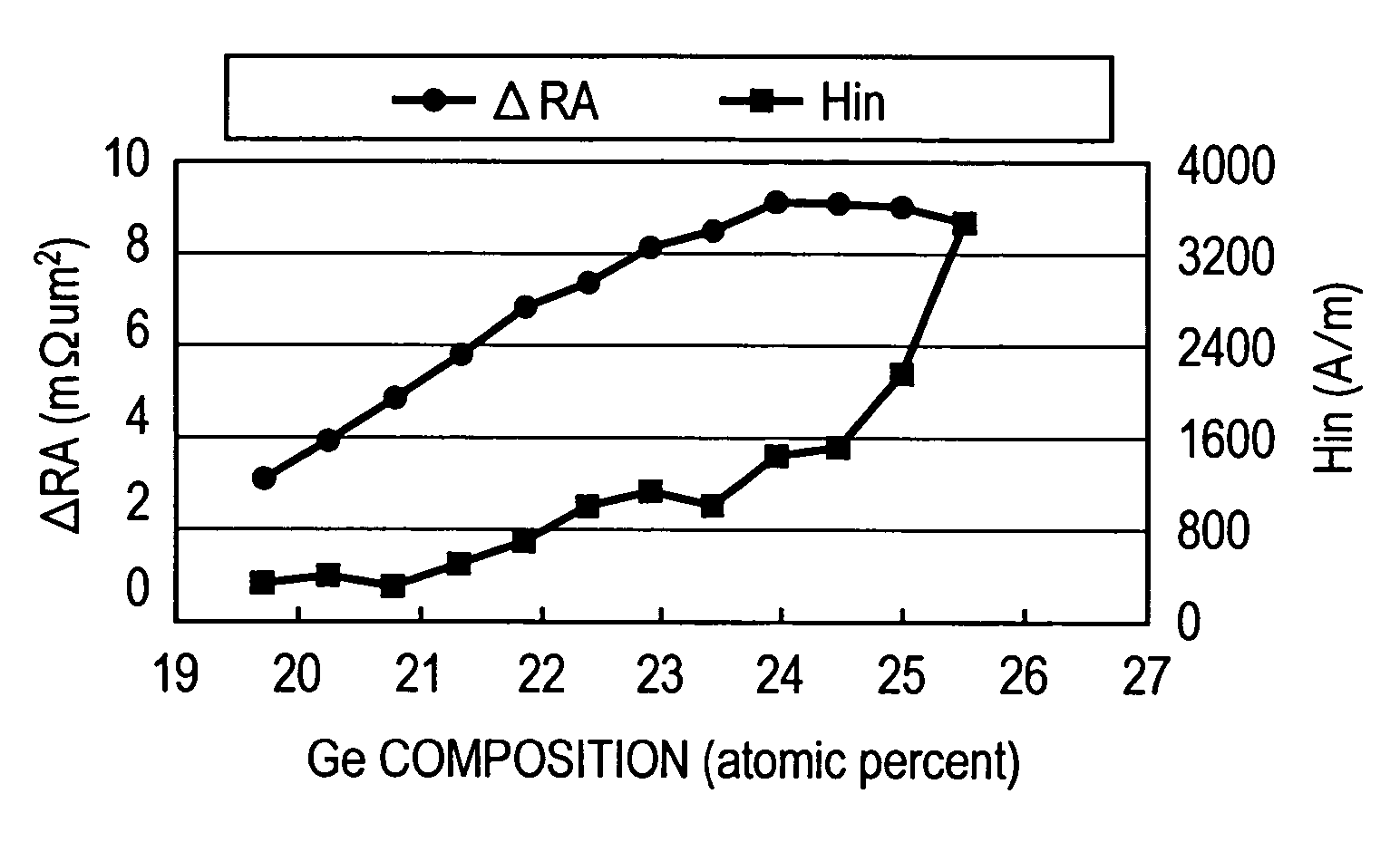

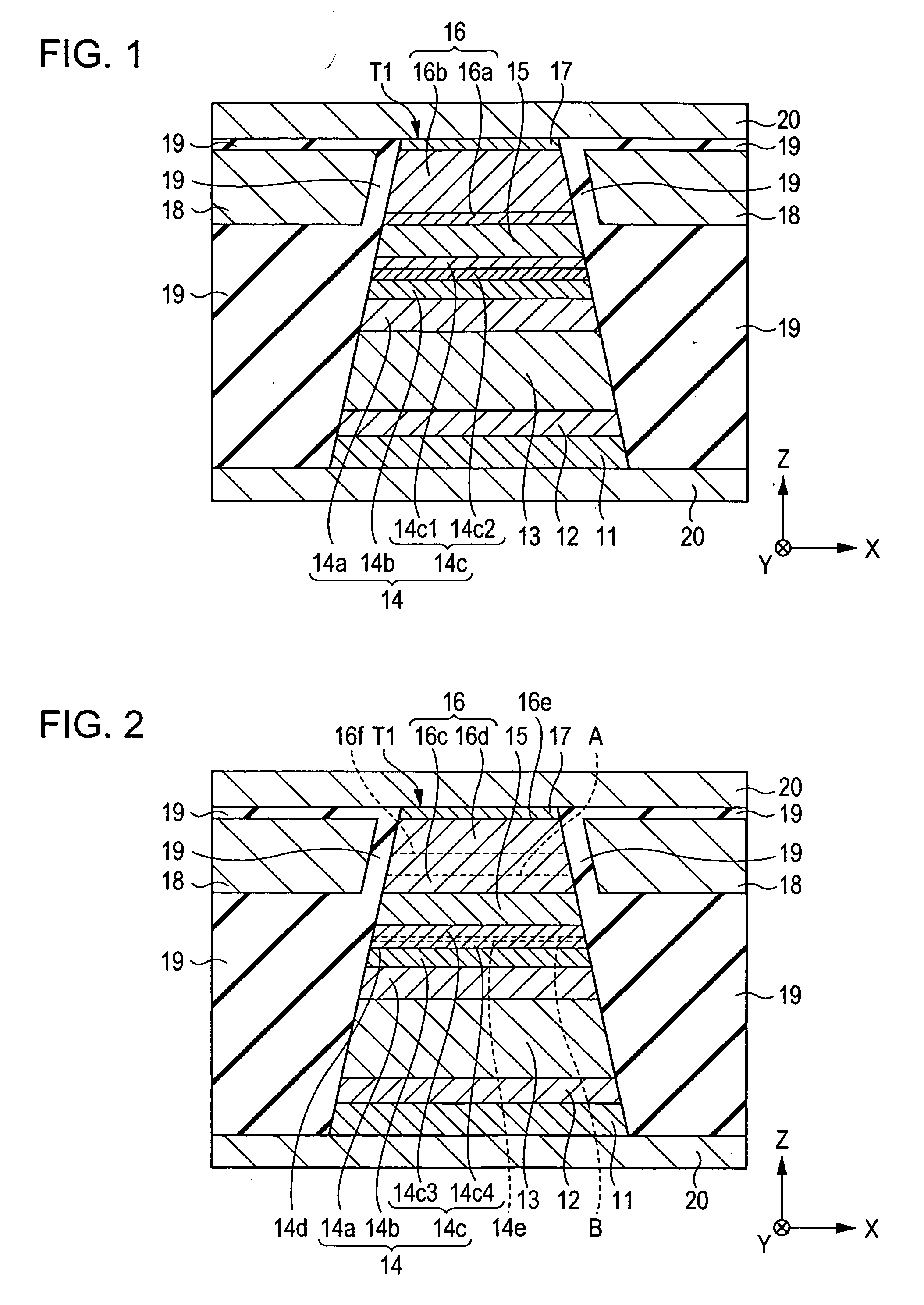

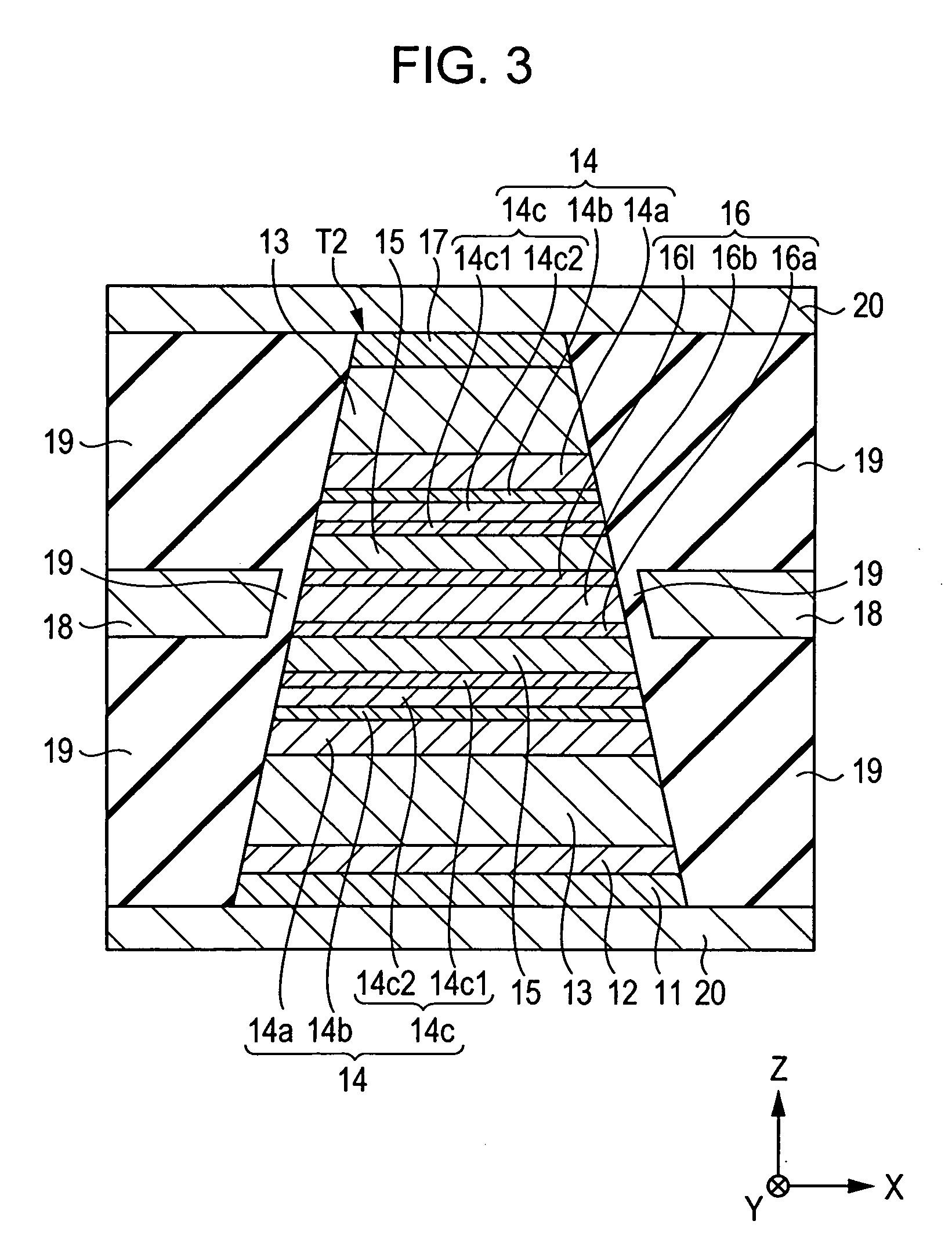

Magnetic sensing element including free layer having gradient composition and method for manufacturing the same

ActiveUS20060188750A1Reduce couplingLarge coefficientNanomagnetismVacuum evaporation coatingCouplingSpins

A magnetic sensing element which allows a high reproduction output and reduction in asymmetry of reproduction waveform to become mutually compatible, as well as a method for manufacturing the same, is provided. In the inside of a second pinned magnetic layer and a free magnetic layer, the atomic percentage of an element Z is decreased in a region close to a non-magnetic material layer. Consequently, the ferromagnetic coupling magnetic field due to magnetostatic coupling (topological coupling) between the pinned magnetic layer and the free magnetic layer can be reduced. At the same time, in a region at a distance from the non-magnetic material layer, the atomic percentage of an element Z is increased, a spin-dependent bulk scattering coefficient is increased, and a product of the amount of change in magnetic resistance and the element area of the magnetic sensing element can be maintained at a high level.

Owner:TDK CORPARATION

Load control circuit and method for achieving reduced acoustic noise

ActiveUS7193404B2Reduce noiseReduce asymmetryDc network circuit arrangementsElectric light circuit arrangementTransformerLow voltage

A load control circuit having first and second terminals for connection in series with a controlled load comprises a bidirectional semiconductor switch for switching at least a portion of both positive and negative half cycles of an alternating current source waveform to the load. The bidirectional semiconductor switch has a control electrode. The load control circuit includes a phase angle setting circuit, including a timing circuit, which sets the phase angle during each half cycle of the AC source waveform when the bidirectional semiconductor switch conducts. The phase angle setting circuit includes a voltage threshold trigger device connected in series with the control electrode of the switch. The phase angle setting circuit further comprises a rectifier bridge connected in series between an output of the timing circuit and the control electrode of the semiconductor switch, wherein the rectifier bridge has a first pair of terminals and a second pair of terminals, the first pair of terminals connected in series between an output of the timing circuit and the control electrode of the semiconductor switch, and the second pair of terminals connected to the voltage threshold trigger device. The load control circuit further includes an impedance in series electrical connection with the semiconductor switch control electrode. Acoustic noise generated in the load connected in series with the load control circuit is reduced, particularly when the load is a toroidal transformer driving a magnetic low voltage lamp and the load control circuit is a two-wire dimmer.

Owner:LUTRON TECH CO LLC

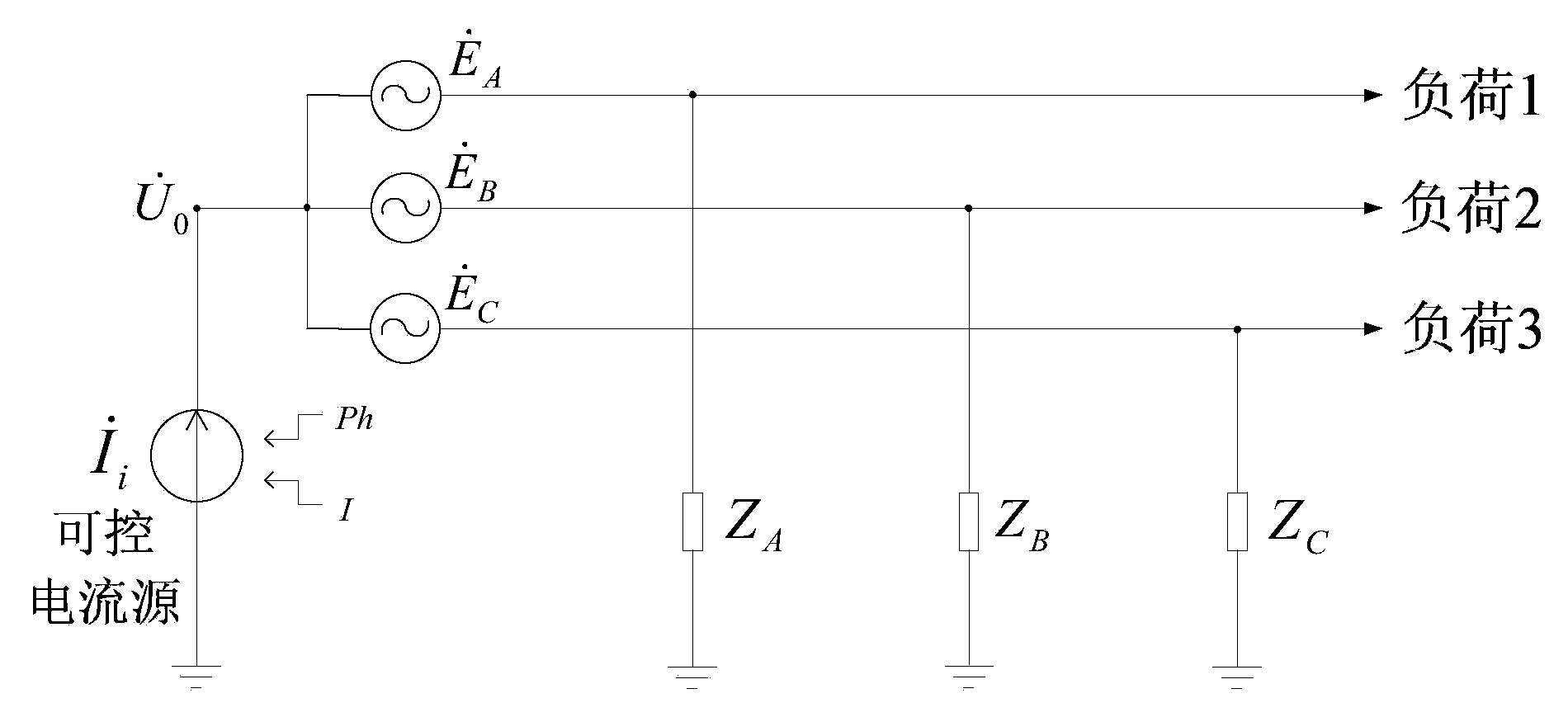

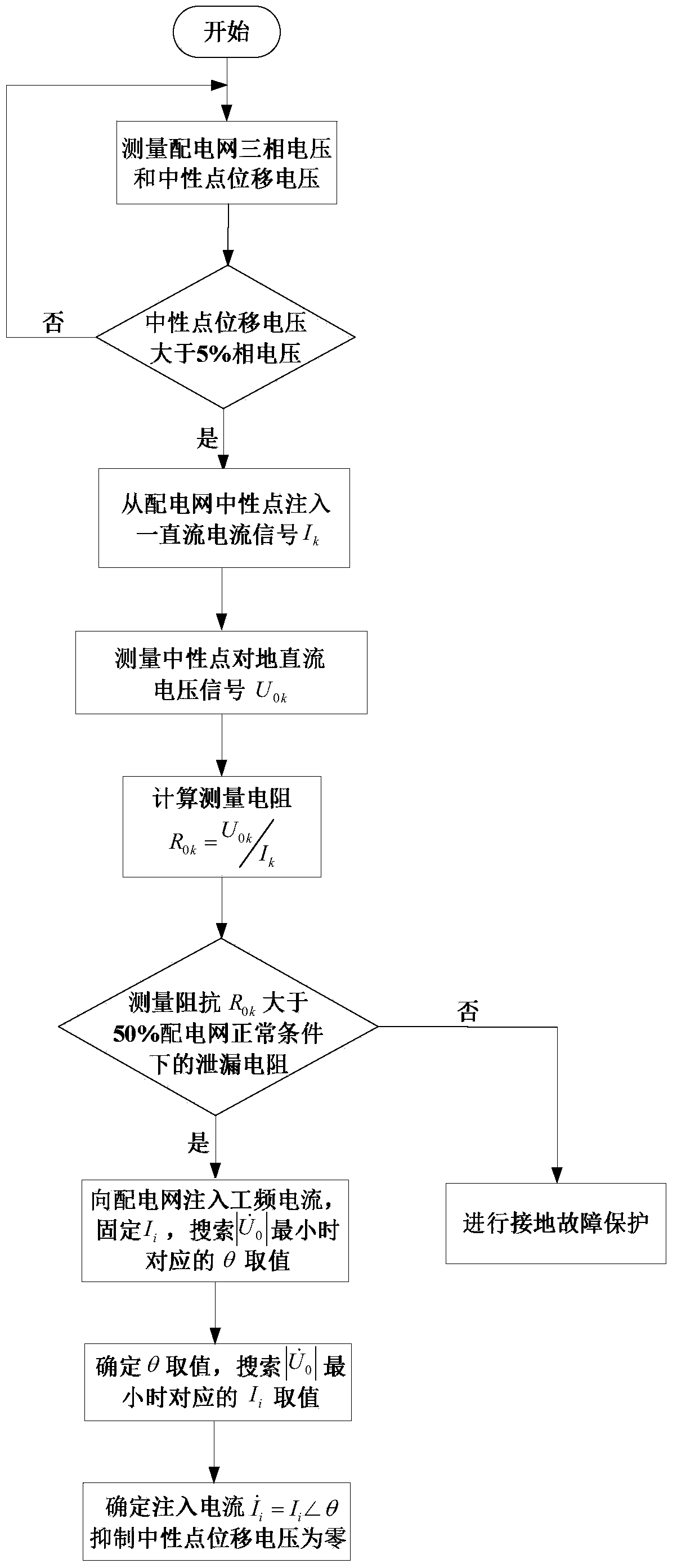

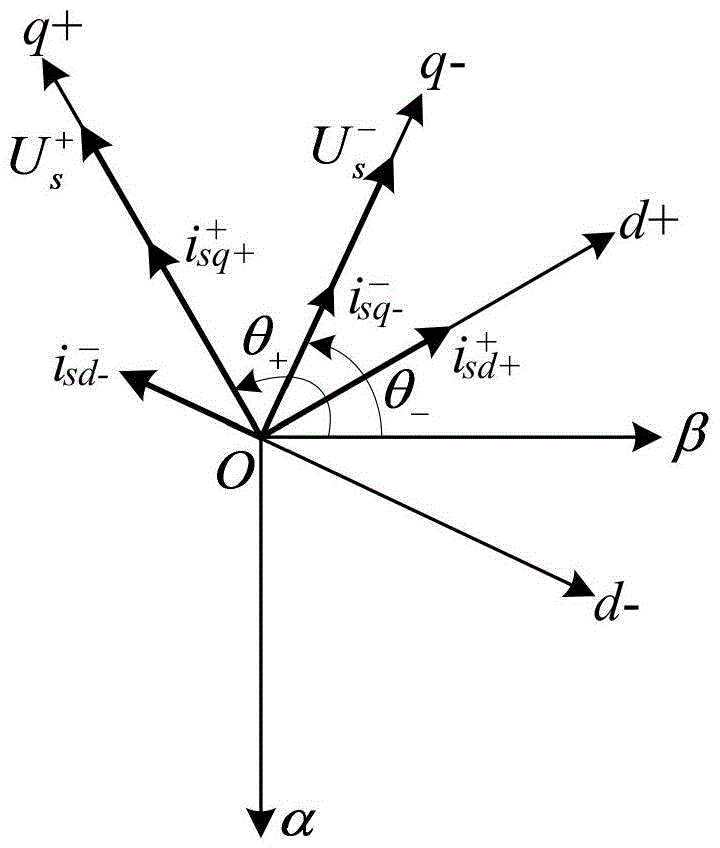

Inhibition method for three-phase imbalance voltages of power distribution network

ActiveCN104167749AReduce asymmetryReduce power consumptionPolyphase network asymmetry elimination/reductionAc network voltage adjustmentOvervoltageControl objective

The invention discloses an inhibition method for three-phase imbalance voltages of a power distribution network. The method includes the following steps: installing a controllable current source between a neutral point of the power distribution network and the ground; measuring three-phase voltages and a neutral-point displacement voltage of the power distribution network in a real-time manner; when the displacement voltage is larger than 5% of a rated phase voltage, identifying whether the operation state of the power distribution network is a three-phase imbalance state; and under a condition of the three-phase imbalance state of the power distribution network, injecting a power frequency current I <*> to the power distribution network through the controllable current source and searching for an optimal injection current phase and amplitude and inhibiting the neutral-point displacement voltage to be zero. The method uses the neutral-point displacement voltage as a control target and forces the neutral-point displacement voltage to be zero through injection of the current to the power distribution network so that neutral-point displacement overvoltage caused by asymmetry of three-phase to-ground parameters of the power distribution network is eliminated completely and thus inhibition of three-phase imbalance overvoltages of the power distribution network is realized.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Liquid crystal display device

ActiveUS20050146659A1Avoid light leakageImprove light leakagePolarising elementsNon-linear opticsPolarizerLiquid crystal cell

A liquid crystal display device includes a liquid crystal cell, first and second polarizers disposed outside the liquid crystal cell, first and second retardation plates arranged between the first and second polarizers, and the liquid crystal cell, and optical layers arranged between the first and second retardation plates and the liquid crystal cell. The first and second retardation plates have lagging axes perpendicular with each other. The first polarizer has an absorption axis inclining by about 45 degrees relative to the lagging axis of the first retardation plate, and inclining by about 90 degrees relative to an absorption axis of the second polarizer. The absorption axes of the first and second polarizers are angularly deviated such that characteristic of a viewing angle in the liquid crystal display device is rendered symmetric, relative to a symmetry axis about which liquid crystal is aligned in different directions.

Owner:HANNSTAR DISPLAY CORPORATION

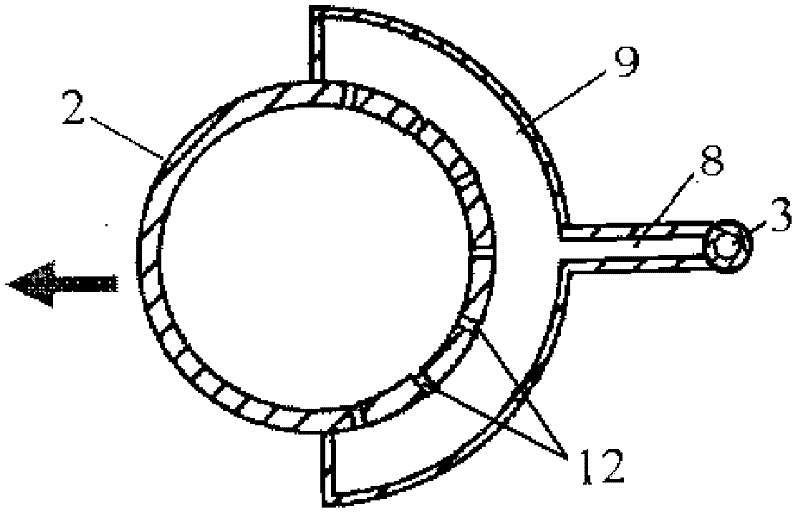

Optical fiber ring capable of eliminating influence of external environmental factors

ActiveCN102589541AReduce asymmetryReduce temperature gradientSagnac effect gyrometersGyroscopeMetallic materials

The invention relates to an optical fiber ring capable of eliminating influence of external environmental factors, and belongs to the technical field of optical measurement and optical fiber sensing. The optical fiber ring comprises a main body formed by winding an optical fiber, and is characterized by further comprising a heat-insulating layer, an optical fiber ring framework and a magnetic shielding material layer, wherein the heat-insulating layer is coated on the surface of the main body and is used for eliminating influence of external factors; the optical fiber ring framework is made of a non-metallic material and is used for being matched with a thermal expansion coefficient of the optical fiber, so that when the outside temperature changes, the accuracy deviation of an optical fiber gyroscope caused by equivalent asymmetry degree due to temperature change of the optical fiber ring can be reduced; and the magnetic shielding material layer is arranged outside the optical fiber ring so as to reduce or eliminate the influence of an external magnetic field on an angle sensor of the optical fiber ring.

Owner:苏州光环科技有限公司

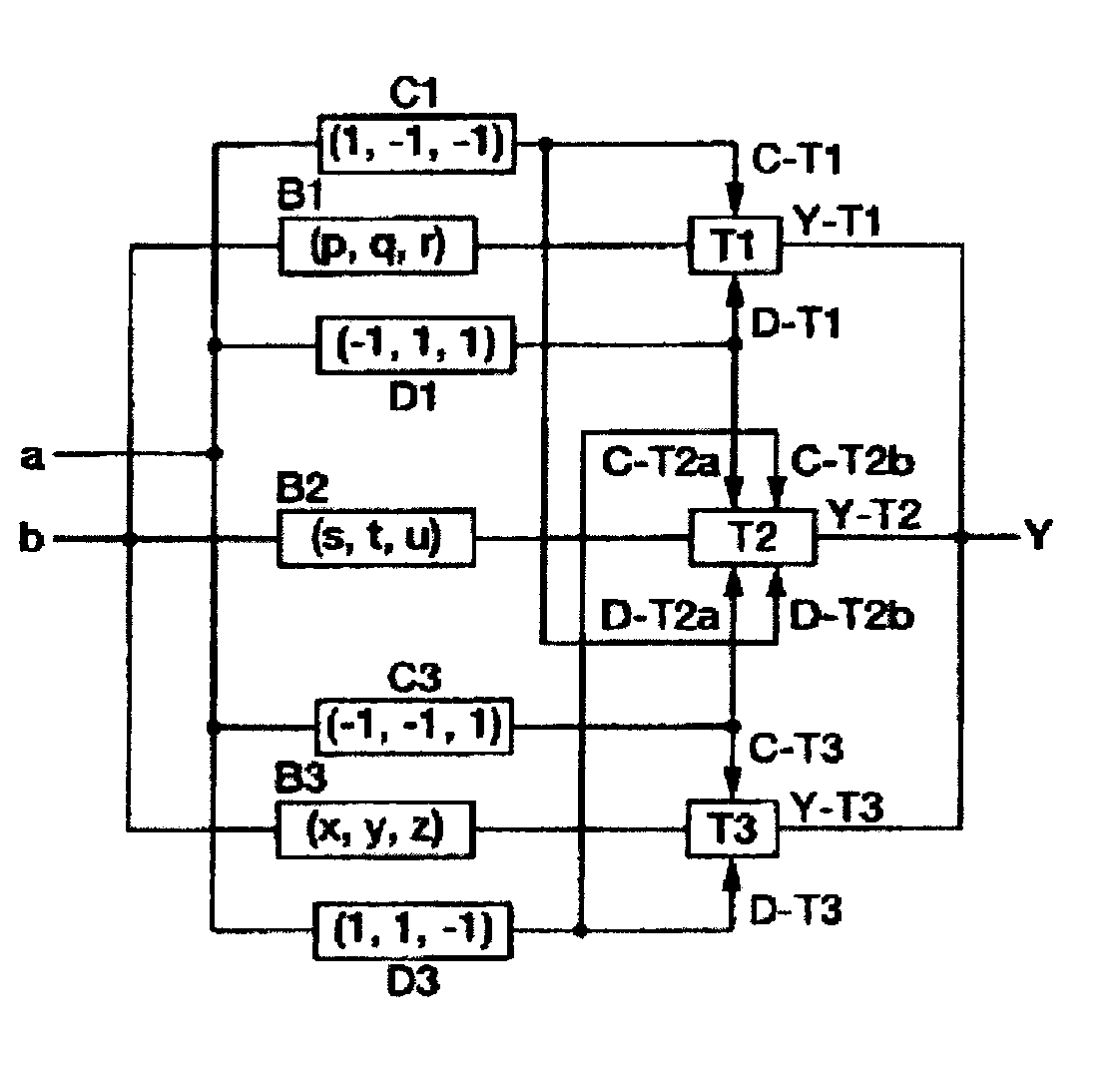

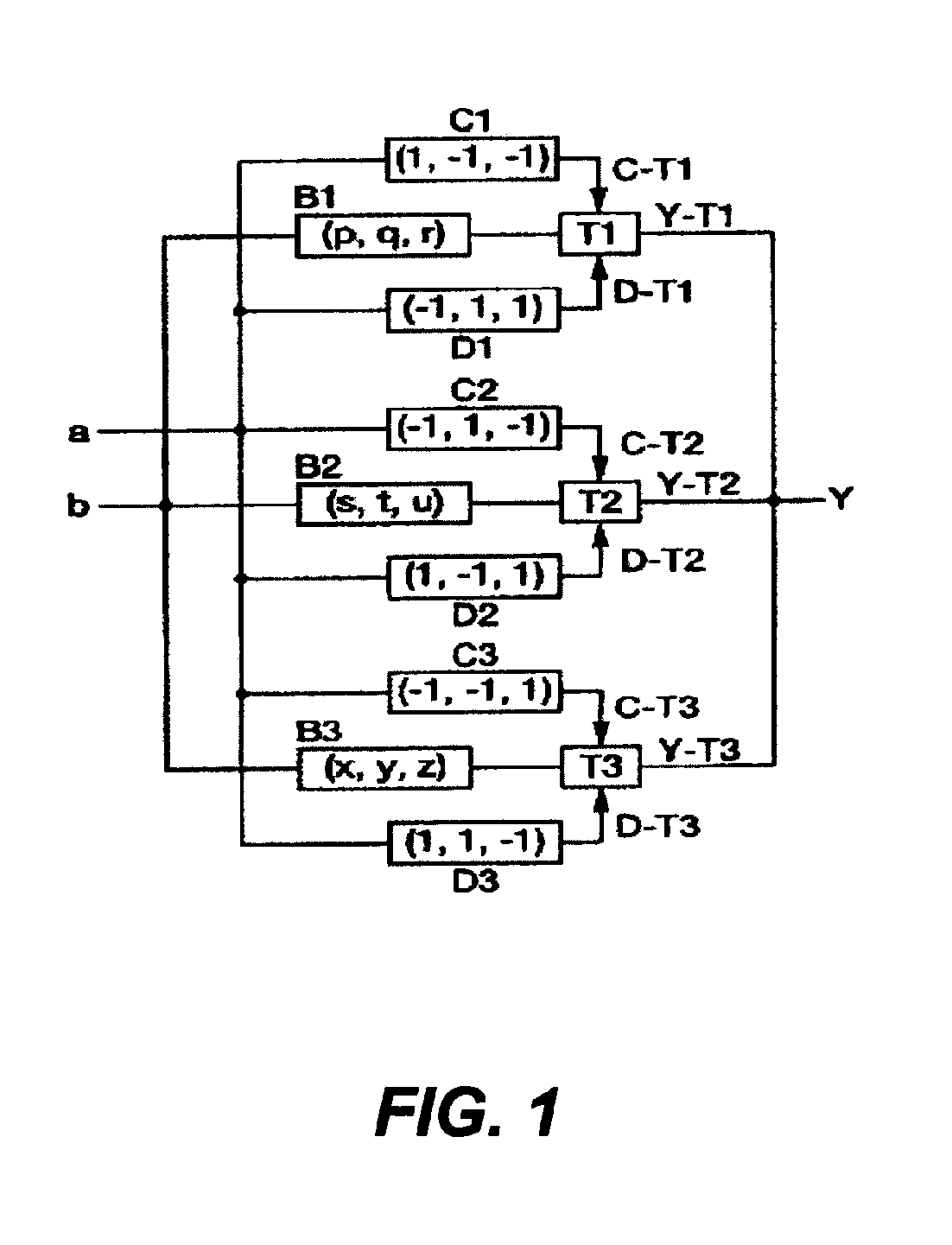

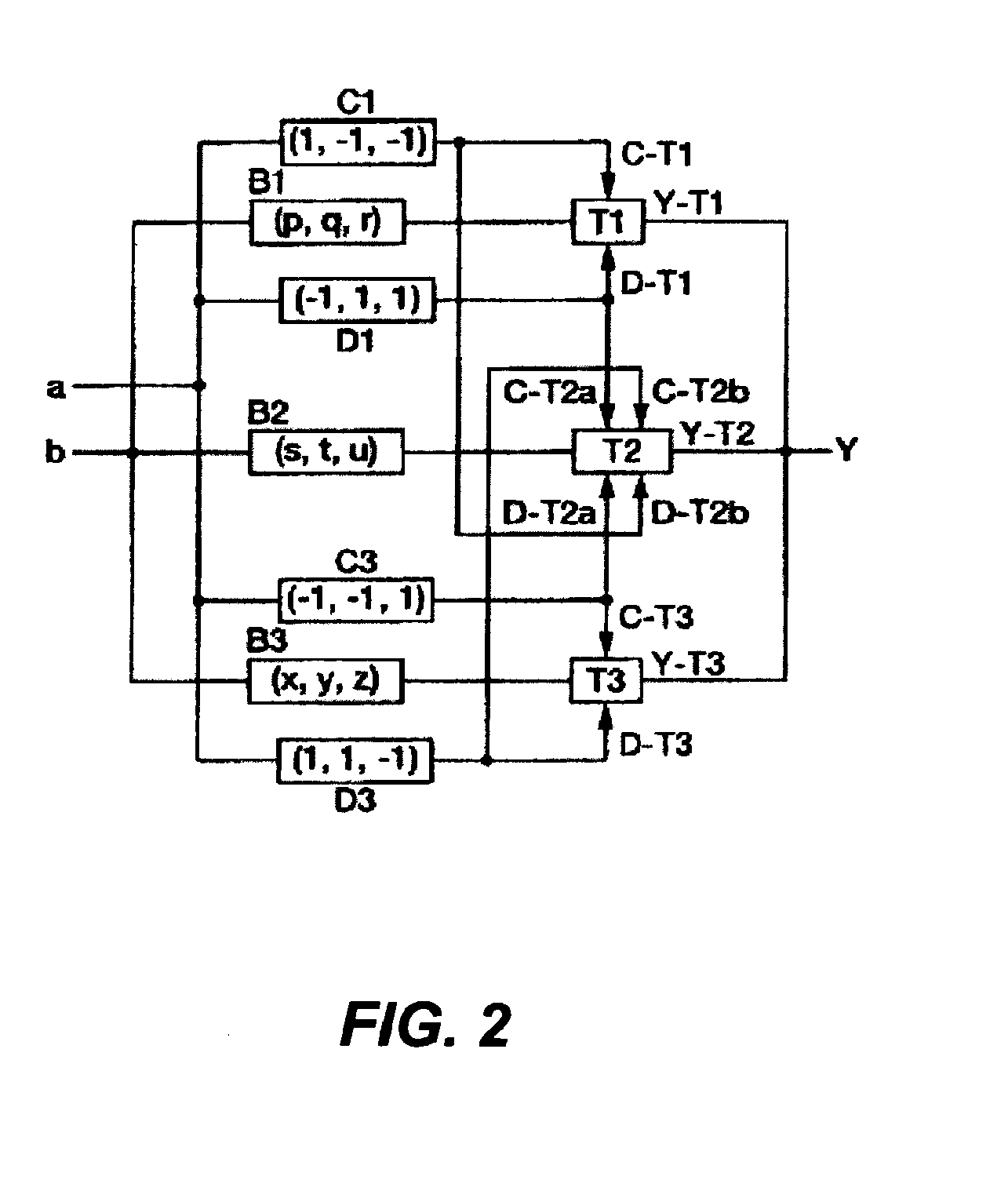

Three-valued logic function circuit

InactiveUS20090295428A1Switch time be decreaseReduce the kinds of basic circuits and the number of transistor necessaryLogic circuits characterised by logic functionMultistate logicAsymmetryLogical Function

There is provided a three-valued logic function circuit capable of remarkably reducing the kinds of basic circuits necessary for realizing all 33̂2=19683 kinds of two-variable three-valued logic function circuits, remarkably reducing asymmetry of the switching time, and improving an operation speed and symmetry of waveform of the logic function circuit. In a three-valued logic function circuit, three transfer gates T1, T2, and T3 are turned on or off by one-variable three-valued logic function circuits C1, D1, C3 and D3, according to three logic values −1, 0, and 1 constituting a first input a, to select outputs of three one-variable three-valued logic function circuits B1, B2, and B3 connected to a second input b. The transfer gate T2 is configured by parallel connection of a switch pair of serial connection of two n-type MOS transistors and a switch pair of serial connection of two p-type MOS transistors.

Owner:JAPAN ADVANCED INST OF SCI & TECH

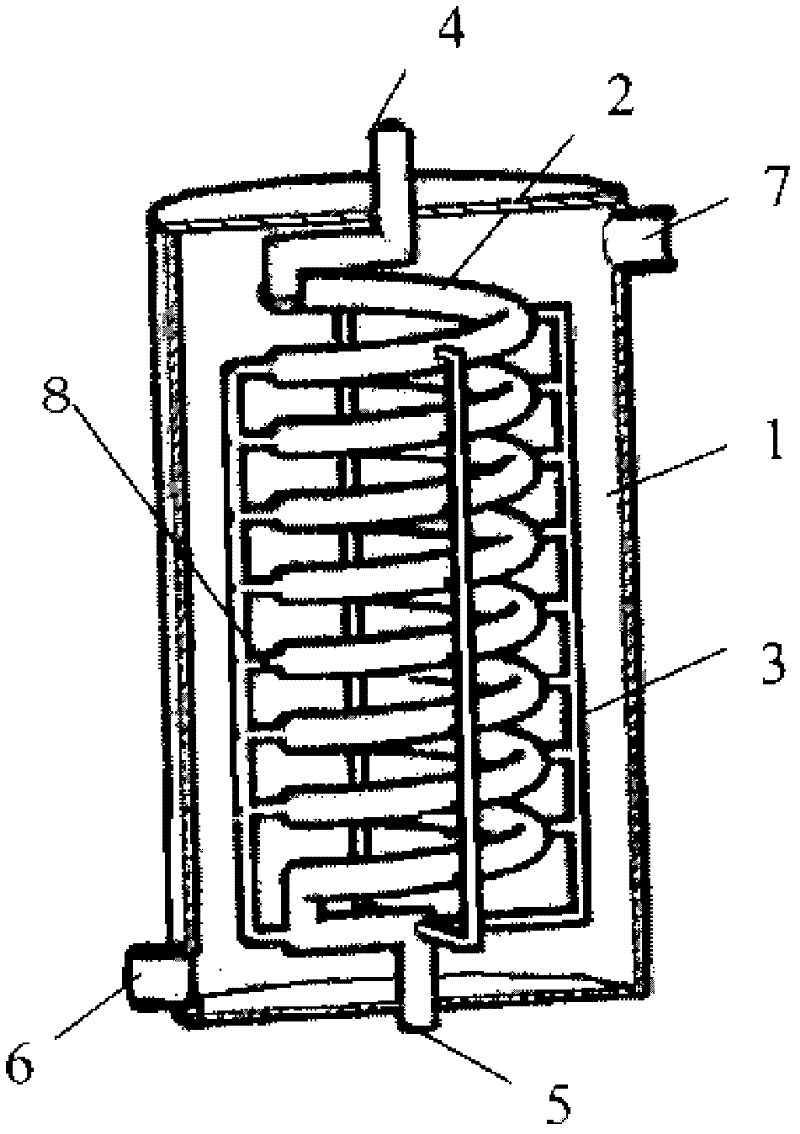

Condenser with liquid separation type spiral tube structure

ActiveCN102313404AImprove heat transfer effectReduce asymmetryEvaporators/condensersTubular elementsCondensation processHeat resistance

The invention discloses a condenser with a liquid separation type spiral tube structure, which belongs to the technical fields of heat exchange and heat transfer. A spiral heat exchange tube is fixed in a shell of the condenser with the liquid separation type spiral tube structure; a liquid guiding tube is distributed on the outer circumference of the spiral heat exchange tube; the upper end of the spiral heat exchange tube is a condensing working substance inlet tube; the lower end of the spiral heat exchange tube is a condensing working substance outlet tube; the upper end of the outer circumference of the shell is a cooling water outlet; and the lower end of the outer circumference of the shell is a cooling water inlet. In a condensing process, a thick liquid film distributed on the side wall surface of the spiral outer circumference is derived in a non-dynamical way by utilizing the combined action of surface tension, capillary force and centrifugal force; a thin liquid film is promoted to transfer heat in a condensation phase change process; and the heat resistance of a condensed liquid film on the side of the outer circumference of a spiral tube is decreased, thereby obviously improving the heat exchange performance on the side of a condensation phase change tube. By using the condenser with the liquid separation type efficient spiral tube, a condensate liquid is separated mainly by means of the centrifugal force and the capillary force without being influenced by gravity, and the condensation heat exchange coefficient can be obviously improved both in a ground environment or a microgravity environment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

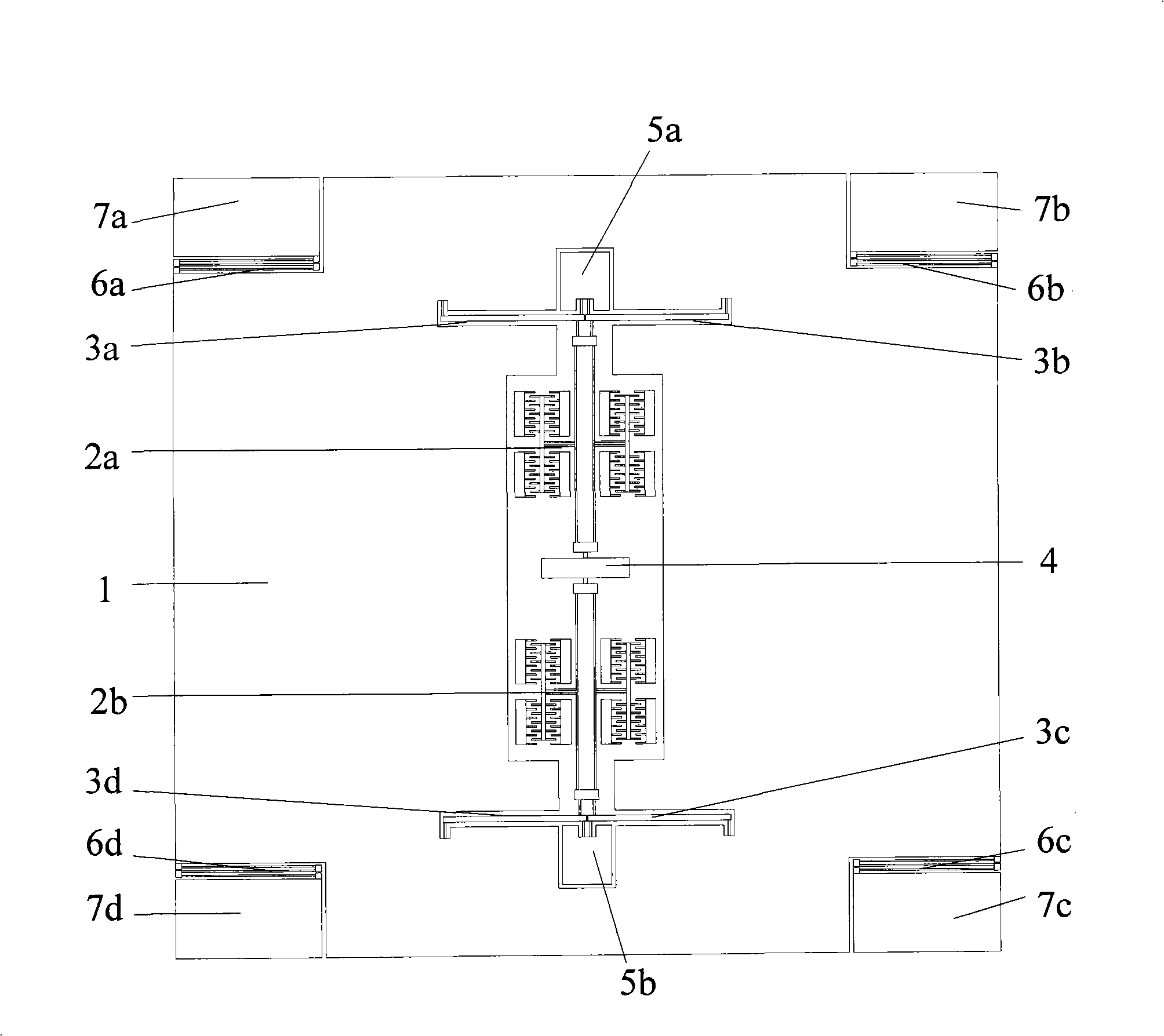

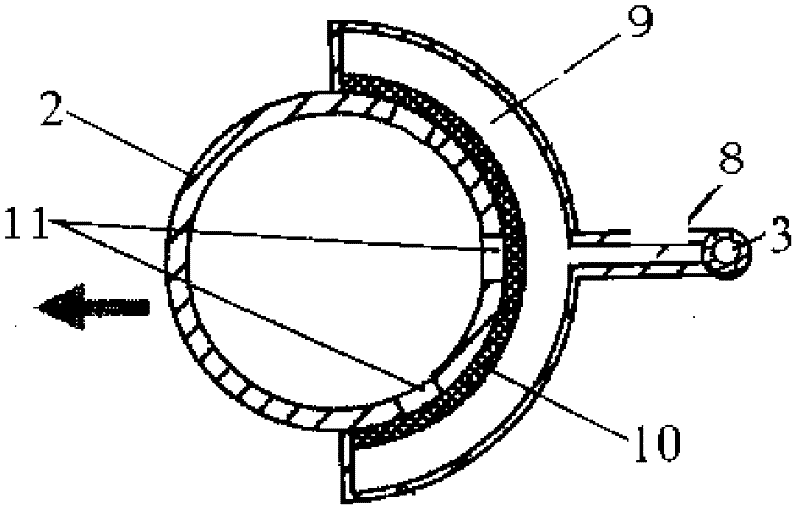

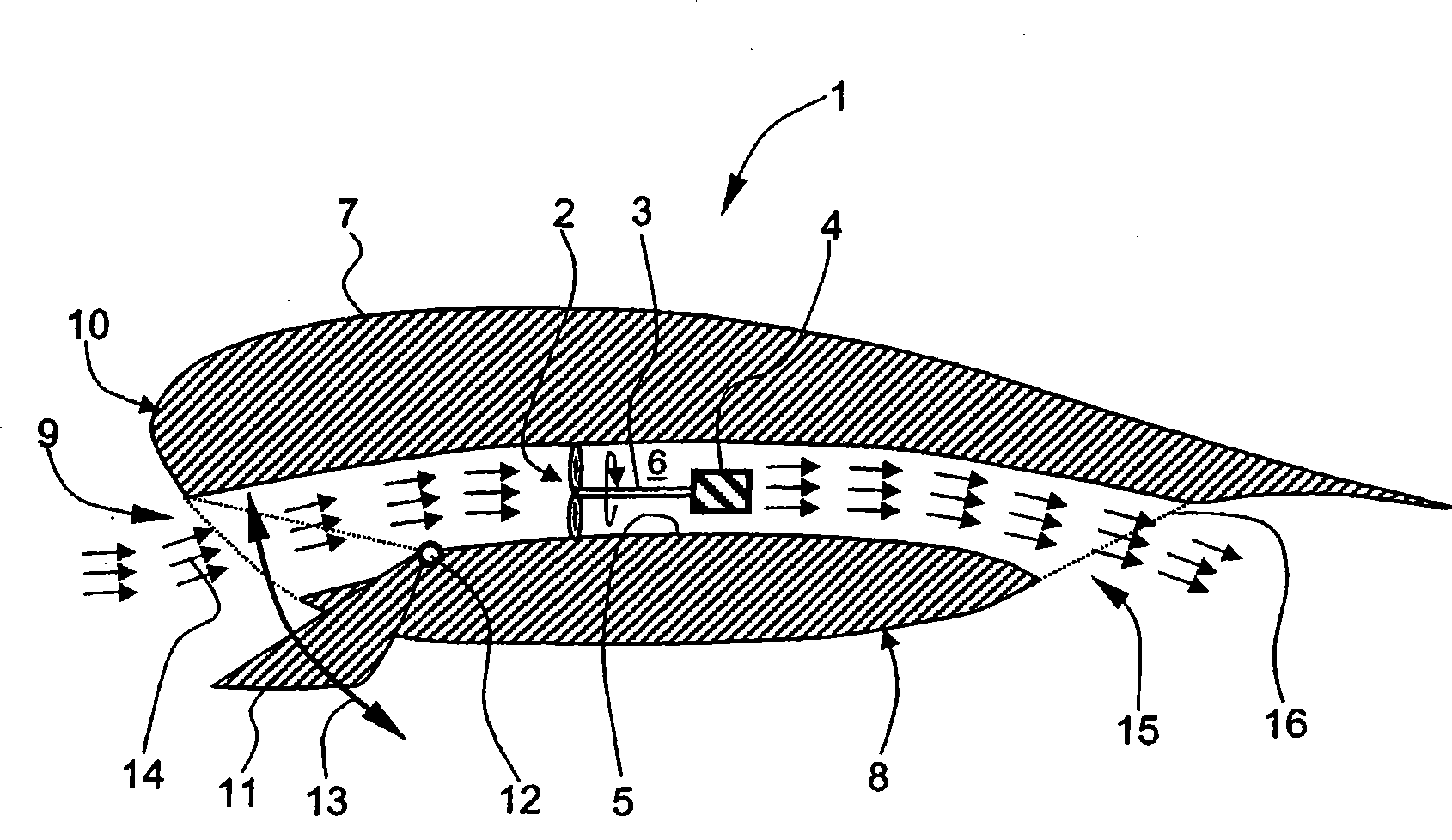

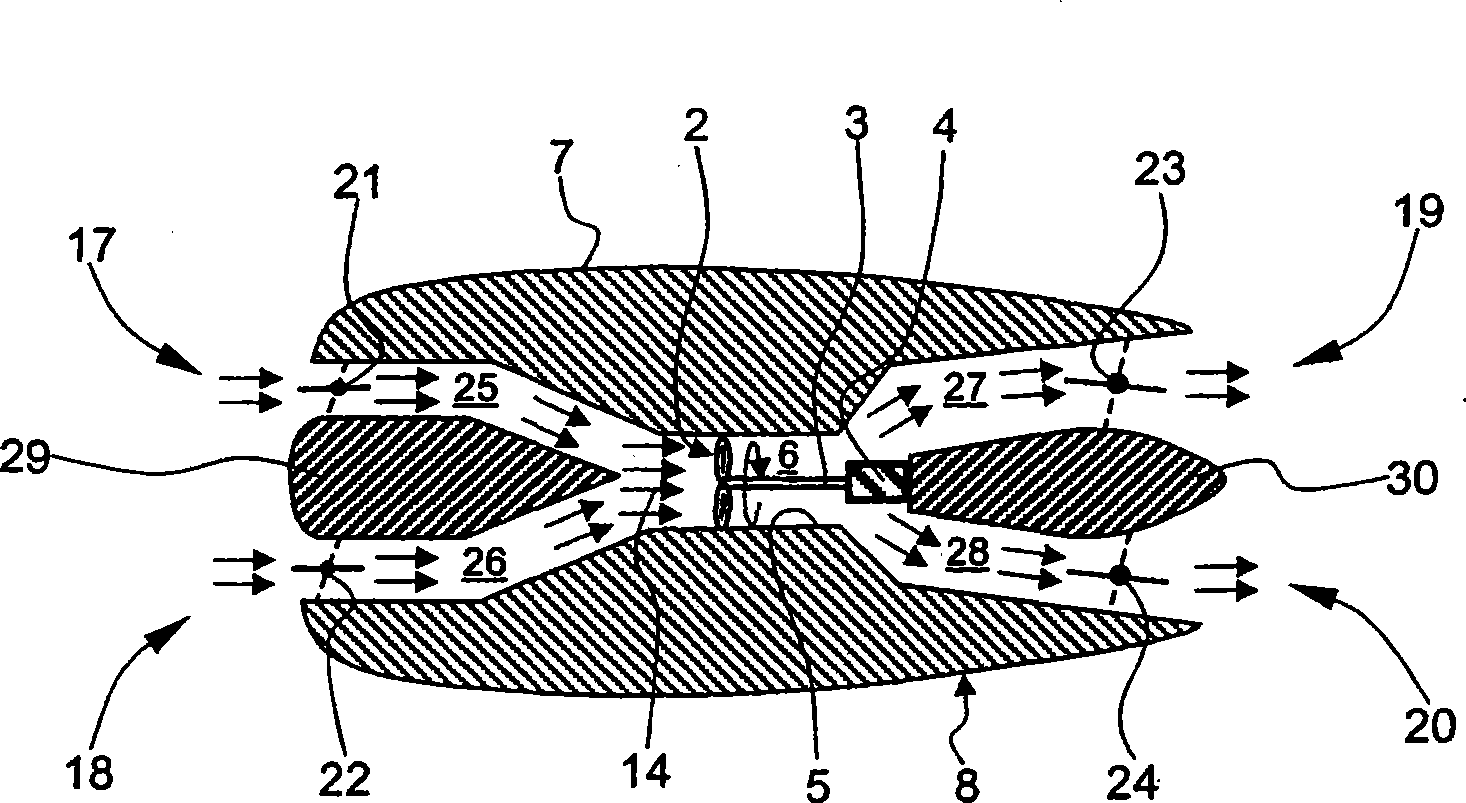

Emergency supply unit with a ram-air turbine adapted to be driven by an air stream and with an energy converter for aircraft

InactiveCN101374724AReduce consumptionReduce asymmetryPower installationsEfficient propulsion technologiesEmergency SupplyOn board

The invention relates to an emergency supply unit (1) with a ram-air turbine (2) which can be driven by an air stream (14) and with an energy converter (4) for at least partly maintaining the functioning of a hydraulic system and / or electrical system on board an aircraft in an emergency situation, wherein the energy converter (4) can be driven by means of the ram-air turbine (2) and the emergency supply unit (1) can selectively be brought into a standby mode or into an operating mode.; According to the invention, at least the ram-air turbine (2) is surrounded substantially concentrically by a casing (5) forming a flow channel (6) and the energy converter (4) is directly coupled to the ram-air turbine (2) via a drive shaft (3) and the air stream (14) can be delivered to the ram-air turbine (2) through at least one air inlet (9, 17, 18), wherein the spatial position of the ram-air turbine (2) remains substantially unchanged when changing between the standby mode and the operating mode. The integration of the ram-air turbine (2) into the flow channel (6) results in a very compact and space-saving design of the emergency supply unit (1) according to the invention, thus offering a plurality of additional installation options, for example in the region of the landing flap rail covering (8) below a wing (7) of an aircraft.; Moreover, the substantially completely encapsulated formation of the emergency supply unit (1) without a pivot arm and with direct coupling of the ram-air turbine (2) to the energy converter (4) through the drive shaft (3) is structurally simple and therefore permits largely maintenance-free operation with greater fail safety.

Owner:AIRBUS OPERATIONS GMBH

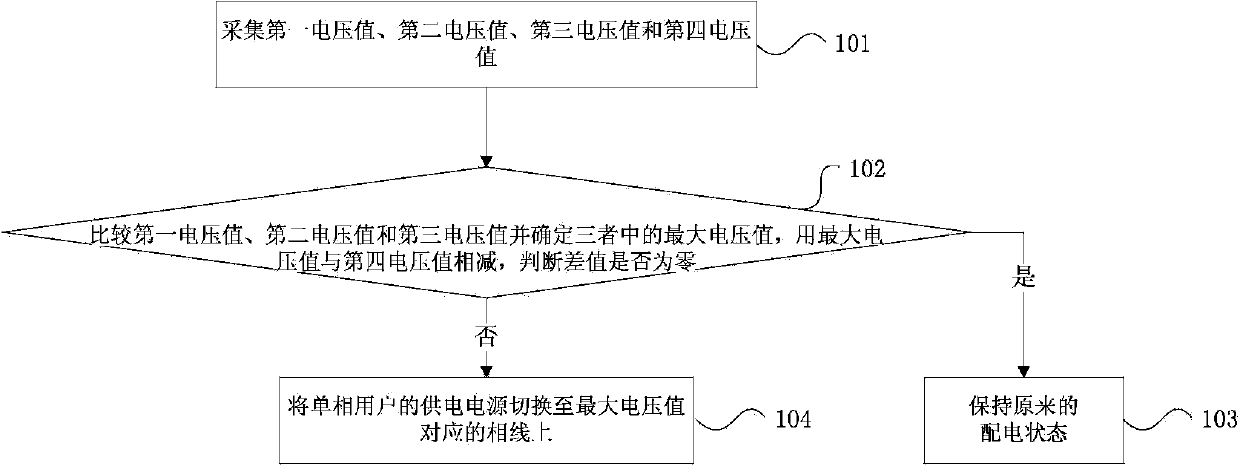

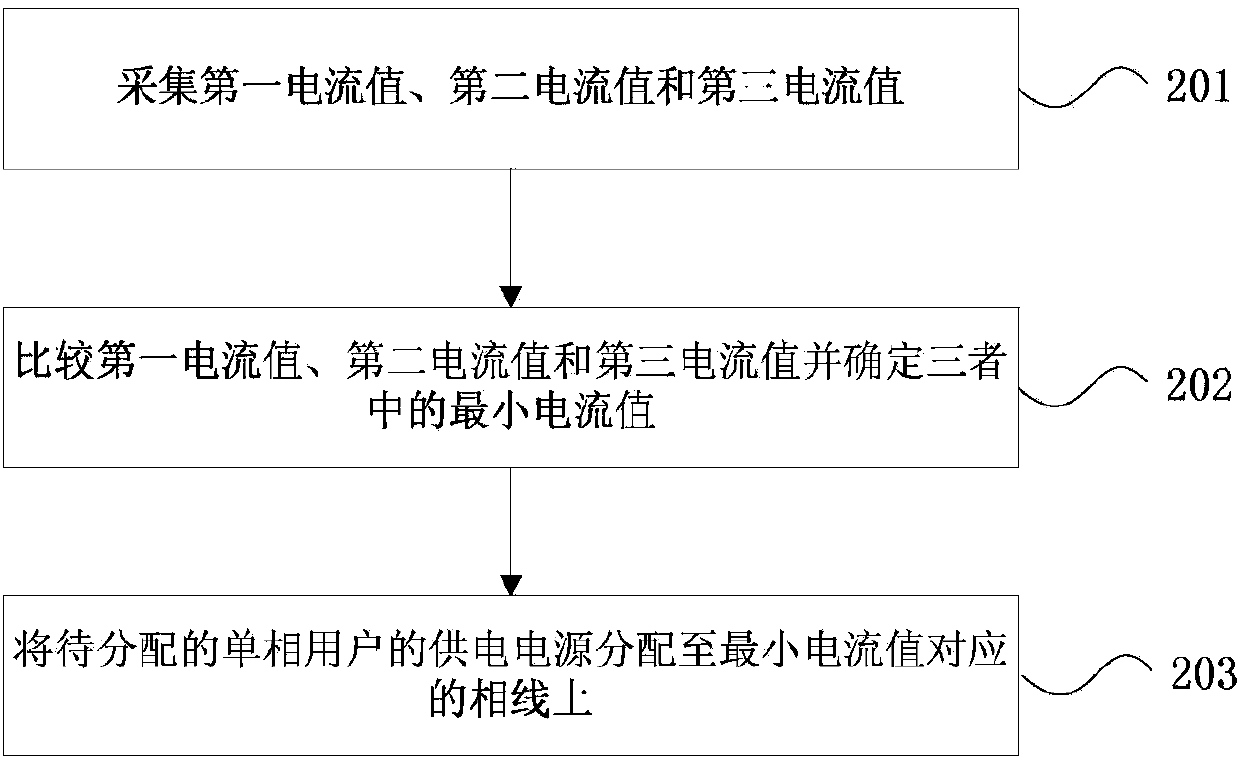

Online automatic power distribution method and device

ActiveCN103997051AHigh practicability and computing efficiencyReduce three-phase load asymmetryPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionSingle phaseSupply & distribution

The invention discloses an online automatic power distribution method and device. The method comprises the steps that a first voltage value corresponding to a phase-A line in a three-phase electric transmission line, a second voltage value corresponding to a phase-B line in the three-phase electric transmission line, a third voltage value corresponding to a phase-C line in the three-phase electric transmission line and a fourth voltage value corresponding to a power supply line of a single-phase user are collected; the first voltage value, the second voltage value and the third voltage value are compared with one another, and the largest voltage value is determined; the difference value of the largest voltage value and the fourth voltage value is calculated, and whether the difference value is zero or not is judged; if the different value is zero, no power distribution instructions are generated, and the original power distribution state is kept; if the difference value is not zero, a power supply of the single-phase user is switched to the phase line corresponding to the largest voltage value. According to the online automatic power distribution method and device, power utilization balance on the three-phase branch circuit can be ensured to the maximum through the power supply distribution strategy, practicability and computational efficiency are high, the three-phase load dissymmetry can be reduced to the maximum, low-voltage electric transmission side line damage is reduced, and power supply safety, reliability and efficiency are improved.

Owner:长沙高升电子电器科技有限公司

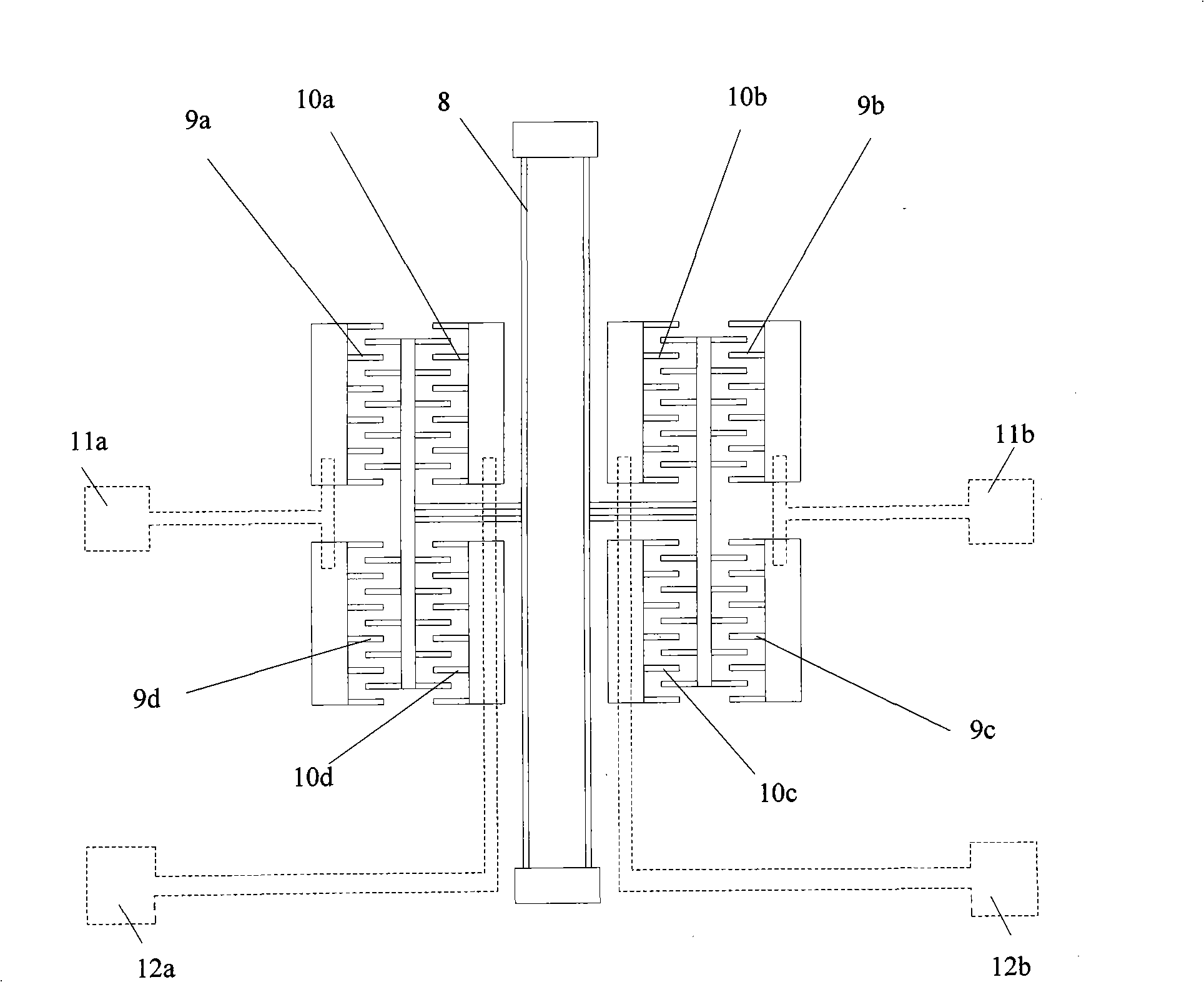

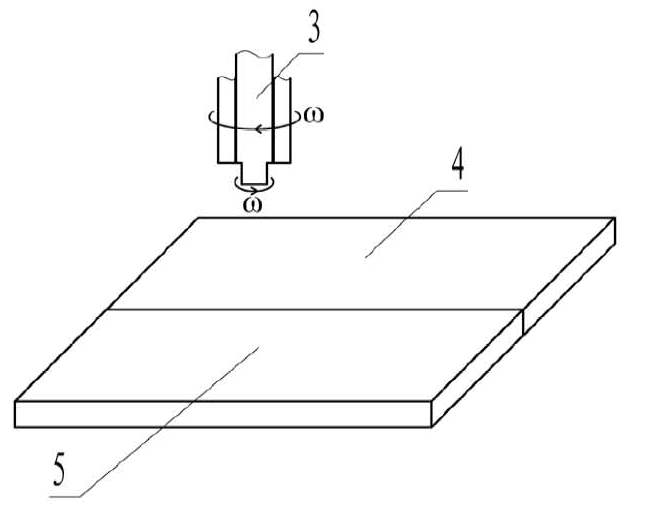

Friction stir welding method for reversely rotating stirring needle and shaft shoulder

InactiveCN101890572AReduce asymmetryImprove mechanical propertiesNon-electric welding apparatusRevolutions per minuteEngineering

The invention discloses a friction stir welding method for reversely rotating a stirring needle and a shaft shoulder, relates to a friction stir welding method, and solves the problems that the conventional friction stir welding method has asymmetrical temperature field, joint structure and residual stress distribution so as to cause asymmetrical joint performance and reduce the bearing capacity of the welding structure. A first welded workpiece and a second welded workpiece are butted and clamped on a working table; the stirring needle pricks a part to be welded at the rotating speed of 100 to 3,000 revolutions per minute; the rotating direction of the shaft shoulder of the stirring head is opposite to that of the stirring needle, and the rotating speed of the shaft shoulder of the stirring head is the same as that of the stirring needle; and when reaching the set pricking depth, the stirring head moves along the weld joint direction at a speed of 100 to 5,000 mm per minute. The directions of driving forces of the stirring needle and the shaft shoulder on the flowing welded materials are opposite, the asymmetry of the friction stir welding head structure and performance is reduced, and the mechanical property of the friction stir welding joint is improved.

Owner:HARBIN INST OF TECH

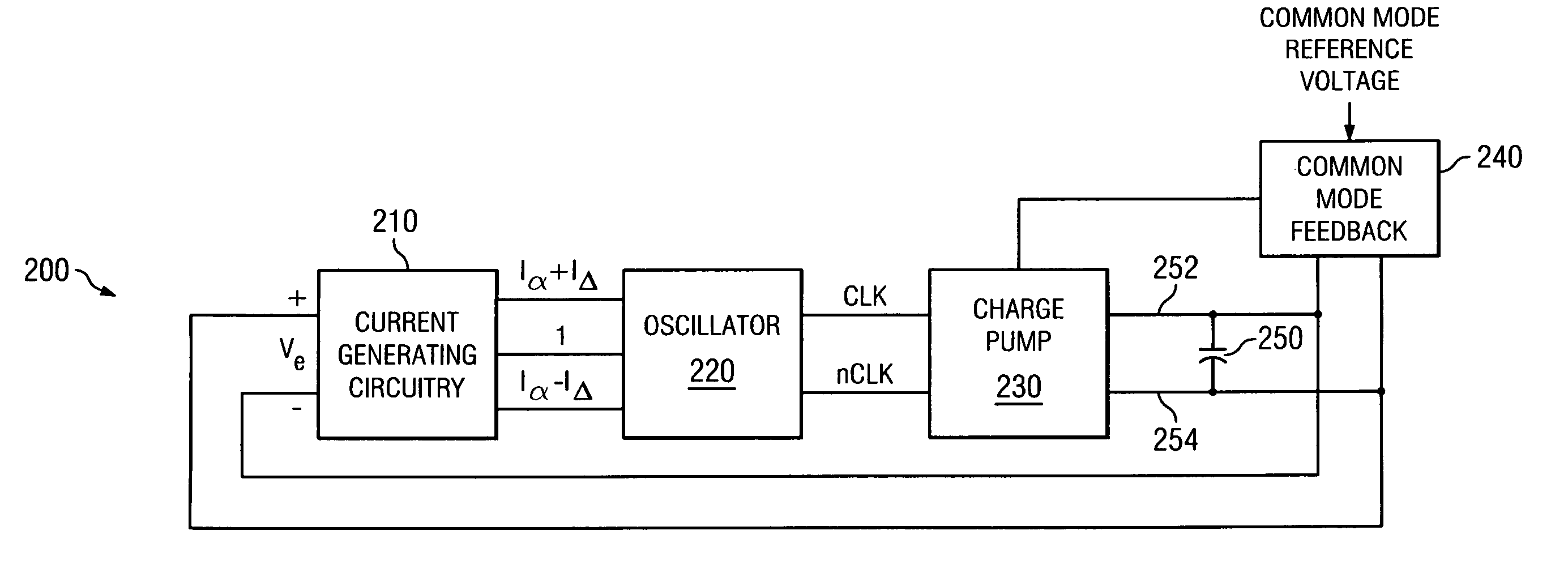

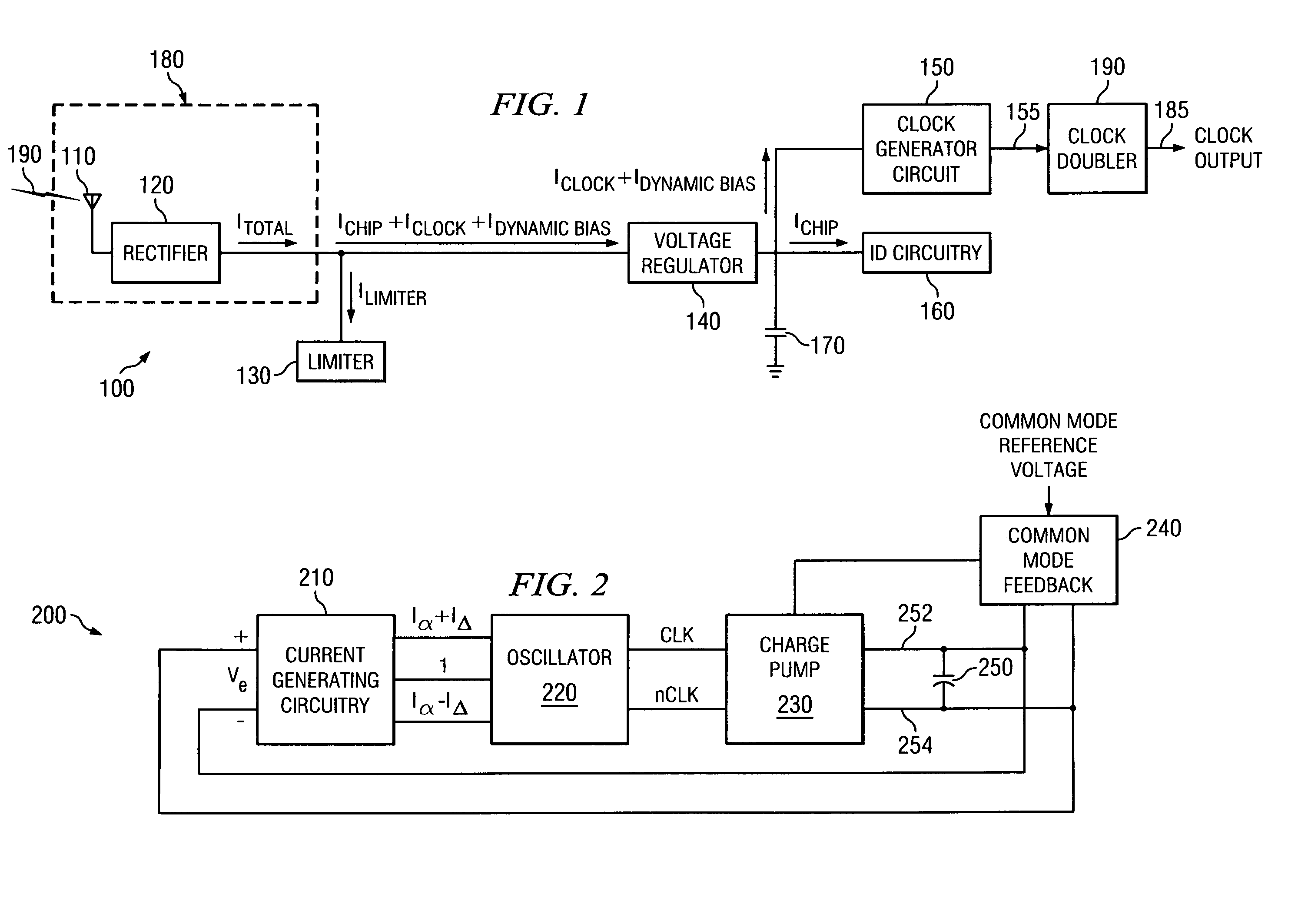

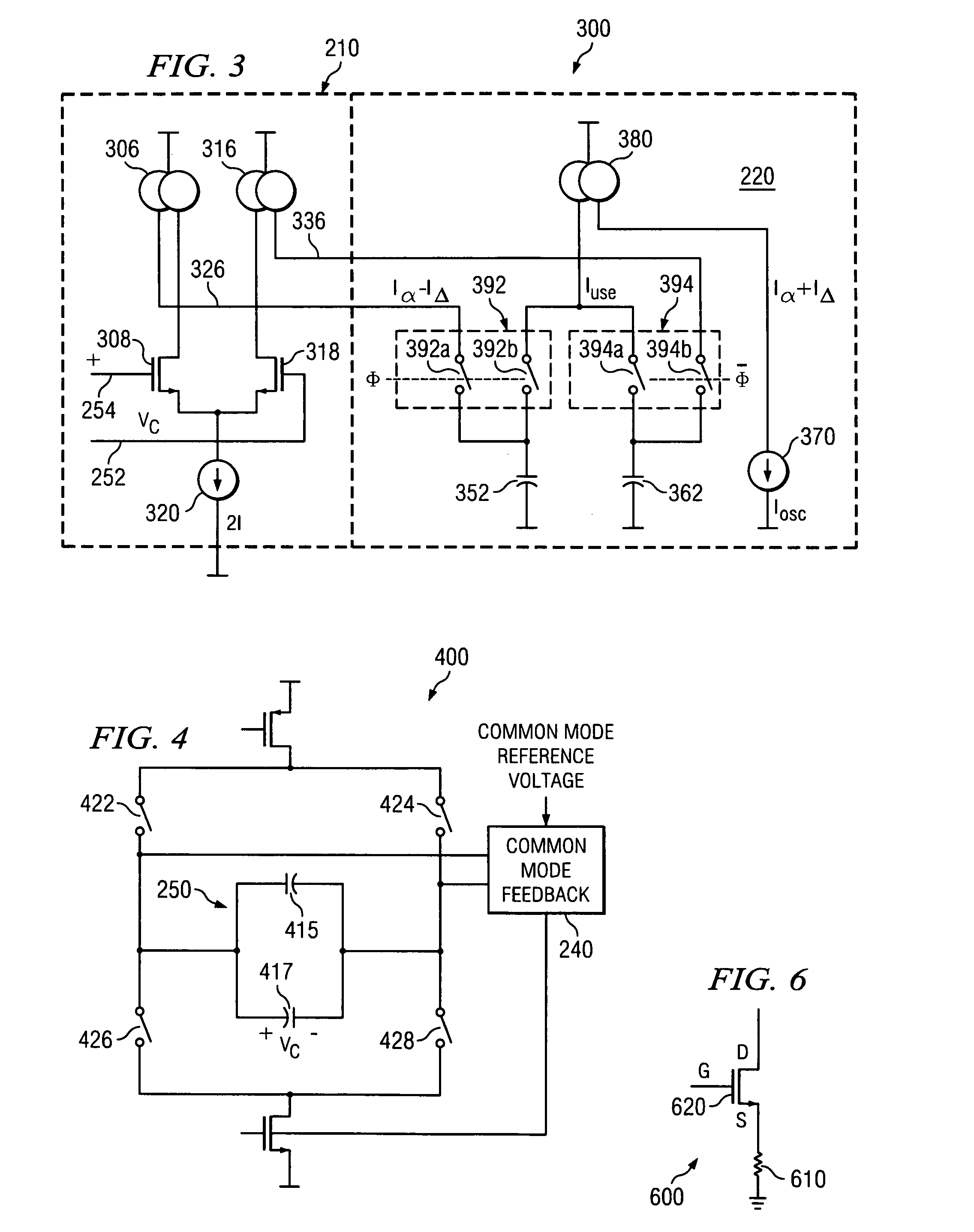

Systems and methods for low power clock generation

ActiveUS7587190B2Reduce asymmetryReduce errorsEnergy efficient ICTDigital data processing detailsRadio frequency energyDc current

Various systems and methods for low power identification are described herein. For example, a radio frequency device including a radio frequency energy receiver. The radio frequency energy receiver is operable to receive a radio frequency energy and to convert the radio frequency energy to a DC current. In addition, the device further includes a first clock generator that generates a first clock at a first frequency and second clock generator that generates another clock based on the first clock. The first clock generator includes a duty cycle correction circuit. The second clock has a positive going clock edge for each edge of the first clock.

Owner:TEXAS INSTR INC

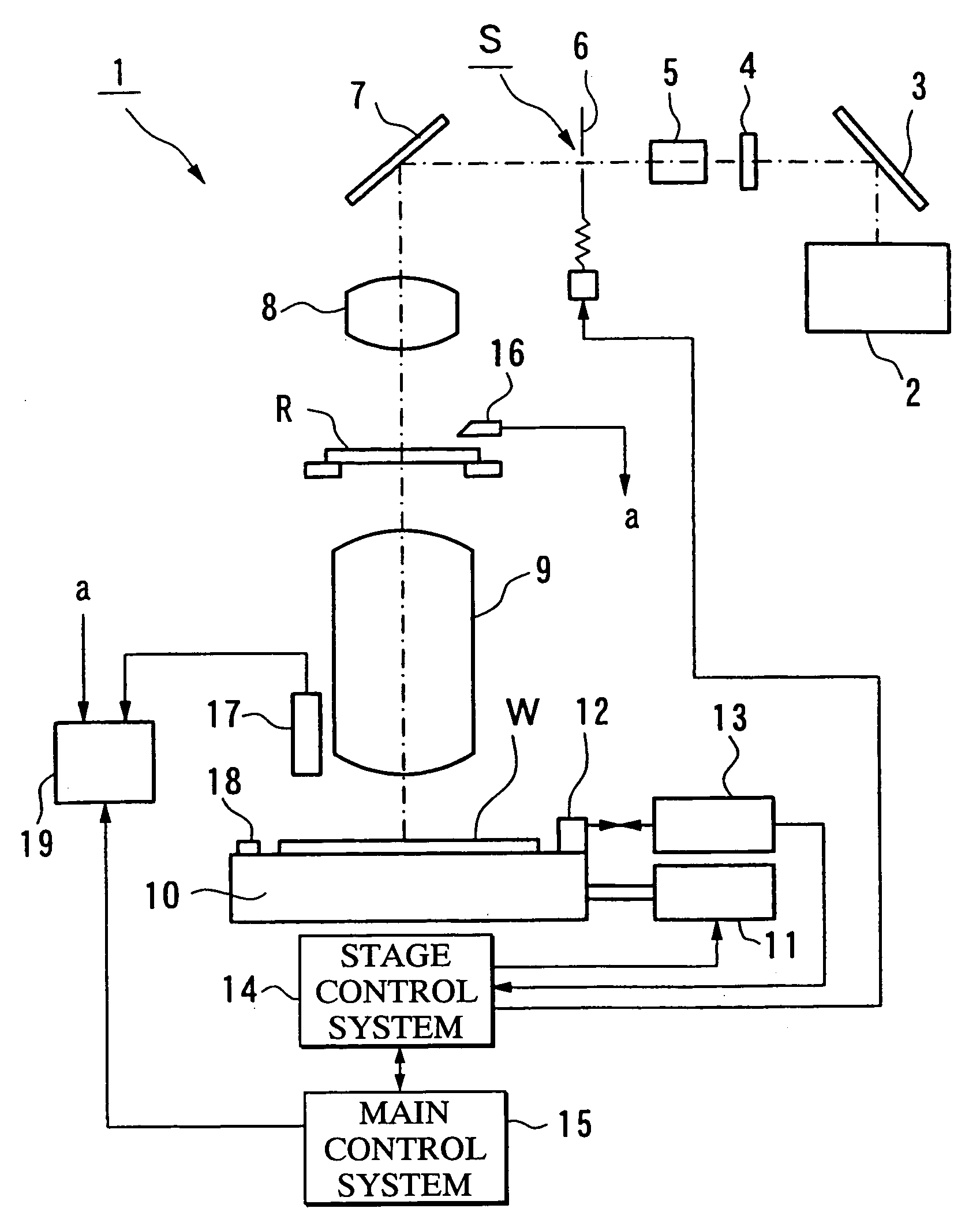

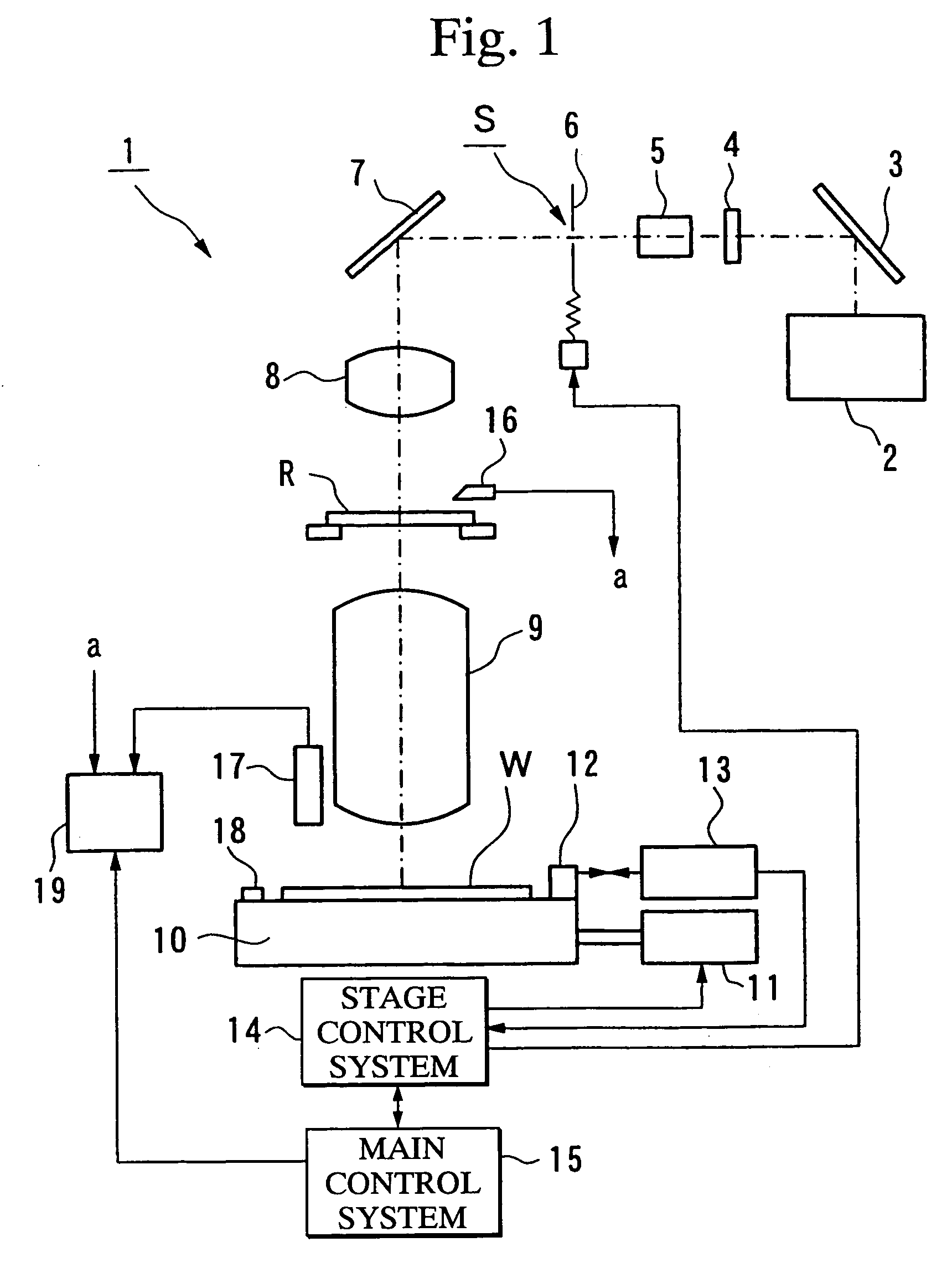

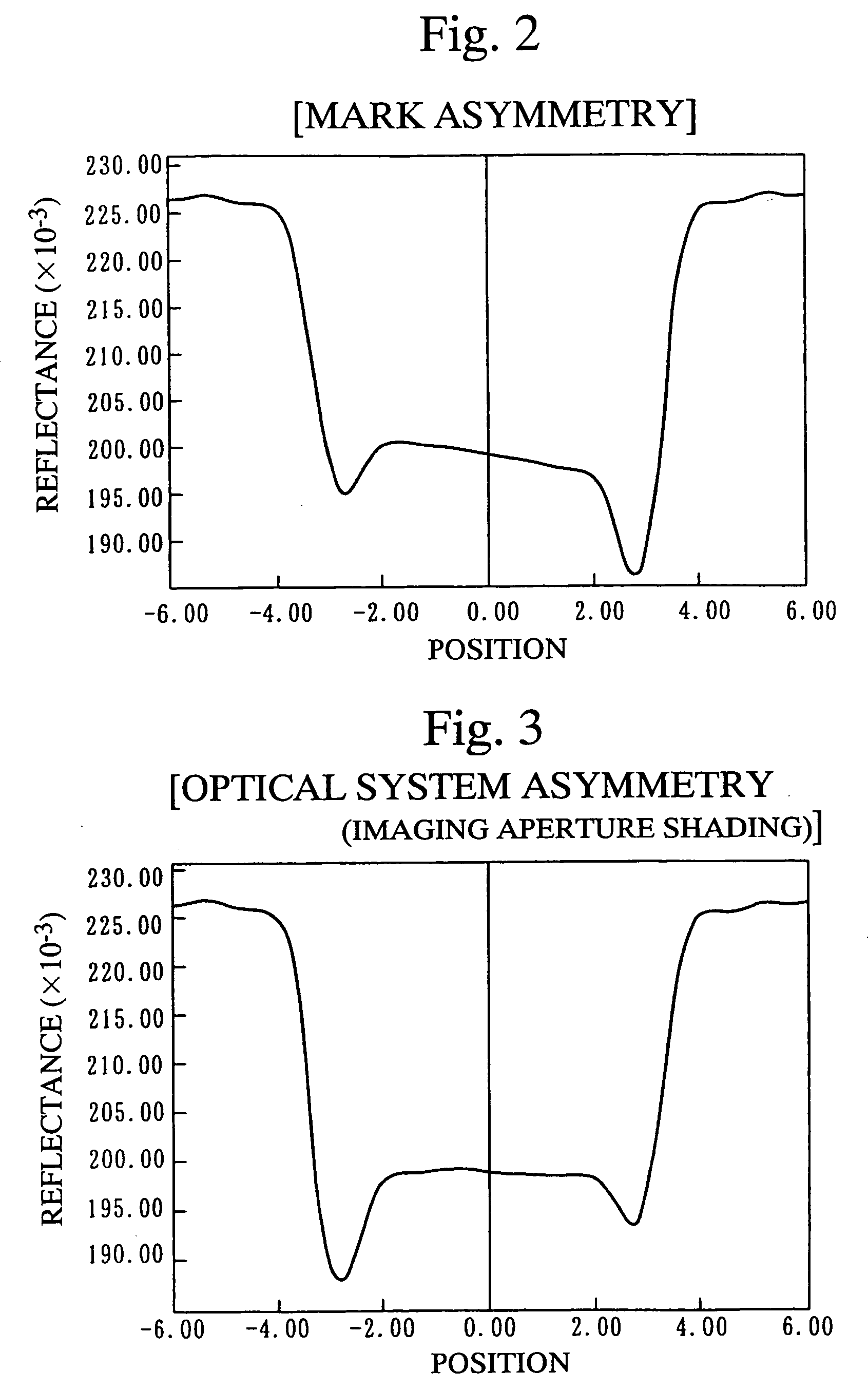

Position measuring device, position measurement method, exposure apparatus, exposure method, and superposition measuring device and superposition measurement method

InactiveUS7106444B2Reduce asymmetryReduce positional deviationPhotomechanical apparatusDigital computer detailsPhysicsMeasurement device

This position measuring device comprising a calculation unit 19 calculates mark position information relating to the position of the mark by using a mark signal obtained by irradiating a detection beam onto the mark formed on an object W, and a correction device 19 for correcting the calculation results from the calculation unit 19 based on the asymmetry of the mark signal.As a result, positional deviation resulting from asymmetry can be detected, and by correcting for this deviation the effect that the image asymmetry has on the measurement can be reduced. Therefore, a more accurate high precision alignment can be performed, and there is no requirement to increase the NA of the detection optical system, nor to prepare a special short wavelength light source, meaning increases in the size and cost of the apparatus can also be prevented.

Owner:NIKON CORP

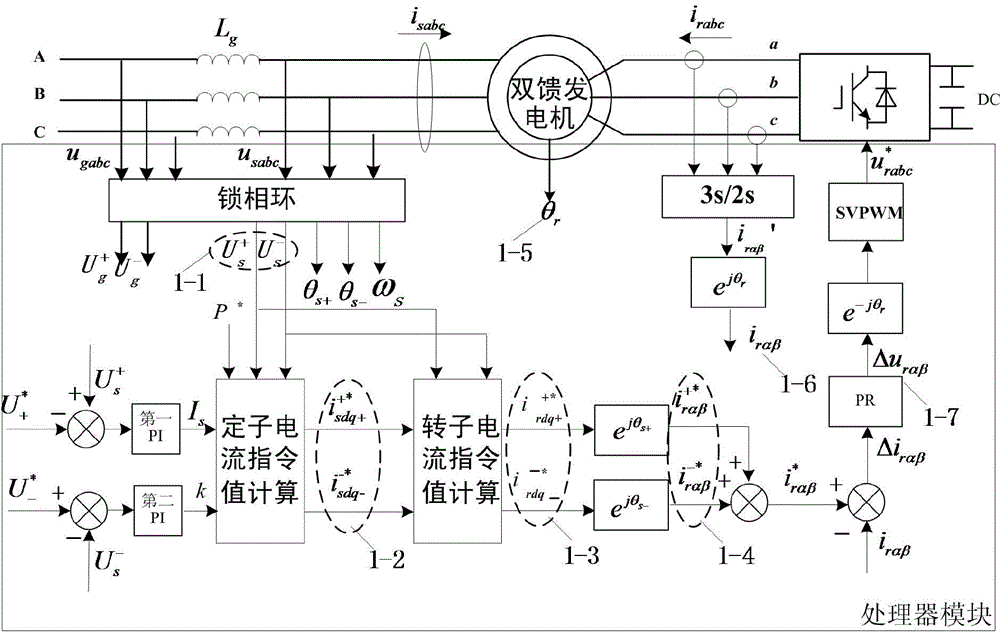

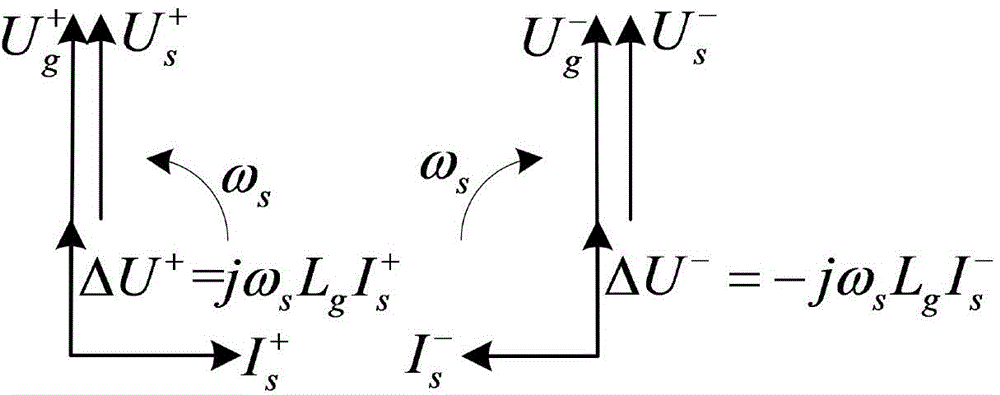

Method for reactive power control of voltage unbalance sudden rise of double-feed wind generator set power network

ActiveCN104538978AAchieve asymmetry controlReduce voltageReactive power adjustment/elimination/compensationReactive power compensationPower flowTerminal voltage

The invention discloses a method for reactive power control of voltage unbalance sudden rise of a double-feed wind generator set power network. The method is characterized by comprising the following steps: 1, decoupling positive and negative sequences of the voltage of a stator of a double-feed motor; 2, calculating the reactive current of the stator; 3, calculating the proportion of positive sequence reactive power in total reactive power; 4, calculating and synthesizing a current instruction value of a rotor; and 5, performing closed-loop control on the current of the rotor. By adopting the method disclosed by the invention, the distribution of the stator current and positive and negative sequence reactive power can be controlled, thereby achieving a target of performing compound control on the degree of asymmetry of generator terminal voltage and reactive power ripple rejection.

Owner:HEFEI UNIV OF TECH

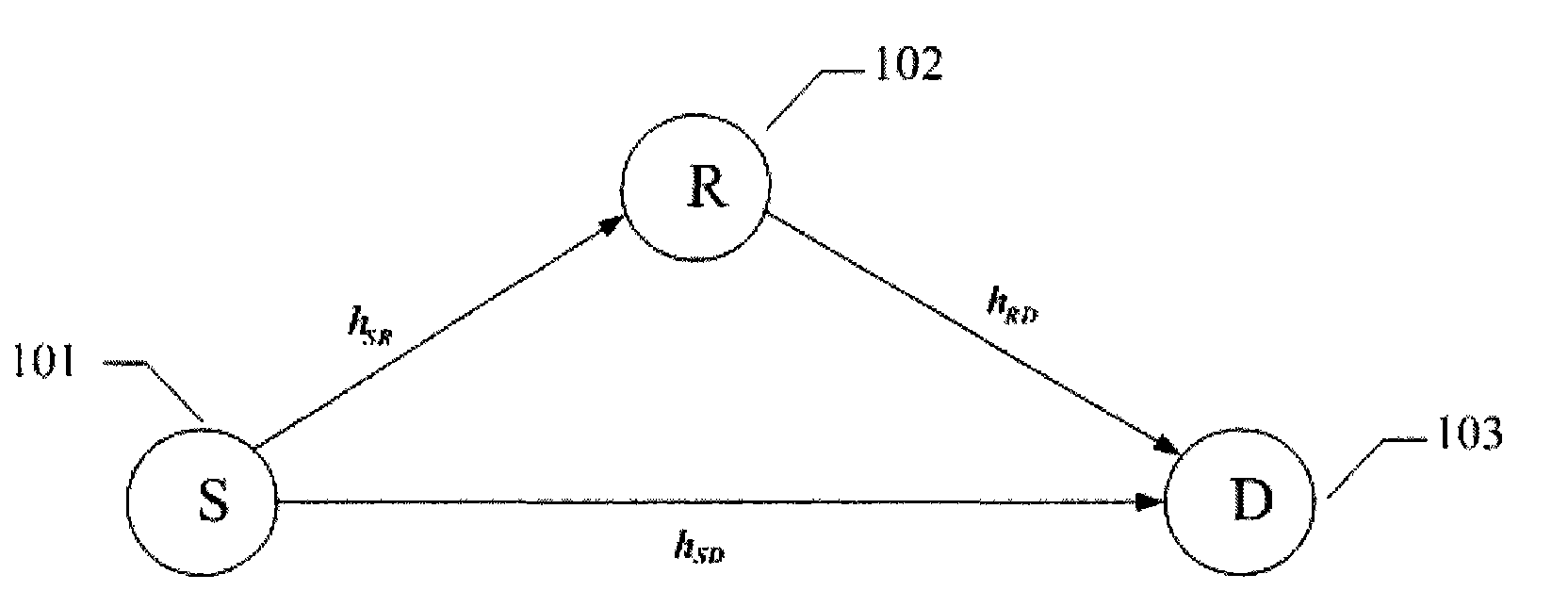

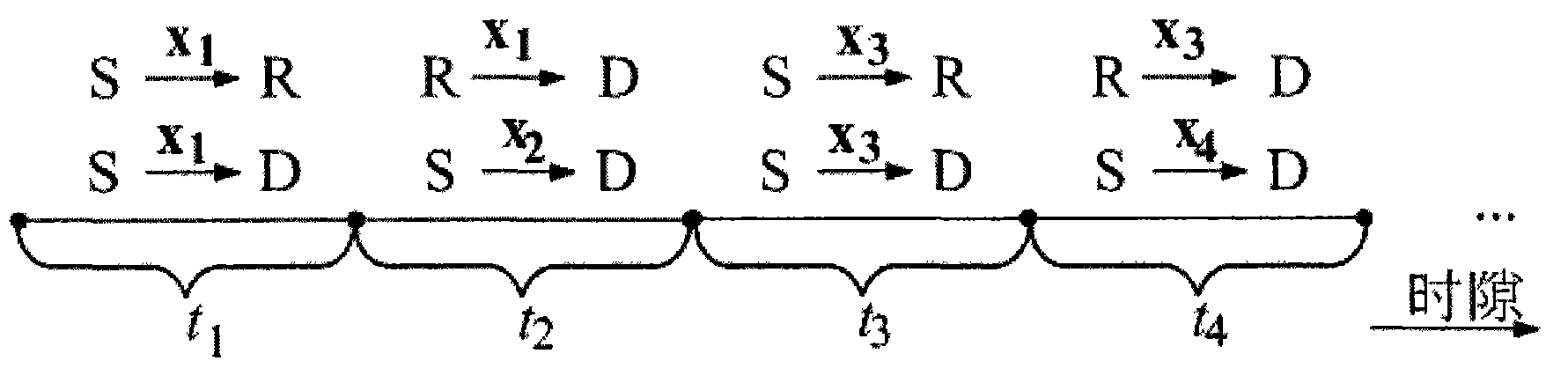

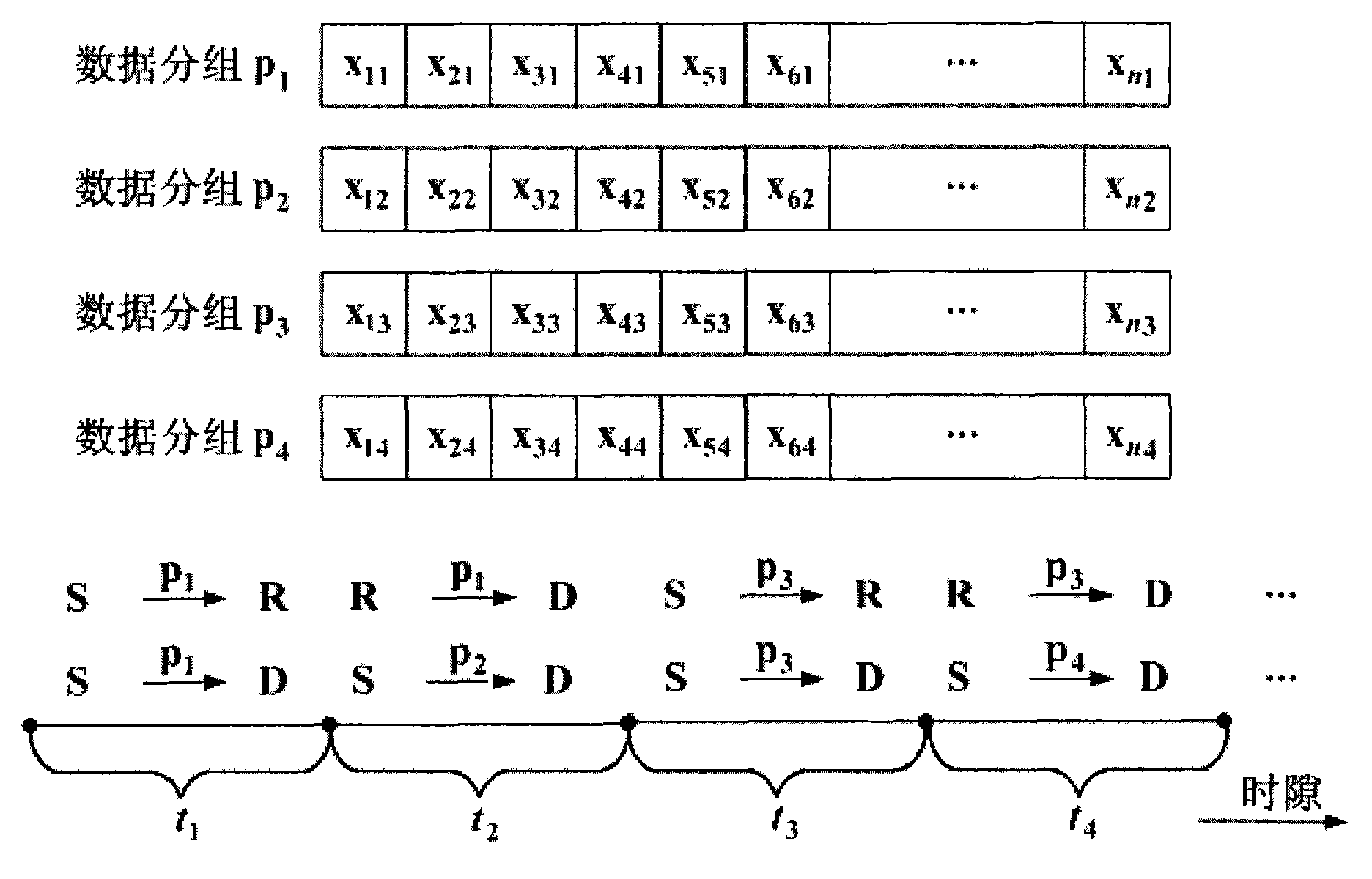

Transmission method, device and system in non-orthogonal cooperative communication network

ActiveCN102098139AReduce asymmetryImprove spectral efficiencyError prevention/detection by using return channelDiversity/multi-antenna systemsComputer network

The invention discloses a retransmission method, a retransmission device and a retransmission system in a non-orthogonal cooperative communication network. The retransmission method comprises the following steps of: during a first time internal, transmitting a first data unit to a destination node from a source node in a first transmission mode and transmitting a second data unit to the destination node from the source node in a second transmission mode; determining whether the first data unit and the second data unit need to be retransmitted; and when one or two of the first data unit and the second data unit need to be retransmitted, retransmitting the data unit needing to be retransmitted to the destination node from the source node during a following second time interval, wherein the transmission mode used for the data unit needing to be retransmitted during the second time interval is the other transmission mode, different from the transmission mode used for the data unit needingto the retransmitted during the first time interval, of the first transmission mode and the second transmission mode.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Method of manufacturing semiconductor light emitting device

InactiveUS7208338B2Improve the level ofMaintain verticalityOptical wave guidanceLaser detailsActive layerAnisotropic etching

A method of manufacturing a ridge type semiconductor light emitting device includes: a process of epitaxially growing a multi-layered semiconductor layer having at least a first conductive type cladding layer, an active layer, a second conductive type first cladding layer, an etching stop layer, and a second conductive type second cladding layer on a substrate; a process of forming a ridge groove for forming a ridge; and a process of forming a current-flow barrier layer in the ridge groove. The process of forming ridge grooves has first and second anisotropic etching processes of performing anisotropic etching, an etching-mask forming process, and an isotropic etching process of performing anisotropic etching.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com