Emergency supply unit with a ram-air turbine adapted to be driven by an air stream and with an energy converter for aircraft

An energy converter, ram air technology, applied in the direction of engine components, gas turbine devices, engines, etc., can solve the problems of difficult installation location, increase the possibility of failure, increase fuel consumption, etc., to save space, increase operating reliability and failure. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

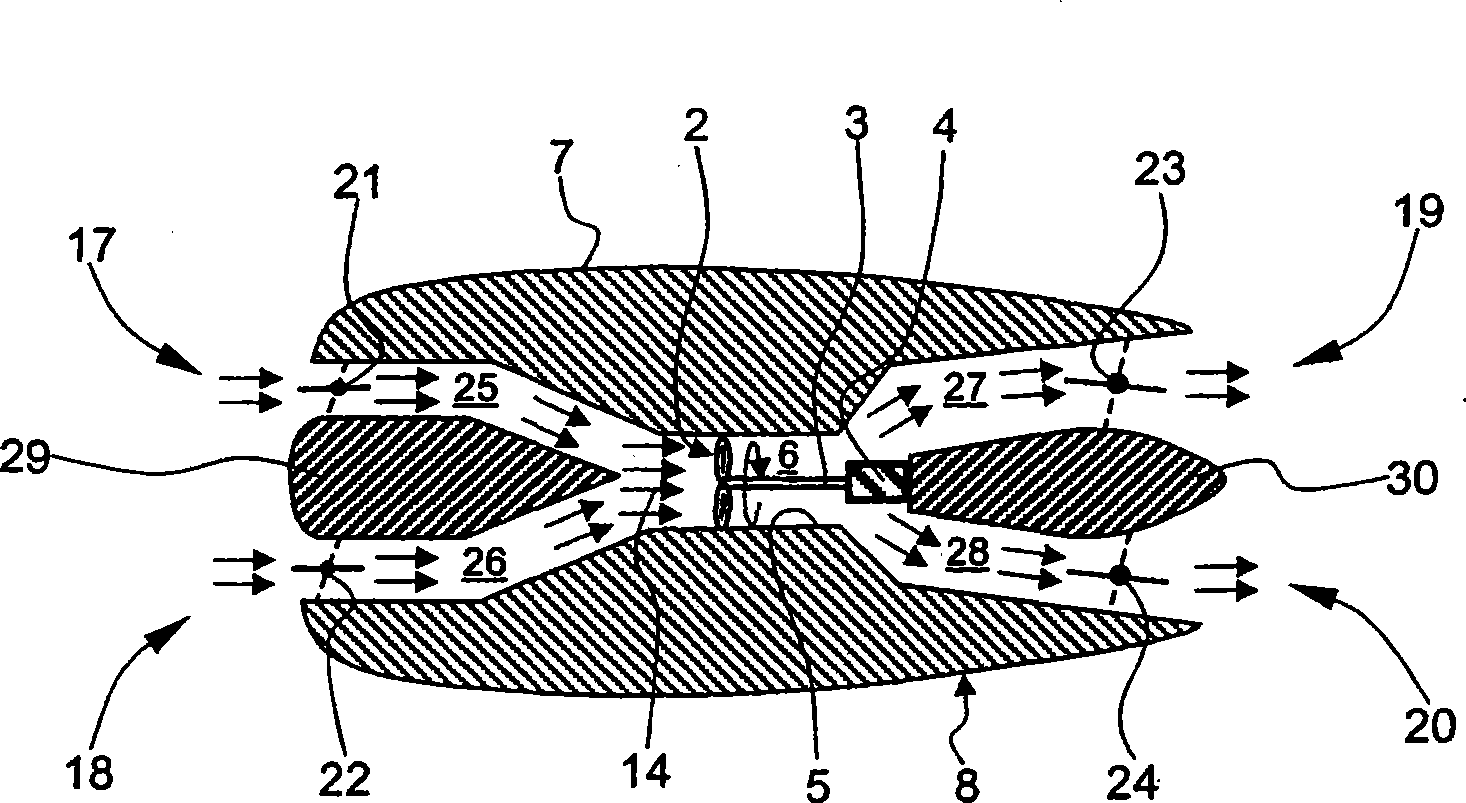

[0017] In the figures, identical structural elements bear the same reference signs in each case.

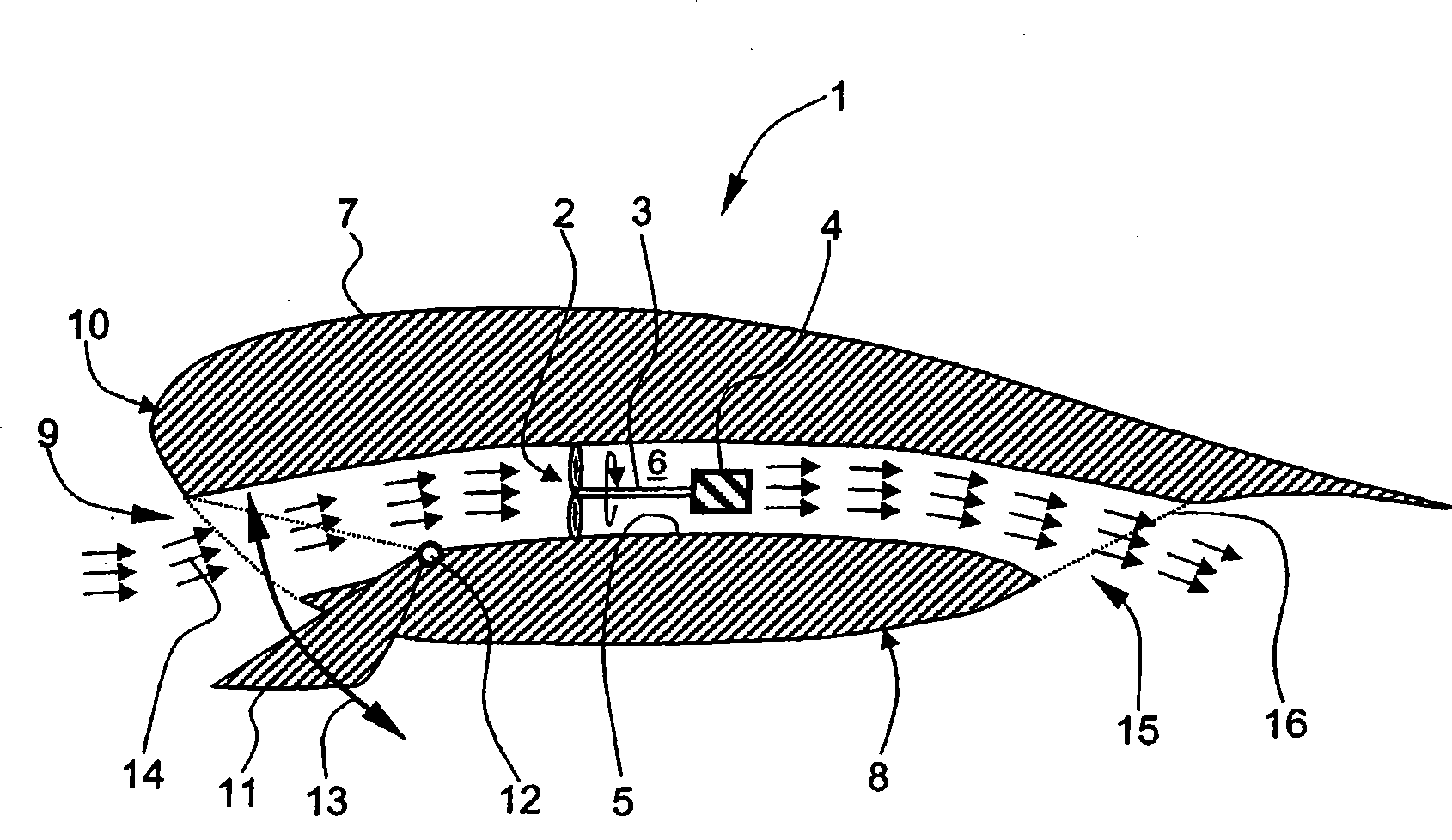

[0018] figure 1 is a schematic sectional view of the emergency energy supply unit.

[0019] The emergency energy supply unit 1 according to the invention comprises a ram air turbine 2 and other components directly connected via a drive shaft 3 to an energy converter 4 , i.e. without the intervention of transmission elements, said elements being substantially coaxially surrounded by a housing 5 so that Air flow channel 6 is formed.

[0020] The housing 5 or the flow channel 6 preferably has a circular cross-sectional geometry, but may also have an at least partially elliptical, oval or angular cross-sectional geometry. For example, housing 5 may be formed using ducting, flexible tubing or the like that substantially concentrically surrounds ram air turbine 2 .

[0021] The drive shaft 3 optionally has a coupling not shown. Thus, the ram air turbine 2 can be started under no-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com