Silicon micro-resonance type accelerometer

An accelerometer and resonant technology, applied in the field of micro-inertial sensors, can solve the problems of poor stability and impact resistance of the accelerometer, poor ability to release residual stress, and low utilization of mass blocks, and improve stability and resistance. Impact capability, release of residual stress, effect of reducing material inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

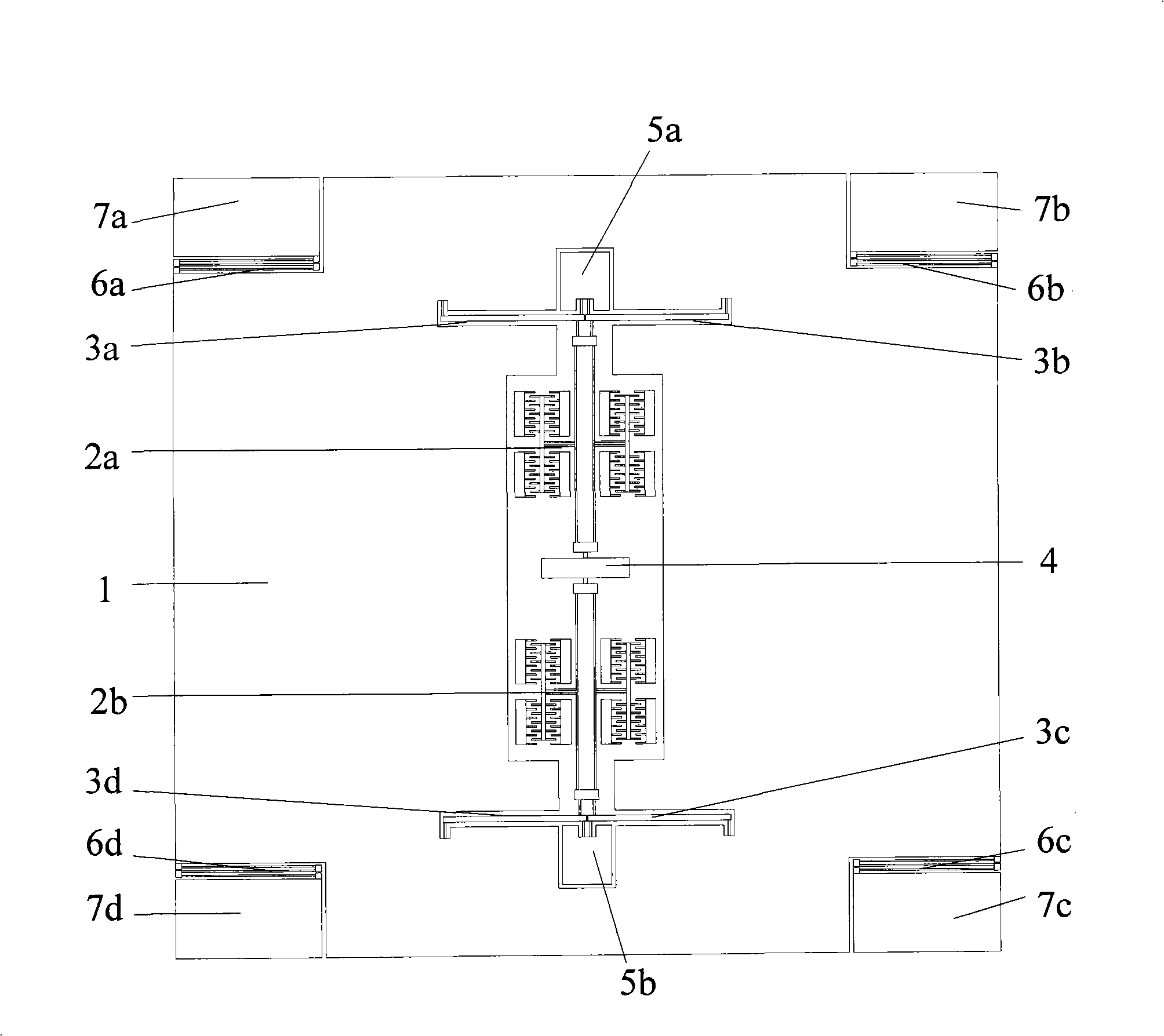

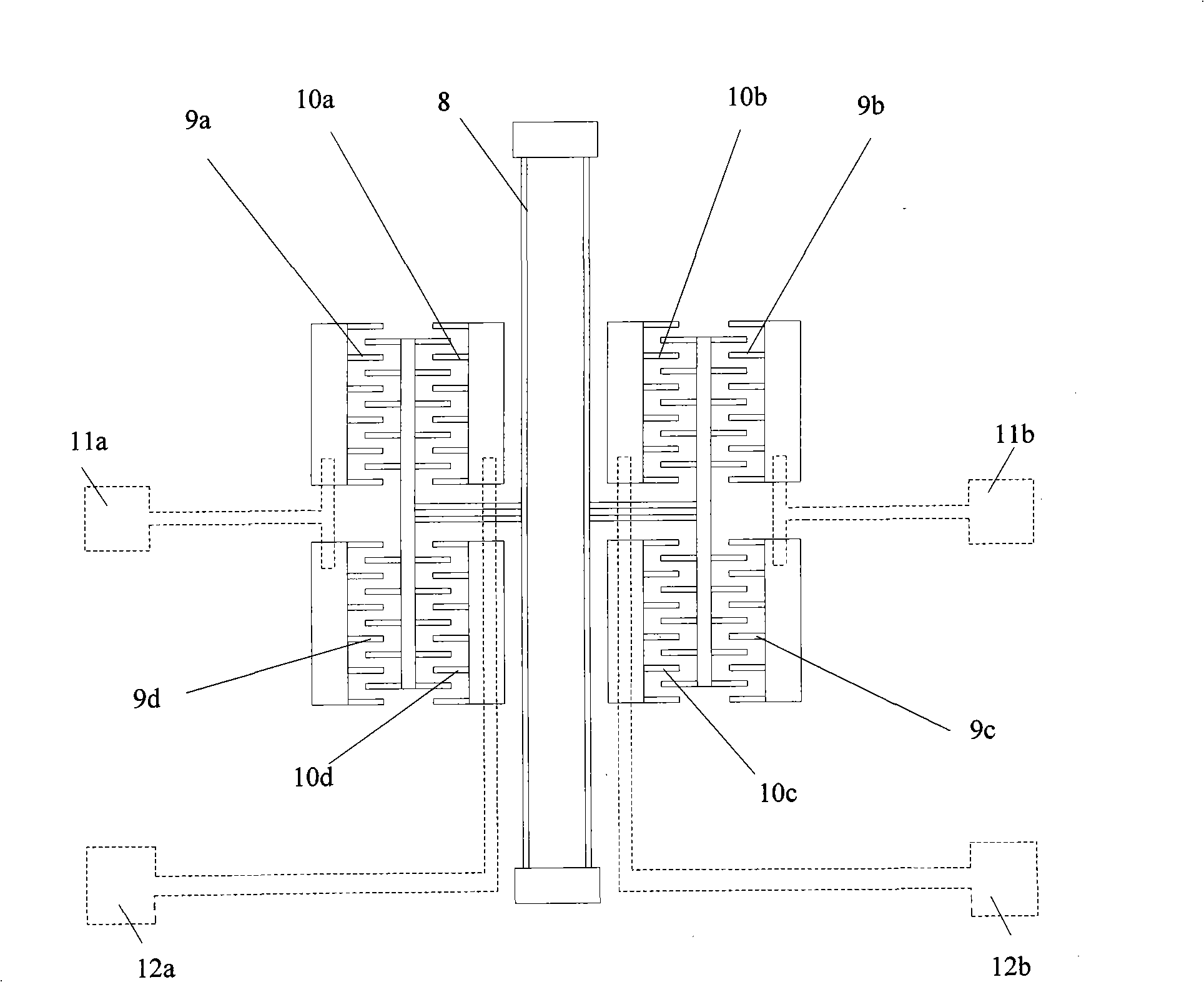

[0013] combine figure 1 , the present invention is based on the resonant silicon micro-accelerometer, which is used to measure the measuring instrument parallel to the level of the base. It consists of upper and lower layers. Signal leads on the glass substrate, the upper mechanical structure of the accelerometer is composed of a mass block 1 and a pair of resonators 2a, 2b, and the resonators 2a, 2b are symmetrically located in the middle of the mass block up and down, which can reduce material inhomogeneity and Due to the asymmetry produced by the processing, the structural parameters of the resonators 2a and 2b are in good consistency, effectively realizing the differential output of the resonant frequency. One end of the resonator 2a, 2b is connected to the fixed base 4 between the resonators 2a, 2b, wherein the other end of the upper resonator 2a is respectively connected to the output ends of the two lever amplifying mechanisms 3a, 3b above it The fulcrum ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com